Preparation method of sodium titanate/graphene composite cathode material of sodium ion battery

A graphene composite, sodium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of insufficient capacity, poor high current discharge performance, poor electronic conductivity and ionic conductivity of sodium titanate, etc. problems, to achieve the effect of being beneficial to storage and diffusion, improving electronic conductivity, and overcoming poor ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of graphite oxide is as follows:

[0031] Take an appropriate amount of concentrated H with a mass fraction of 95-98% 2 SO 4 Add to the reaction vessel placed in the ice bath, start stirring, and add graphite and KMnO at 20-100rpm 4 React for 30-60 minutes; then raise the temperature of the reaction solution to 40±2°C, react for 30-60 minutes; then control the temperature of the reaction solution at 95-100°C, add deionized water to the solution for 30-60 minutes; then add an appropriate amount H with a mass fraction of 5% 2 o 2 Finally, the reaction solution was filtered, and the filter residue was washed with 5% HCl until there was no SO in the filtrate. 4 2- (with BaC1 2 solution detection); then use deionized water to wash the filter residue to neutrality, and vacuum filter to obtain paste-like graphite oxide;

[0032] Among them, graphite is natural flake graphite or artificial graphite, with a particle size of 0.04-30 μm; concentrated ...

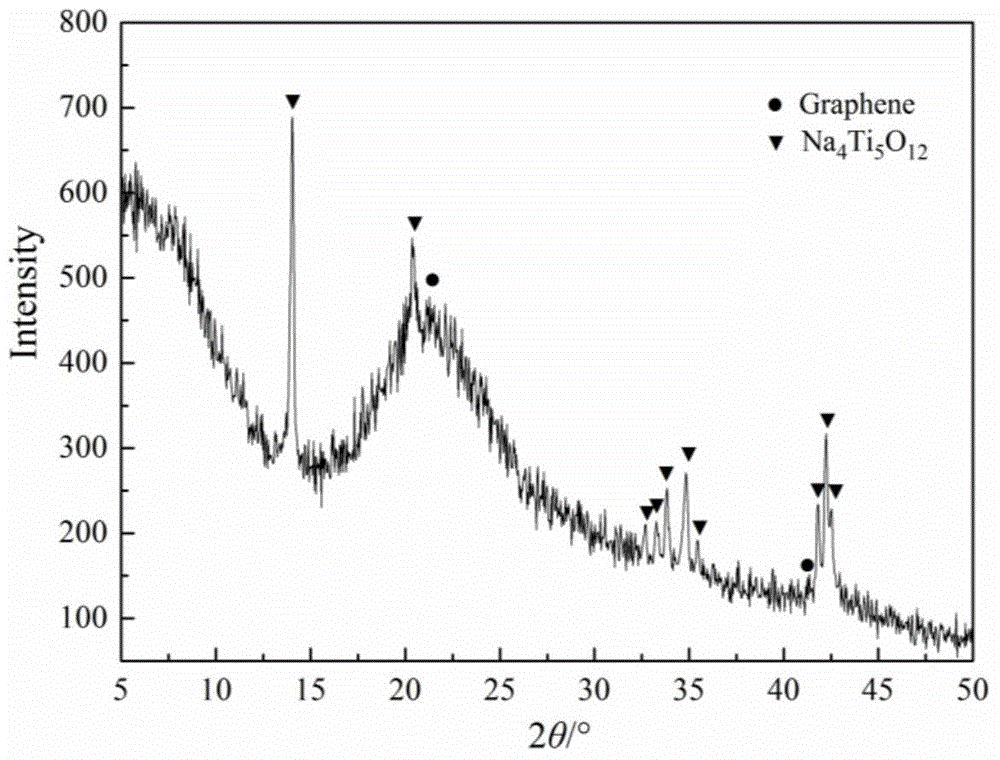

Embodiment 1

[0034] 1. Take 10g of graphite oxide and add it to 50mL of absolute ethanol, then add 0.1g of γ-aminopropyltriethoxysilane, and conduct ultrasonic treatment at a constant temperature of 60°C for 30min to obtain a graphene oxide solution;

[0035] 2. Add 8g of tetraethyl titanate to 400mL of absolute ethanol, stir at 20-50rpm, add formic acid to adjust the pH of the solution to 5, then add the graphene oxide solution obtained in step 1, and mix evenly to obtain titanium-containing Graphene oxide solution; then take the sodium acetate aqueous solution containing 0.028mol sodium acetate, add the sodium acetate aqueous solution dropwise to the titanium-containing graphene oxide solution at a rate of 0.5mL / min, and stir the reaction at 20-50rpm 20min, and after standing still for 2h, wash with deionized water for 3 to 5 times, vacuum filter, and dry to obtain the composite precursor;

[0036] 3. Mix 10g of the composite precursor prepared in step 2 with 5mL of deionized water and 0...

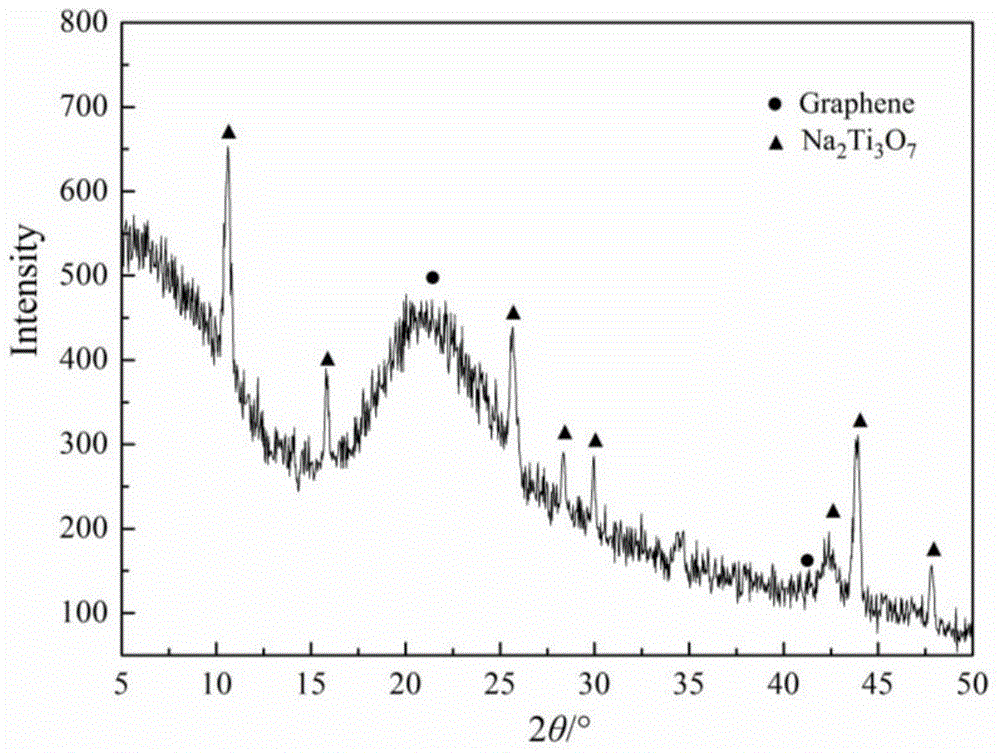

Embodiment 2

[0041] 1. Take 10g of graphite oxide and add it to 200mL of absolute ethanol, then add 0.5g of γ-(2,3-glycidoxy)propyltrimethoxysilane, and conduct ultrasonic treatment at a constant temperature of 30°C for 240min to obtain graphene oxide solution;

[0042] 2. Add 32g of tetrabutyl titanate to 320mL of absolute ethanol, stir at 20-50rpm, add HCl to adjust the pH of the solution to 2, then add the graphene oxide solution obtained in step 1, and mix evenly to obtain titanium-containing Graphene oxide solution; Then get the sodium oxalate aqueous solution that contains 0.031mol sodium oxalate, with the drop rate of 3mL / min, the sodium oxalate aqueous solution is added dropwise in the graphene oxide solution containing titanium, at 20~ Stir and react at 50rpm for 60min, then let stand for 6h, wash with deionized water for 3 to 5 times, vacuum filter and dry to obtain a composite precursor;

[0043] 3. Take 10g of the composite precursor prepared in step 2, mix it with 15mL of dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com