Road surface dust suppressant and preparation method thereof

The technology of a dust suppressant and a surfactant is applied in the field of road dust suppressant and its preparation, which can solve the problems of rolling dust and other problems of heavy-duty transport vehicles, so as to solve the problem of rolling dust, solve the problem of dust pollution, and reduce maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

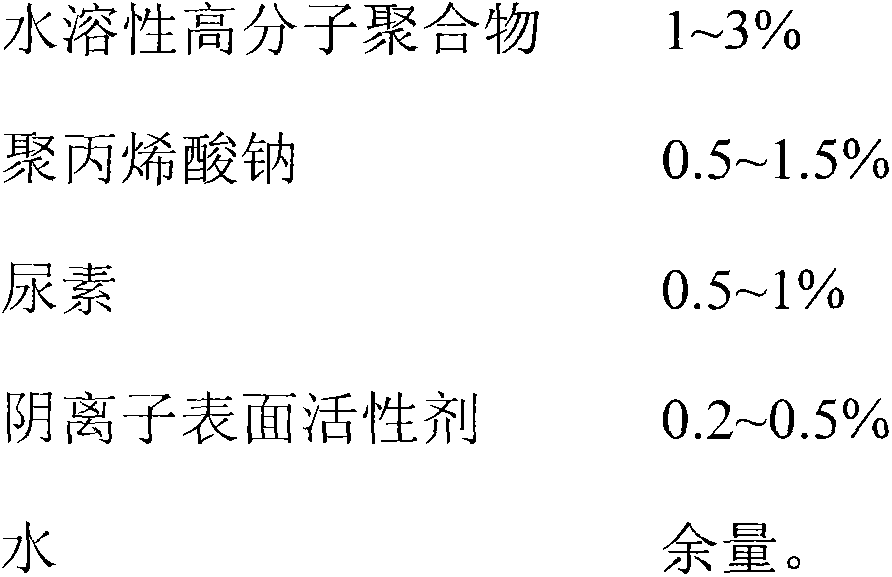

Method used

Image

Examples

Embodiment 1

[0015] Dissolve 3g of carboxymethyl starch in 100ml of water and stir evenly. After it dissolves completely, add 1g of sodium polyacrylate, 1g of urea, and 0.5g of sodium dodecylbenzene sulfonate in sequence, and stir until it dissolves evenly to obtain the road inhibitor. Dust finished product.

[0016] The content of each component in the above-mentioned dust suppressant solution is: carboxymethyl starch 2.8%, sodium polyacrylate 0.95%, urea 0.95%, sodium dodecylbenzenesulfonate 0.47%. Moisture absorption performance, suitable for muddy road sites.

Embodiment 2

[0018] Dissolve 1.5g of carboxymethyl cellulose in 100ml of water, stir evenly, add 0.8g of sodium polyacrylate, 0.6g of urea, and 0.3g of sodium dodecylbenzenesulfonate in turn after it dissolves completely, and stir until it dissolves evenly. The finished road dust suppressant can be obtained.

[0019] The content of each component in the above-mentioned dust suppressant solution is: 1.5% of carboxymethyl cellulose, 0.78% of sodium polyacrylate, 0.58% of urea, and 0.29% of sodium dodecylbenzenesulfonate. The finished dust suppressant has a good Wetting and hygroscopic properties, suitable for streets and cement roads.

Embodiment 3

[0021] Take 1.2g of carboxymethyl starch dissolved in 100ml of water, stir evenly, after it is completely dissolved, add 0.6g of sodium polyacrylate, 0.6g of urea, 0.3g of sodium dodecylbenzenesulfonate, and stir until it dissolves evenly Obtain the finished road dust suppressant.

[0022] The content of each component in the above dust suppressant solution is: 1.2% carboxymethyl starch, 0.58% sodium polyacrylate, 0.58% urea, 0.29% sodium dodecylbenzenesulfonate. Moisture absorption performance, suitable for indoor cement floor and cladding, etc.

[0023] The road surface dust suppressant of the present invention is a liquid dust suppressant with strong anti-compressive function integrating comprehensive properties such as coagulation, penetration, moisture absorption and water retention. The dust suppressant is composed of three main parts: coagulation, moisture absorption and water retention. One is the coagulation factor. It is made of water-soluble polymer materials to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com