Surface modification method of copper powder for conductive paste

A conductive paste and surface modification technology, applied in the direction of coating, etc., can solve the problems of difficulty in inhibiting oxidation and inapplicability, and achieve the effects of improved stability, low cost, and no special equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

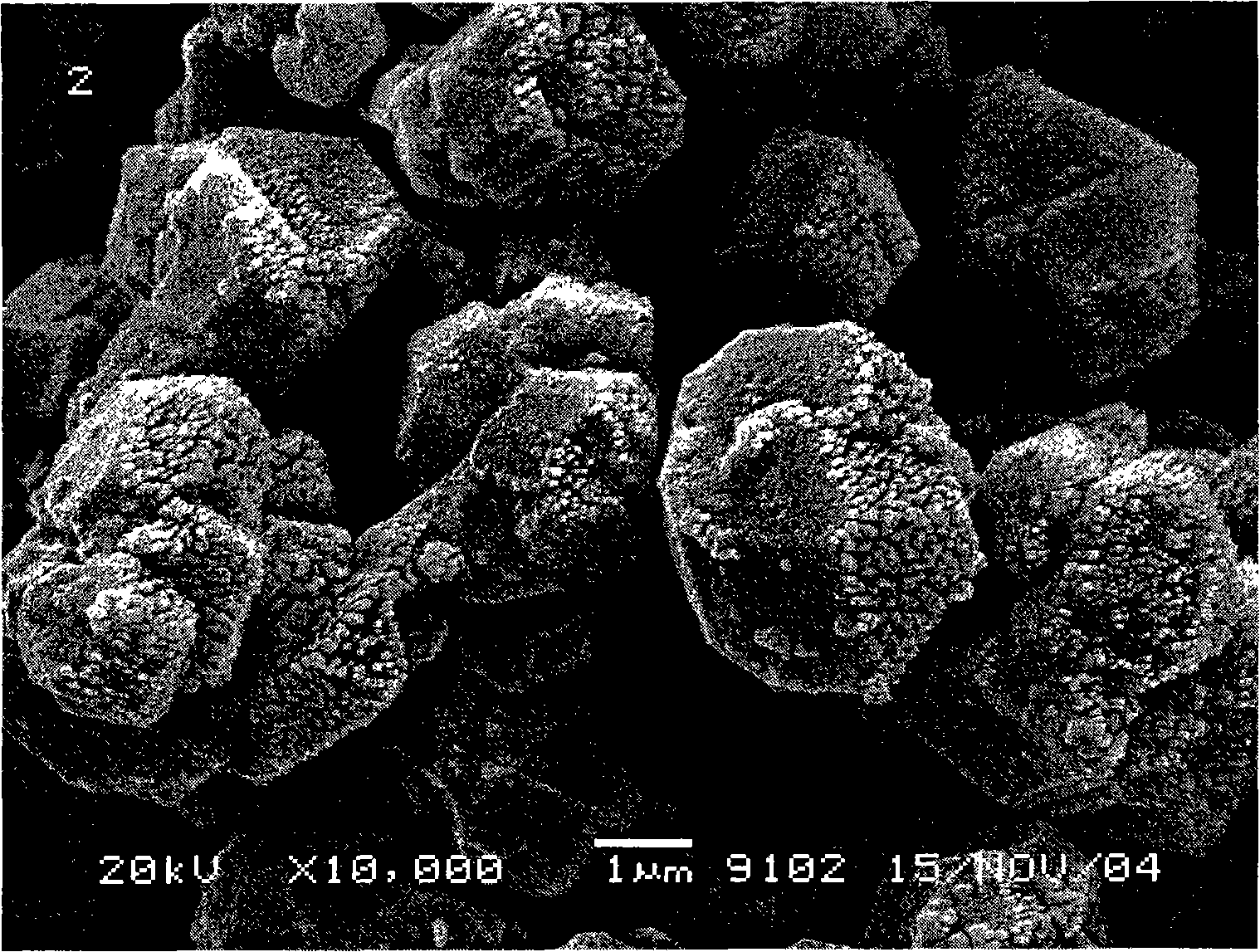

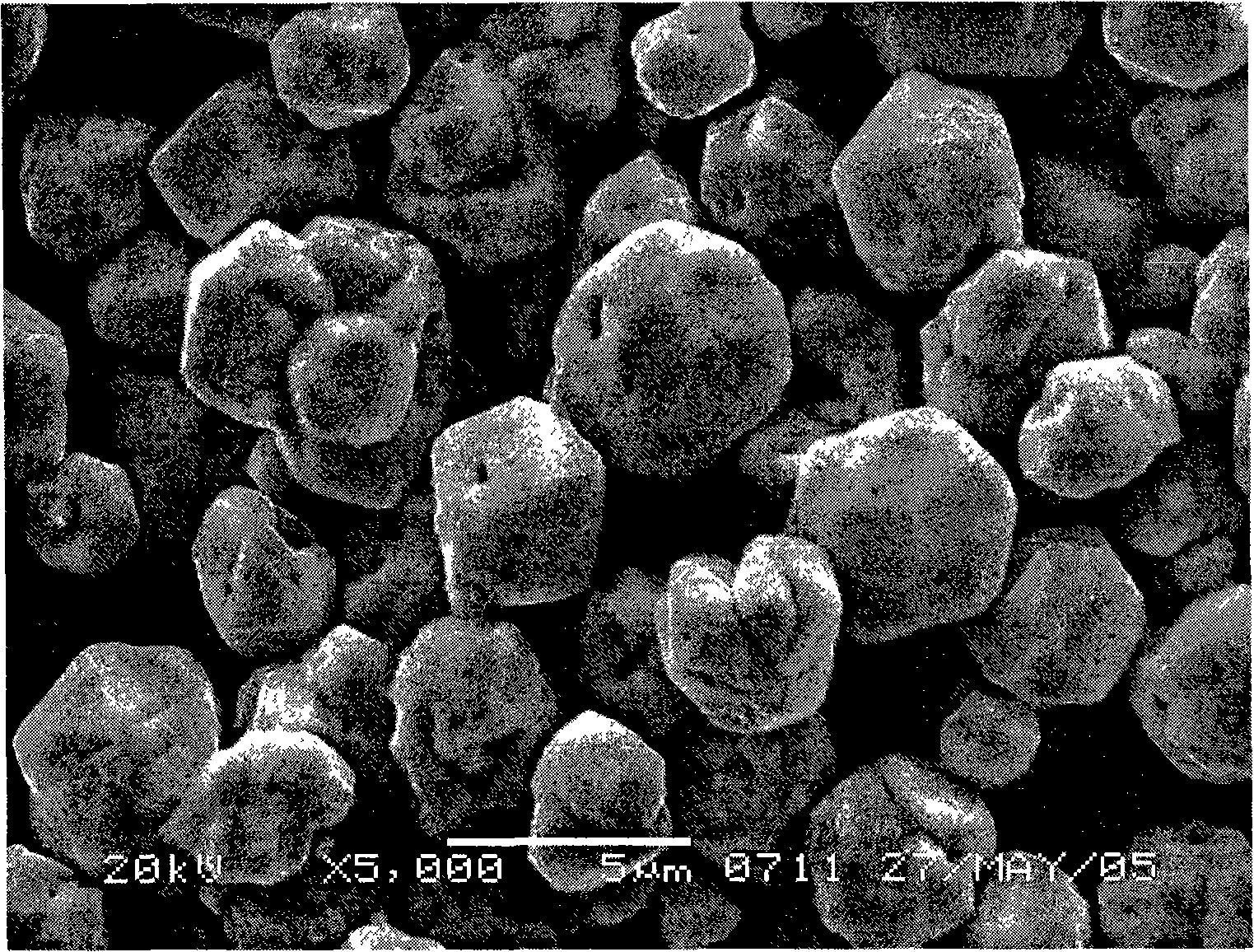

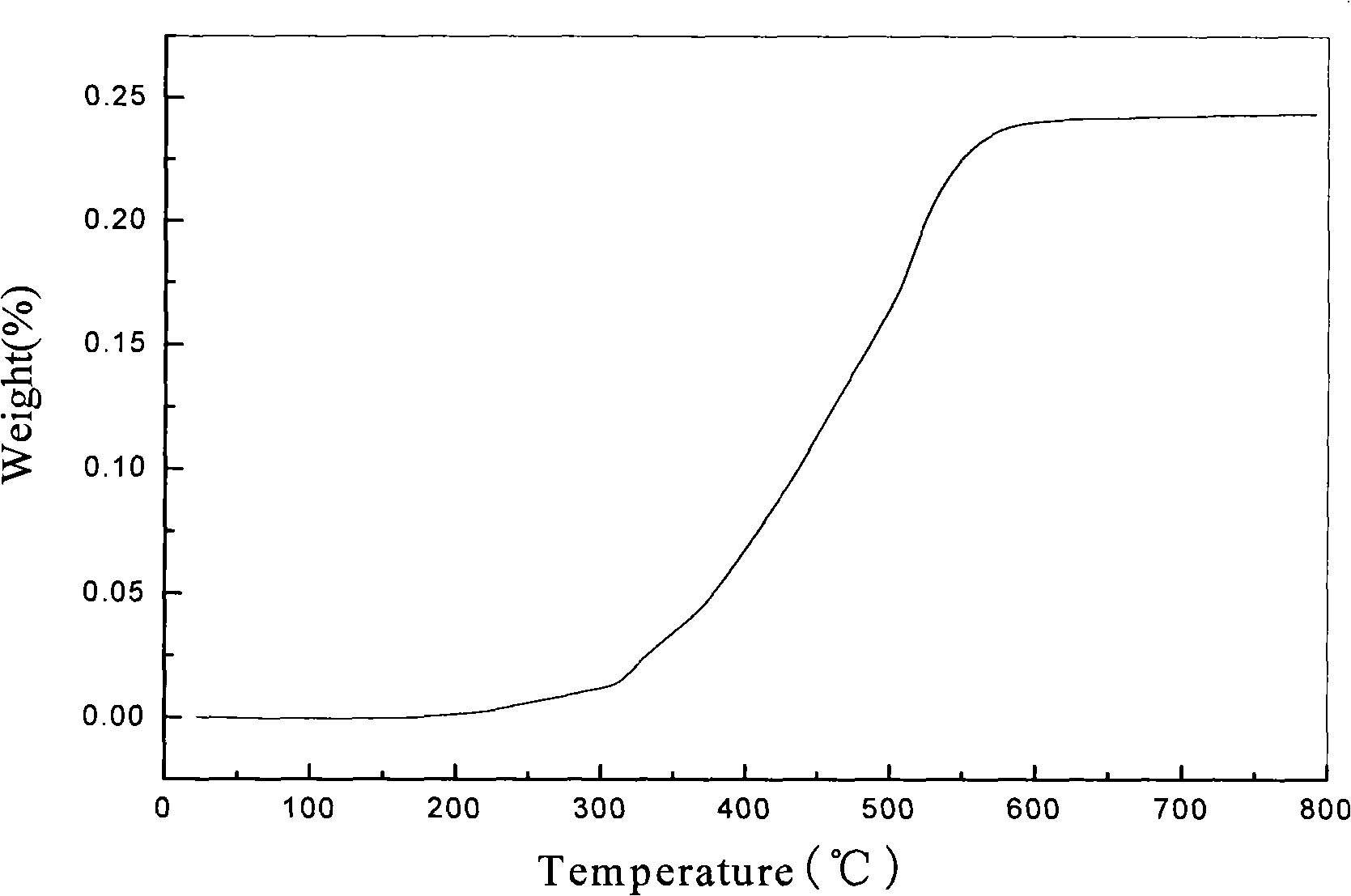

Image

Examples

Embodiment 1

[0034] Add 80g copper powder to 0.5L aqueous solution containing 0.05mol glycerol, add 0.15mol of formic acid and oleic acid mixed acid, the mixing ratio is 4:1, stir and mix for 60min, add 0.2mol of sodium hypophosphite, Under a protective atmosphere, gradually raise the temperature to 70°C, keep the reaction for 120 minutes, add 0.25 mol of diethylenediamine, keep the reaction for 90 minutes, then separate the liquid from the solid, wash and dry in vacuum.

Embodiment 2

[0036] Add 120g of copper powder to 0.5L aqueous solution containing 0.1mol glycerol, add 0.37mol of mixed acid of citric acid and oleic acid, the mixing ratio is 5:1, stir and mix for 90min, add 0.3mol of hydrazine hydrate, in Under a protective atmosphere, after gradually raising the temperature to 50°C, heat-retain for 90 minutes, add 0.45 mol of tetramethylethylenediamine, heat-retain for 90 minutes, then separate liquid from solid, wash and dry in vacuum.

Embodiment 3

[0038] Add 65g copper powder to 0.5L aqueous solution containing 0.05mol triethylene glycol, add 0.2mol tartaric acid and oleic acid mixed acid, the mixing ratio is 6:1, stir and mix for 60min, add 0.4mol glucose, in a protective atmosphere , and gradually raise the temperature to 90°C, keep the reaction for 150 minutes, add 0.12mol of diethylenediamine, keep the reaction for 90 minutes, then separate the liquid from the solid, wash and dry in vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com