Composite material vacuum auxiliary forming process

A vacuum-assisted molding technology, applied to improve the internal and surface quality of vacuum-assisted molding products, the field of vacuum-assisted molding technology, can solve problems affecting product quality stability, molding failure, resin short circuit, etc., to achieve process stability and The effect of improving and improving the inherent quality of products, saving manufacturing costs, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare a glass fiber reinforced composite plate with a size of 400mm×300mm×10mm

[0029] Raw materials: prefabricated parts: made of glass fiber fabric with an area density of 400;

[0030] Resin system: 196 # 100 parts of polyester resin; 1 part of methyl ethyl ketone peroxide; 1 part of cobalt naphthenate;

[0031] Release cloth 3: use 0.1mm thick polytetrafluoroethylene glass fiber cloth;

[0032] Release cloth 5: polyester film with a thickness of 0.08 mm;

[0033] Mesh resin diversion medium 13: 40-mesh woven mesh cloth is used;

[0034] Exhaust channel 10: use 60-mesh woven mesh cloth;

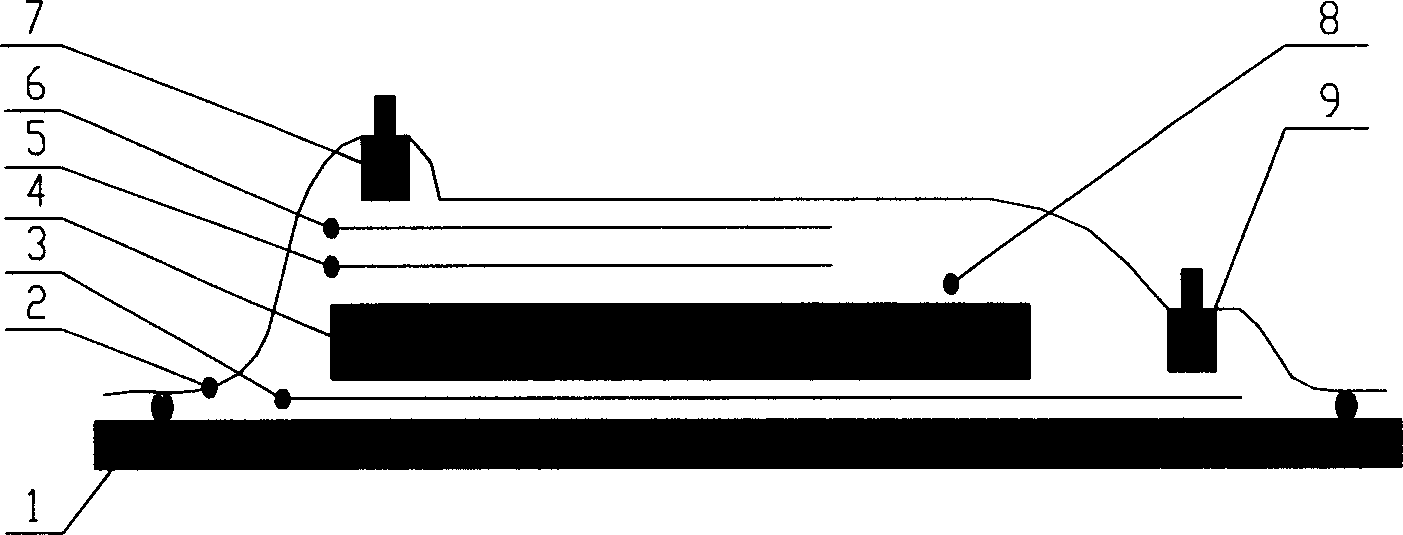

[0035] Forming process: the laying structure of each layer is shown in Figure 5. Cut the fiber-reinforced fabric into several cloth pieces of 420mm×310mm to make prefabricated part 4, prepare 3 pieces of release cloth of 420mm×310mm, one piece of release cloth 5 of 400mm×300mm and one piece of mesh resin diversion medium 13, each of 300m...

Embodiment 2

[0038] Prepare a glass fiber reinforced composite plate with a size of 4000mm×2000mm×25mm

[0039] Raw material used is with embodiment one.

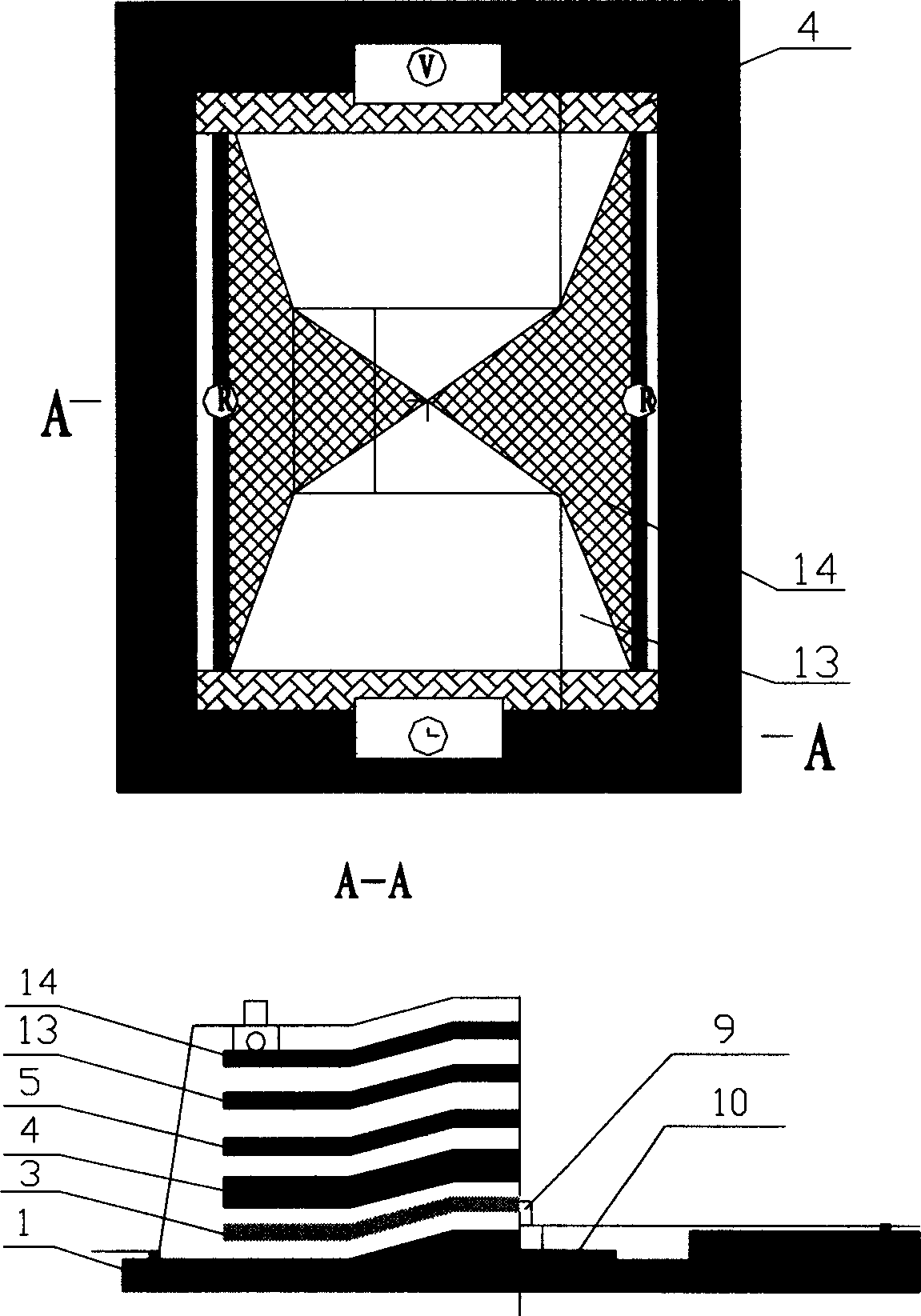

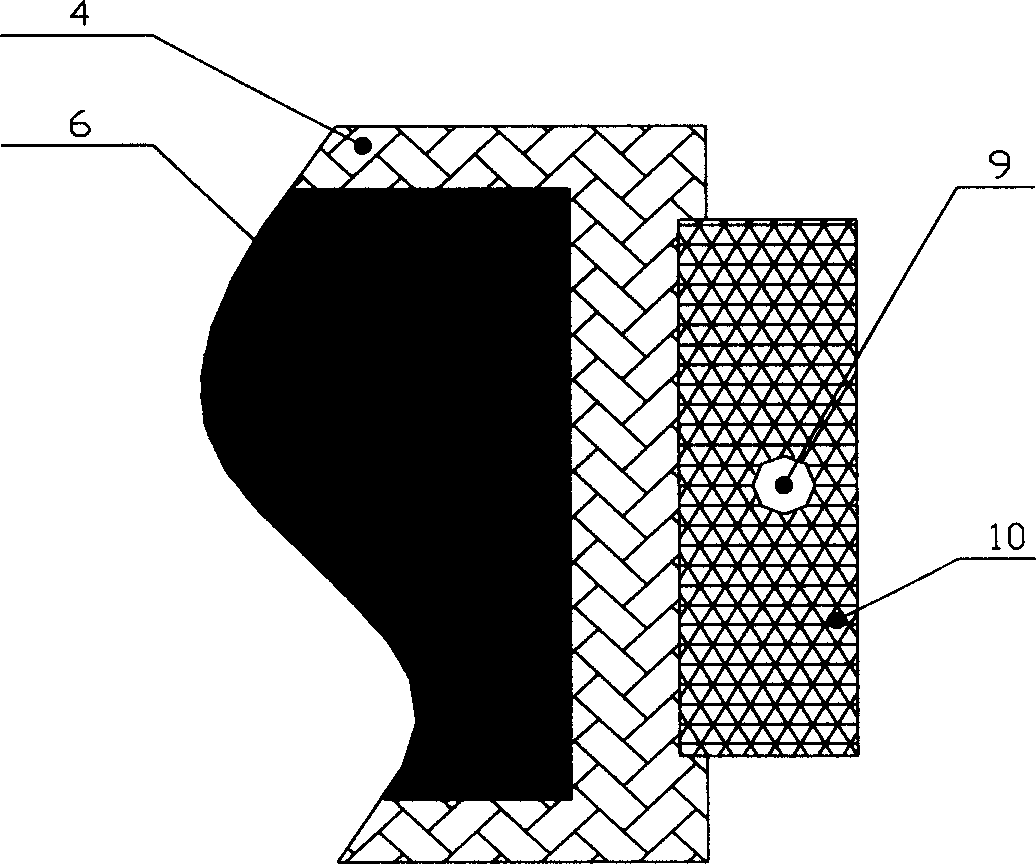

[0040] Forming process: The laying structure of each layer during the forming process is shown in Figure 6. Cut the fiber reinforced fabric into several cloth pieces of 4100mm×2100mm to make prefabricated part 4, prepare 3 pieces of release cloth of 4100mm×2100mm, one piece of release cloth 5 of 4000mm×2100mm and one piece of mesh resin flow guide medium 13, the shape The dimensions are bottom×height=4000mm×1050mm triangular mesh resin diversion medium 14 two pieces, 500mm×200mm exhaust channel 10 two pieces.

[0041] On the plane formwork 1, lay the release cloth 3 and the prefabricated part 4 in sequence, lay the release cloth 5 and the lower layer of resin diversion medium 13 in the center on the prefabricated part 4 in sequence, and in the area of the lower layer of resin diversion medium, the top Lay the triangular upper layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com