Lithium ion battery silicon-carbon anode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult dispersion of nano-silica powder, low initial efficiency of materials, and low initial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

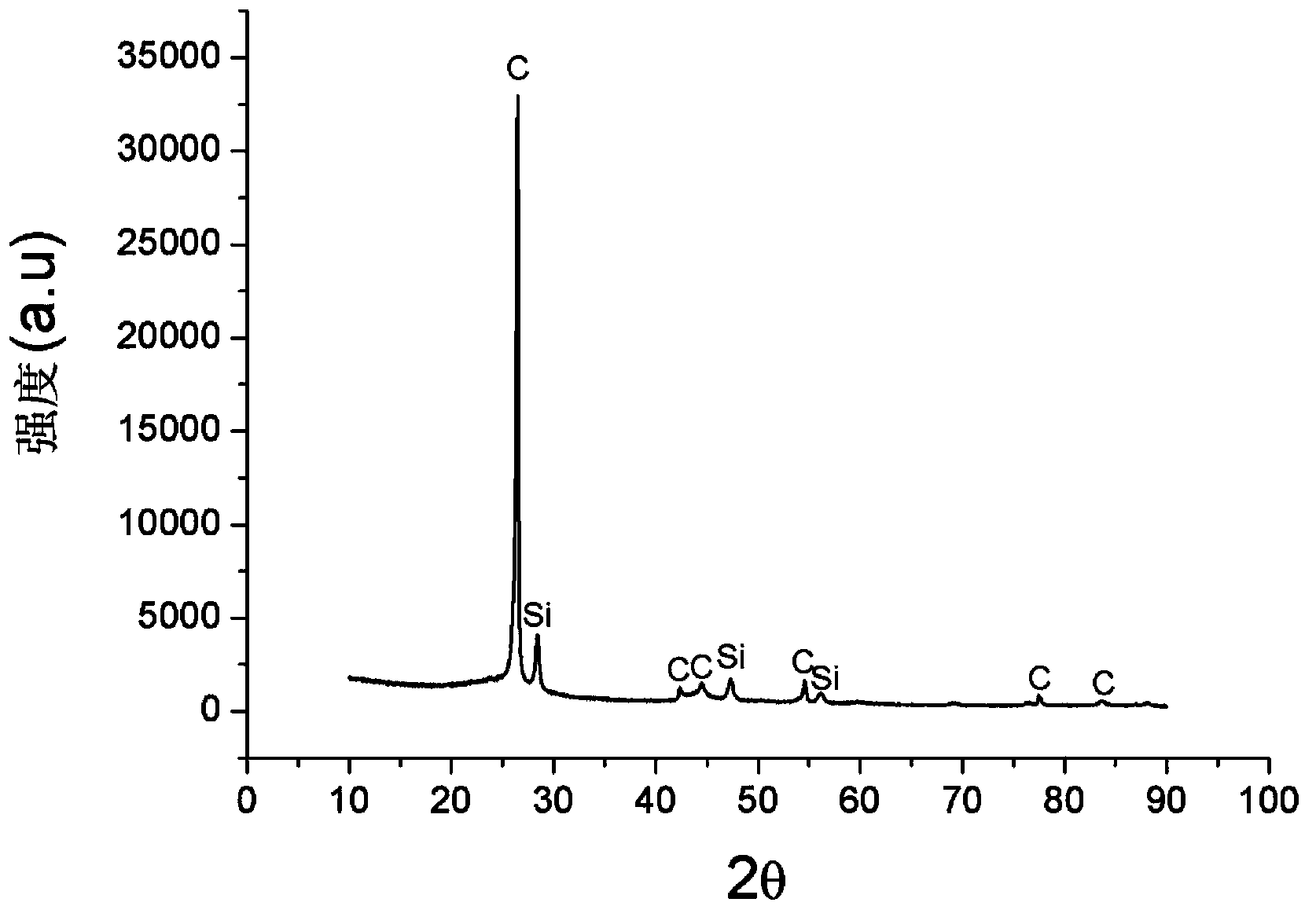

Image

Examples

Embodiment 1

[0062] (1) Put D 50 10g of silicon powder with a particle size of 130nm, add it to a mixed solution of ethanol and acetone with a mass ratio of 8:2, the mass of the mixed solution is 100g, and then add 0.3g of cetyltrimethylammonium bromide to mix In solution; then at a frequency of 30kHz and a power density of 1.2W / cm 2 In the ultrasonic equipment, ultrasonic stirring is performed for 15 minutes to form a uniform nano-silicon suspension.

[0063] (2) Dissolve 17.5 g of lauric acid in 175 g of methanol, and slowly drop the lauric acid solution into the nano-silicon suspension, stir in a disperser at 1500 rpm for 1 h; then add 80 g of D 50 Artificial graphite with a particle size of 1 μm is added to it, and stirring is continued for 3 hours to obtain a uniformly mixed slurry. The slurry is dried to obtain a nano silicon / graphite polymer.

[0064] (3) Dissolve 25 grams of phenolic resin in 500g of ethanol to form a phenolic resin solution, and slowly add the nano silicon / graphite pol...

Embodiment 2

[0077] (1) Put D 50 10 grams of nano silicon powder with a particle size of 30nm is added to 1000 grams of ethanol solution, and then 0.5g of polyoxyethylene sorbitan monooleate is added to the solution, the frequency is 40kHz, the power density is 1.2W / cm 2 In the ultrasonic equipment, ultrasonic for 30 minutes to form a uniform nano-silicon suspension.

[0078] (2) Dissolve 30 grams of tetradecanoic acid in 150g ethanol, slowly drip the tetradecanoic acid solution into the nano-silicon suspension, and stir for 2h in a disperser with a rotating speed of 500rpm; then, the 100g D50 particle size is 0.5μm artificial graphite was added to it, and stirring was continued for 5 hours to obtain a uniformly mixed slurry. The slurry is dried to obtain a nano silicon / graphite polymer.

[0079] (3) Dissolve 50 g of pitch in 300 g of tetrahydrofuran to form a pitch suspension, and slowly add the nano-silicon / graphite polymer to the pitch suspension, stir at 2000 rpm for 1 hour to obtain a unif...

Embodiment 3

[0088] (1) Put D 50 10 grams of nano silicon powder with a particle size of 200nm is added to the mixed solution of isopropanol and methanol with a mass ratio of 9:1. The mass of the mixed solution is 50 grams, and then 0.03g of polyethylene glycol is added to the mixed solution. Isooctyl phenyl ether, the frequency is 10kHz, the power density is 1.2W / cm 2 In the ultrasonic equipment, ultrasonic stirring is performed for 10 minutes to form a uniform nano-silicon suspension.

[0089] (2) Dissolve 5 grams of arachidic acid in 100g of a mixed solution of ethanol and acetone with a mass ratio of 9:1, and slowly drop the arachidic acid solution into the nano-silicon suspension, in a disperser with a rotation speed of 2000 rpm Stir for 0.5h; then add 50g D 50 Natural graphite with a particle size of 10 μm is added, and stirring is continued for 1 hour to obtain a uniformly mixed slurry. The slurry is dried to obtain a nano silicon / graphite polymer.

[0090] (3) Dissolve 15 grams of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com