Shape forming process and application thereof for creating structural elements and designed objects

a technology of shape forming and design objects, applied in auxillary shaping apparatus, conductive materials, non-conductive materials with dispersed conductive materials, etc., can solve the problems of adding to the development cycle time, consuming unnecessary time, materials, and waste of composite parts,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0058]FIG. 9 illustrates an example of a shaped object produced using a structural element such as described with examples provided herein. In FIG. 9, a wiring board 900 is fabricated to have a desired shape, such as to conform to specifications for a wearable electronic device. In an example of FIG. 9, non-electrically conductive fibers and resins are integrated with conductive wires (tapes, strips, foils) and resins into a circuit board with curved shape and conductive traces in a given orientation in free space. The wiring board 900 can include sections 910, each of which is formed separately using a tool such as described with any of the examples provided herein. Electrical components can be formed or assembled on the surface of the wiring board 900. In some embodiments, the sections formed using, for example, a three-dimensional printing tool such as described with an example of FIG. 1, with structural elements include a fiber core or resin exterior which carry conductive trace...

examples

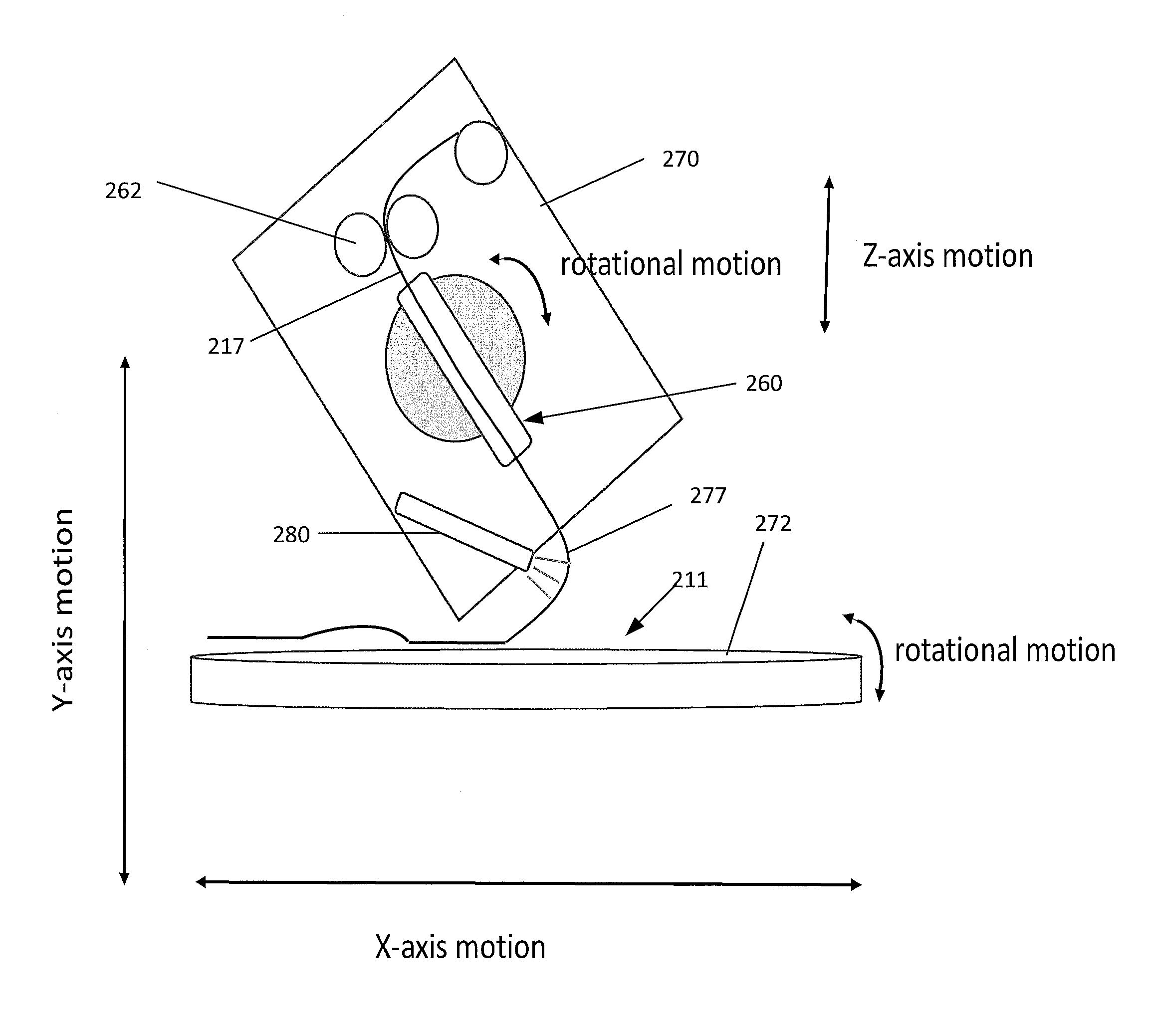

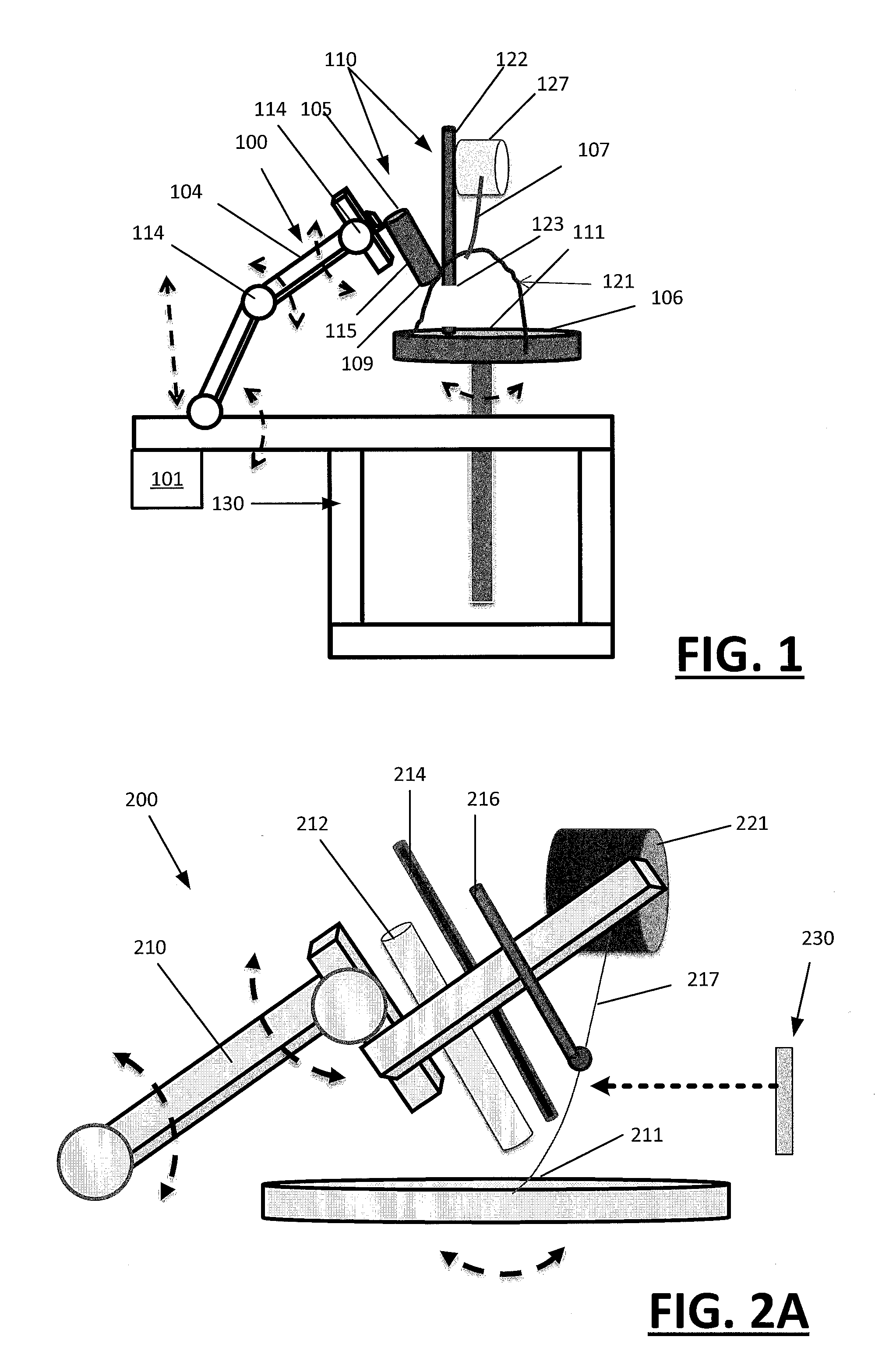

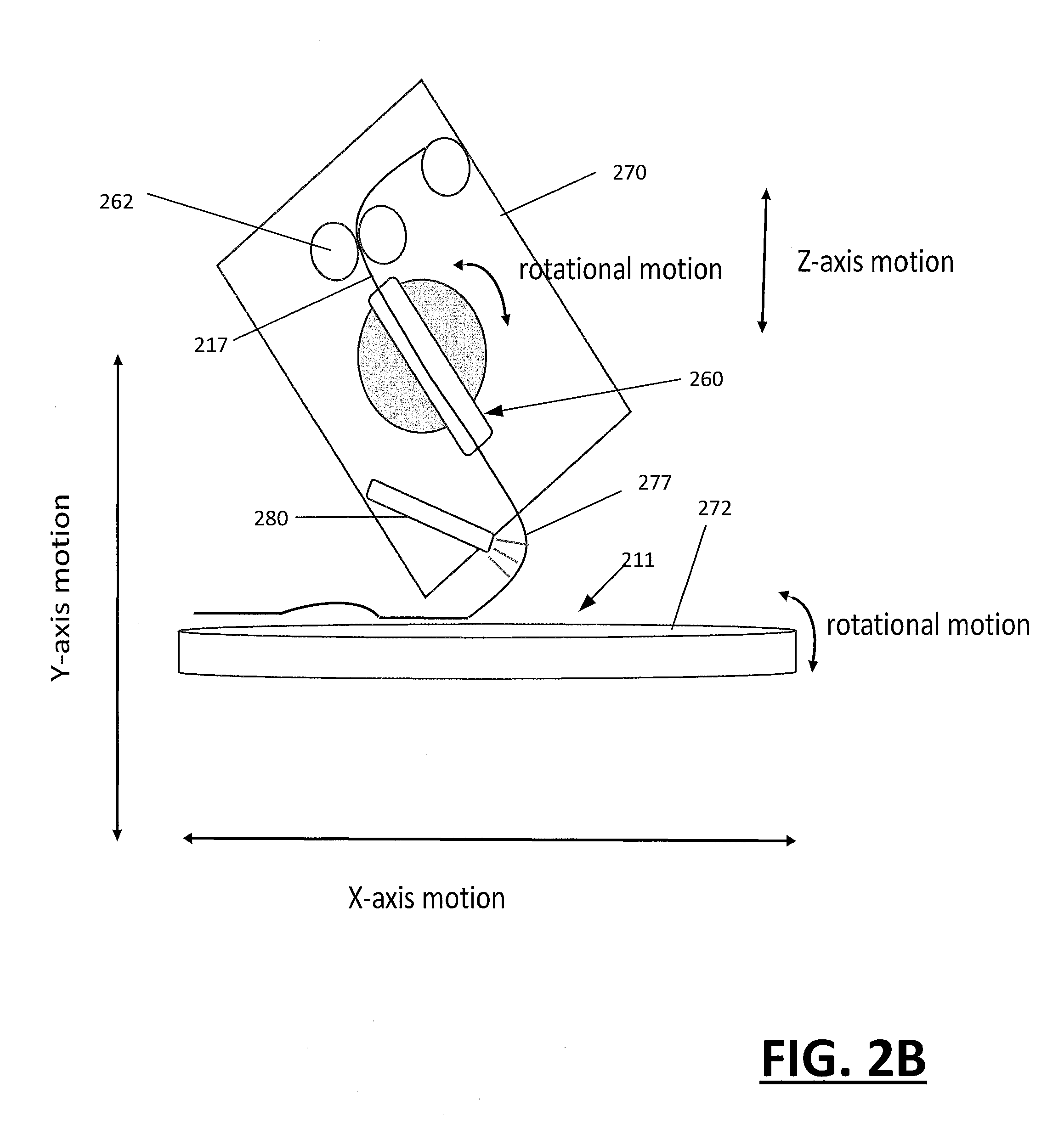

[0060]With reference to examples provided above, the tool 100 can be implemented as 3-axis machine with 3 stepper motors and a microcontroller. In such an example, the robotic arm 104 can, for example, enable movement of about 6 inches in Z-direction, and 18 inches in x and y directions.

[0061]The fiber source can correspond to, for example, a reel of S-glass fiber roving purchased from AGY CORORATION (provided under the product name of ZENTRON758-AB-675)

[0062]In some variations, a glass roving can be created by pulling a bobbin and pushed through a tube into a feedblock. The individual fiber can be around 10-20 microns in diameter and the roving can be around 0.5 mm in diameter The glass roving can be pulled / pushed in a controlled metering fashion using a stepper motor driven soft wheel and a steel bearing. Simultaneously a resin delivery mechanism can be implemented using a UV curable liquid resin, which can be metered to a feedblock using a syringe pump. A fiber coated with resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com