High-wear-resistance and high-tenacity medical zirconium alloy and preparation method and application thereof

A zirconium alloy, high-strength technology, applied in the field of high-performance medical alloy materials, to achieve the effect of convenient operation, simple processing process and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

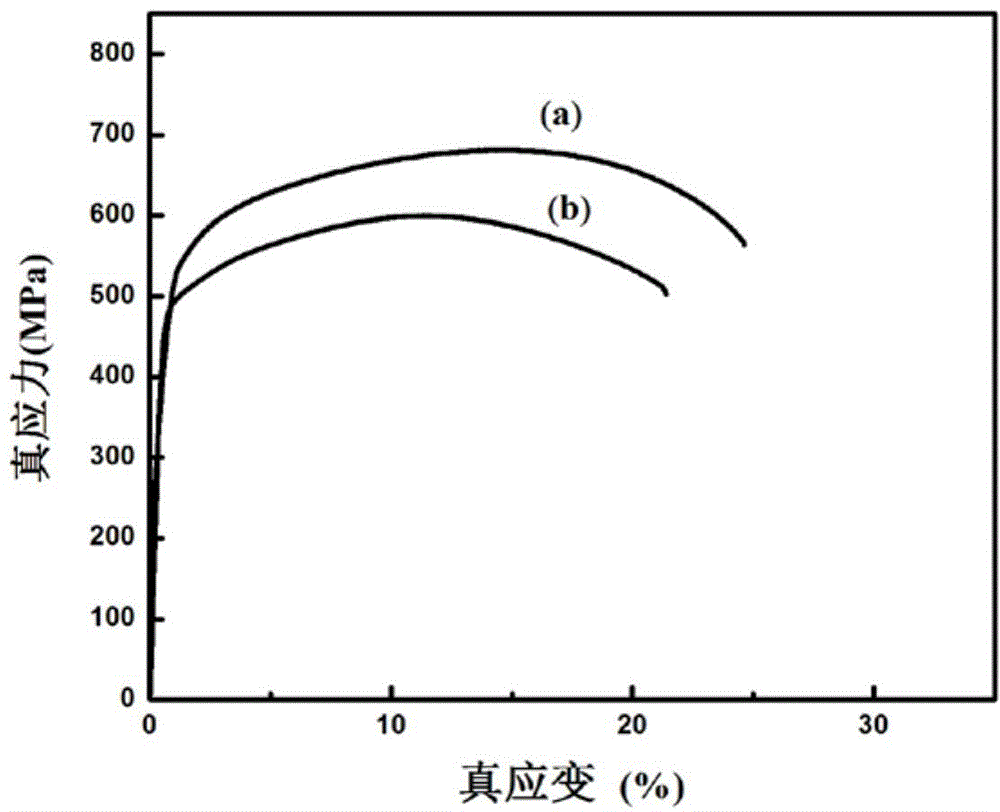

Embodiment 1

[0043] Step 1: Plastic deformation treatment of zirconium-niobium alloy

[0044] A plate-shaped 95.8Zr-2.1Nb-2.1Hf zirconium-niobium alloy sample (commercially available) with a thickness of 10mm was rolled at room temperature by a twin-roll mill, with a deformation of about 0.4mm per pass, and rolled several times until the thickness was about 4mm , so that the amount of plastic deformation is 60%.

[0045] Step 2: Surface pretreatment of plastically deformed zirconium-niobium alloy

[0046] Use 180# to 2000# sandpaper to grind the plastically deformed zirconium-niobium alloy, then mechanically polish it, then immerse it in acetone and alcohol and clean it with an ultrasonic cleaner for 30 minutes to remove surface oil, and finally dry the surface deal with.

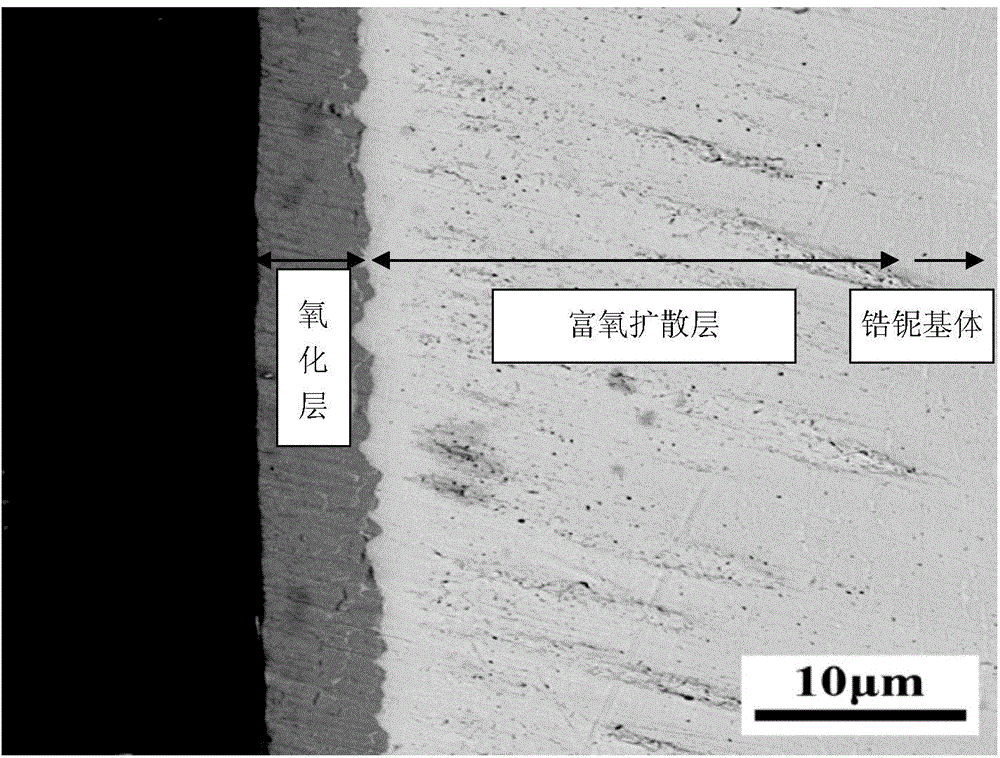

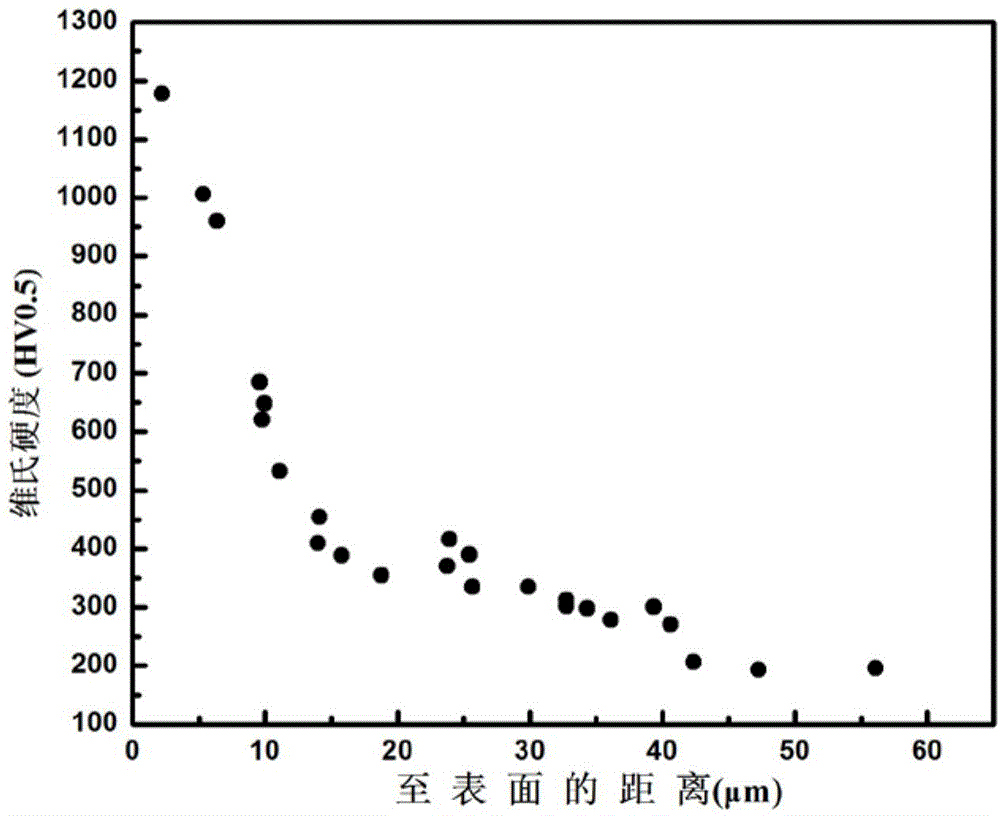

[0047] Step 3: High-temperature oxidation treatment of plastically deformed zirconium-niobium alloy

[0048] Put the surface-pretreated zirconium-niobium alloy in a resistance furnace, heat up for oxidation treatment i...

Embodiment 2

[0056] Step 1: Plastic deformation treatment of zirconium-niobium alloy

[0057] A plate-shaped 95.8Zr-2.1Nb-2.1Hf zirconium-niobium alloy sample (commercially available) with a thickness of 10mm was subjected to room temperature rolling treatment by a twin-roll mill to make the plastic deformation amount to 65%.

[0058] Step 2: Surface pretreatment of plastically deformed zirconium-niobium alloy

[0059] Use 180# to 2000# sandpaper to grind the plastically deformed zirconium-niobium alloy, then mechanically polish it, then immerse it in acetone and alcohol and clean it with an ultrasonic cleaner for 30 minutes to remove surface oil, and finally dry the surface deal with.

[0060] Step 3: High-temperature oxidation treatment of plastically deformed zirconium-niobium alloy

[0061] Put the surface-pretreated zirconium-niobium alloy in a resistance furnace, heat up for oxidation treatment in air environment, and the oxidation process conditions are as follows:

[0062] Oxida...

Embodiment 3

[0069] Step 1: Plastic deformation treatment of zirconium-niobium alloy

[0070] A plate-shaped 91.8Zr-8.2Nb zirconium-niobium alloy sample (commercially available) with a thickness of 10 mm was rolled at room temperature by means of a twin-roll rolling mill, so that the plastic deformation amount was 55%.

[0071] Step 2: Surface pretreatment of plastically deformed zirconium-niobium alloy

[0072] Use 180# to 2000# sandpaper to grind the plastically deformed zirconium-niobium alloy, then mechanically polish it, then immerse it in acetone and alcohol and clean it with an ultrasonic cleaner for 30 minutes to remove surface oil, and finally dry the surface deal with.

[0073] Step 3: High-temperature oxidation treatment of plastically deformed zirconium-niobium alloy

[0074] Put the surface-pretreated zirconium-niobium alloy in a resistance furnace, heat up for oxidation treatment in air environment, and the oxidation process conditions are as follows:

[0075] Oxidation eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com