Tin-silver-copper ternary weldable alloy electroplating solution and electroplating method

A technology of alloy electroplating and tin-silver-copper, which is applied in tin-silver-copper ternary solderable alloy electroplating bath and electroplating field, can solve the problems such as large difference in precipitation potential of three kinds of metal ions, achieve wettability, cathode grain Fine and dense, increase the effect of cathode polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

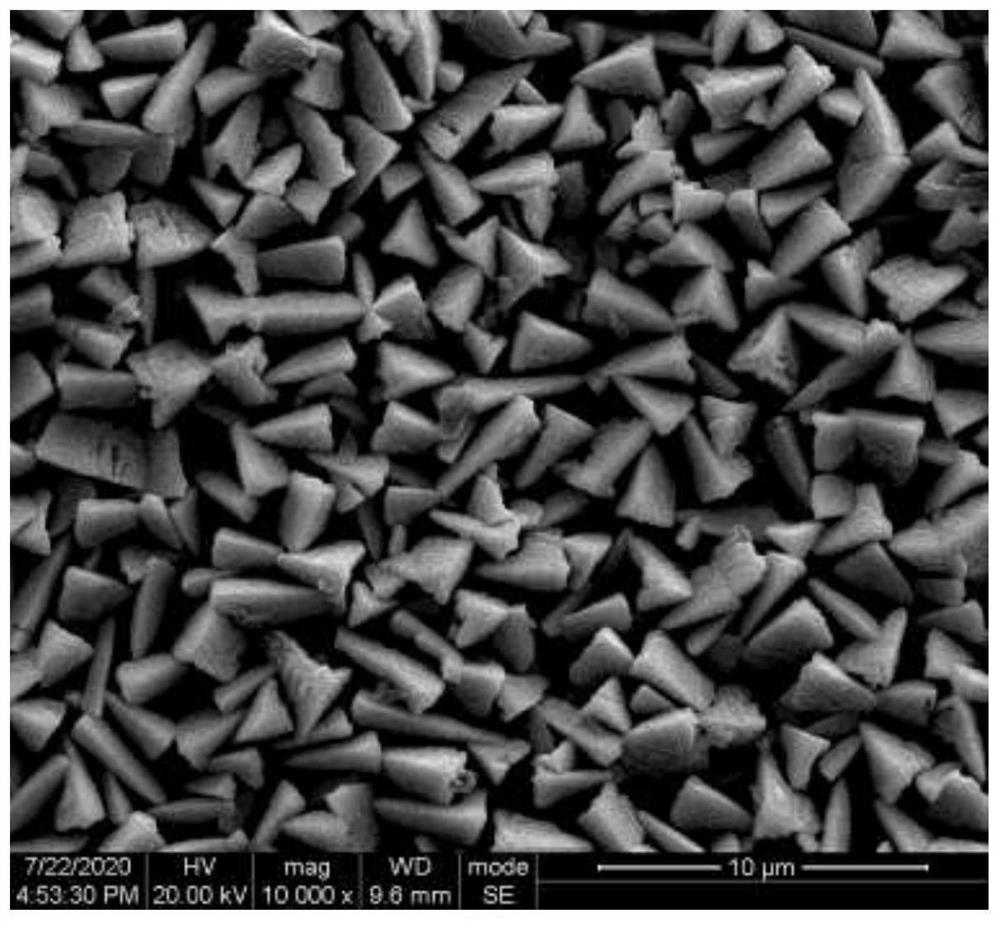

Embodiment 1

[0051] (1) The components and concentrations in the plating solution are as follows:

[0052]

[0053]

[0054] (2) Plating solution configuration method:

[0055] Add 0.0015 mol of silver oxide into 10 ml of methanesulfonic acid solution, heat and stir until the silver oxide completely reacts and disappears to obtain a silver salt solution. To form a heating reflux device, put 5ml of methanesulfonic acid solution in it, heat to 130°C, after the temperature stabilizes, slowly add 0.001mol basic copper carbonate in small amounts for several times, and continue heating after all the basic copper carbonate is added Reflux for 3h. After heating, the device was cooled to room temperature, and deionized water was added to dissolve the solid and filtered to obtain a concentrated copper salt solution. Add 0.00004 mol of benzylidene acetone into 10 ml of deionized water, heat to 40° C. and stir until the solid benzylidene acetone is completely dissolved to obtain a brightener s...

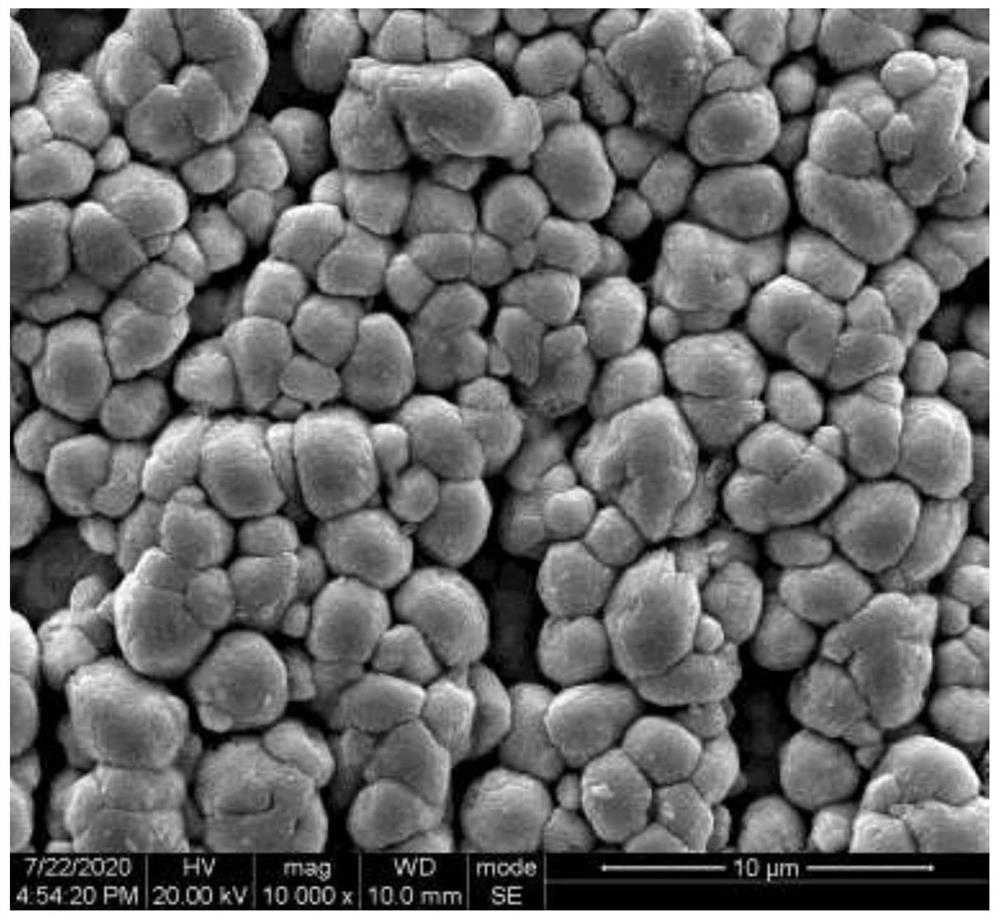

Embodiment 2

[0134] (1) The components and concentrations in the plating solution are as follows:

[0135]

[0136]

[0137] (2) Plating solution configuration method:

[0138] Add 0.003 mol of silver oxide into 10 ml of methanesulfonic acid solution, heat and stir until the silver oxide completely reacts and disappears to obtain a silver salt solution. To form a heating reflux device, put 5ml of methanesulfonic acid solution in it, heat it to 130°C, after the temperature stabilizes, slowly add 0.002mol basic copper carbonate in small amounts for several times, and continue heating after all the basic copper carbonate is added Reflux for 3h. After heating, the device was cooled to room temperature, and deionized water was added to dissolve the solid and filtered to obtain a copper salt solution. Add 0.00004 mol of benzylidene acetone into 10 ml of deionized water, heat to 40° C. and stir until the solid benzylidene acetone is completely dissolved to obtain a brightener solution. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com