Acid single flow cell

A flow battery, single-liquid technology, applied in the field of acid single-liquid flow battery, can solve the problems of deposition of sulfur in the diaphragm, occupying volume and weight, cross-contamination, etc., to reduce charging voltage, improve energy efficiency, and reduce concentration polarization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

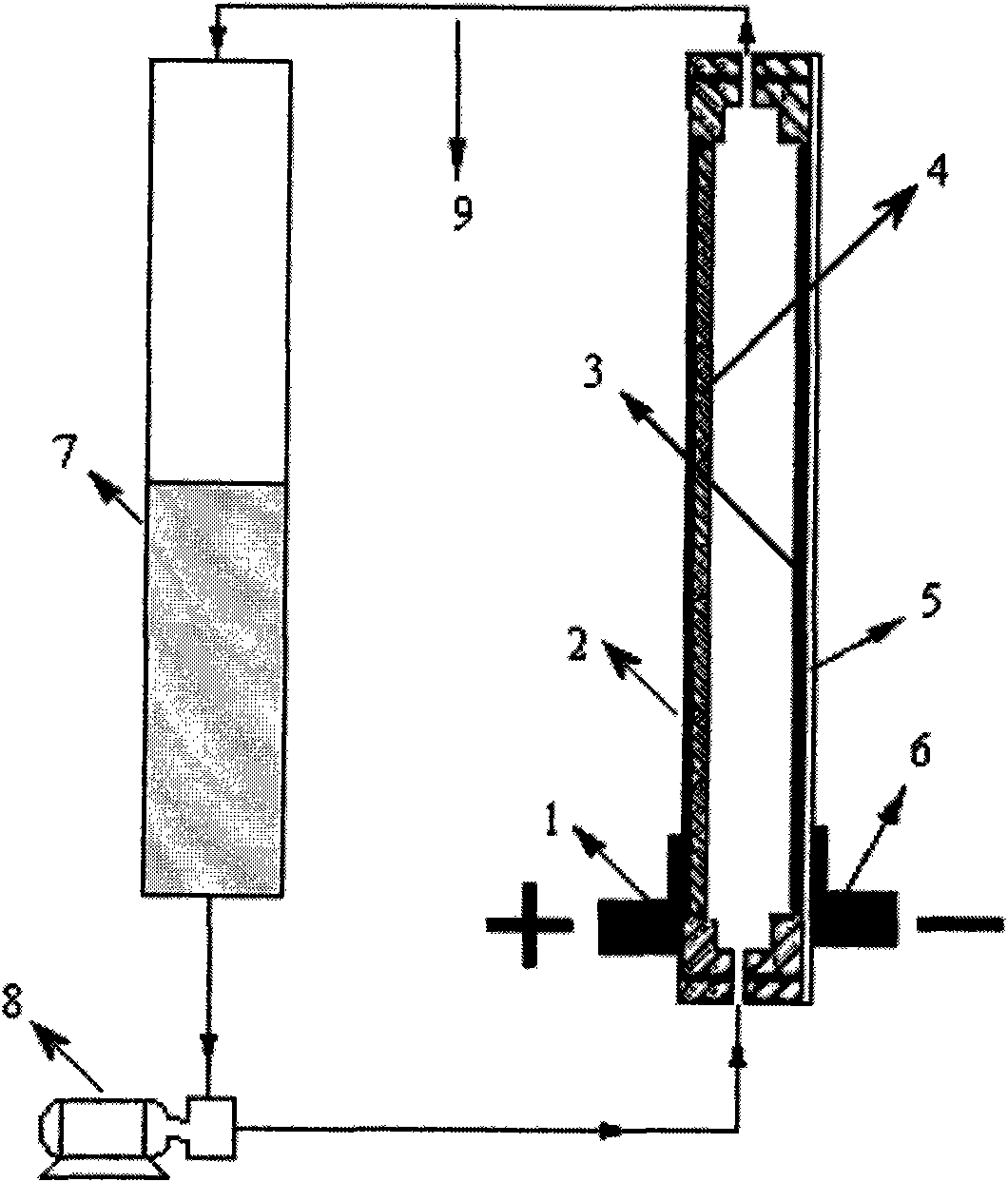

[0036] Embodiment 1-3 is such as figure 1 A single acidic single flow battery is shown.

[0037] After mixing 30 grams of lead sulfate plus 5 grams of 20% sulfuric acid solution, apply it on 4*6cm 2 On the lead-calcium alloy (containing 0.4% of calcium) plate frame, the lead dioxide electrode plate that the rated capacity is 2000mAh is obtained through pre-charge formation. With 4*6cm 2 The titanium-based gold-plated electrode is the negative current collector, 500ml2MH 2 SO 4 -0.5MIN 2 (SO 4 ) 3 The solution is an electrolyte. The HB-2B peristaltic pump is used as the power pump, and the electrolyte is circulated at a speed of 220ml / h. The electromotive force of the battery is 2.11V, the average discharge voltage is 1.65-2.05V at a discharge rate of 1000mA, and the energy efficiency of the process is 85.5%.

Embodiment 2

[0039] Add 32 grams of lead sulfate to 5 grams of 20% sulfuric acid solution and 1 gram of Pb 3 o 4 After mixing evenly, apply on 4*6cm 2 On the lead alloy plate frame containing 1.2% antimony, the lead dioxide plate with a rated capacity of 2200mAh is obtained through pre-charging. With 4*6cm 2 The graphite electrode is the negative current collector, 500ml2.5MH 2 SO 4 -0.1M H 3 PO 4 -0.65MCdSO 4 The solution is an electrolyte. The HL-2B peristaltic pump is used as the power pump, and the electrolyte is circulated at a speed of 270ml / h. The electromotive force of the battery is 2.055V, the average discharge voltage is 1.985V at a discharge rate of 1000mA, and the energy efficiency of the process is 90.3%.

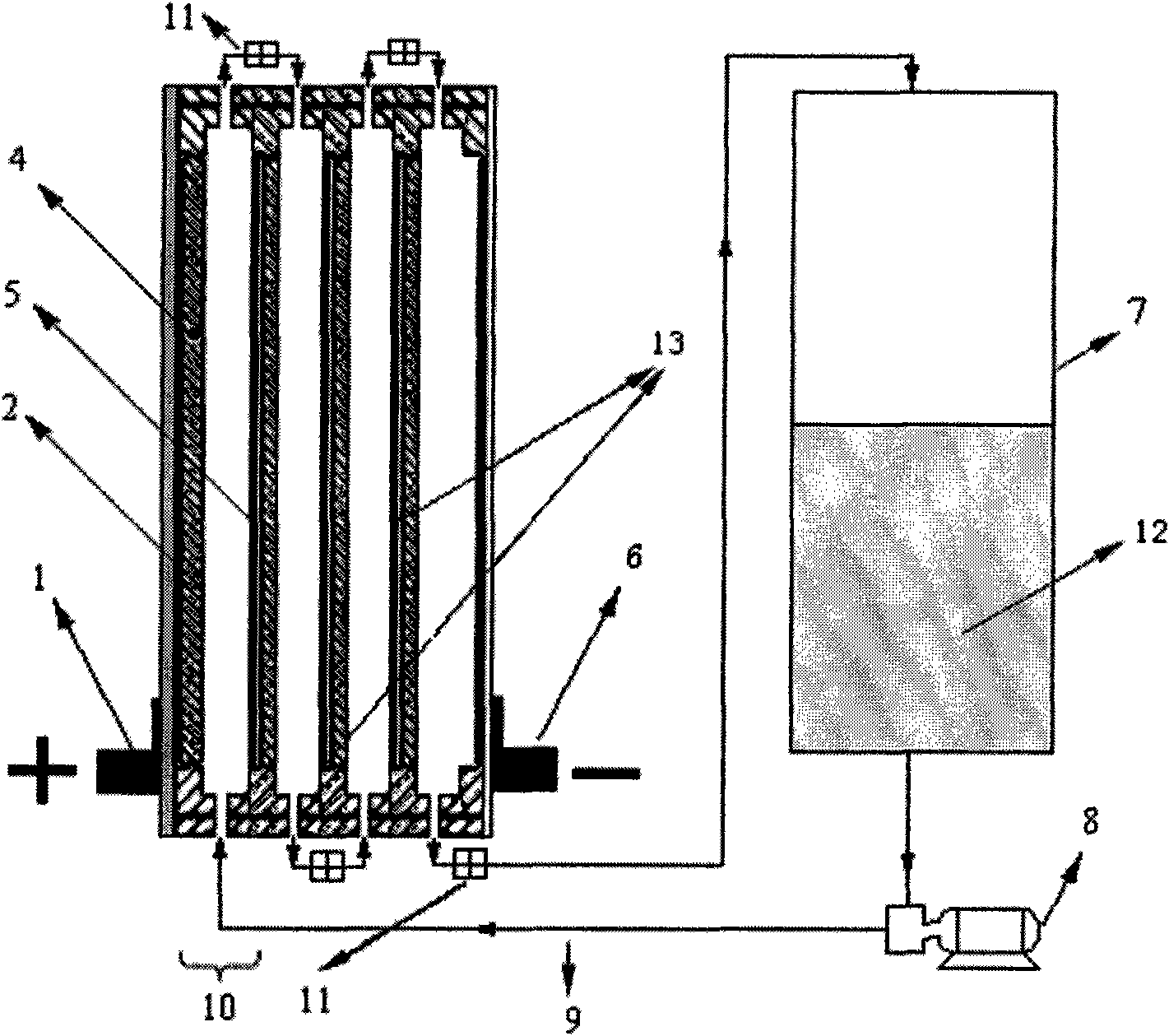

Embodiment 3

[0041] Two lead dioxide plates with a rated capacity of 3000mAh were used as positive electrodes, which were respectively placed on both sides of the negative electrode collector. With 5*8cm 2 The double-sided silver-plated stainless steel electrode is the negative current collector, 500ml2.5MH 2 SO 4 -0.1M HClO 4 -0.65MCdSO 4 The solution is an electrolyte, and 0.5 g / L of ammonium triacetate is added to the electrolyte. The MP-10RN magnetic circulation pump is used as the infusion pump, and the electrolyte is circulated at a flow rate of 500ml / h. The electromotive force of the battery is 2.11V, the average discharge voltage is 1.9V at a discharge rate of 3000mA, and the energy efficiency of the process is 87.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com