Graphene and oxide ceramic composite material and preparation method

A technology of oxide ceramics and composite materials, which is applied in the field of graphene and oxide ceramic composite materials and preparation, can solve the problems of interface bonding and other problems, and achieve the effects of enhanced strength, low preparation cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

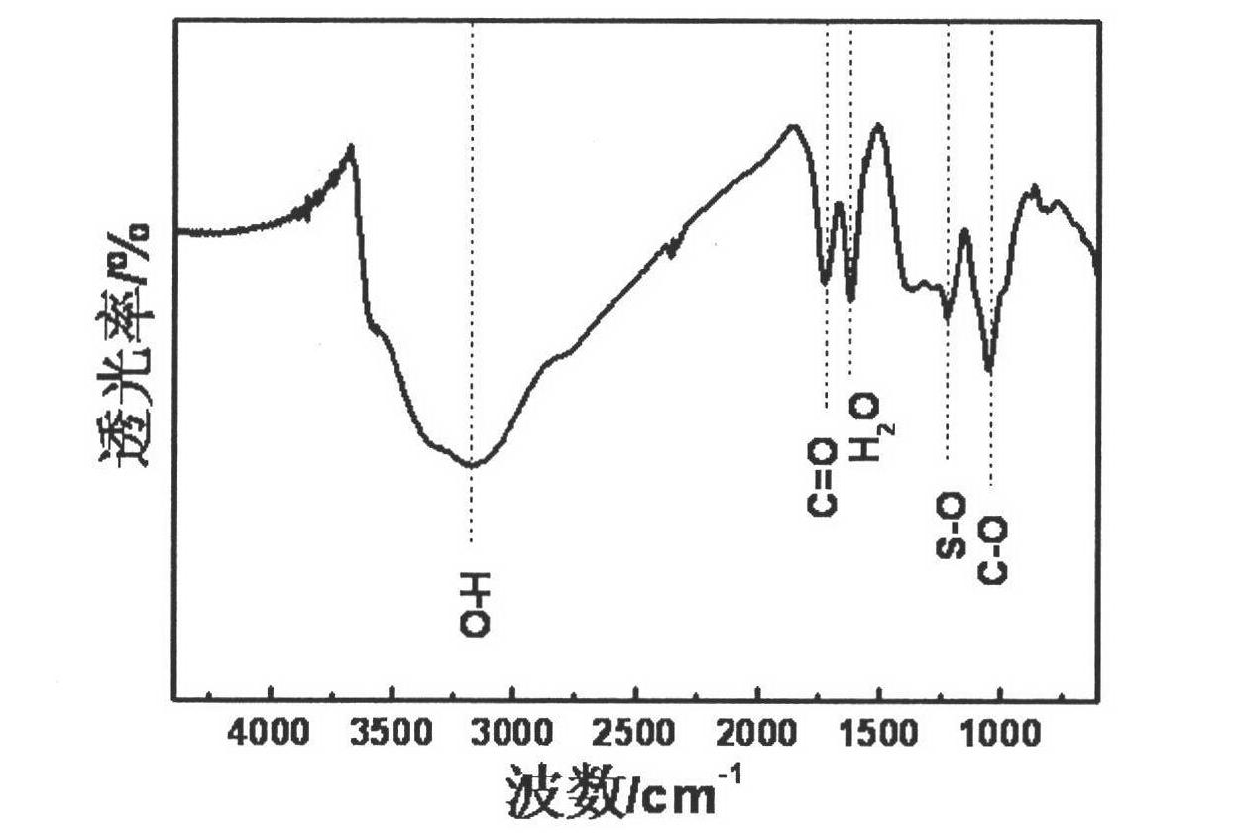

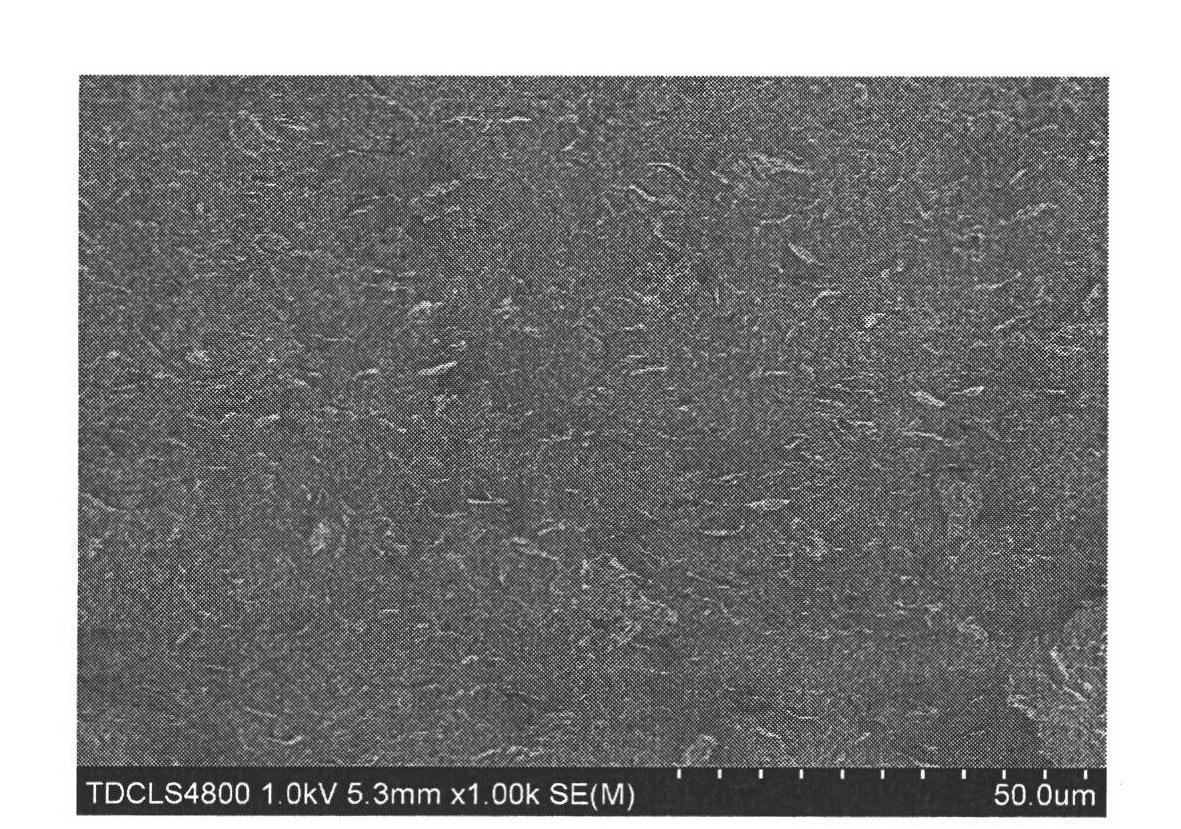

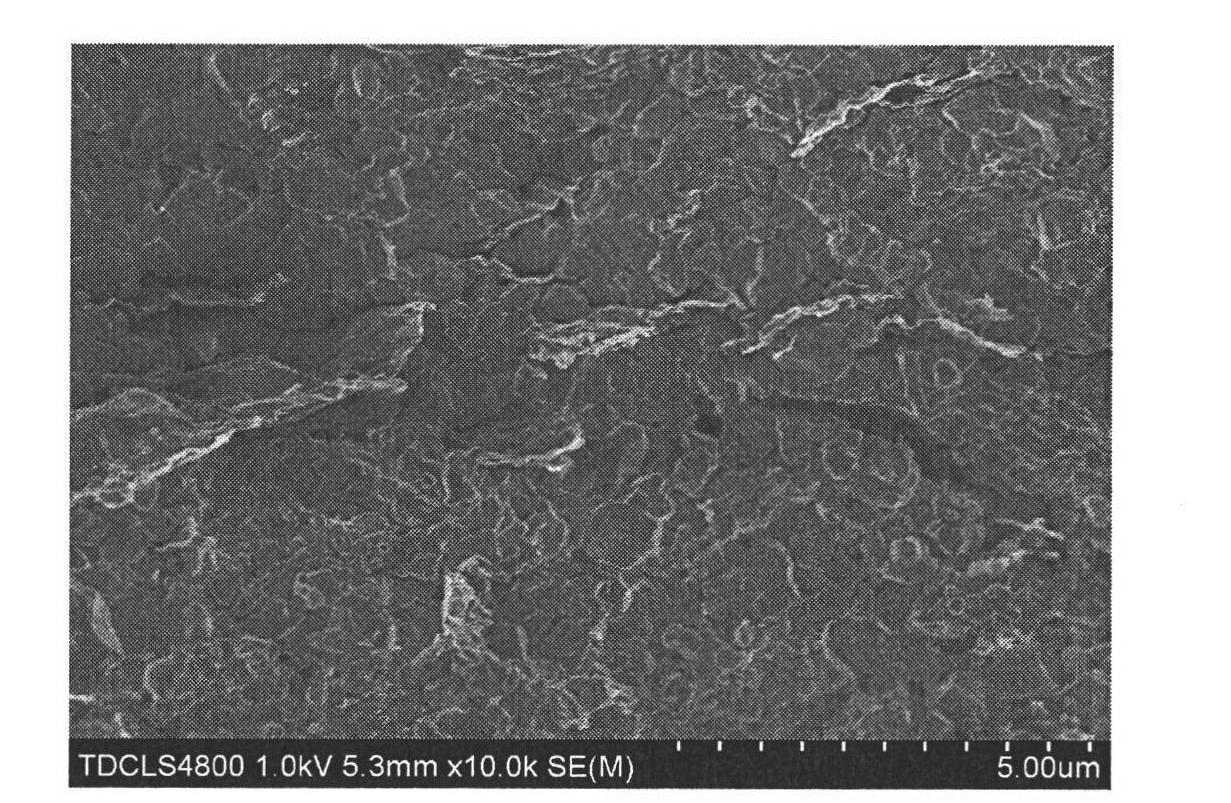

[0024] Embodiment 1: Prepare high-purity graphite oxide (G.I.Titelman, V.Gelman, S.Bron, et al.Characteristics and microstructure of aqueous collagen dispersions of graphite oxide) with improved Hummer method. Weigh 4g of zirconia powder and 0.3g of graphite oxide, add them to 40ml of absolute ethanol, and disperse them ultrasonically for 1 hour to obtain a dispersion of graphite oxide and zirconia. Ball mill them at a speed of 800r / min for 6 hours. After ball milling, pour the mixture into a beaker for 65 ℃ water bath for 24 hours to obtain a free-flowing powder, which was ground to obtain a powder. Weigh ~0.4g, and dry press with 60MPa pressure to obtain a green body. Put the green body into a vacuum tube furnace (Shenyang Kejing Equipment Manufacturing Co., Ltd., GSL-1600X), maintain an argon atmosphere, heat up to 1300°C for 2 hours at 5°C / min, cool down to room temperature naturally, take out the graphene and oxidize Zirconium ceramic composite. Using scanning electron ...

Embodiment 2

[0025] Embodiment 2: Using the same method as in Example 1, the addition of graphite oxide is 0.5g, and pyrolyzed to obtain graphene and zirconia ceramic composite material. The measured conductivity is 429.26S / m.

Embodiment 3

[0026] Embodiment 3: Using the same method as in Example 1, the addition of graphite oxide is 0.8g, and pyrolyzed to obtain graphene and zirconia ceramic composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com