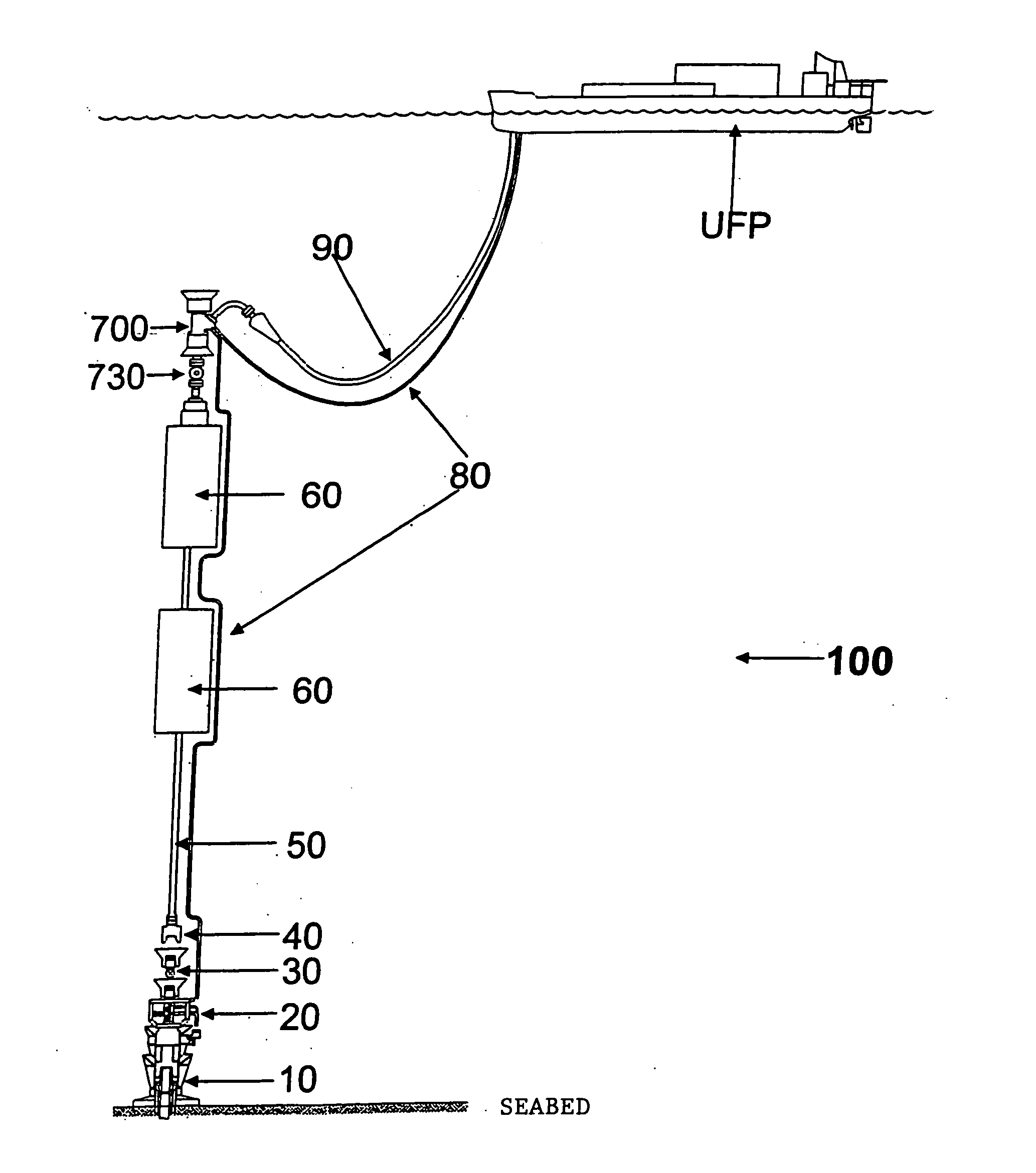

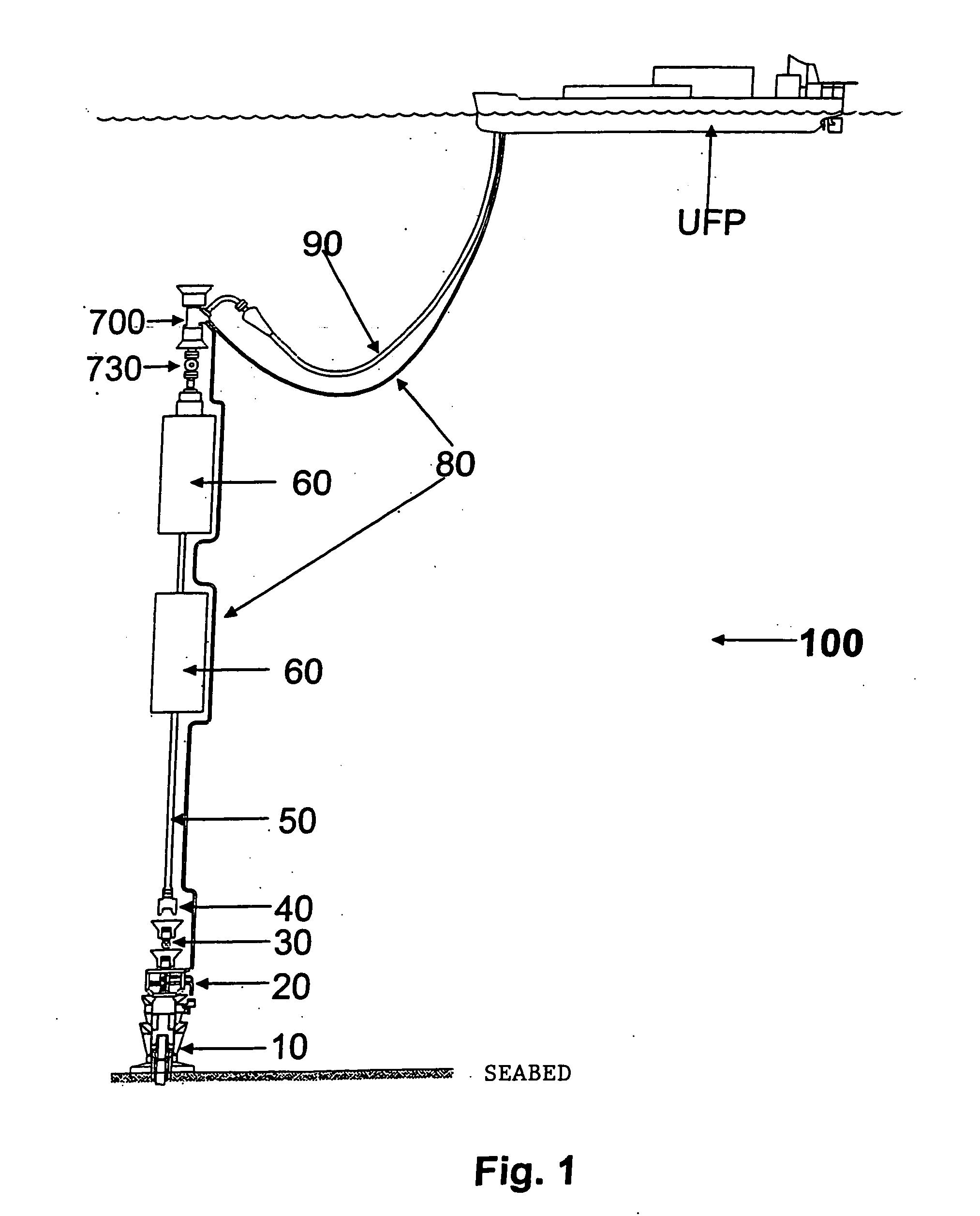

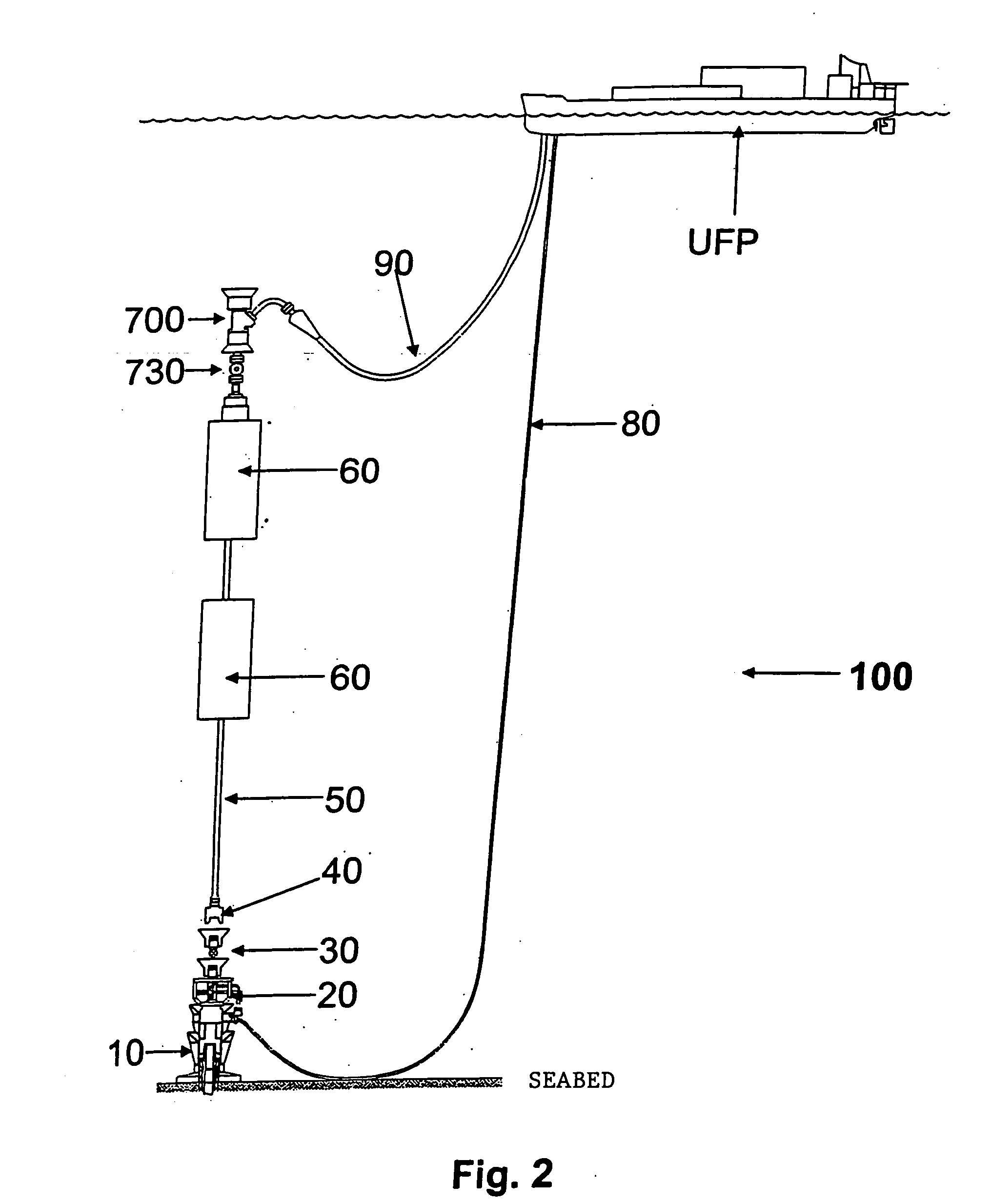

Self-supported riser system and method of installing same

a self-supporting, riser technology, applied in the direction of passenger handling apparatus, transportation and packaging, borehole/well accessories, etc., can solve the problems of high operational cost, construction and assembly of the riser, and the practicability of lowering, so as to reduce the maneuvering steps and save the time of the rig

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0101] In accordance with the first embodiment, generally shown in FIGS. 6 to 18, the installation method of the riser system (100) comprises the following steps: [0102] a) hoisting the buoy assembly (60), by means of a crane (G), (FIG. 6), from a dock and placing it in a transportation raft (802). As an alternative, the buoy assembly may be placed on the raft by sliding it on the dock surface. Following the placement on the raft, sea fastening the buoy assembly to avoid dislocation of the buoy assembly on the raft during the oceanic transport; [0103] b) transporting the raft (802) and the buoy assembly (60), with the aid of a tug (803), (FIG. 7), to the location at which the riser system (100) is to be installed; [0104] c) in the proximity of a semi-submersible platform (804) for lowering the riser (50), (FIG. 8), connecting the buoy assembly (60): i) utilizing a cable (805) to a semi-submersible platform (804) and ii) utilizing a cable (806) connecting the buoy assembly to the tug...

second embodiment

[0119] According to this second embodiment, shown on FIGS. 19 to 21, the installation method of the riser system (100) of the following invention includes the following steps: [0120] a) mounting the WCT (20), the BOP preventor (30) and the connection tool (40) on a temporary support unit (901), located in the moon pool region (902) of the installation platform (804). Connecting the riser (50), formed of riser sections, to the connection tool (40), (FIG. 19A) and detail of joint (810) (FIG. 19B); [0121] b) connecting and lowering the sections (810), whose conjoint forms the riser (50), until the required length for the installation of the first buoys (60) is reached; maneuvering the buoy in the moon pool region (902) of the installation platform in order to enclose the riser sections (810) in the center of the buoy through use of the opening (903), so that the buoy (60) is attached to the riser sections (810), (FIG. 20A and detail in FIGS. 20B and 20C); [0122] c) connecting new riser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com