Heat-conducting electric insulation silicon rubber thermal interface material and preparation method thereof

A thermal interface material, silicone rubber technology, applied in the field of rubber nanocomposite materials, can solve the problem of low thermal conductivity and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

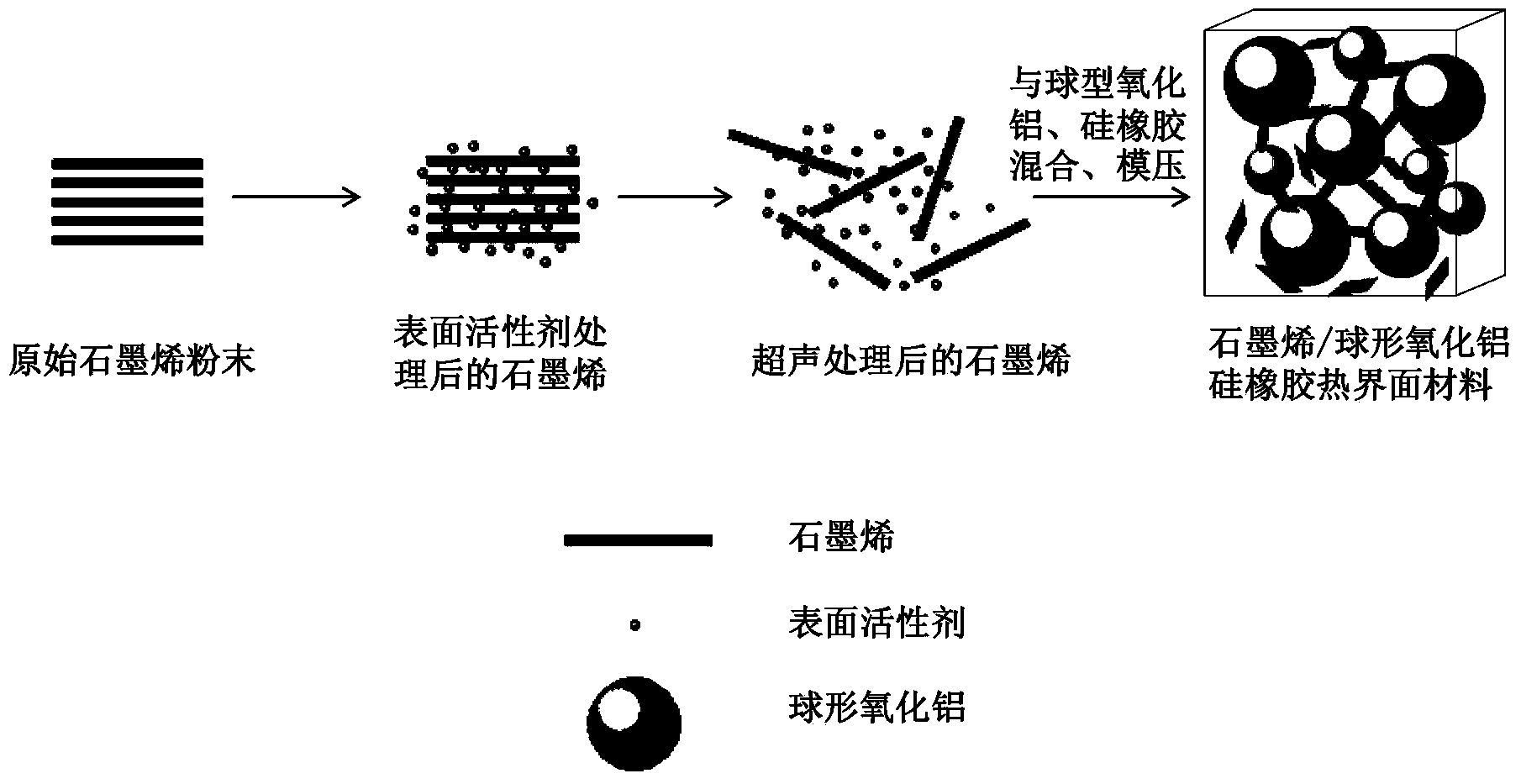

Embodiment 1

[0036] Sodium lauryl sulfate is added to toluene to prepare a 20mg / ml solution, and then 1 part of graphene powder is added to the solution, wherein the graphene powder mass (g) is related to the volume of the surfactant toluene solution (ml ) with a ratio of 1:500, and then ultrasonically oscillated by a 900W ultrasonic cell breaker for 60 minutes to infiltrate the graphene surface with the active agent, and finally peel the graphene into a thinner sheet structure and uniformly disperse it to obtain graphite Graphene dispersion; 200 parts of spherical thermally conductive alumina fillers were added to the graphene dispersion, and stirred evenly to make a thermally conductive filler slurry for use. Dissolve 100 parts of raw liquid silicone rubber with a viscosity of 200000cs in n-hexane, mix it with the thermally conductive filler slurry, dry the mixed mixture at 100°C, and divide it into two parts of equal mass, A component and B component. Add 3 parts of hydrogen-containing ...

Embodiment 2

[0038]Sodium lauryl sulfate is added in toluene to prepare a 20mg / ml solution, and then 2 parts of graphene powder are added to the solution, wherein the graphene powder mass (g) is related to the volume of surfactant toluene solution (ml ) with a ratio of 1:500, and then ultrasonically oscillated by a 900W ultrasonic cell breaker for 60 minutes to infiltrate the graphene surface with the active agent, and finally peel the graphene into a thinner sheet structure and uniformly disperse it to obtain graphite Graphene dispersion; 200 parts of spherical thermally conductive alumina fillers were added to the graphene dispersion, and stirred evenly to make a thermally conductive filler slurry for use. Dissolve 100 parts of raw liquid silicone rubber with a viscosity of 200000cs in n-hexane, mix it with the thermally conductive filler slurry, dry the mixed mixture at 100°C, and divide it into two parts of equal mass, A component and B component. Add 3 parts of hydrogen-containing sil...

Embodiment 3

[0040] Sodium lauryl sulfate is added to toluene to prepare a 20mg / ml solution, and then 1 part of graphene powder is added to the solution, wherein the graphene powder mass (g) is related to the volume of the surfactant toluene solution (ml ) with a ratio of 1:500, and then ultrasonically oscillated by a 900W ultrasonic cell breaker for 60 minutes to infiltrate the graphene surface with the active agent, and finally peel the graphene into a thinner sheet structure and uniformly disperse it to obtain Graphene dispersion: 300 parts of spherical heat-conducting alumina fillers are added to the graphene dispersion, stirred evenly to make a heat-conducting filler slurry, and set aside. Dissolve 100 parts of raw liquid silicone rubber with a viscosity of 200000cs in n-hexane, mix it with the thermally conductive filler slurry, dry the mixed mixture at 100°C, and divide it into two parts of equal mass, A component and B component. Add 3 parts of hydrogen-containing silicone oil cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com