A kind of preparation method and product thereof of lithium iron phosphate material with high capacity and high compaction density

A lithium iron phosphate, high-pressure compaction technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low compaction density of powder, difficult to crush, low compaction density of pole pieces, etc., to achieve The effect of shortening the required time, improving production efficiency, and increasing the uniformity of carbon coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

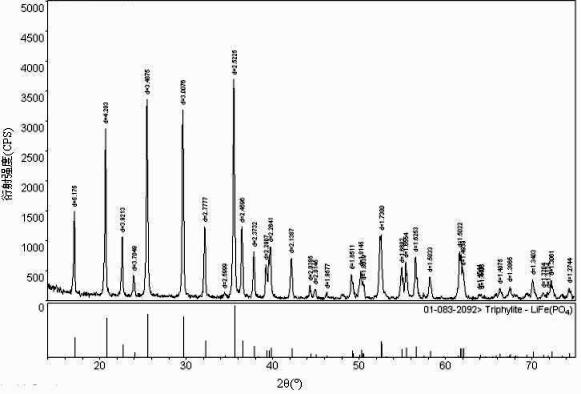

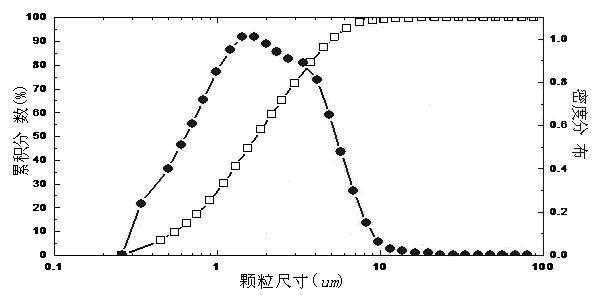

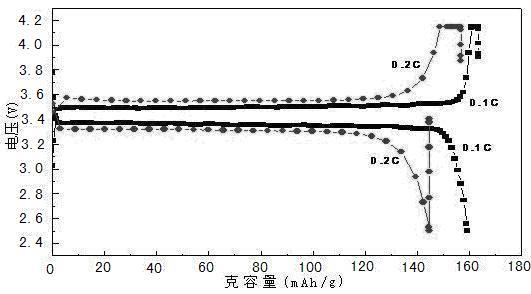

Embodiment 1

[0045] 3080 grams of lithium hydroxide monohydrate, 6209 grams of iron oxyhydroxide (specific surface area 100m 2 / g and the primary particle size of the particles is less than 100nm), 8444 grams of ammonium dihydrogen phosphate, 117 grams of titanium dioxide and 1046 grams of sucrose are mixed, put into a wet stirring ball mill, add 30 kg of water, add 200 kg of zirconia balls, and mix for 5 hours after ball milling , to obtain a mixed slurry with a particle size of D50=200-600nm, and then use a centrifugal spray dryer to obtain a spray powder under the conditions of an inlet temperature of 200°C and an outlet temperature of 100°C; the spray The powder is put into an atmosphere protection furnace, and under a nitrogen atmosphere of 10 liters / min, the temperature is raised to 400°C at a rate of 3°C / min for 2 hours, and then cooled to room temperature at a rate of 2°C / min to obtain a pre-fired product. 14kg pre-burned product, 56g specific surface area is 770m 2 / g of superfin...

Embodiment 2

[0050] 3080 grams of monohydrate lithium hydroxide, 6394 grams of iron oxyhydroxide (specific surface area 100m 2 / g and the primary particle size of the particles is less than 100nm), 8444 grams of ammonium dihydrogen phosphate, 64 grams of magnesium hydroxide and 1046 grams of sucrose are mixed, put into a wet stirring ball mill, add 30 kg of water, add 200 kg of zirconia balls, and mix by ball milling for 2 Hours later, a mixed slurry with a particle size of D50=200-600nm was obtained, and then the mixed slurry was used in a centrifugal spray dryer to obtain a spray powder at an inlet temperature of 230°C and an outlet temperature of 100°C; The sprayed powder is placed in an atmosphere protection furnace, and under a nitrogen atmosphere of 10 liters / min, the temperature is raised to 400°C at a rate of 5°C / min for 4 hours, and then the rate is lowered to room temperature at a rate of 3°C / min to obtain pre-calcined product. 14kg pre-burned product, 252g specific surface area...

Embodiment 3

[0053] 3080 grams of monohydrate lithium hydroxide, 5746 grams of ferric oxide (specific surface area 10m 2 / g and the primary particle size of the particles is less than 100nm), 8444 grams of ammonium dihydrogen phosphate, 97.6 grams of niobium pentoxide and 1060 grams of sucrose are mixed, put into a wet stirring ball mill, add 30 kg of water, add 200 kg of zirconia balls, and mix by ball milling After 2 hours, a mixed slurry with a particle size of D50=200-600nm was obtained, and then the mixed slurry was used in a centrifugal spray dryer to obtain a spray powder under the conditions of an inlet temperature of 220°C and an outlet temperature of 95°C; Put the sprayed powder into an atmosphere protection furnace, raise the temperature at a rate of 3°C / min to 400°C for 2 hours under a nitrogen atmosphere of 20 liters / min, and then lower it to room temperature at a rate of 2°C / min to obtain the desired Burn the product. 14kg pre-burned product, 54.6g specific surface area is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com