Recycling treatment method of waste and old lithium iron phosphate battery anode materials

A lithium iron phosphate battery and positive electrode material technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of difficult control conditions, difficult wastewater treatment, difficult environmental pollution, etc., to achieve easy access to equipment, easy operation Easy, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

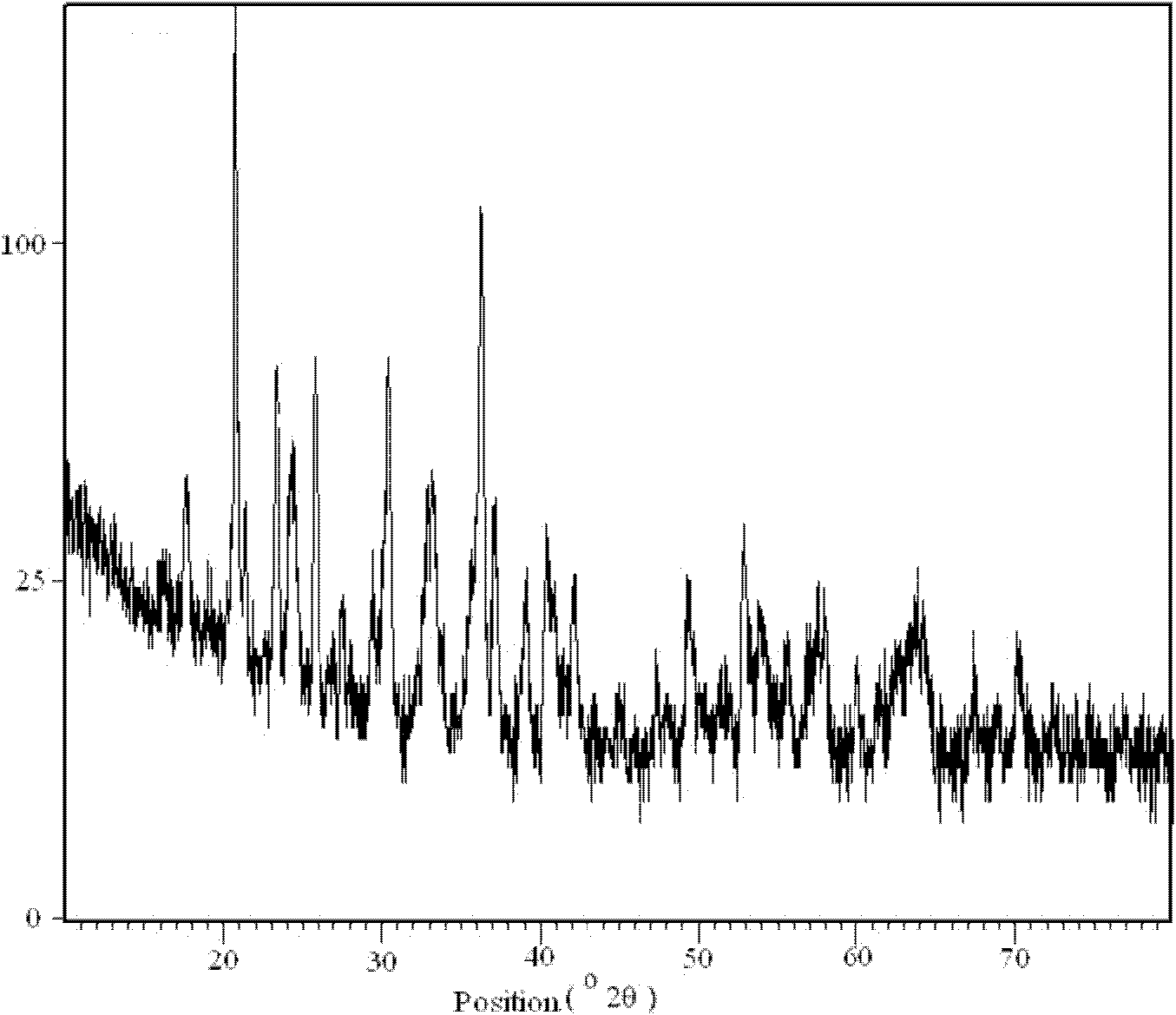

[0024] Two 1865140 steel shell 10Ah cells after 2500 cycles were fully discharged and then peeled off the battery case, the positive and negative electrodes and separators were manually separated, and the lithium iron phosphate positive electrode was placed in NMP at room temperature for ultrasonic treatment to the positive electrode. The powder is completely separated from the aluminum foil current collector; the aluminum foil is taken out, the positive electrode powder is collected by filtration, and the residue is distilled and recycled for recycling; the filtered lithium iron phosphate positive electrode powder is placed in a muffle furnace and kept at 500°C for 3 hours in air Obtain 157.2g dark red solid powder, the XRD figure of this powder is referring to figure 1 , it can be seen that the waste lithium iron phosphate material after heat preservation treatment at 500°C still retains the pure phase structure of lithium iron phosphate to a certain extent, but at the same t...

Embodiment 2

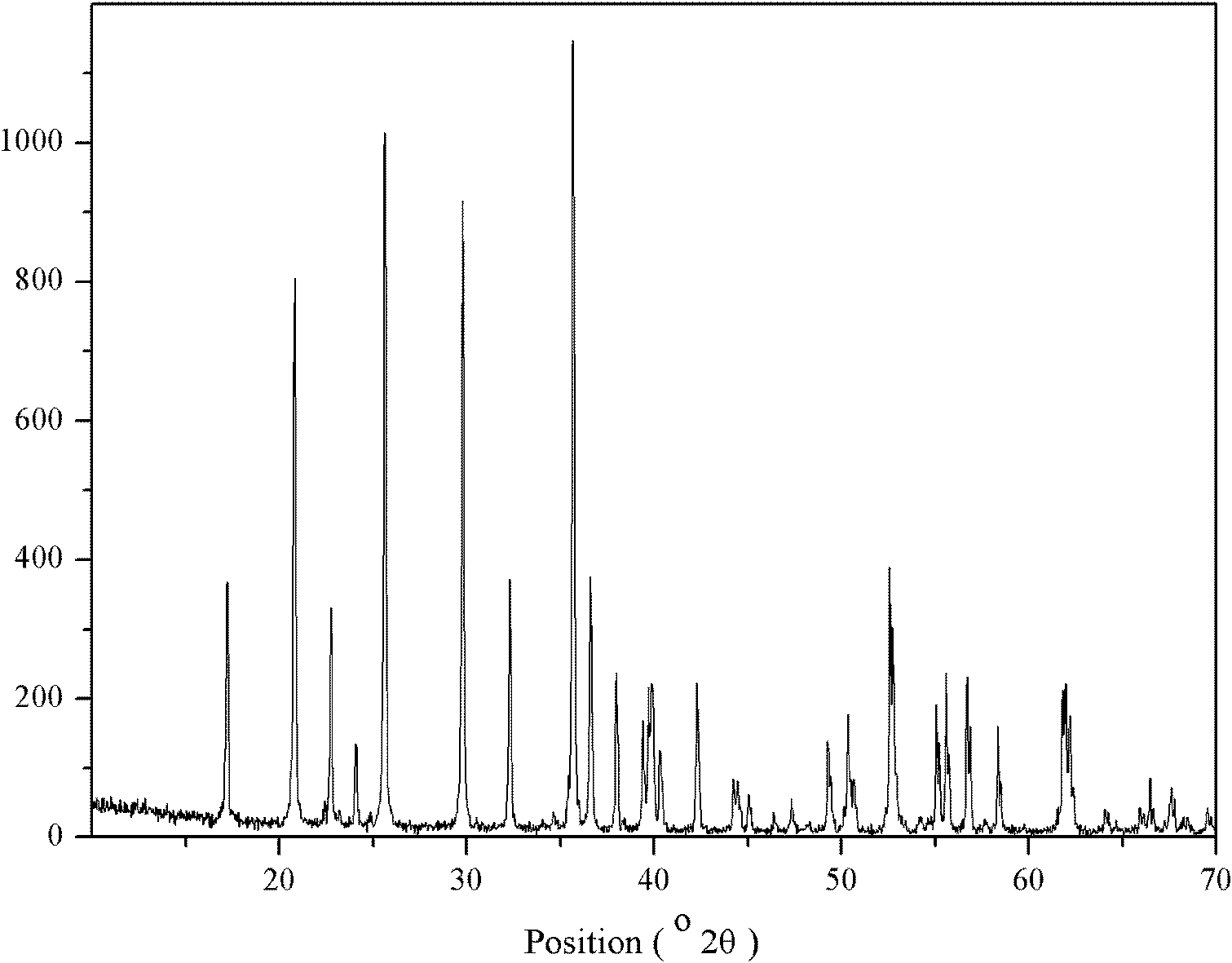

[0026] Get the 70g solid powder sample after insulation treatment in embodiment 1, pour in the ball mill jar that fills dehydrated alcohol, add Li 2 CO 3 The molar ratio of Li:Fe:P in the sample was adjusted to be 1.05:1:1, and then 8 g of graphite carbon black was added and mixed by ball milling for 5 hours. After drying, grinding and sieving the ball-milled samples, they were calcined at 700°C for 18 hours in a nitrogen protective atmosphere to obtain the regenerated lithium iron phosphate product. The carbon content was 4.1% as detected by the carbon-sulfur analyzer, and its XRD data ( figure 2 ) shows that the regenerated sample is lithium iron phosphate, containing a very small amount of impurities. The lithium iron phosphate sample, conductive carbon black and polytetrafluoroethylene (PTFE) were uniformly mixed at a mass ratio of 82:10:8 to make a simulated battery positive electrode sheet, which was assembled with a metal lithium sheet to form a half-cell, which was t...

Embodiment 3

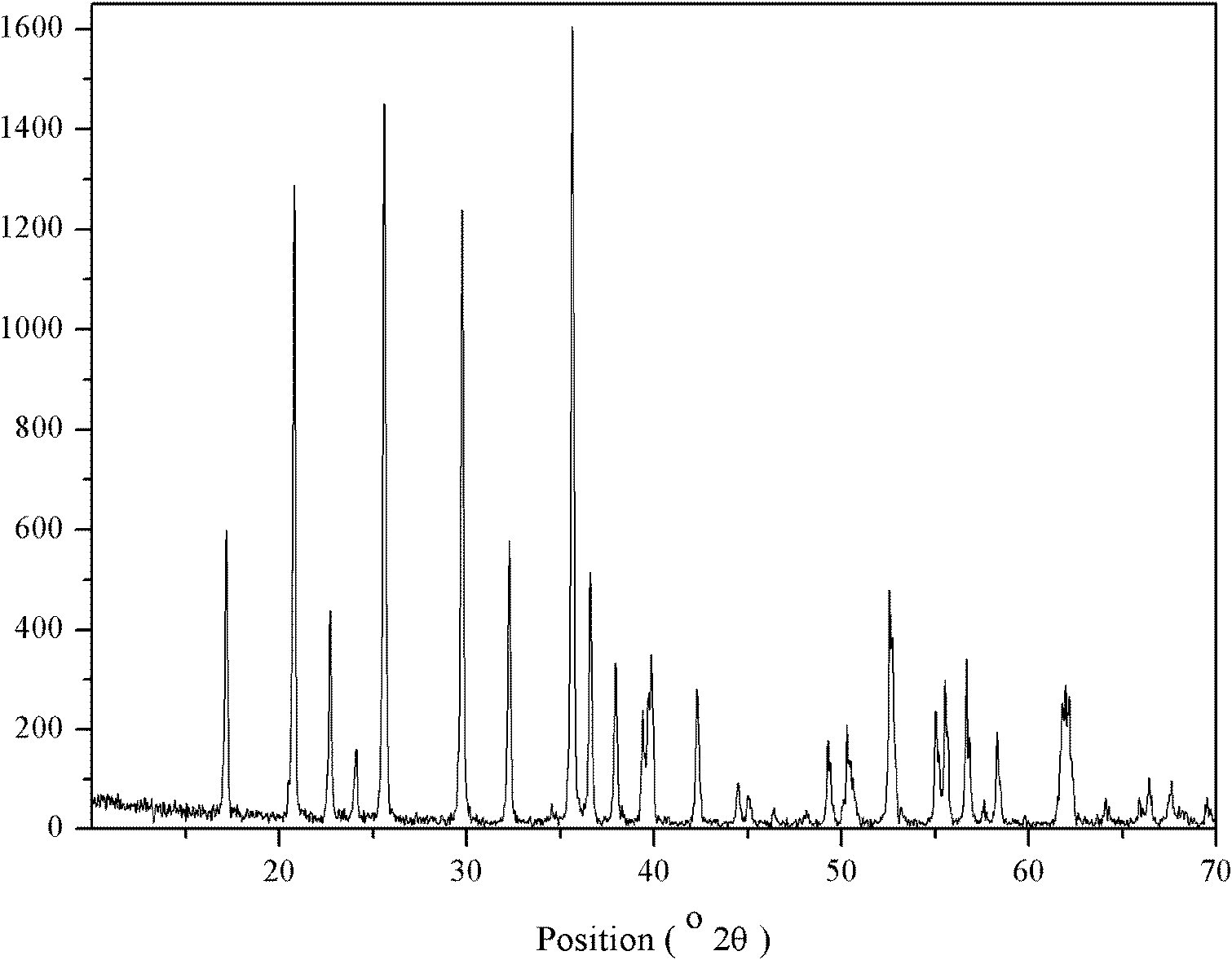

[0028] Get 70g solid powder sample after insulation treatment in embodiment 1, pour in the ball mill jar that fills acetone, add Li 2 CO 3 and LiH 2 PO 4 Adjust the molar ratio of Li:Fe:P in the sample to 1.02:1:1.02, then add 8g of graphite carbon black and 2g of glucose and fully ball mill and mix for 6h. After drying, grinding and sieving the ball-milled samples, they were calcined at 750°C for 20 hours in a nitrogen protective atmosphere to obtain the regenerated lithium iron phosphate product. The carbon content was 3.4% as detected by a carbon-sulfur analyzer, and its XRD data ( image 3 ) shows that the regenerated sample is relatively pure lithium iron phosphate. Then the lithium iron phosphate sample, conductive carbon black and polytetrafluoroethylene (PTFE) were uniformly mixed at a mass ratio of 82:10:8 to make a simulated battery positive pole piece, which was assembled with a metal lithium sheet to form a half-cell. According to the analysis and detection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com