Aggregate Delivery Unit

a technology of delivery unit and aggregate, which is applied in the direction of furnace, cap, borehole/well accessories, etc., can solve the problems of complex exploration, drilling and completion of hydrocarbon and other wells, large unit size, and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

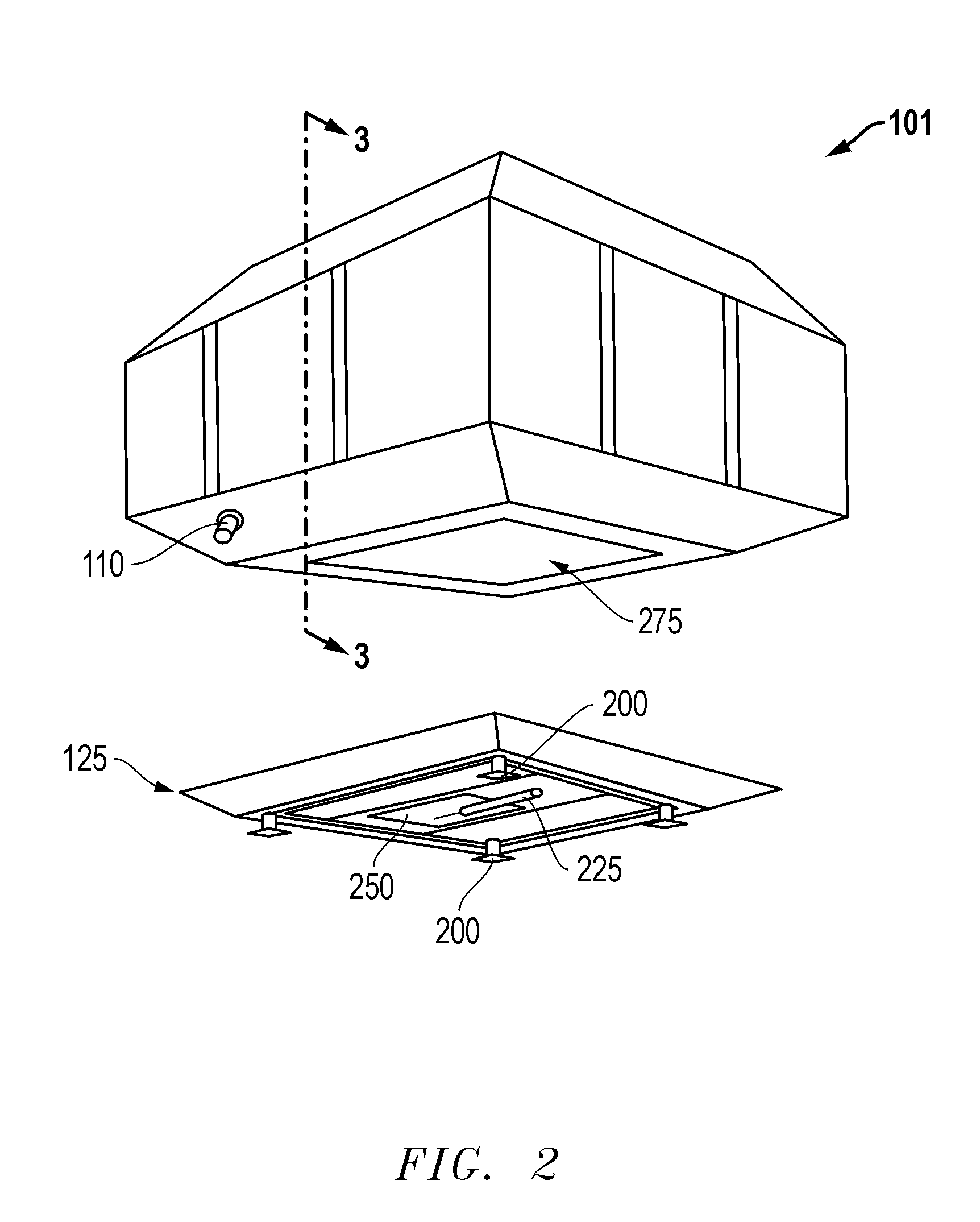

[0025]Embodiments are described with reference to certain aggregate delivery units for delivering proppant to a well at an oilfield during a fracturing operation. However, other types of aggregate may be accommodated by the units for a host of different industrial applications. For example, embodiments of aggregate delivery units described herein may be used in a variety of operations to store and deliver a host of other types of aggregates such as, but not limited to, cement, plastics, fertilizer, feed, and other agricultural products. Regardless, the aggregate delivery unit includes a modular container for housing the aggregate and / or means for monitoring delivery of the aggregate in substantially real-time during an operation.

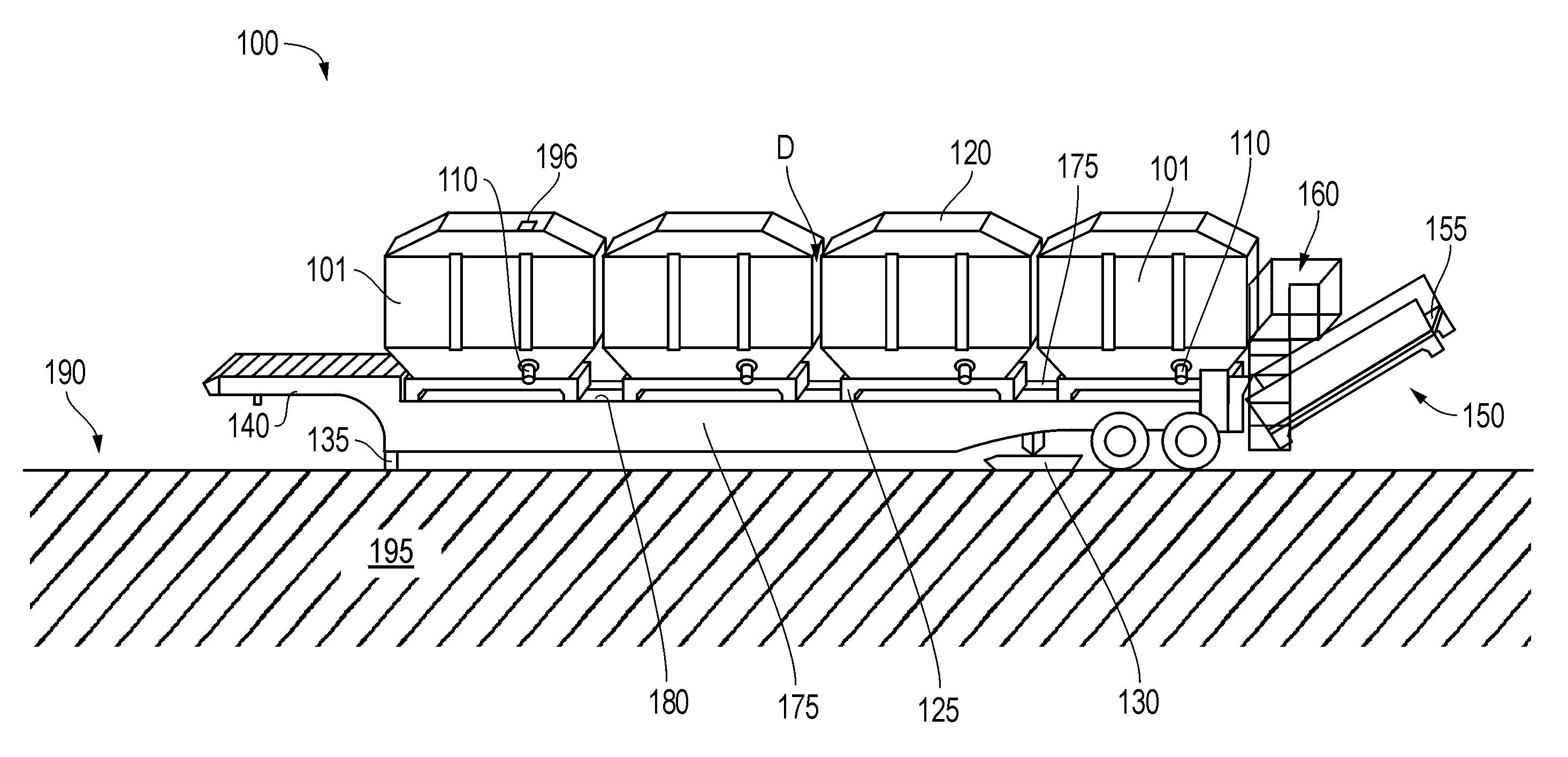

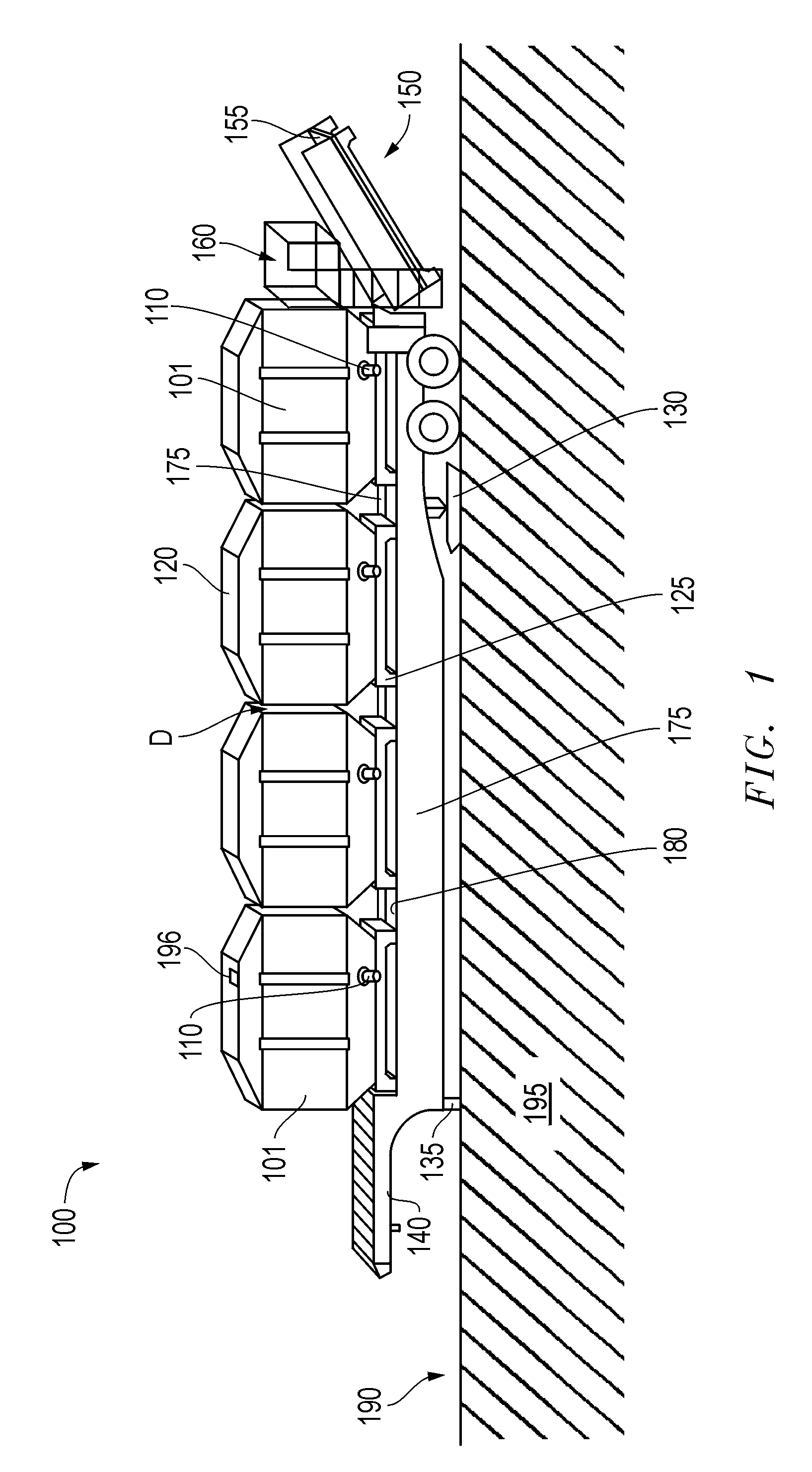

[0026]Referring now to FIG. 1, a perspective view of an aggregate delivery unit 100 is depicted at an oilfield or wellsite location 190. The aggregate delivery unit 100 may have, but is not limited to, a capacity of 2,000-6,000 cubic feet provided by modular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com