Negative electrode material used for lithium battery and preparation method and application thereof

A technology for anode materials and lithium batteries, applied in nanotechnology for materials and surface science, battery electrodes, circuits, etc., can solve problems such as poor cycle performance of silicon anode materials, high delithiation potential, and breakage of silicon nanowires. Achieve the effects of improving kinetic and thermodynamic properties, high mechanical strength, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

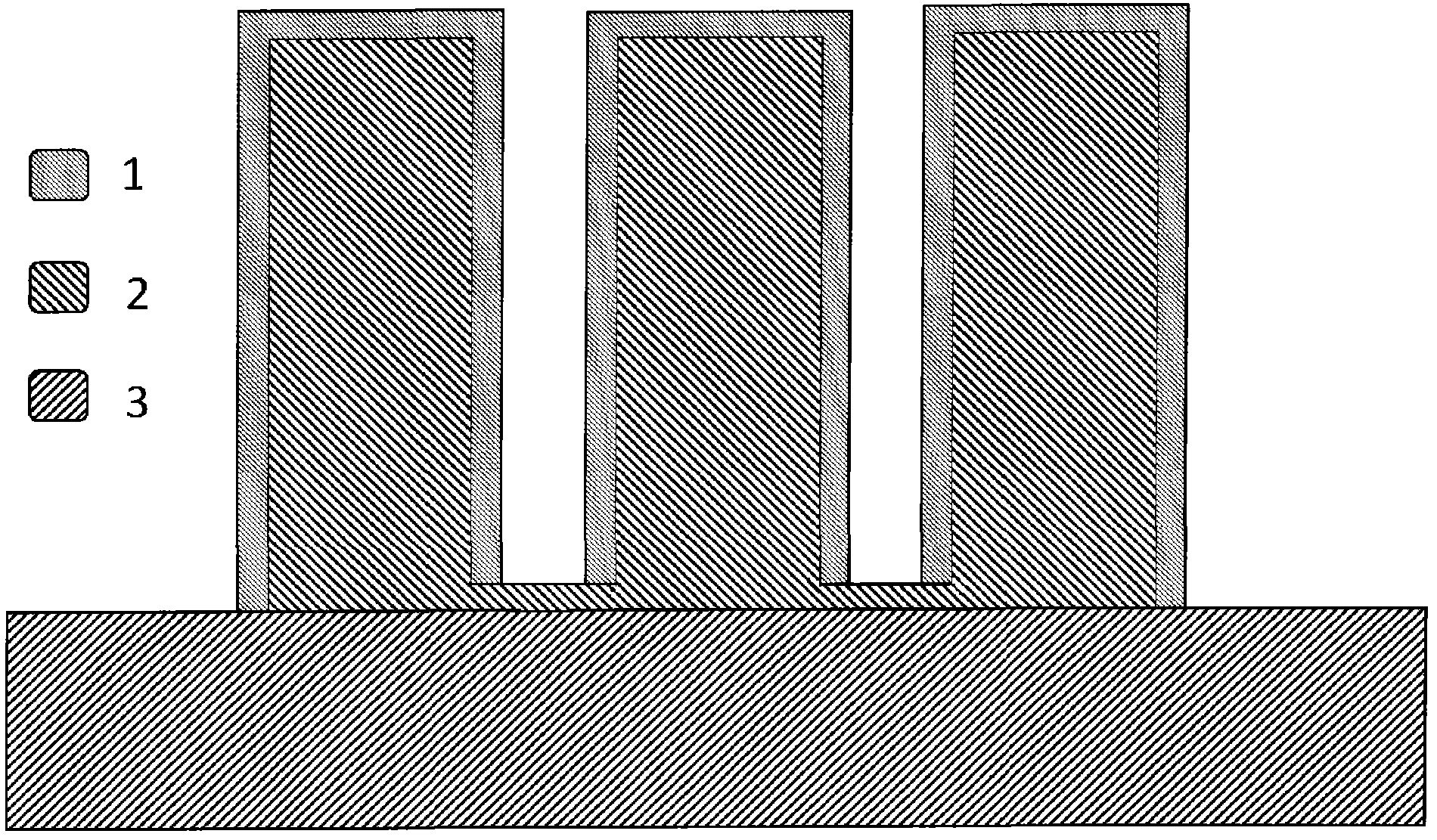

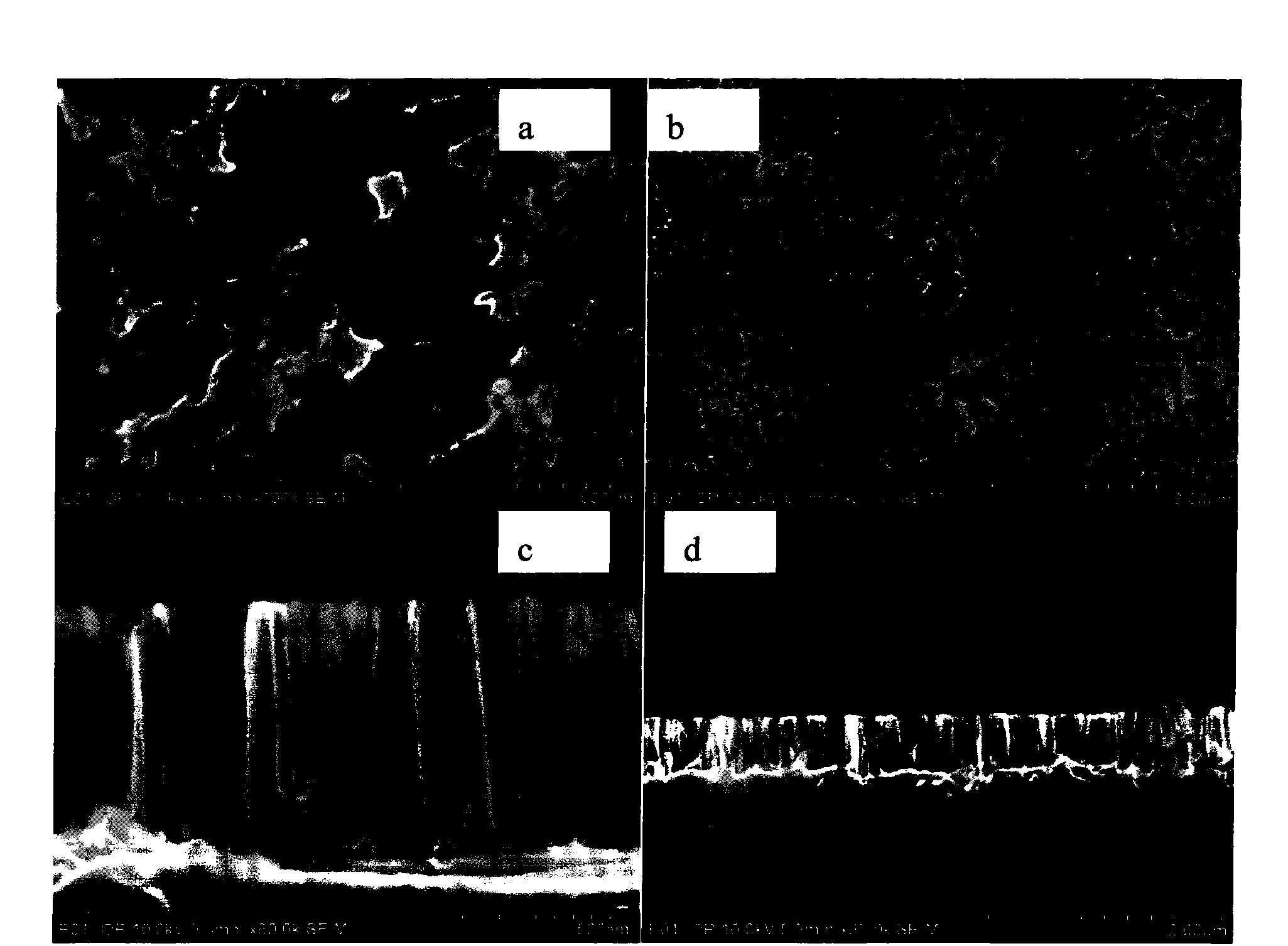

[0115] This example is used to illustrate the negative electrode material and its preparation method. Wherein, the negative electrode material is prepared by combining magnetron sputtering and chemical etching, which specifically includes the following steps:

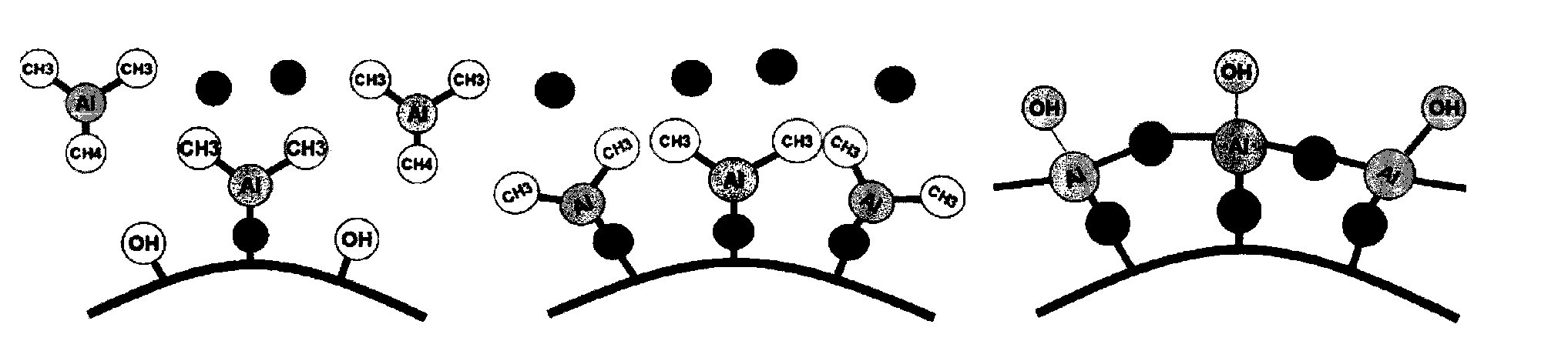

[0116] (1) Put the commercial titanium metal target (99.9%) in the sputtering chamber; clean the substrate material quartz with acetone, alcohol and deionized water and fix it on the sample stage after thorough drying, and fix the sample stage In the sample preparation chamber of the magnetron sputtering instrument; vacuumize the sample preparation chamber to make the vacuum degree reach 10 -3 Pa, then the argon gas with 20sccm gas flow rate is passed to the sample preparation chamber, the DC power supply is turned on, the corresponding power is adjusted to be 80W and the preparation time is half an hour, and the dense titanium film deposited with a thickness of 500 nanometers is the conductive substrate material layer;...

Embodiment 2

[0130] This example is used to illustrate the negative electrode material and its preparation method. Similar to Example 1, this example uses a method combining magnetron sputtering and chemical etching to prepare the negative electrode material. The difference is that this example reduces the deposition time of the silicon film to 12 minutes, shortening the chemical etching time Time to 1 minute, the diameter of the columnar and / or fibrous micro-nano hairs in the obtained negative electrode material is 50 nanometers.

[0131] The charge-discharge curve of the simulated battery of embodiment 2 sample is as Figure 4 As shown, the test results are shown in Table 1.

Embodiment 3

[0133] This example is used to illustrate the negative electrode material and its preparation method. Similar to Example 1, this example uses a method combining magnetron sputtering and chemical etching to prepare the negative electrode material. The difference is that this example increases the deposition time of the silicon film to 20 hours and increases the chemical etching The time to 100 minutes, the diameter of the columnar and / or fibrous micro-nano hairs in the obtained negative electrode material is 10 microns.

[0134] The charge-discharge curve of the simulated battery of embodiment 3 sample is as Figure 4 As shown, the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com