Underwater super-oleophobic oil-water separation mesh membrane and preparation method thereof

An oil-water separation mesh membrane and underwater superoleophobic technology are applied in the field of oil-water separation mesh membrane and its preparation, and can solve the problems of oil-water mixture not suitable for separating oil, the preparation method is not simple enough, and cannot be adapted to strong alkali environment, etc. The preparation cost is low, the oil-water separation effect is good, and the cleaning effect is easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

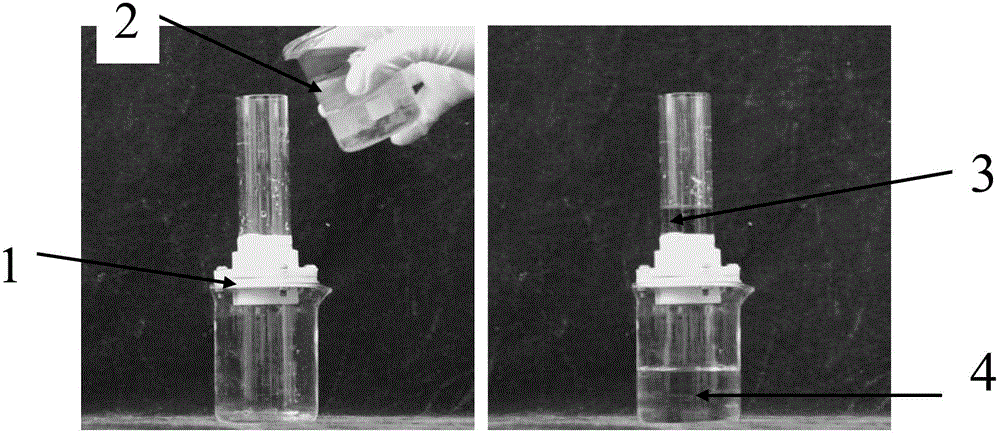

[0037] Embodiment 1, preparation is coated with the oil-water separation omentum of glutaraldehyde cross-linked chitosan

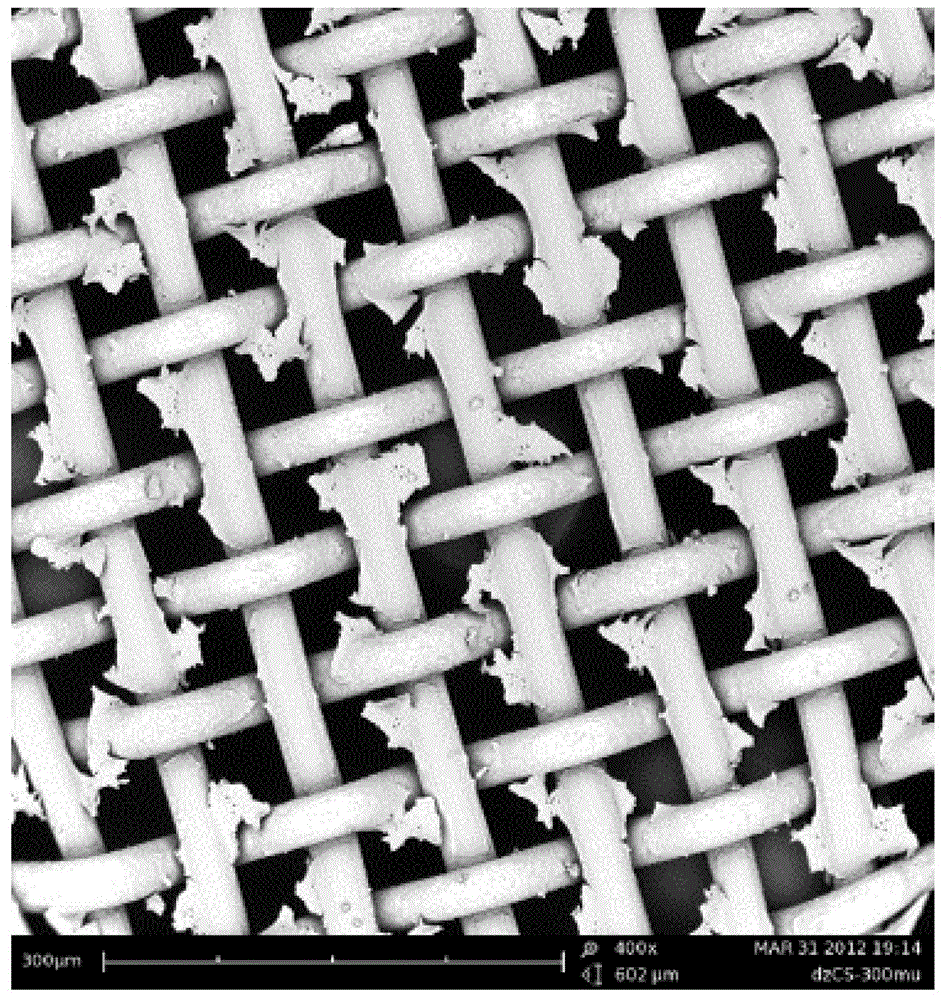

[0038] (1) The 300-mesh copper mesh was successively immersed in ethanol and acetone for ultrasonic cleaning for 5 minutes, soaked in hydrochloric acid for 1 hour, deposited copper particles by electrochemical deposition to increase its roughness, and dried at room temperature;

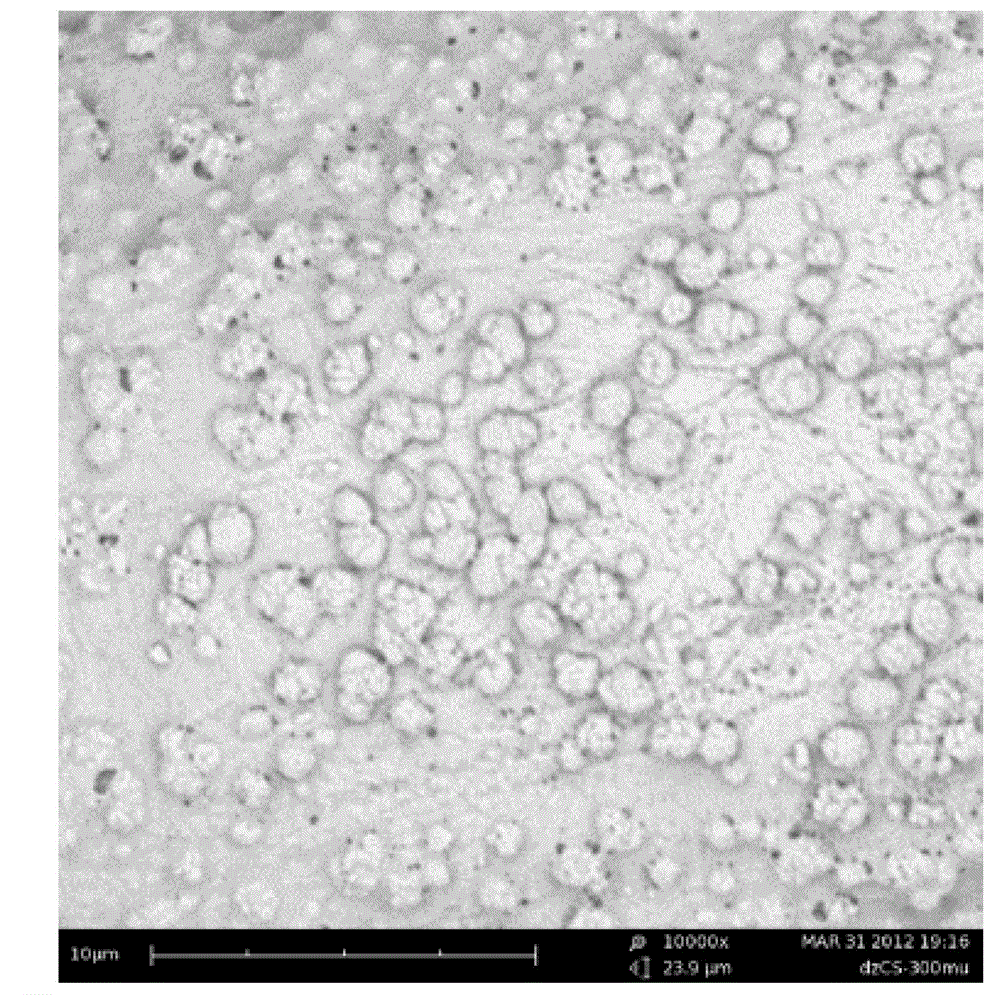

[0039] (2) At room temperature, add 100ml of water, 2ml of glacial acetic acid, 2g of chitosan, and 0.1ml of 1wt% glutaraldehyde aqueous solution to a 250ml beaker, stir and mix evenly to obtain glutaraldehyde cross-linked chitosan, then the obtained The mass percentage composition of glutaraldehyde crosslinked chitosan in the mixed solution is 2%;

[0040] (3) Dip the copper mesh obtained in step (1) into the mixed solution obtained in step (2) for 30 minutes, then take it out and dry it;

[0041] (4) The mesh obtained in step (3) is immersed in 4wt% sodium hydroxide aqueous sol...

Embodiment 2

[0044] Embodiment 2, preparation is coated with the oil-water separation omentum of chitosan / montmorillonite composite

[0045] (1) The 100-mesh stainless steel mesh was immersed in ethanol and acetone and ultrasonically cleaned for 5 minutes each, and dried at room temperature;

[0046] (2) At room temperature, add 100ml of water, 4ml of hydrochloric acid, 2g of chitosan and 0.5g of montmorillonite into a 250ml beaker, stir and mix evenly with magnetic force to obtain a chitosan / montmorillonite composite, then the obtained mixed solution The mass percentage composition of chitosan / montmorillonite compound is 2.4%;

[0047] (3) Dip the stainless steel wire mesh obtained in step (1) into the mixed solution obtained in step (2) for 10 seconds, then take it out and dry it;

[0048] (4) Immerse the stainless steel wire mesh obtained in step (3) in 1wt% potassium hydroxide aqueous solution, keep it for 10s, then take it out to dry, and form a chitosan / montmorillonite with a thickn...

Embodiment 3

[0051] Embodiment 3, preparation is coated with the oil-water separation omentum of chitosan / polyvinyl alcohol copolymer

[0052] (1) Soak the 400-mesh nylon net in ethanol and acetone for 5 minutes, and then dry it at room temperature;

[0053] (2) At room temperature, add 100ml of water, 3ml of sulfuric acid, 1.5g of chitosan and 1g of polyvinyl alcohol (the degree of polymerization is 1700) into a 250ml beaker, stir and mix evenly to obtain chitosan / polyvinyl alcohol copolymer, Then the mass percent composition of chitosan / polyvinyl alcohol copolymer in the mixed solution obtained is 2.4%;

[0054] (3) Soak the nylon mesh obtained in step (1) in the mixed solution obtained in step (2) for 1 hour, then take it out and dry it;

[0055] (4) Immerse the net obtained in step (3) in 0.5wt% barium hydroxide aqueous solution, keep it for 30min, then take it out to dry, and form a chitosan / polyvinyl alcohol copolymer with a thickness of 2 microns on the surface of the nylon net Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com