Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "Die back" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

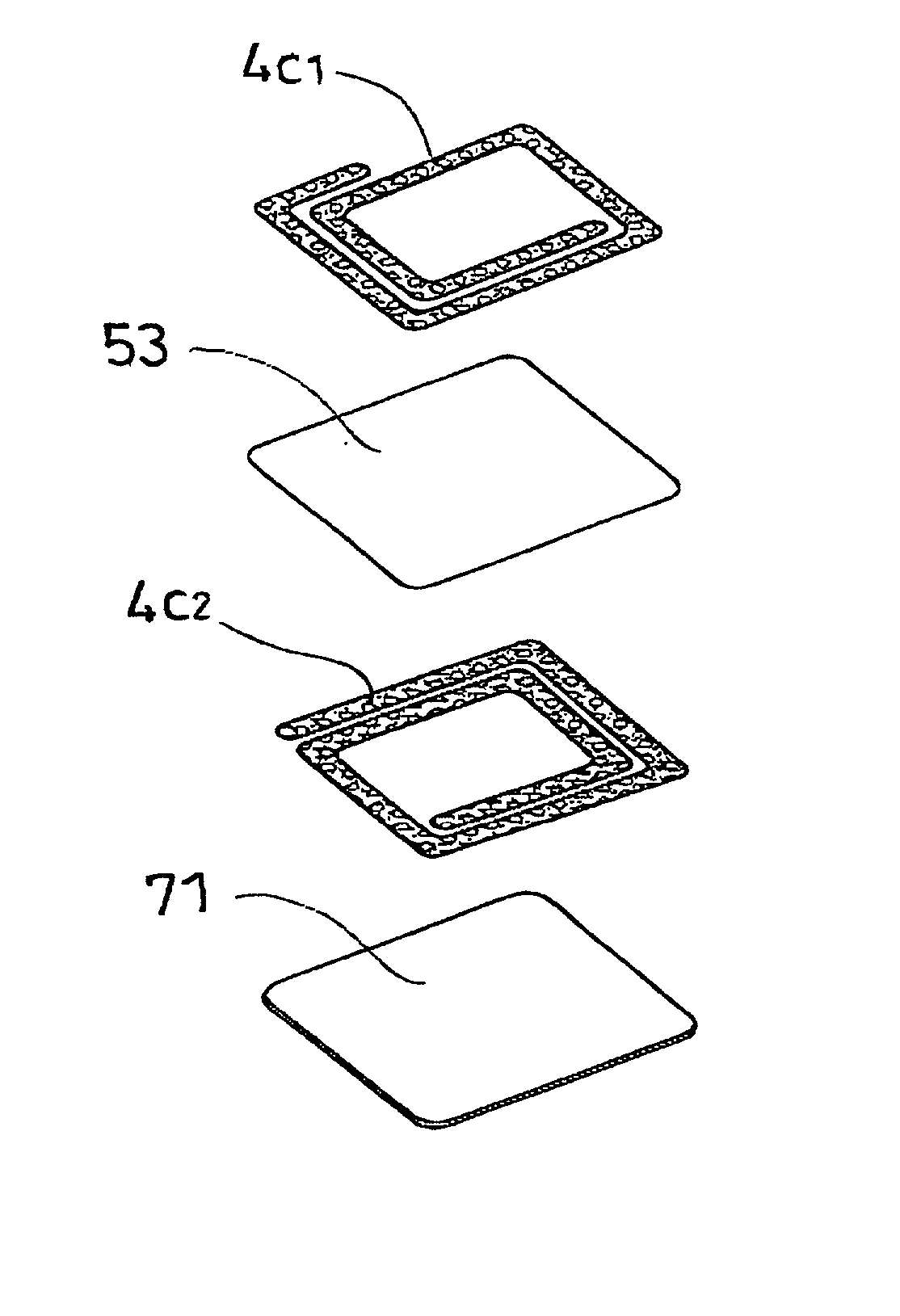

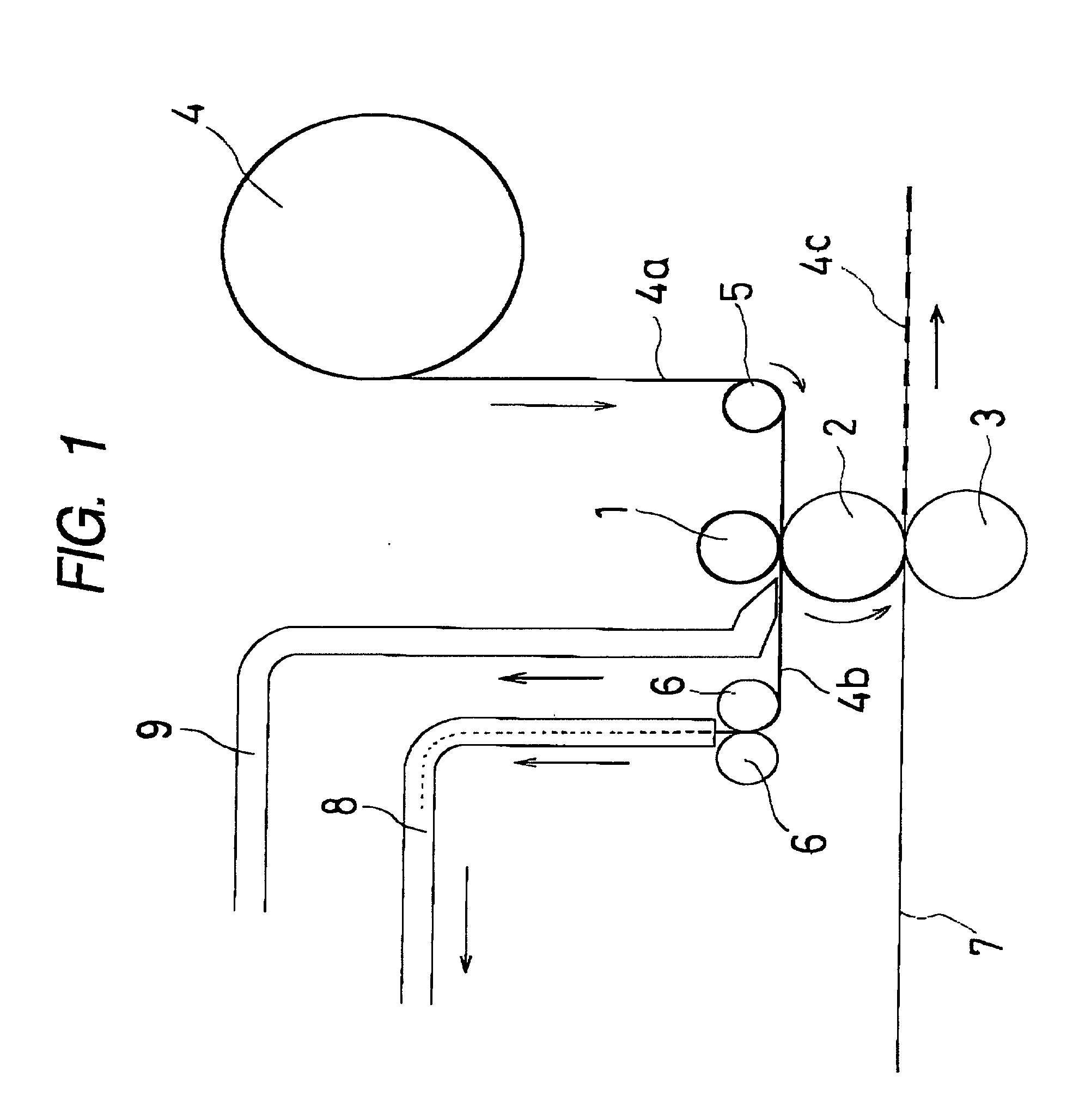

Process for producing resonant tag

InactiveUS6618939B2Easy to manufactureStable resonant characteristicWave amplification devicesElectrical connection printed elementsMetal foilAdhesive

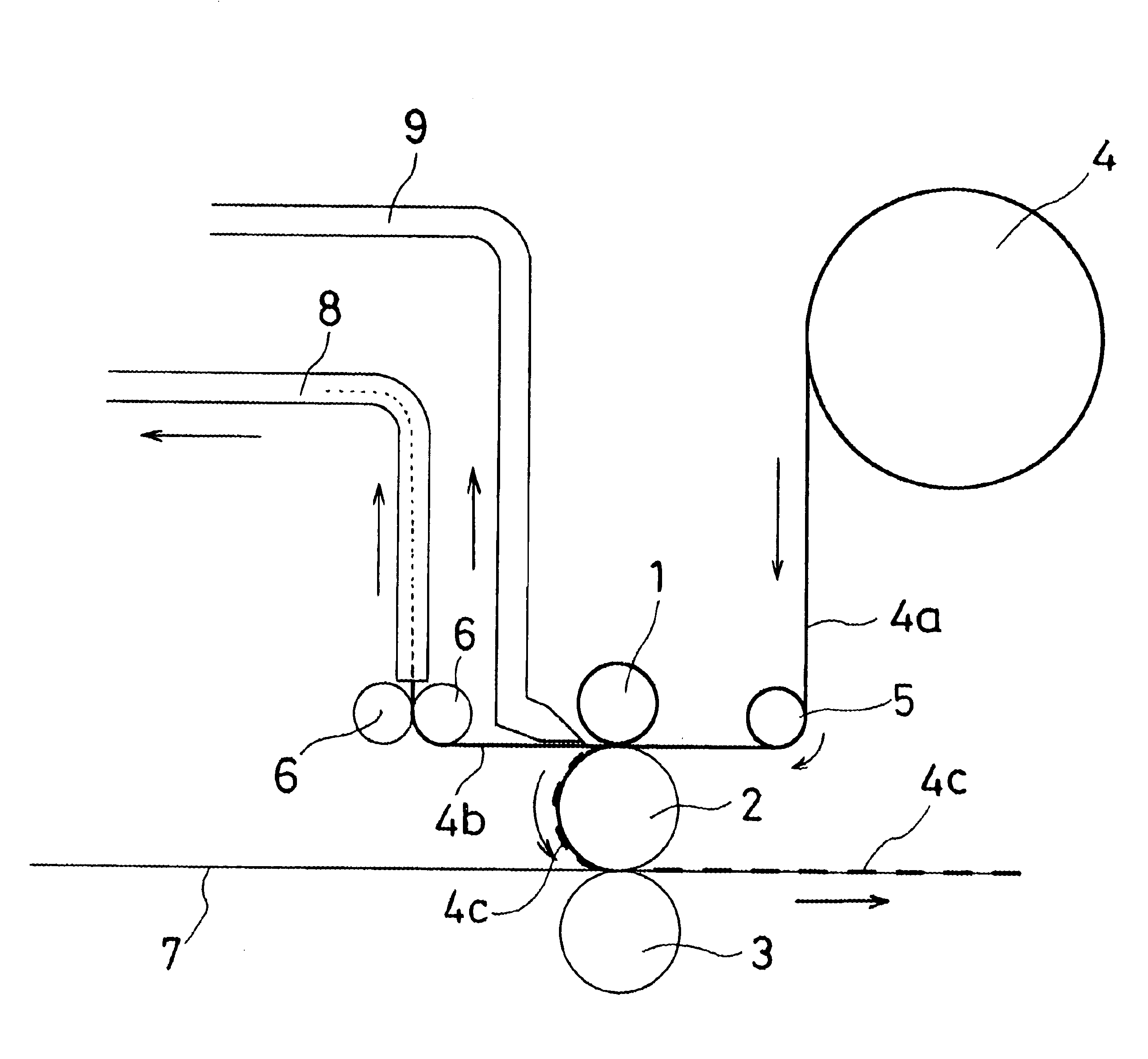

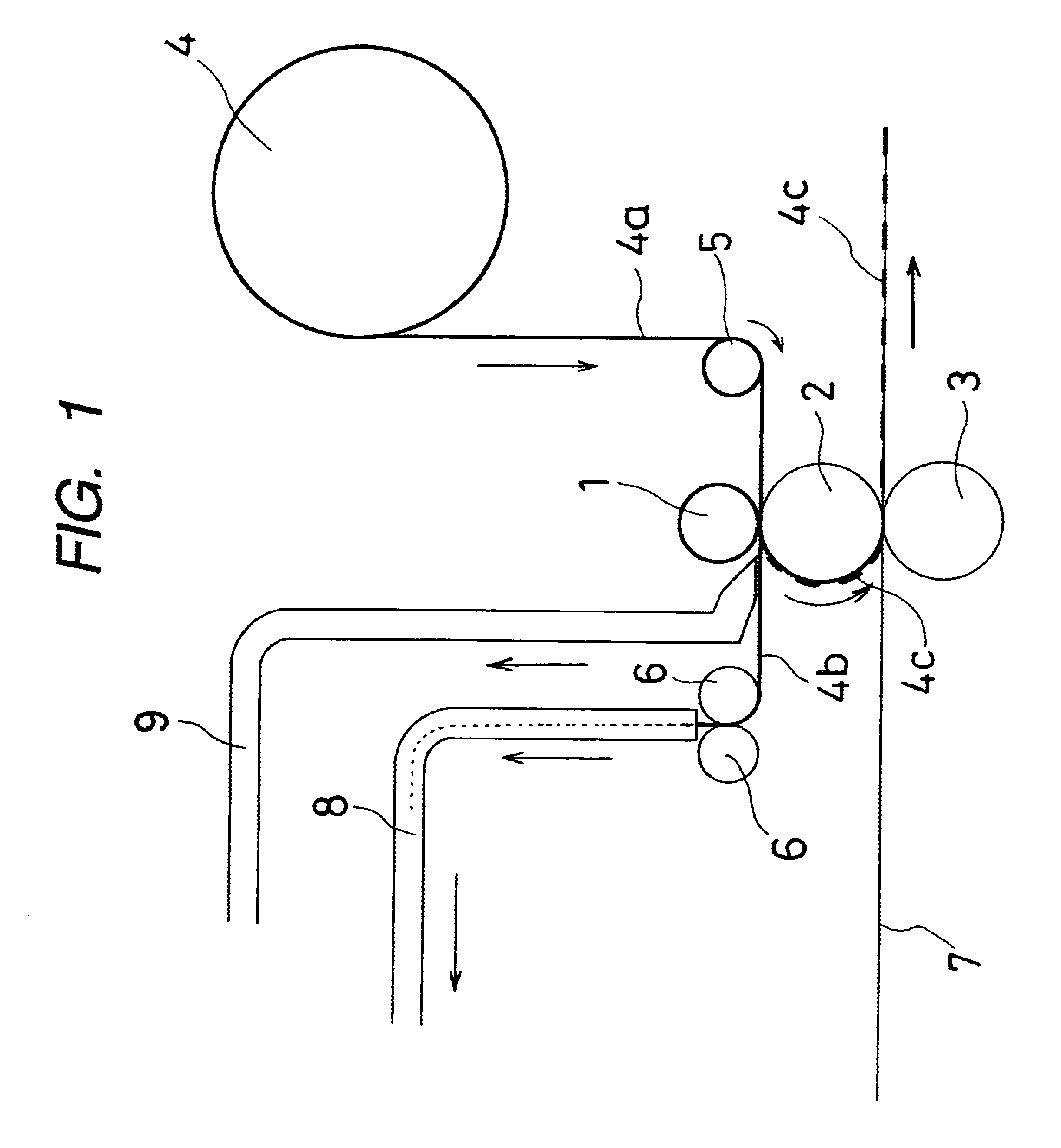

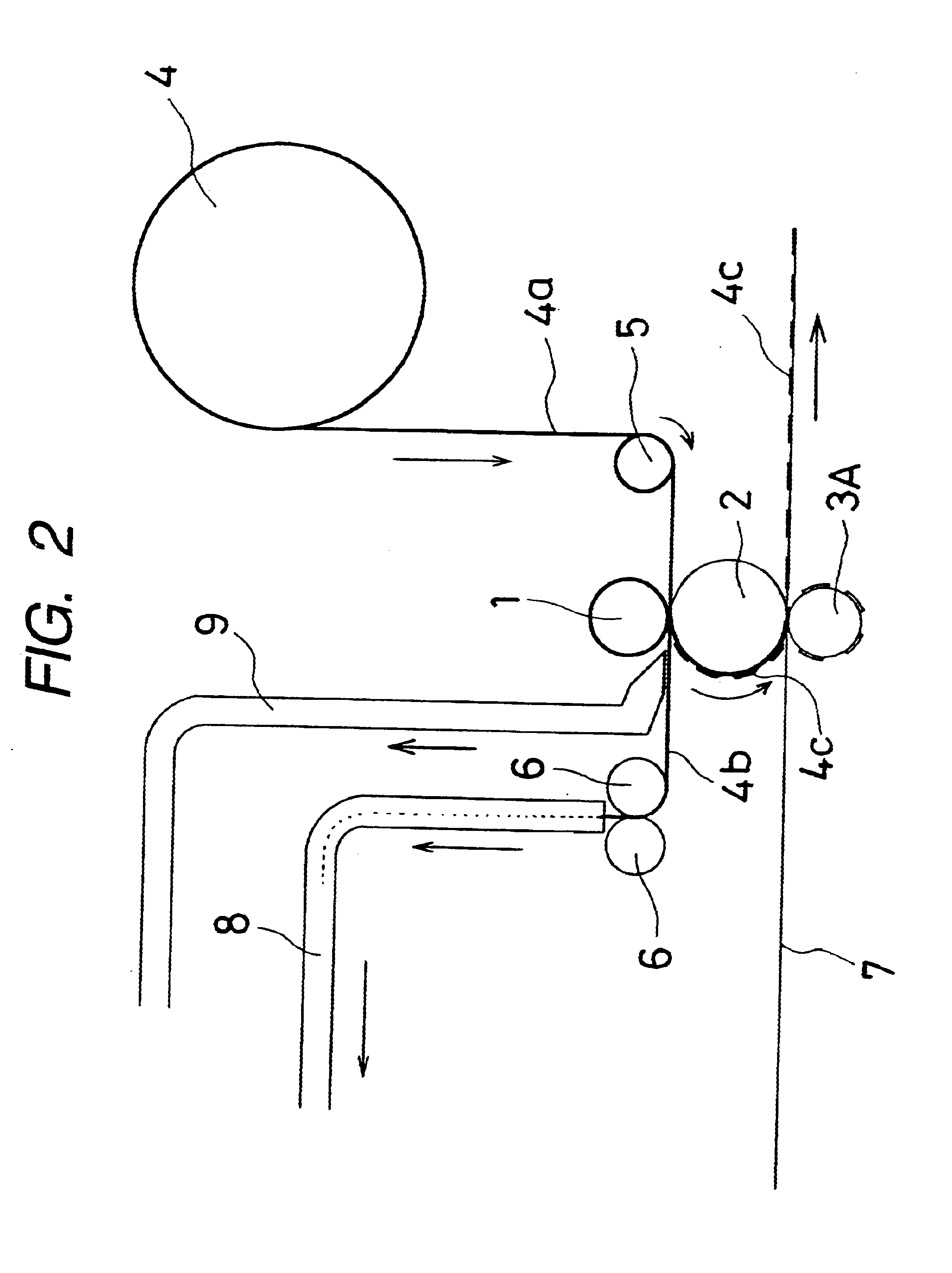

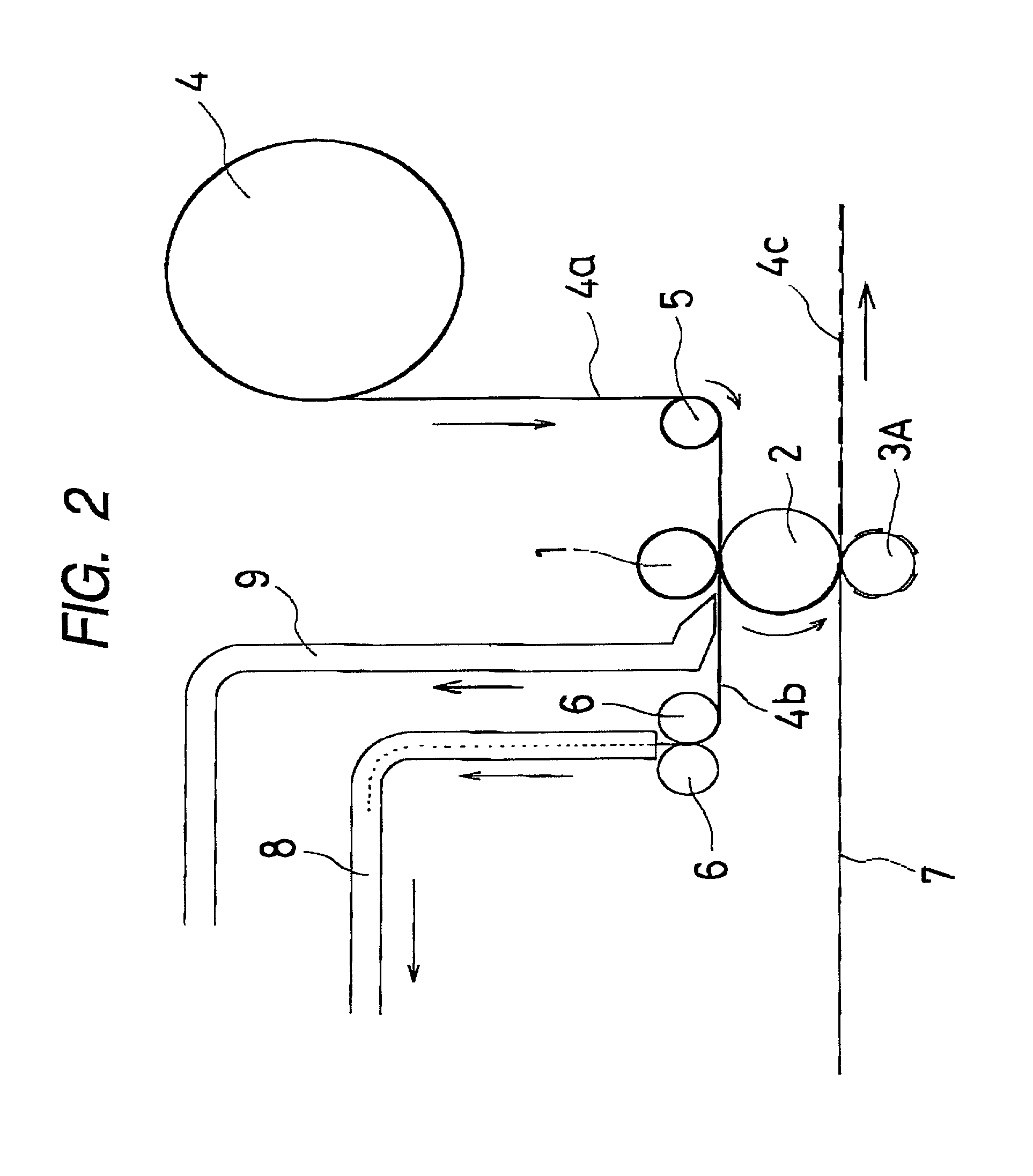

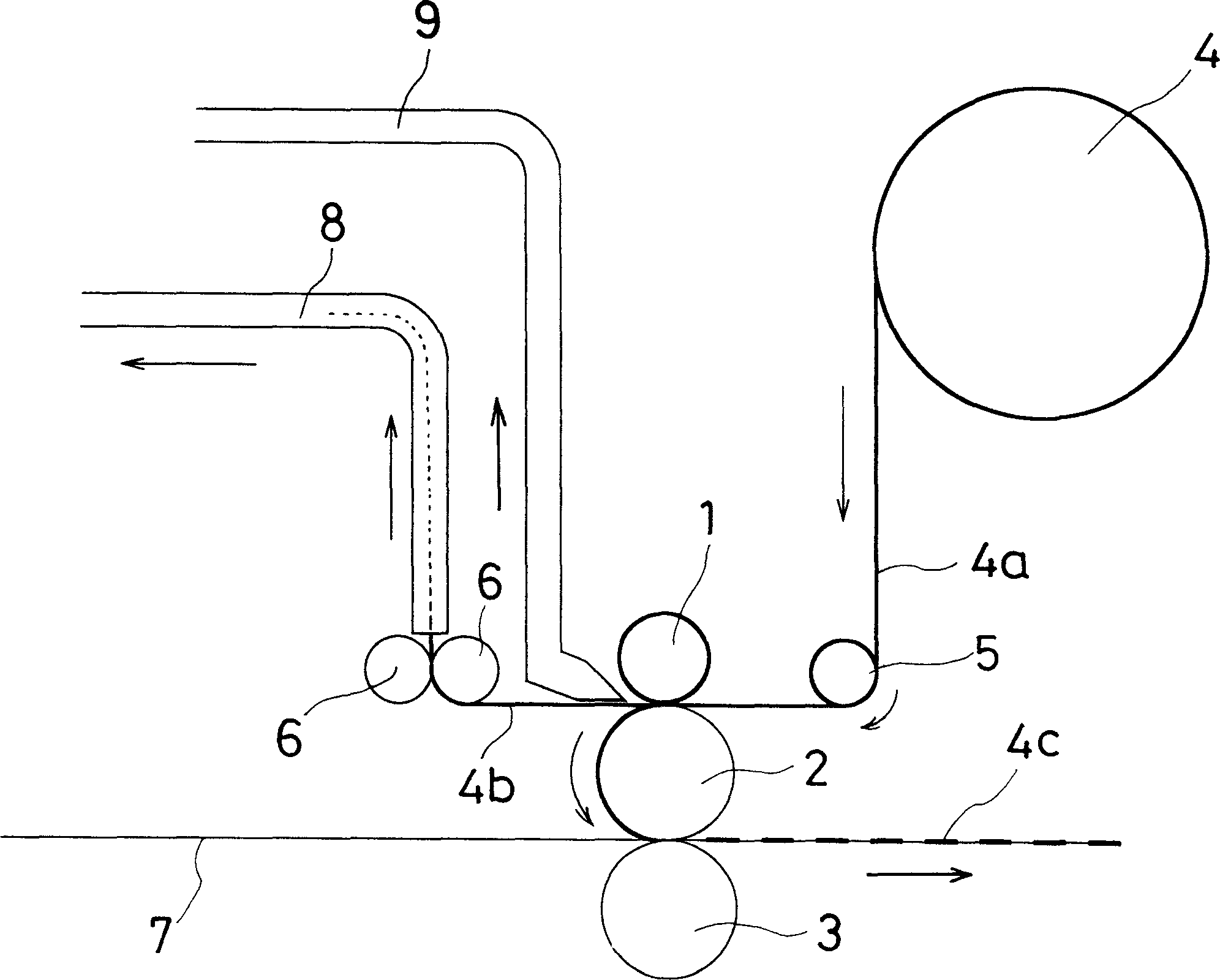

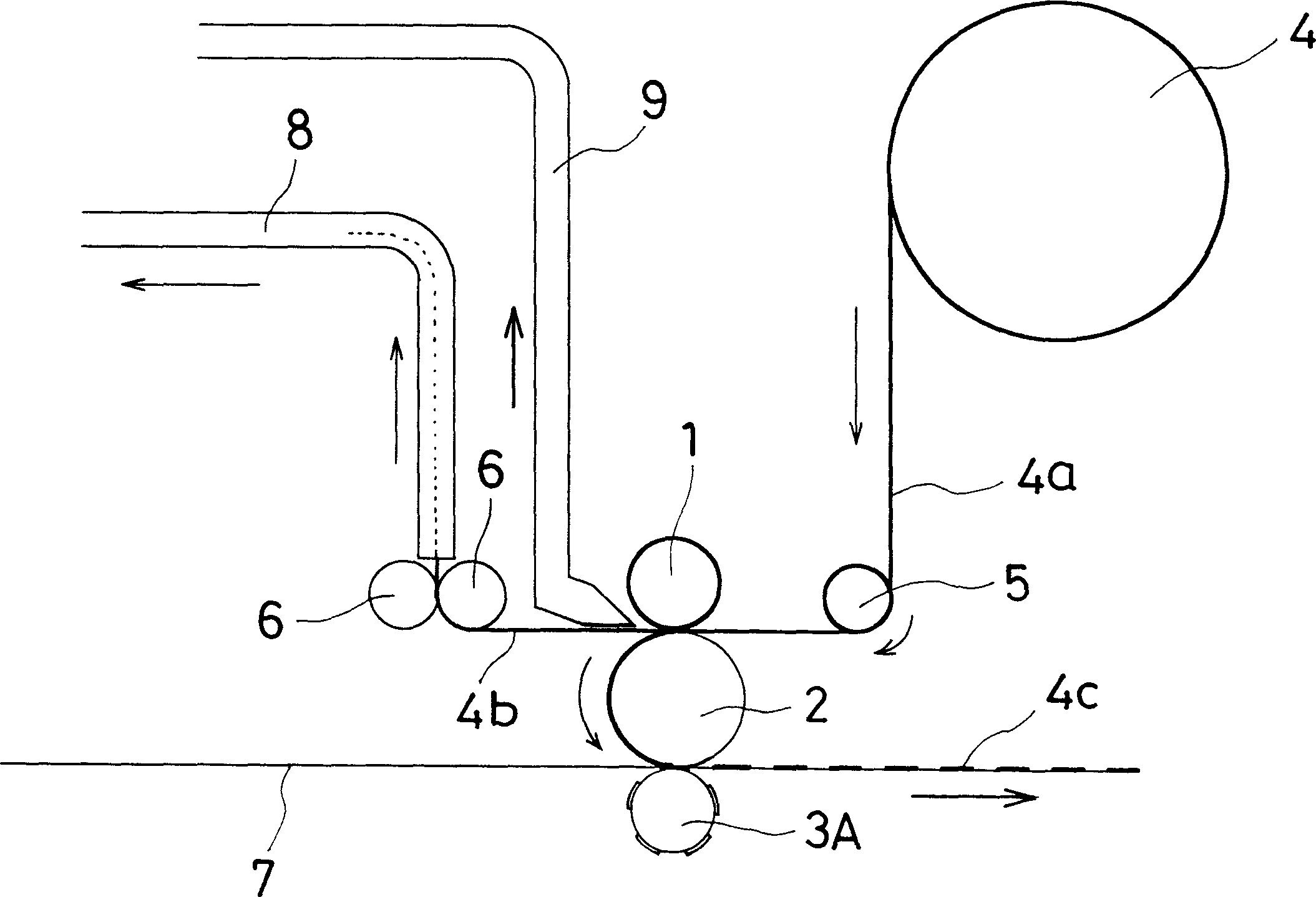

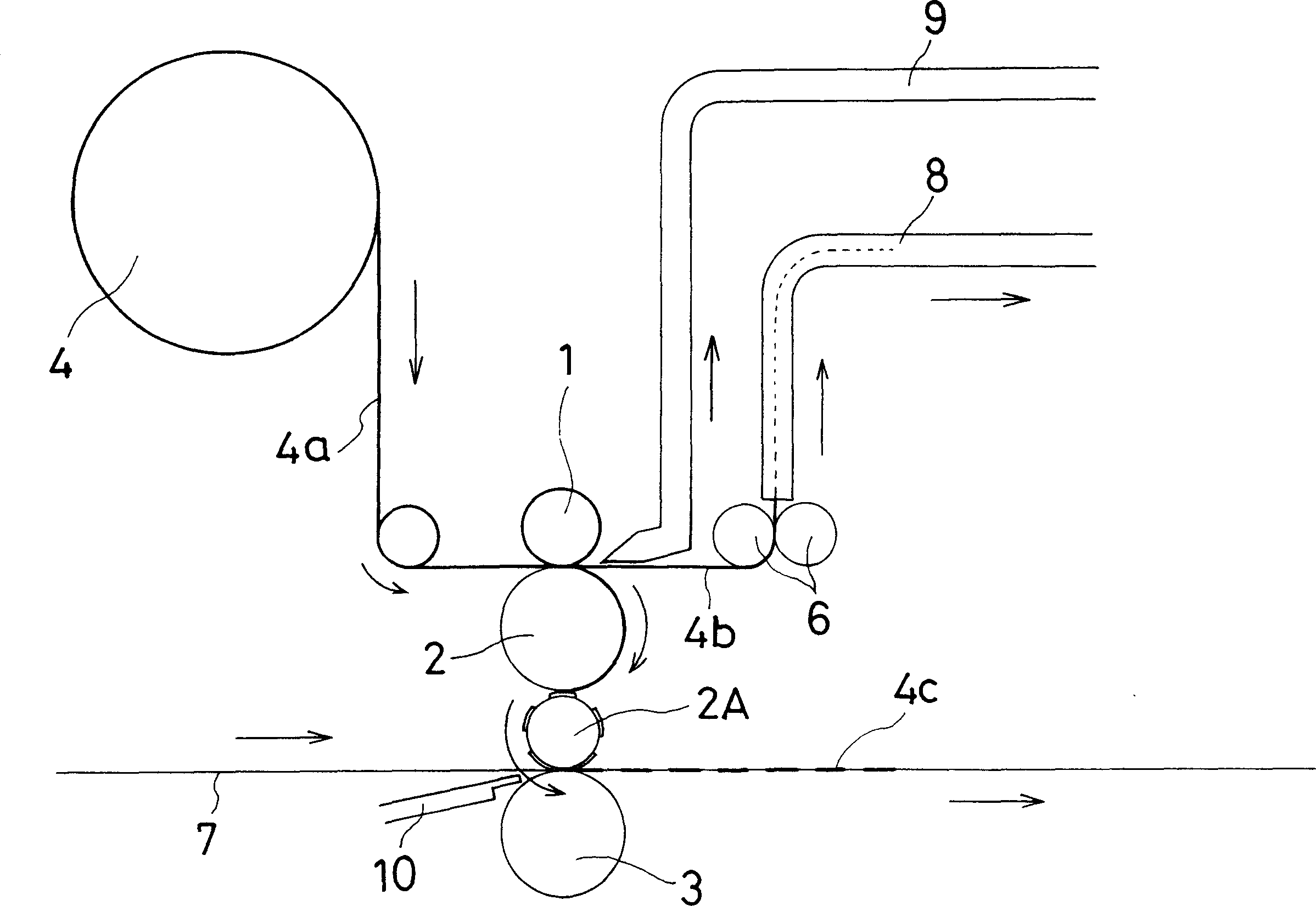

A process for producing a resonant tag, wherein a metal foil having a thermal adhesion adhesive applied to at least one face thereof is stamped out into a circuit-like shape and is adhered to a base sheet, the process comprising: stamping out the metal foil into a predetermined shaped metal foil portion (4c) while being passed through a die roll (1) having thereon a stamping blade with a predetermined shape and a transfer roll (2) in contact with the die roll (1) which functions also as a die back-up roll; holding this metal foil portion obtained by the stamping-out operation onto the surface of the transfer roll by suction holes formed in the transfer roll; and thermally adhering the stamped metal foil portion to the base sheet (7) in contact with the transfer roll (2) at its another face by an adhesive roll (3) in contact with the transfer roll through the base sheet. The present invention has such advantages as no damage to the base sheet since the stamping-out operation for the metal foil and the thermal adhesion operation thereof to the base sheet are carried out in separate positions, and no requirement of carrier sheet because the resultant metal foil portion obtained by the stamping-out operation is sucked and held onto the surface of the transfer roll.

Owner:NOVATRON ELECTRONICS HANGZHOU

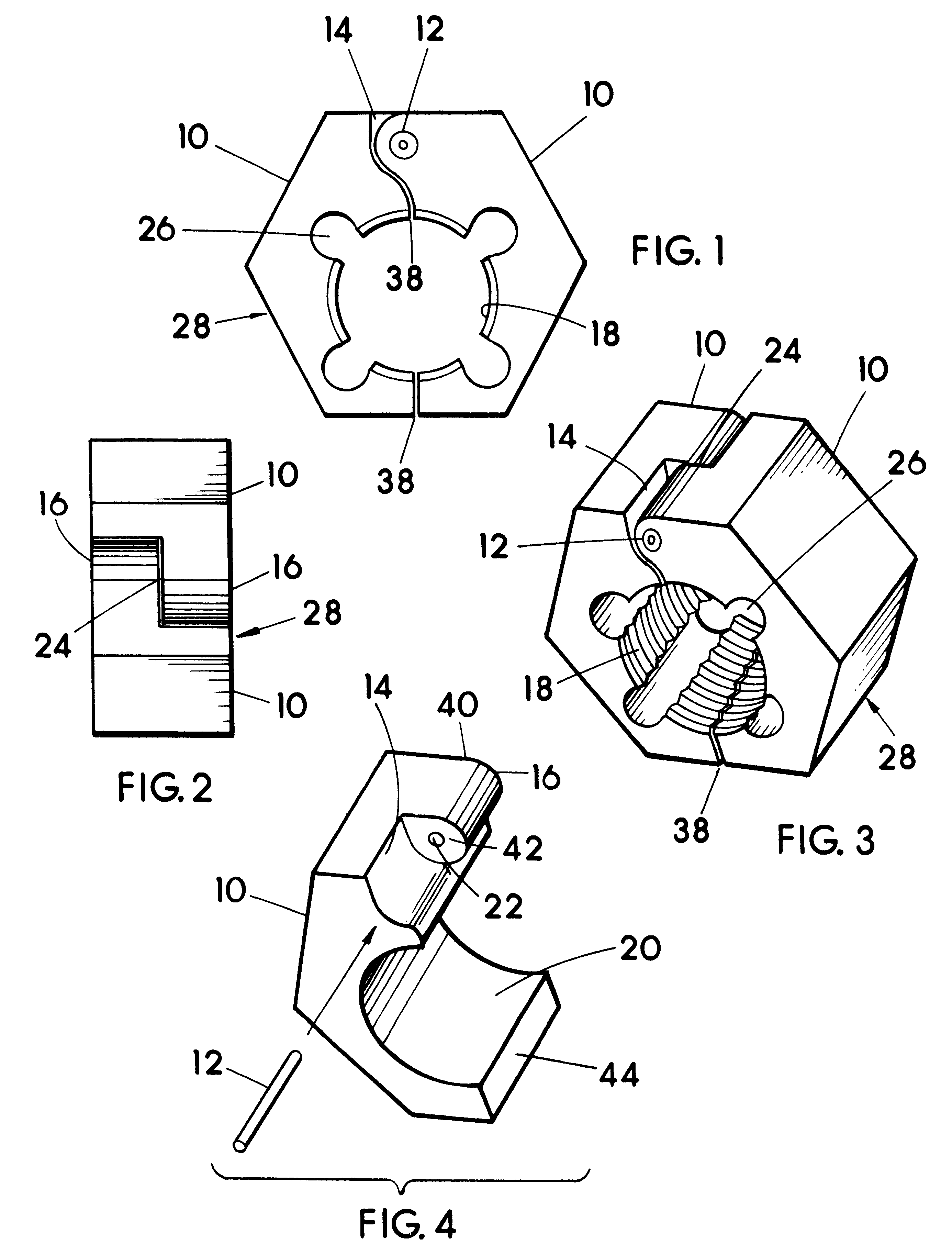

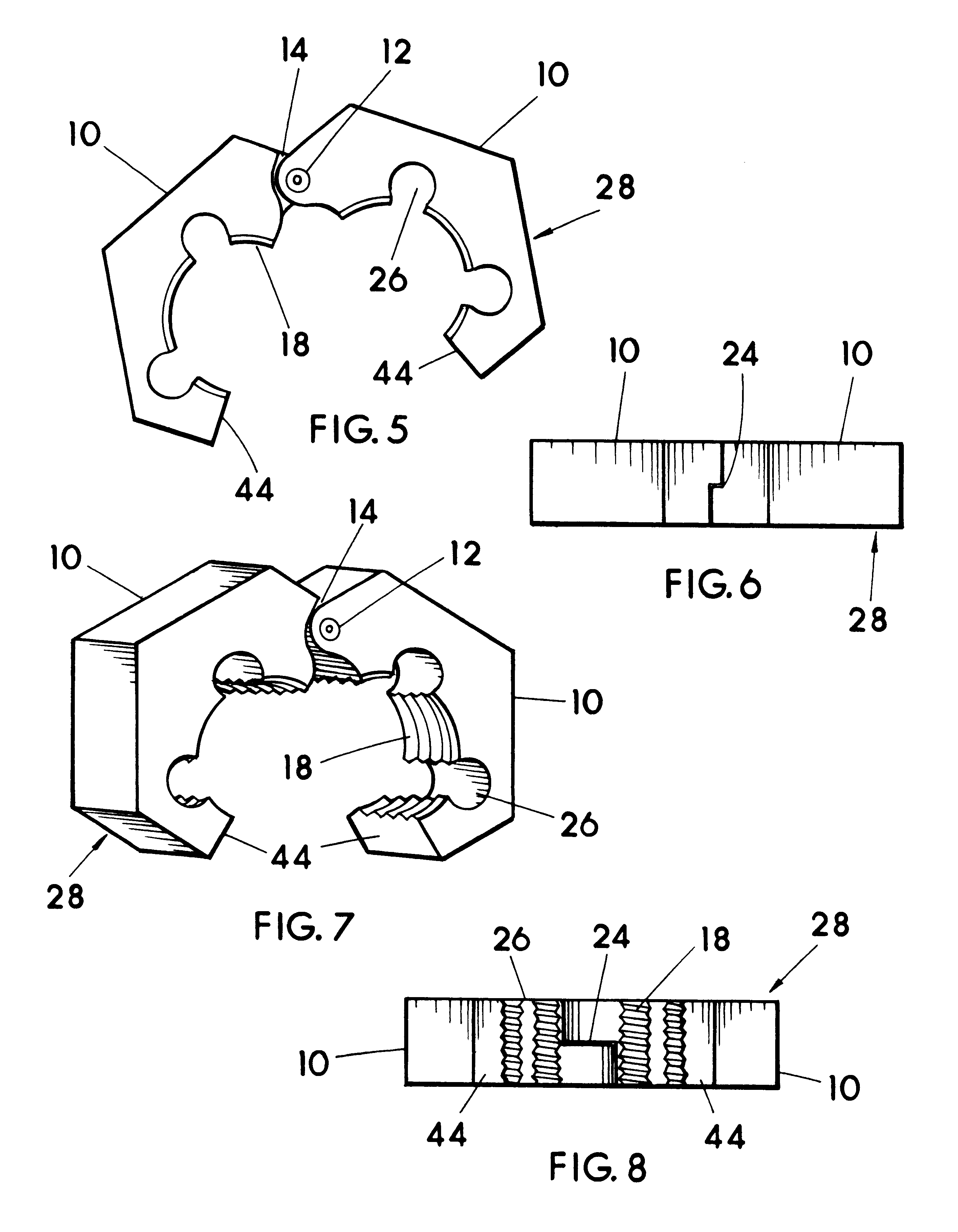

Thread chasing tool and method

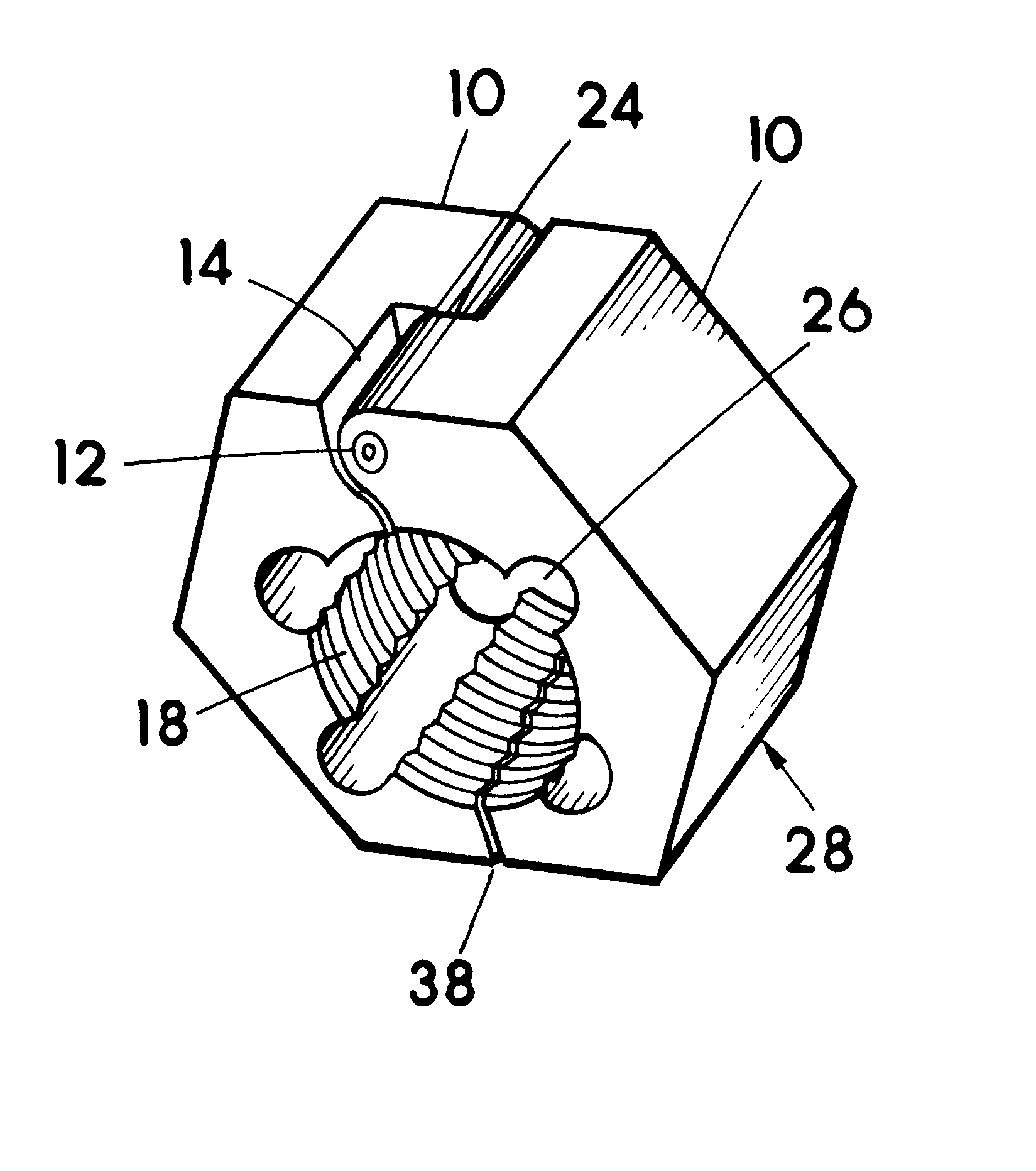

A pivoting split thread chasing die for rethreading and cleaning damaged or inhibited studs or bolts; and a method of manufacturing the die. The identical main body halves of the pivoting split die, when assembled together with an assembly pin form a pivoting split die with opposing front and rear faces and a hexagonal outside periphery. Threads are formed on the inside periphery of the pivoting split die allowing for engagement with the threads of a stud or bolt. One or more material reliefs are formed on the inside periphery of the pivoting split die to enhance the cleaning and rethreading ability of the pivoting split die threads. These reliefs also serve as points for which debris can escape while performing a rethreading procedure. To rethread or clean a damaged or inhibited bolt or stud, apply an appropriate lubricant to the area to be rethreaded or cleaned. Open up the pivoting split die and install around existing good threads of the stud or bolt and close pivoting split die until minimal closure gap exists. Select the appropriate wrenching tool and work the pivoting split die back and forth (counter-clockwise and clockwise) over the damaged or inhibited threads until the pivoting split die begins to move about the threads freely.

Owner:KEYS WESLEY CYRUS MR

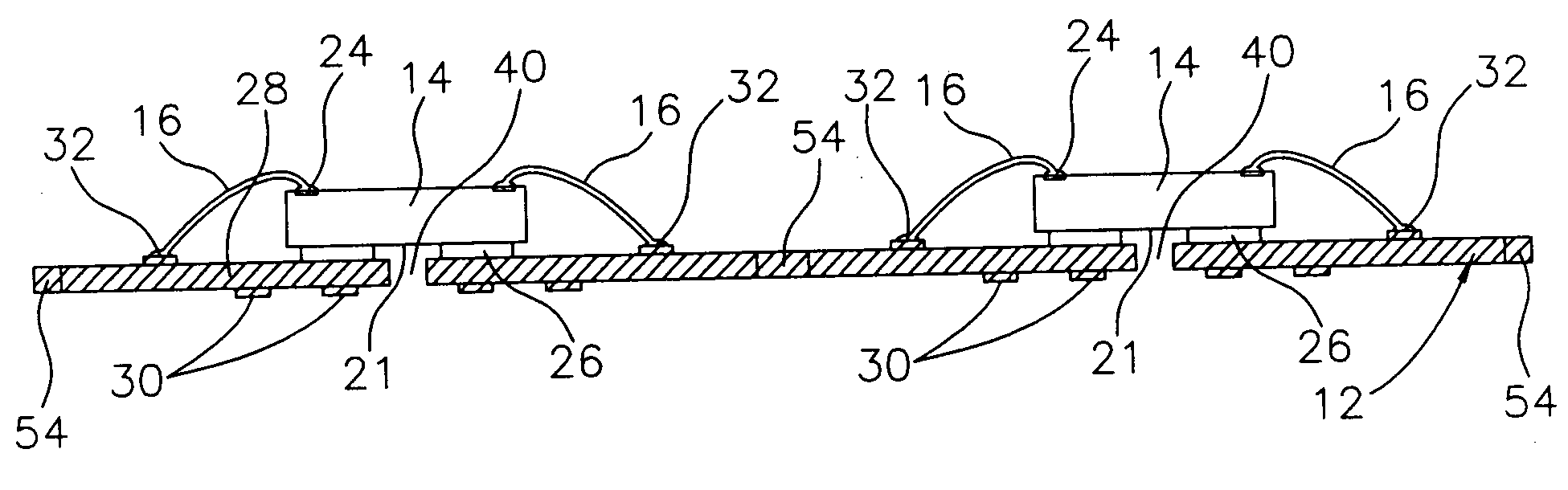

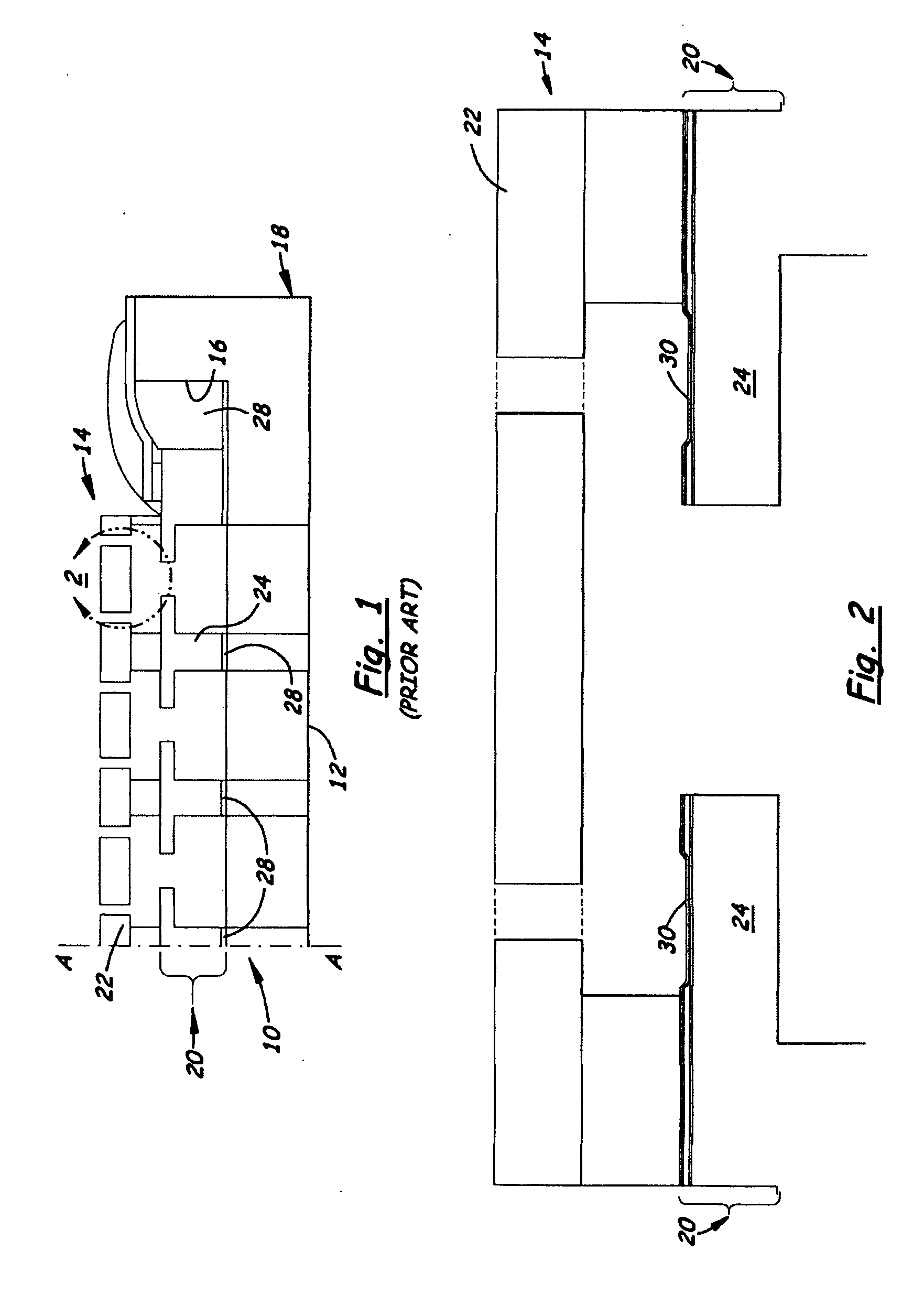

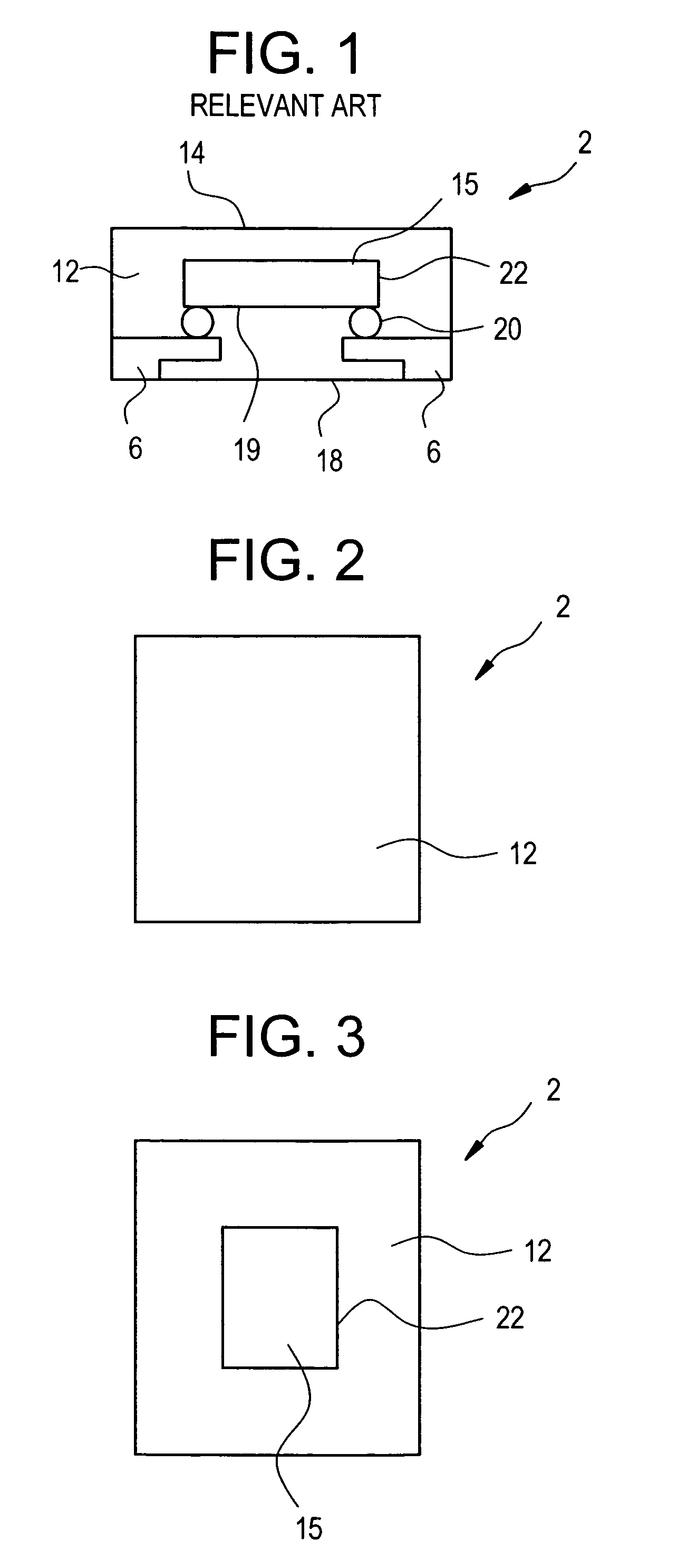

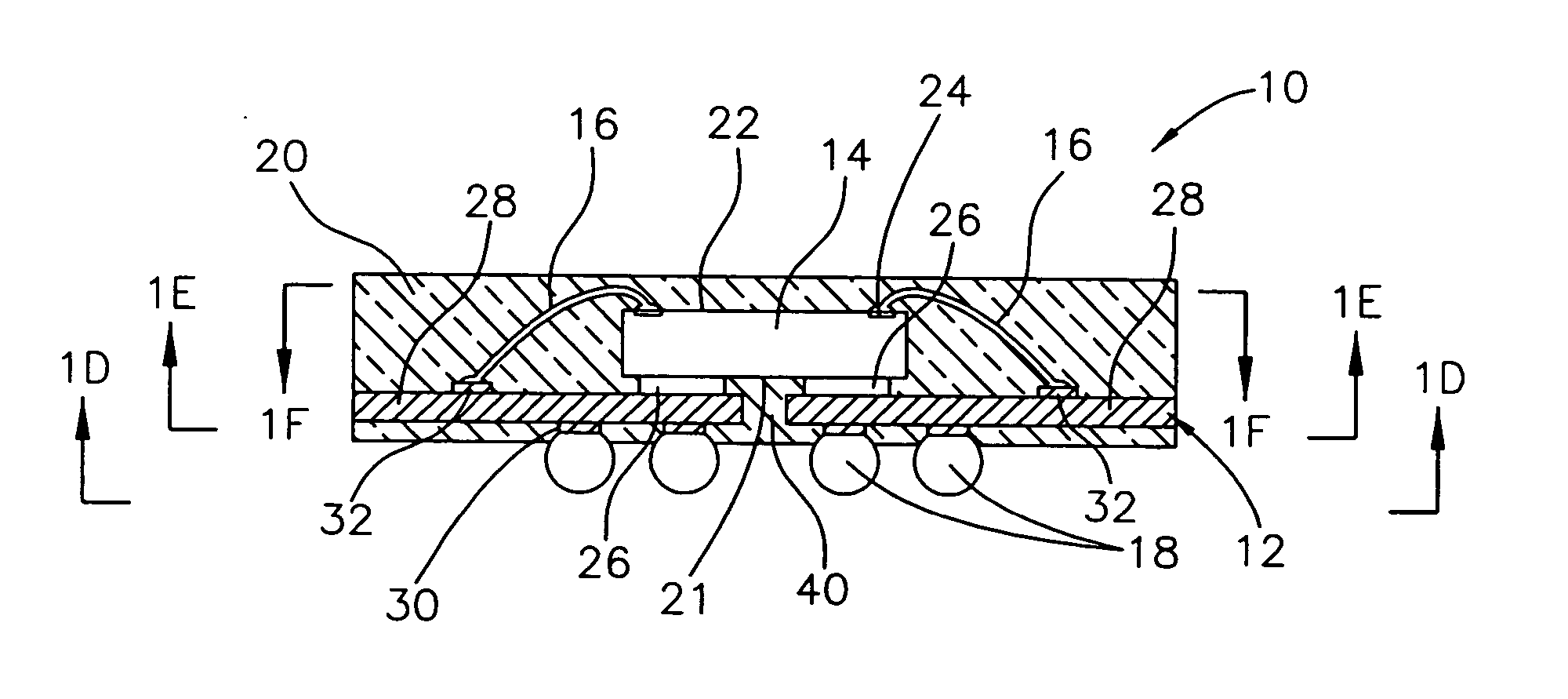

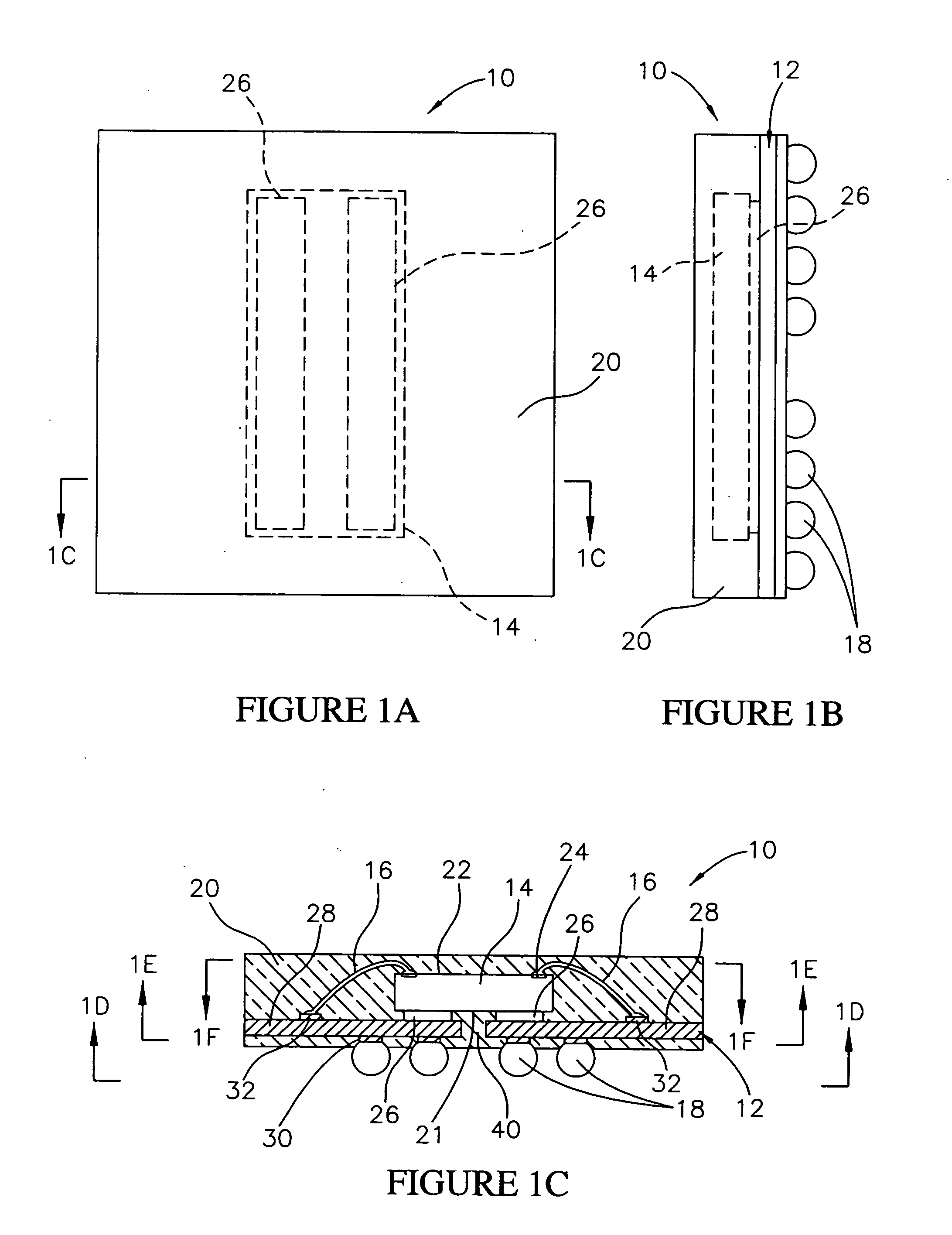

Semiconductor component having chip on board leadframe and method of fabrication

A semiconductor component includes a chip on board leadframe, a semiconductor die back bonded and wire bonded to the leadframe, an encapsulant on the die and an area array of terminal contacts on the leadframe. The leadframe includes leadfingers, interconnect bonding sites for wire bonding the die, terminal bonding sites for the terminal contacts, and bus bars which electrically connect selected leadfingers to one another. The interconnect bonding sites are located on the leadframe relative to the bus bars such that shorting to the bus bars by wire interconnects is eliminated. A method for fabricating the component includes the steps of attaching the die to the leadframe, bonding the wire interconnects to the die and to the interconnect bonding sites, forming the encapsulant, and then forming the terminal contacts on the terminal bonding sites.

Owner:MICRON TECH INC

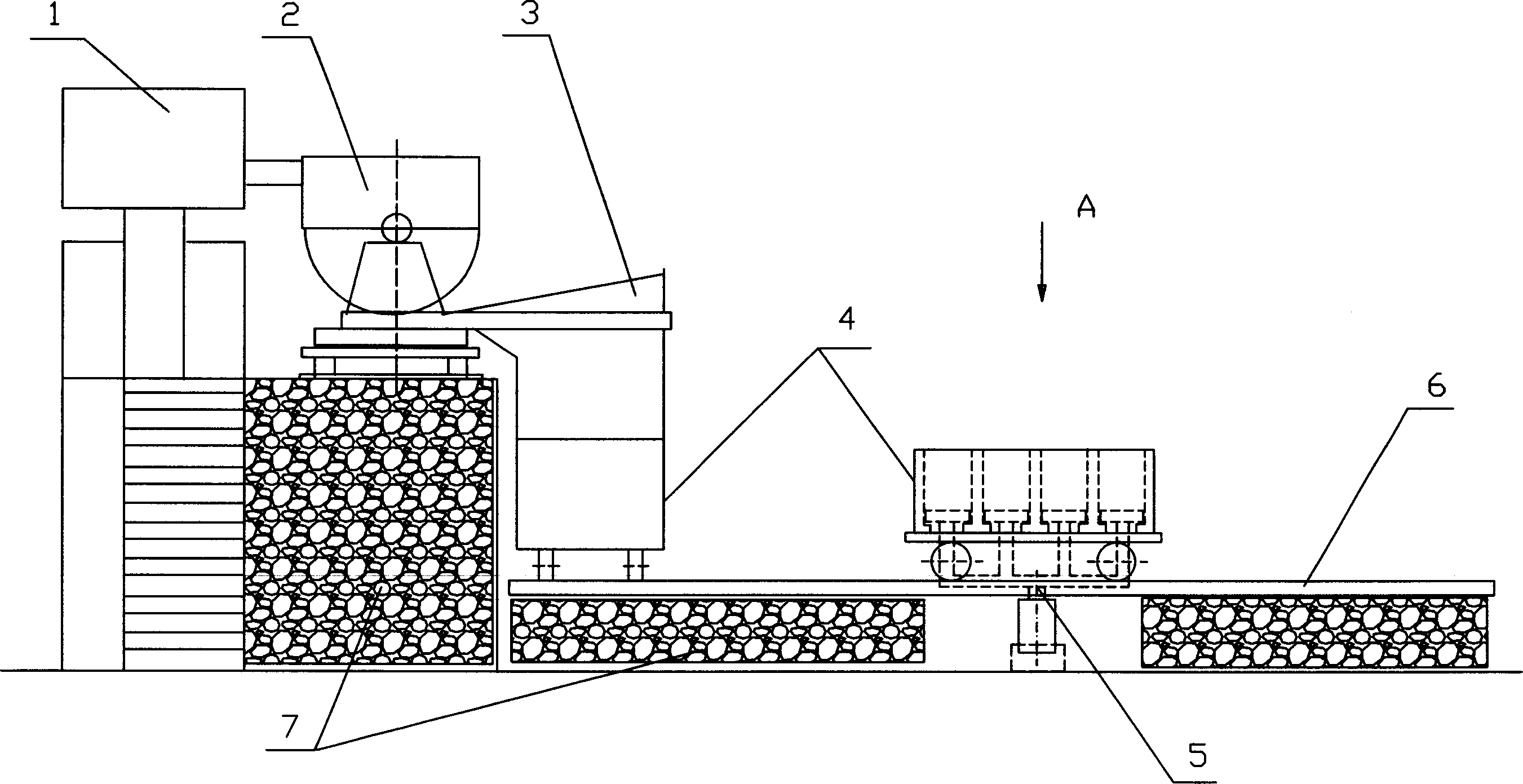

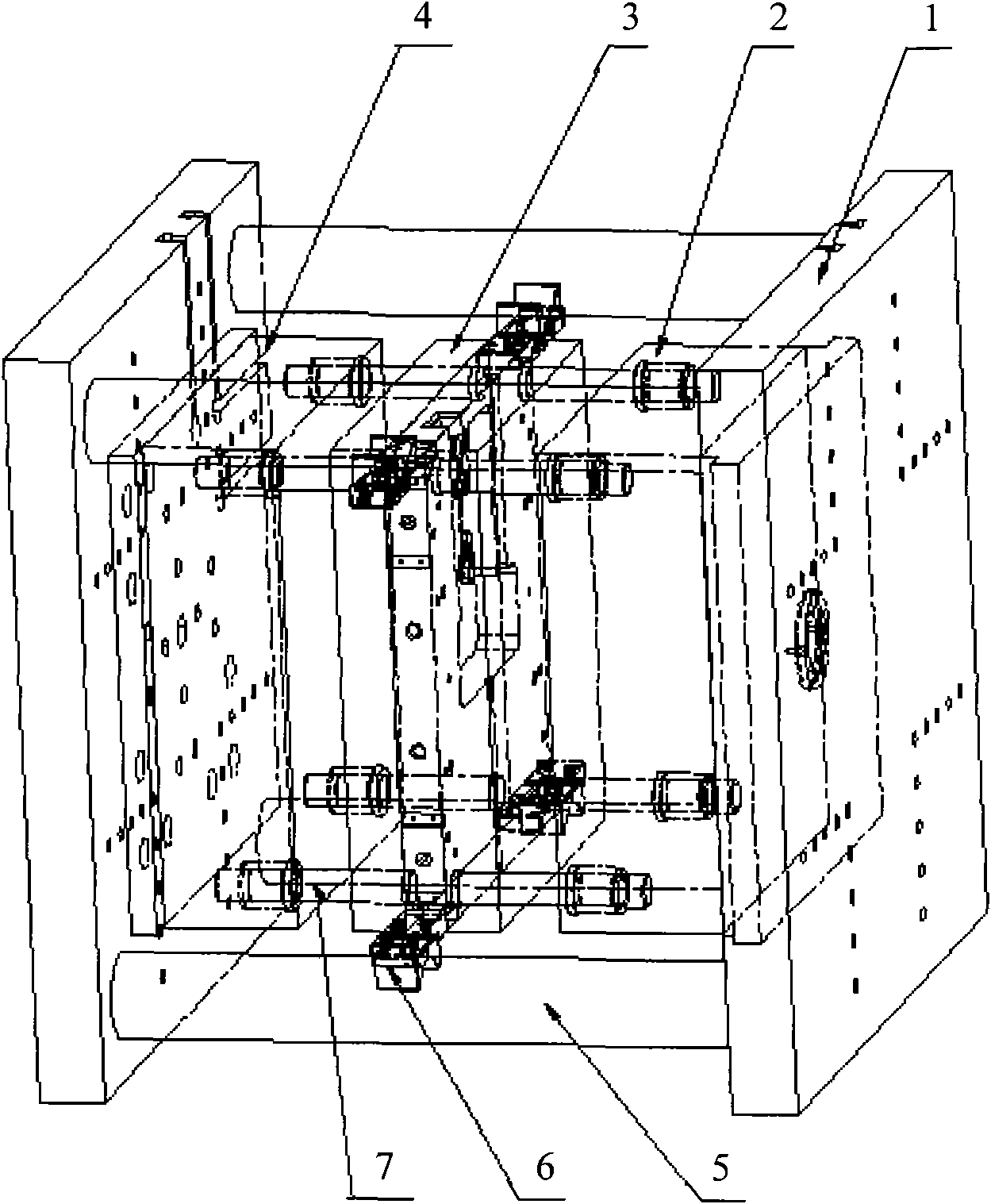

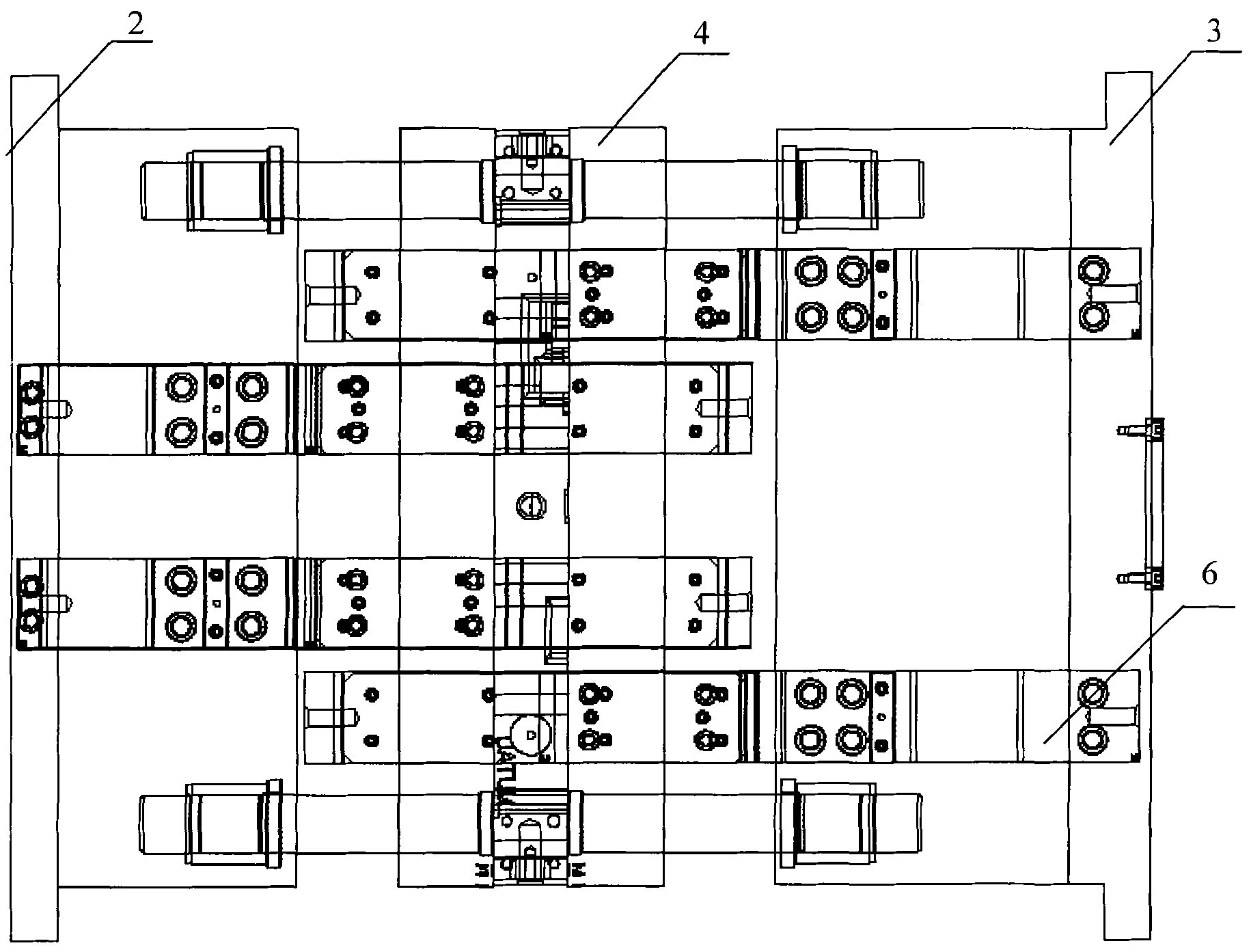

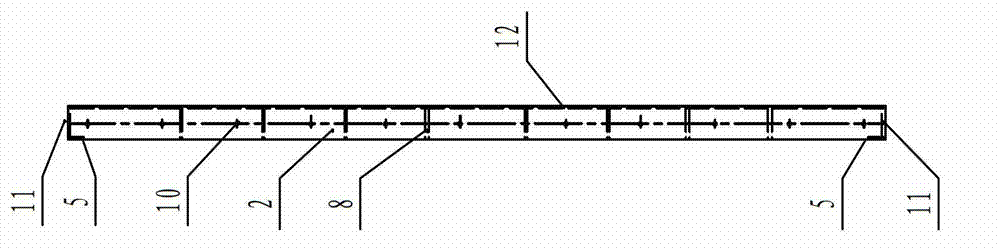

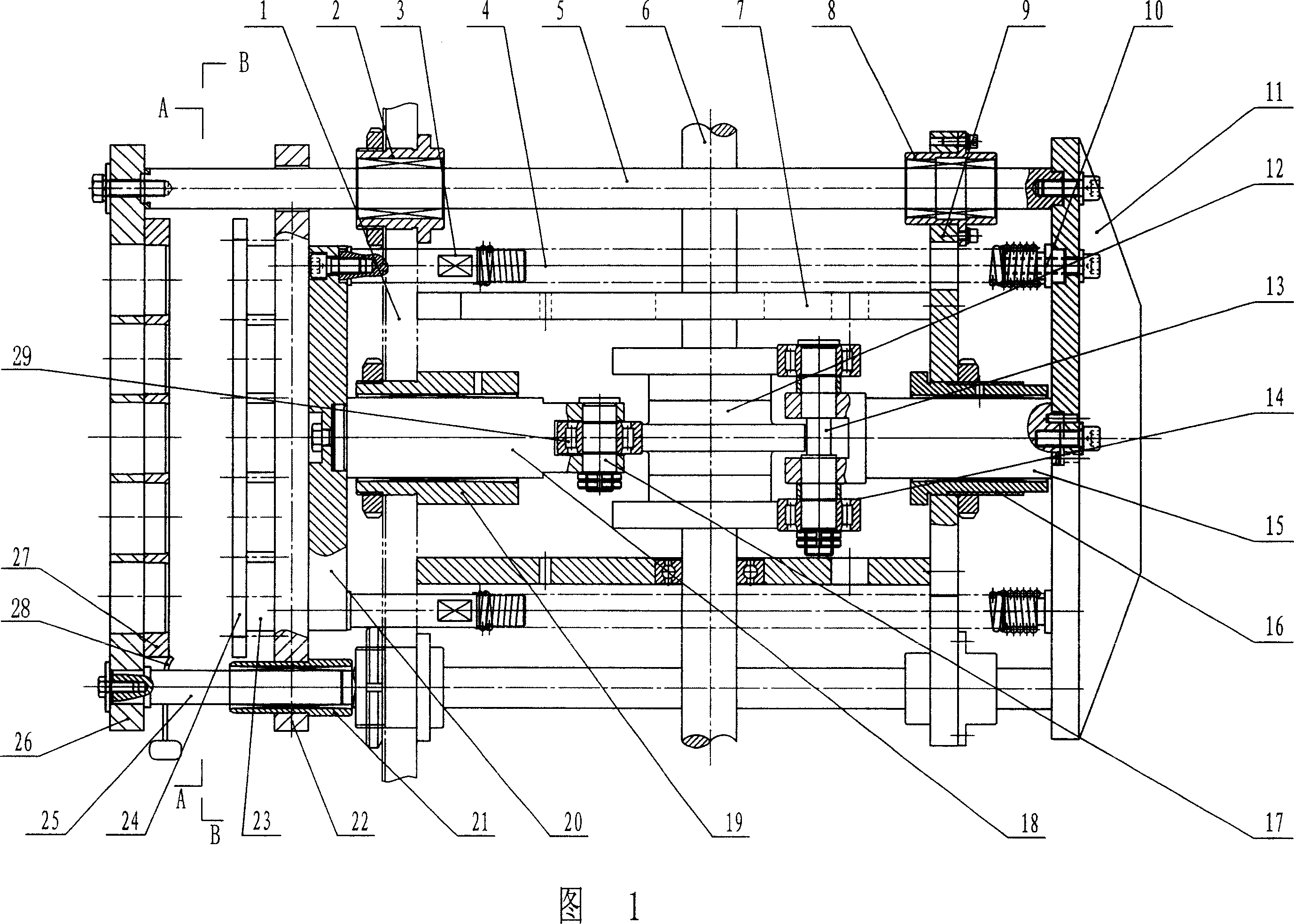

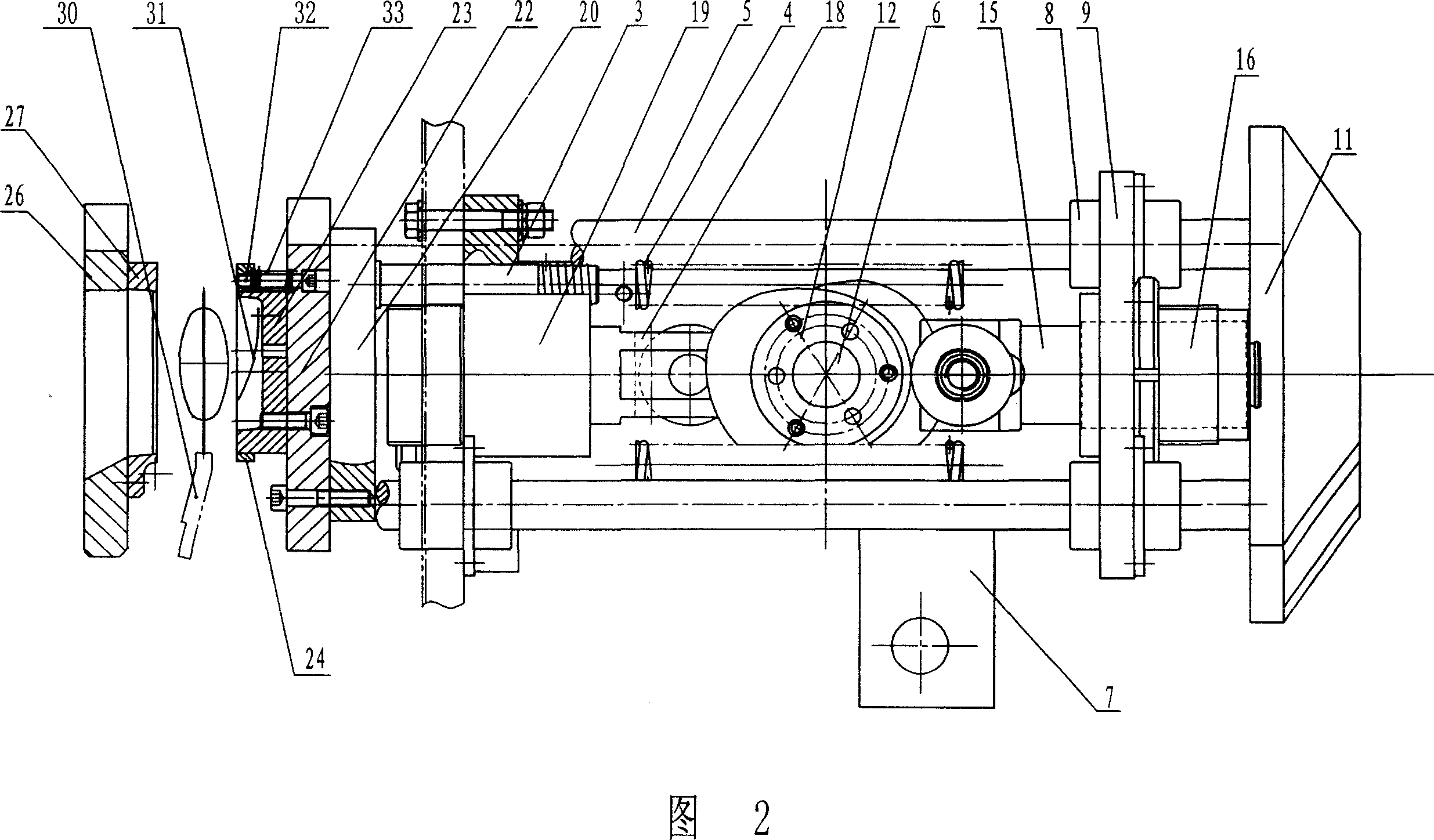

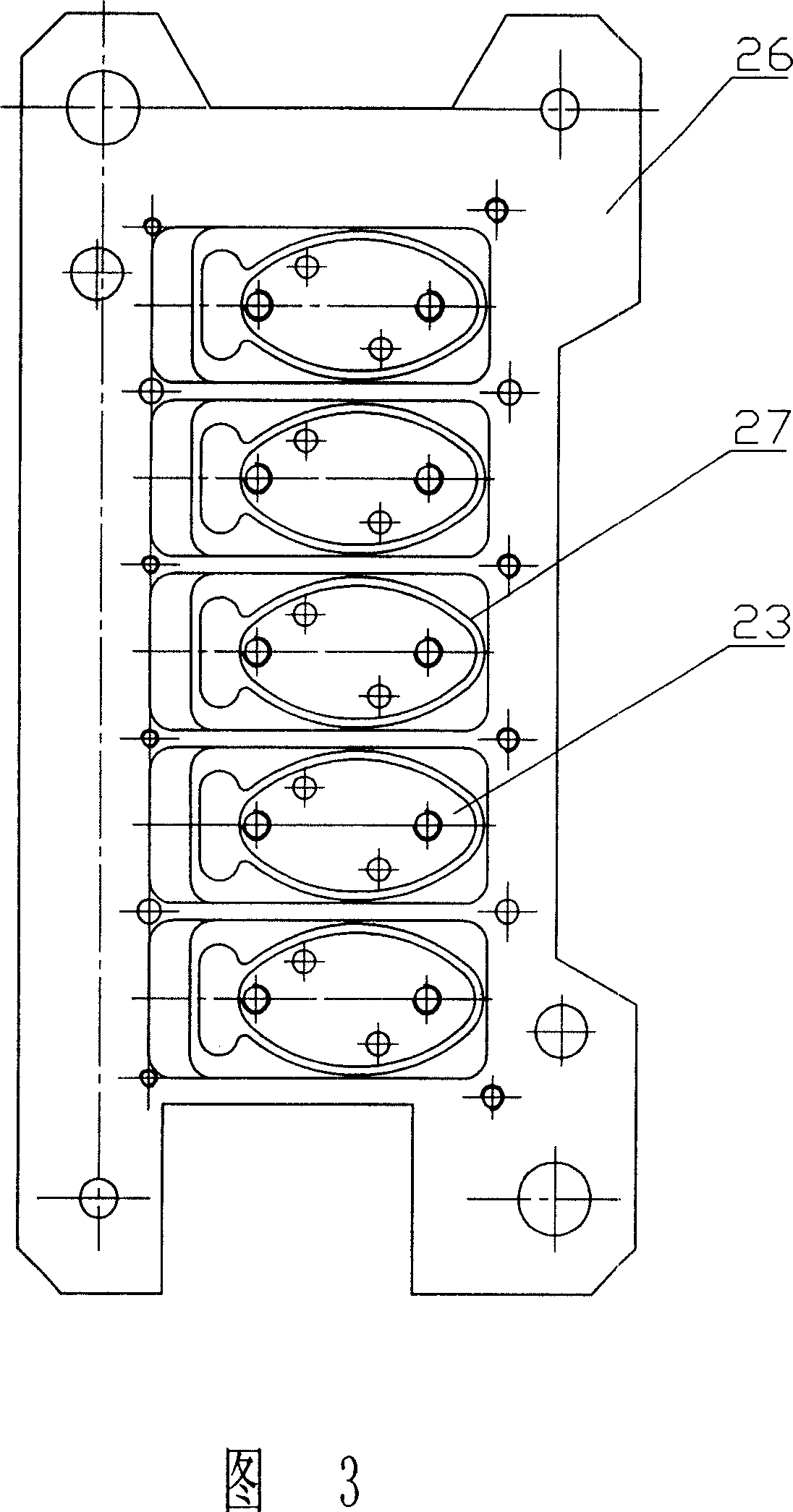

Precise multifunctional incremental pressing die and its making process

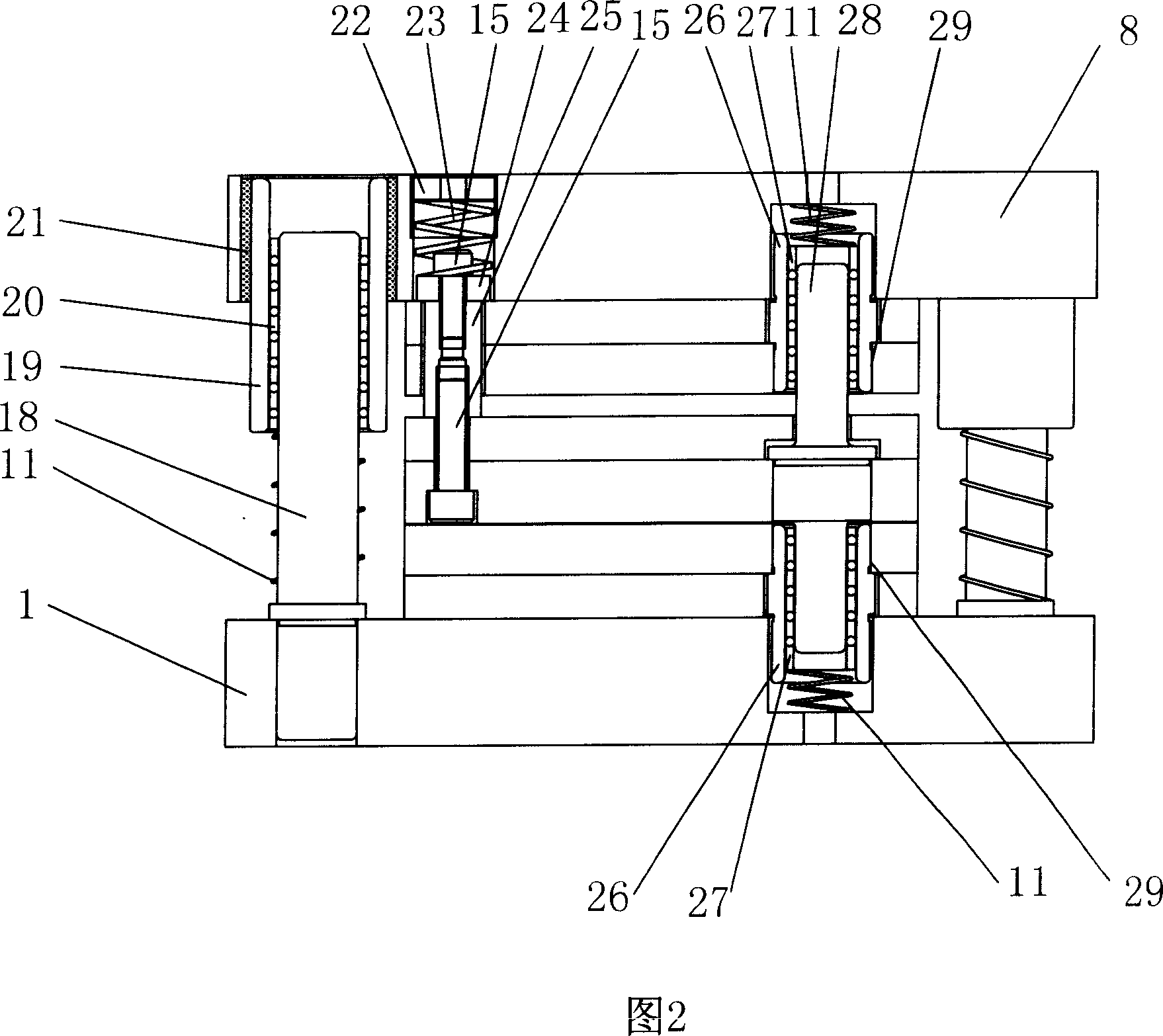

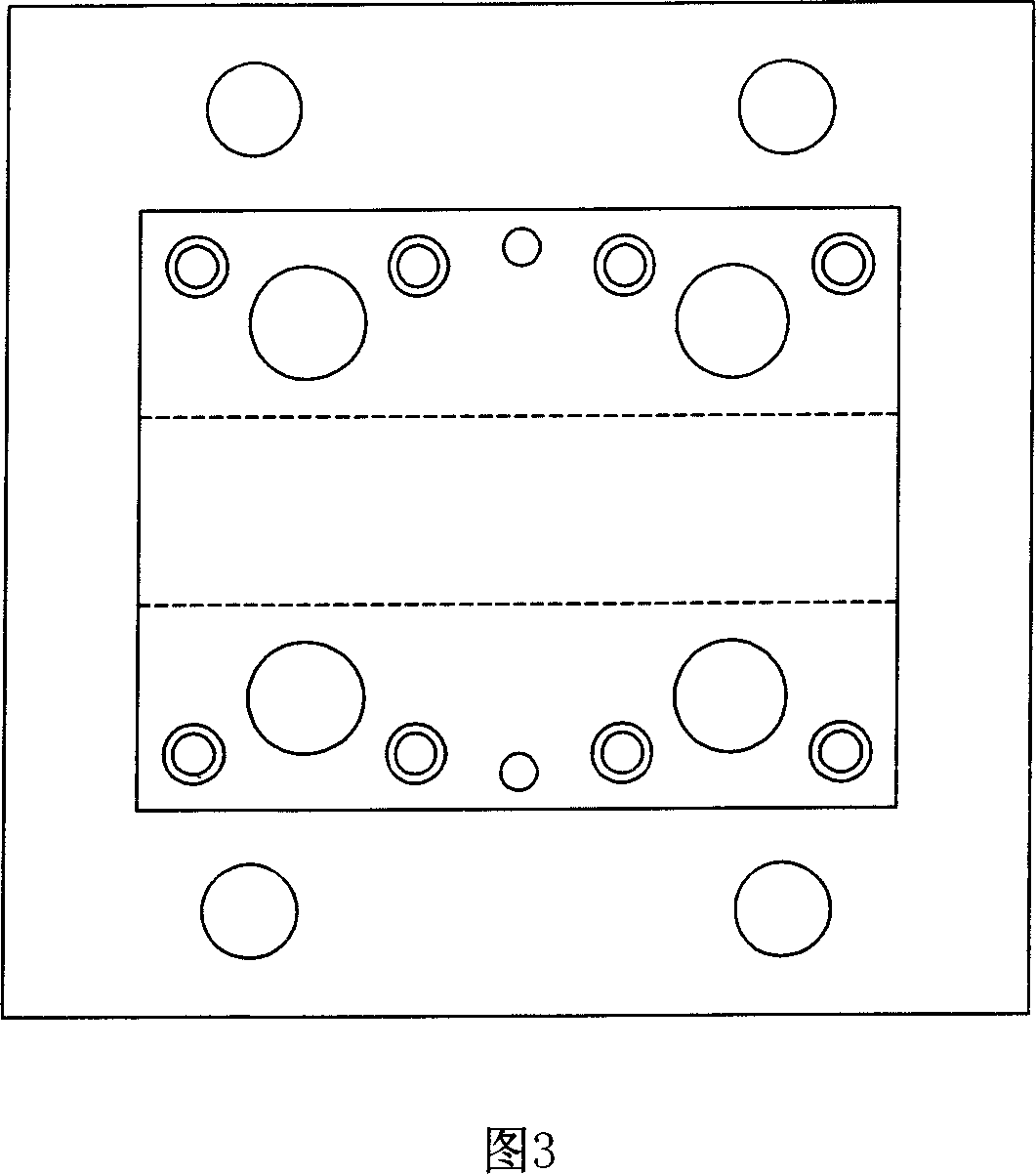

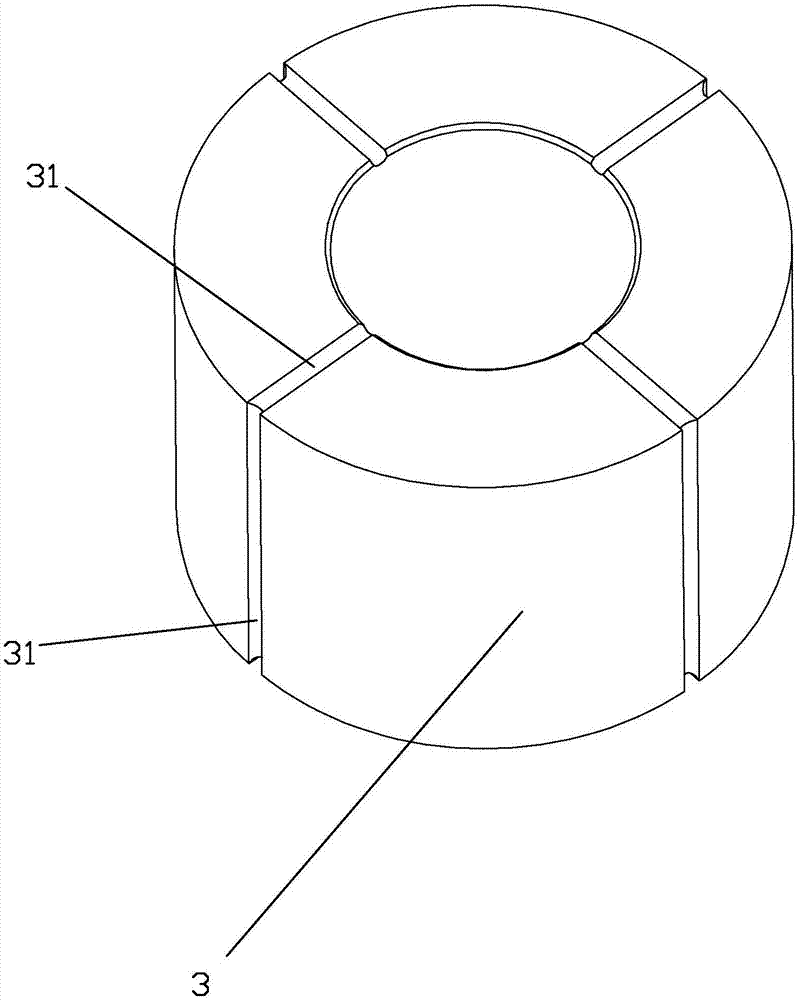

InactiveCN1931469AEasy maintenance, adjustment and replacementSimple structureShaping toolsDying backMechanical engineering

The precise multifunctional incremental pressing die includes a lower die, an upper die, an internal guiding mechanism and an outer guiding mechanism. The upper die includes an upper die seat, a convex die back plate, an unloading back plate, and an unloading plate. The lower die includes a lower die seat, a concave back plate and a concave die plate. The outer guiding mechanism includes a large guide pin, a large ball sleeve, a large guide sleeve and a spring. The internal guiding mechanism includes a small guide pin, a small ball sleeve, a small guide sleeve and a spring. The making process features that the unloading plate and the concave die plate are fastened together.

Owner:GELIPU ELECTRONICS SHENZHEN CITY

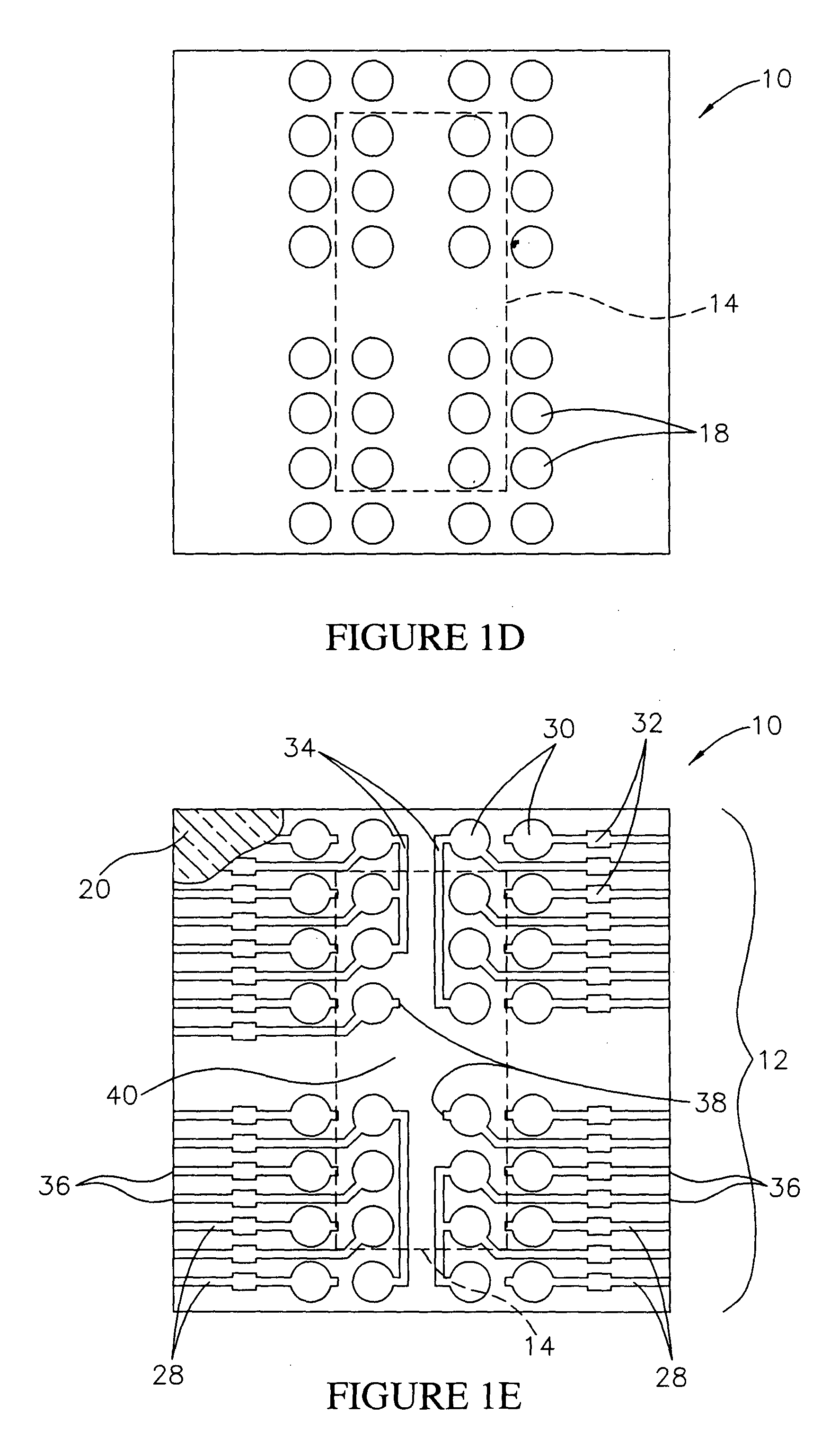

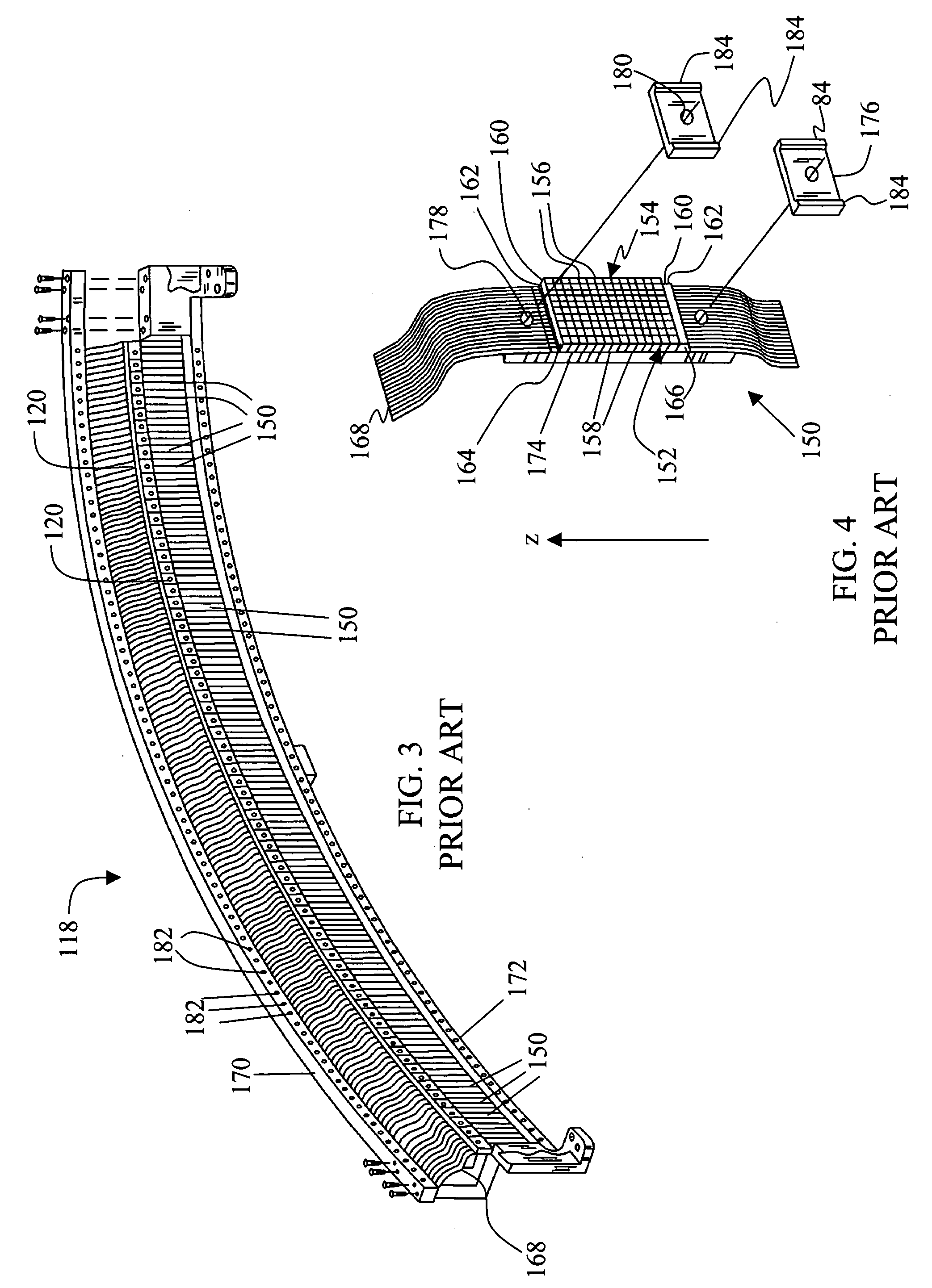

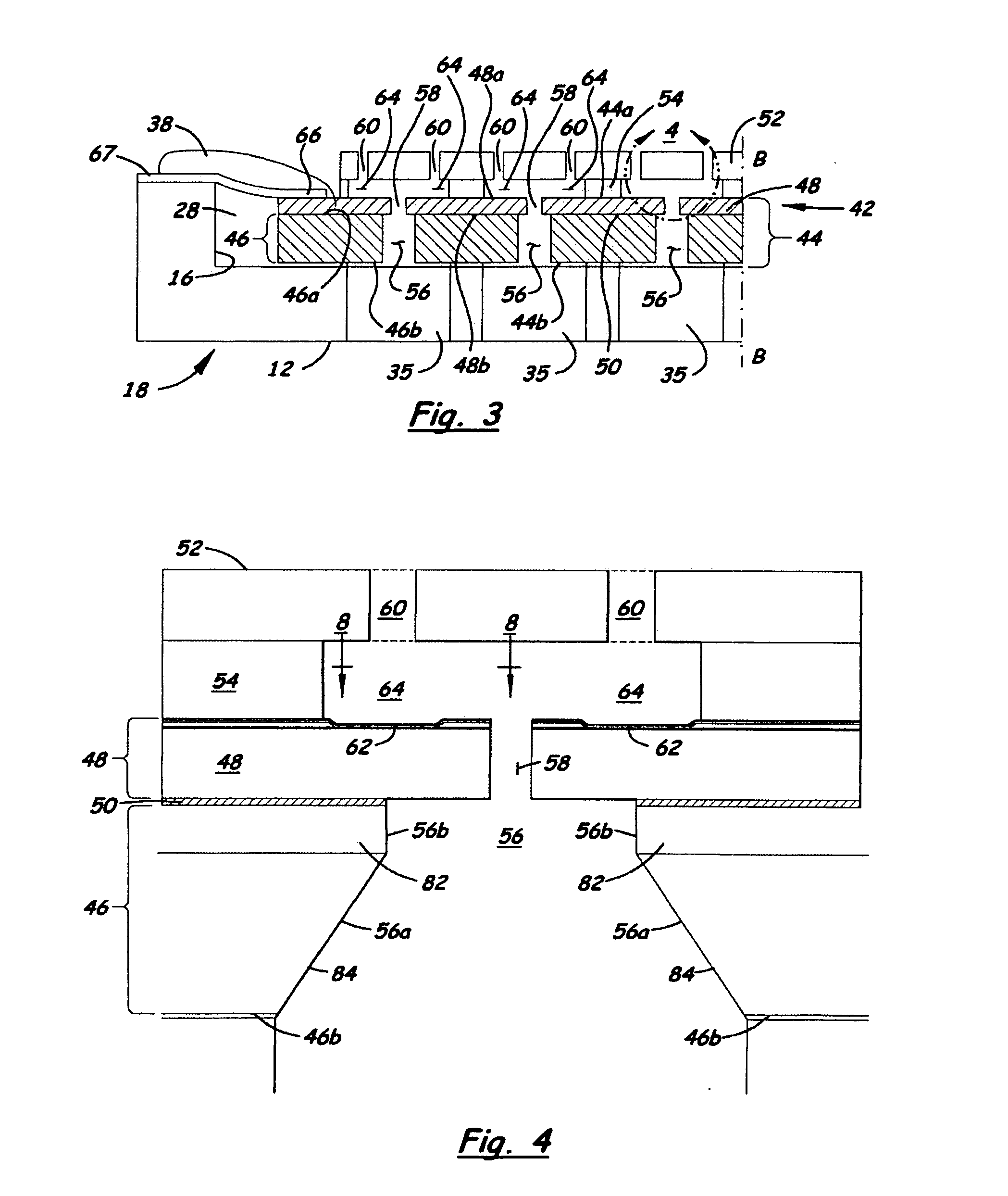

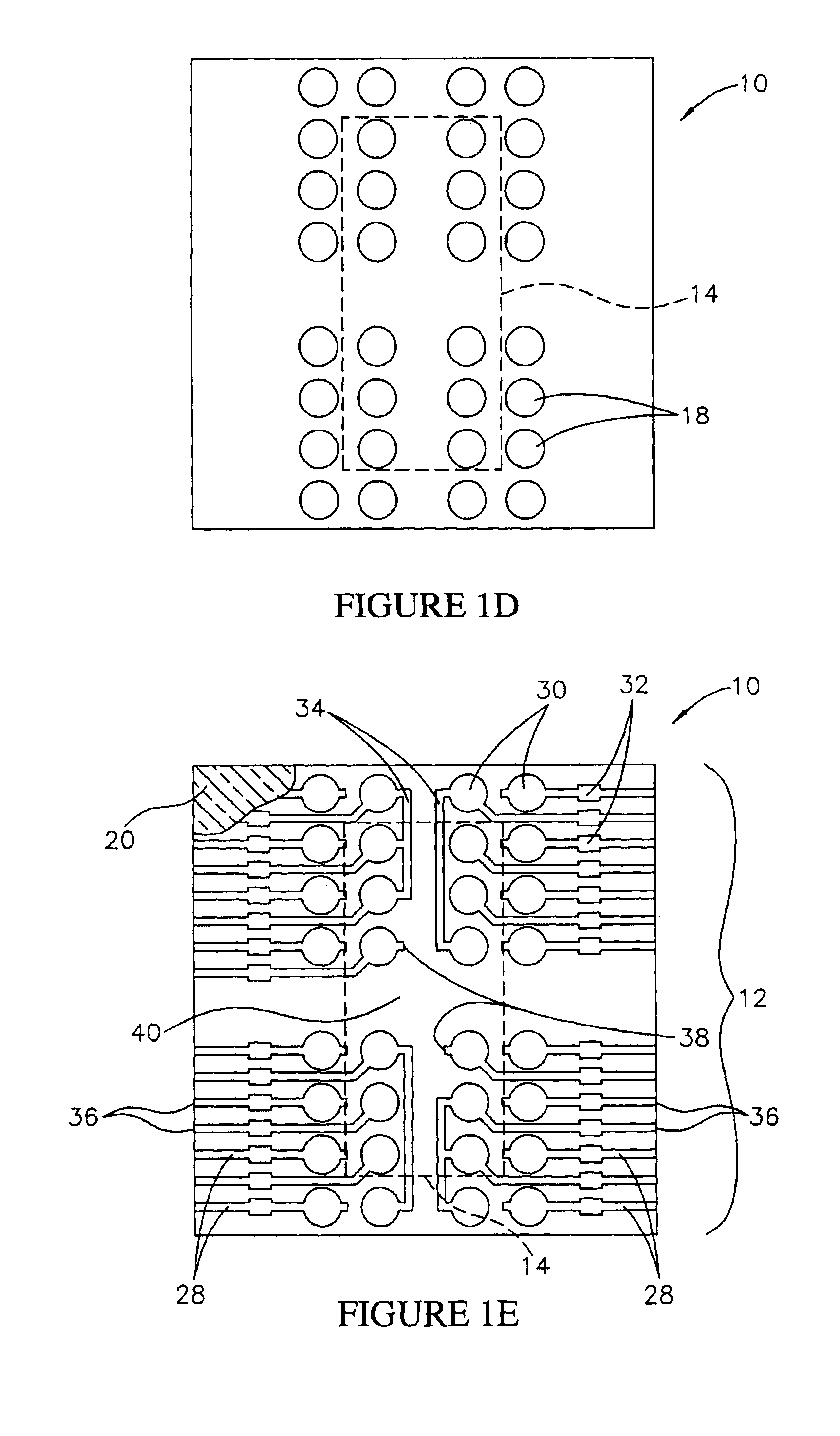

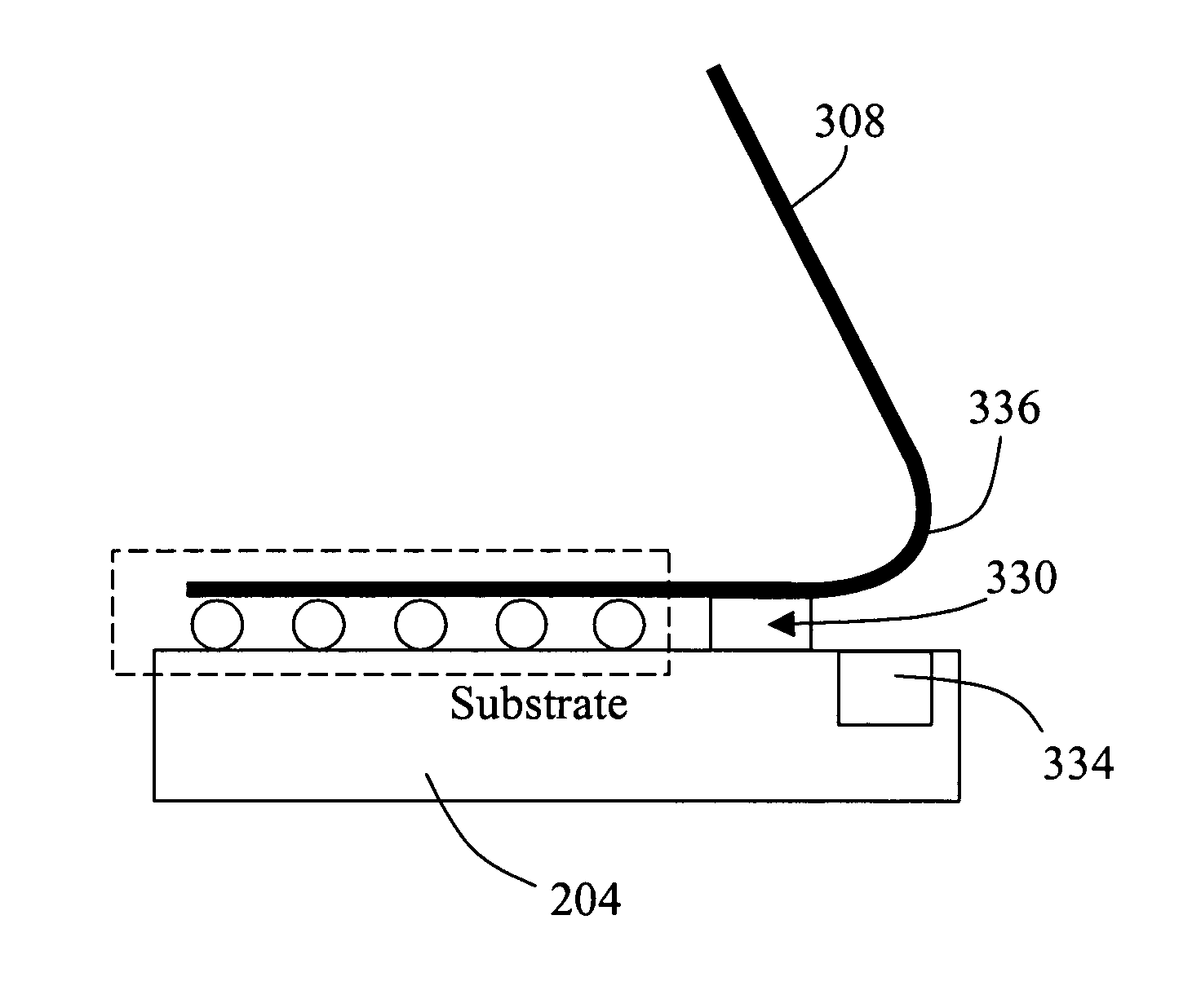

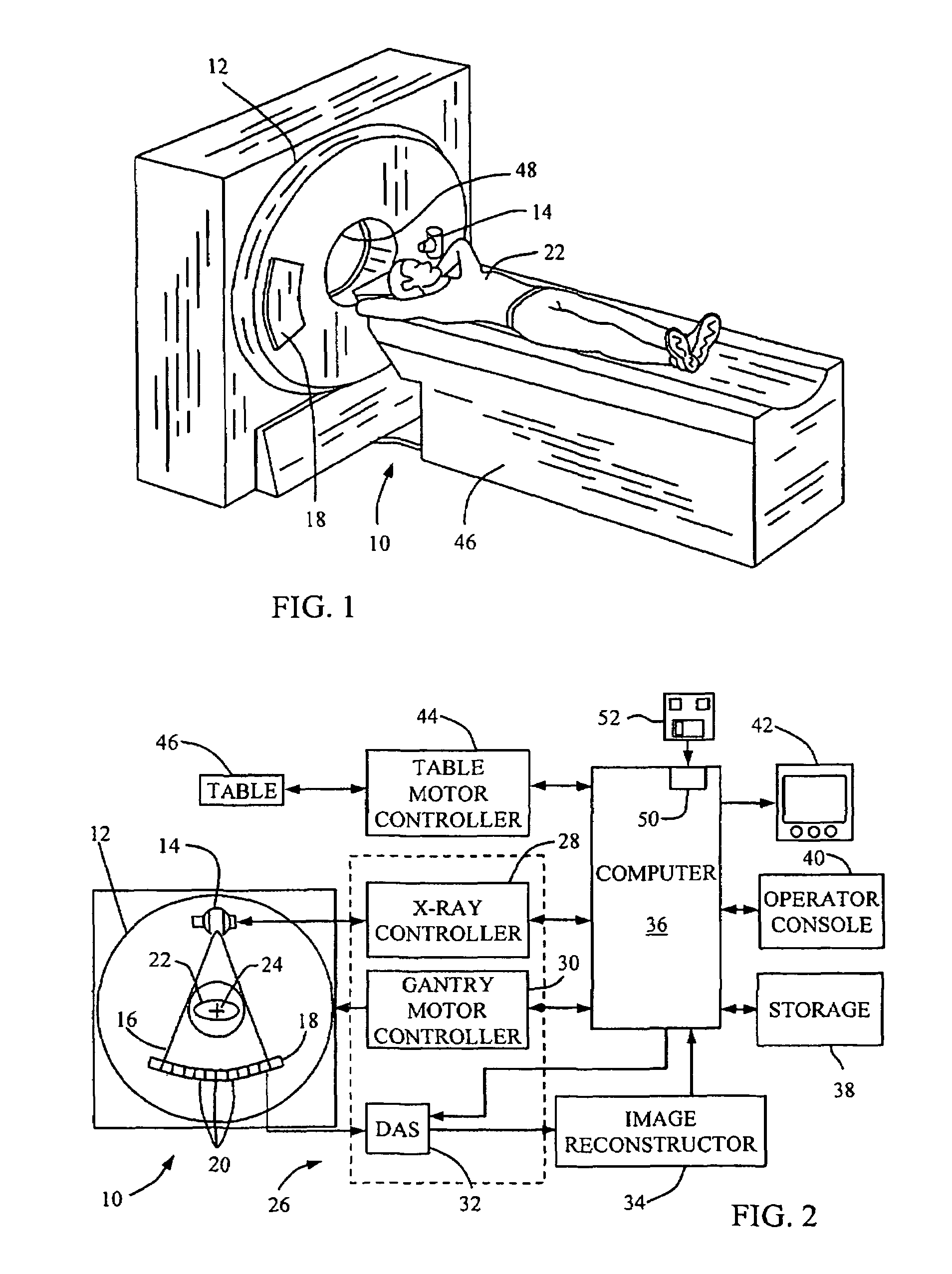

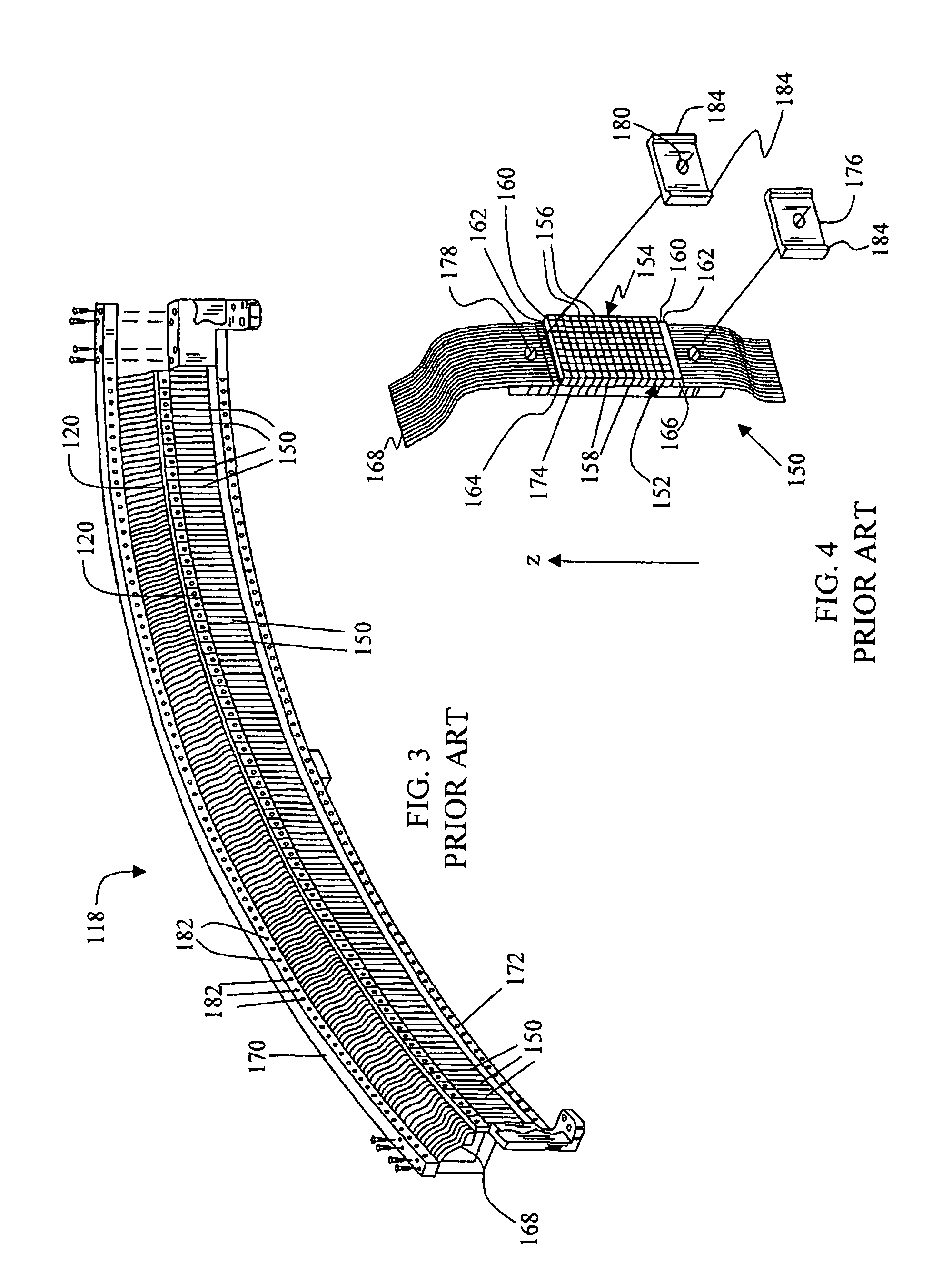

Module assembly for multiple die back-illuminated diode

InactiveUS20060071173A1Solid-state devicesMaterial analysis by optical meansElectrical conductorEngineering

A computerized tomography imaging scanner module includes a plurality of scintillators, a plurality of back-illuminated photodiodes optically coupled with the scintillators, a multi-layer substrate having a plurality of substrate electrical conductors to which the photodiodes are electrically coupled, wherein each of the plurality of substrate conductors is connected to a different one of the back-illuminated photodiodes, and a flexible cable having a plurality of flex electrical conductors to which the substrate is electrically coupled, wherein each of the plurality of flex electrical conductors is connected to a different output of the multi-layer substrate.

Owner:GENERAL ELECTRIC CO

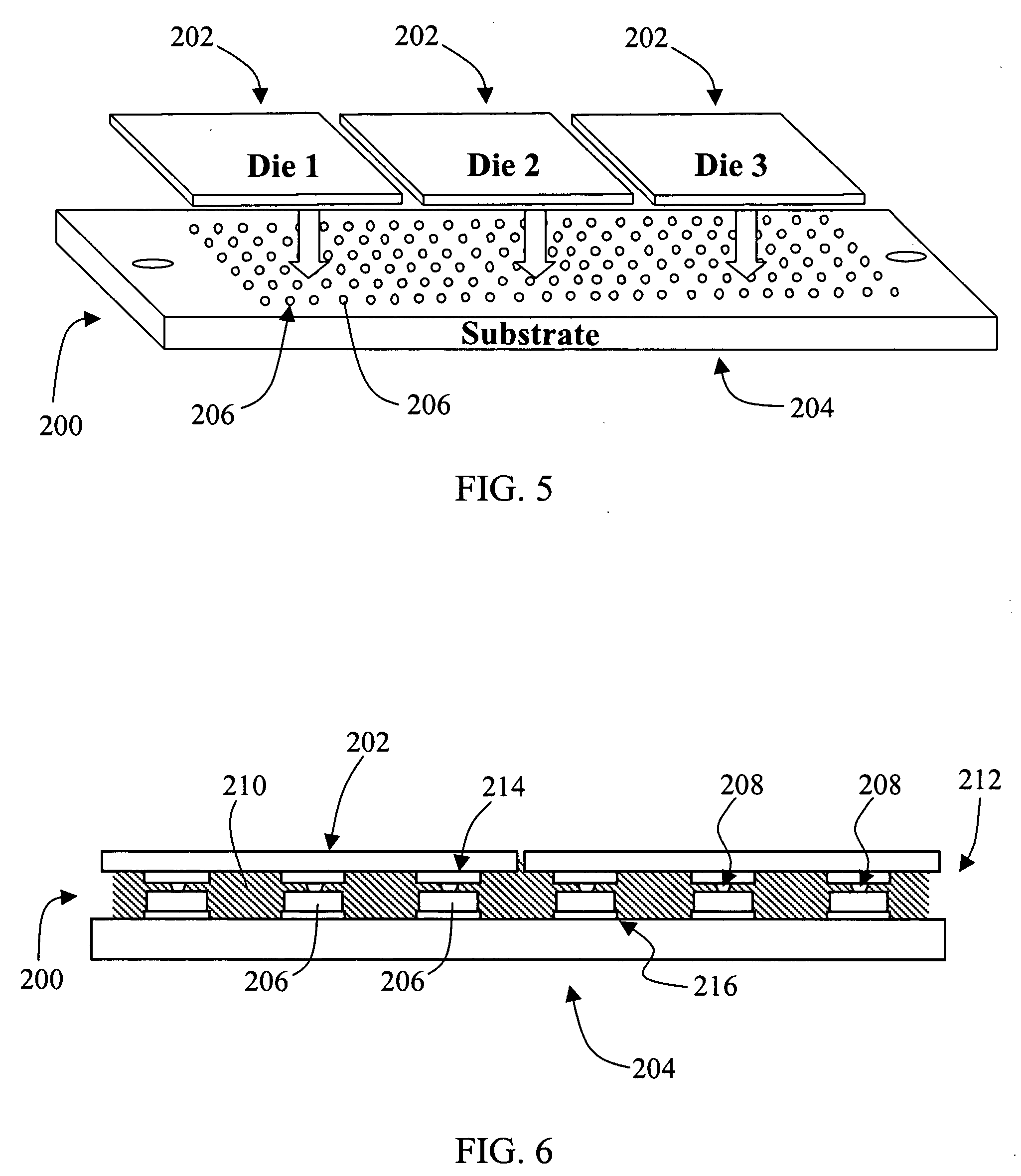

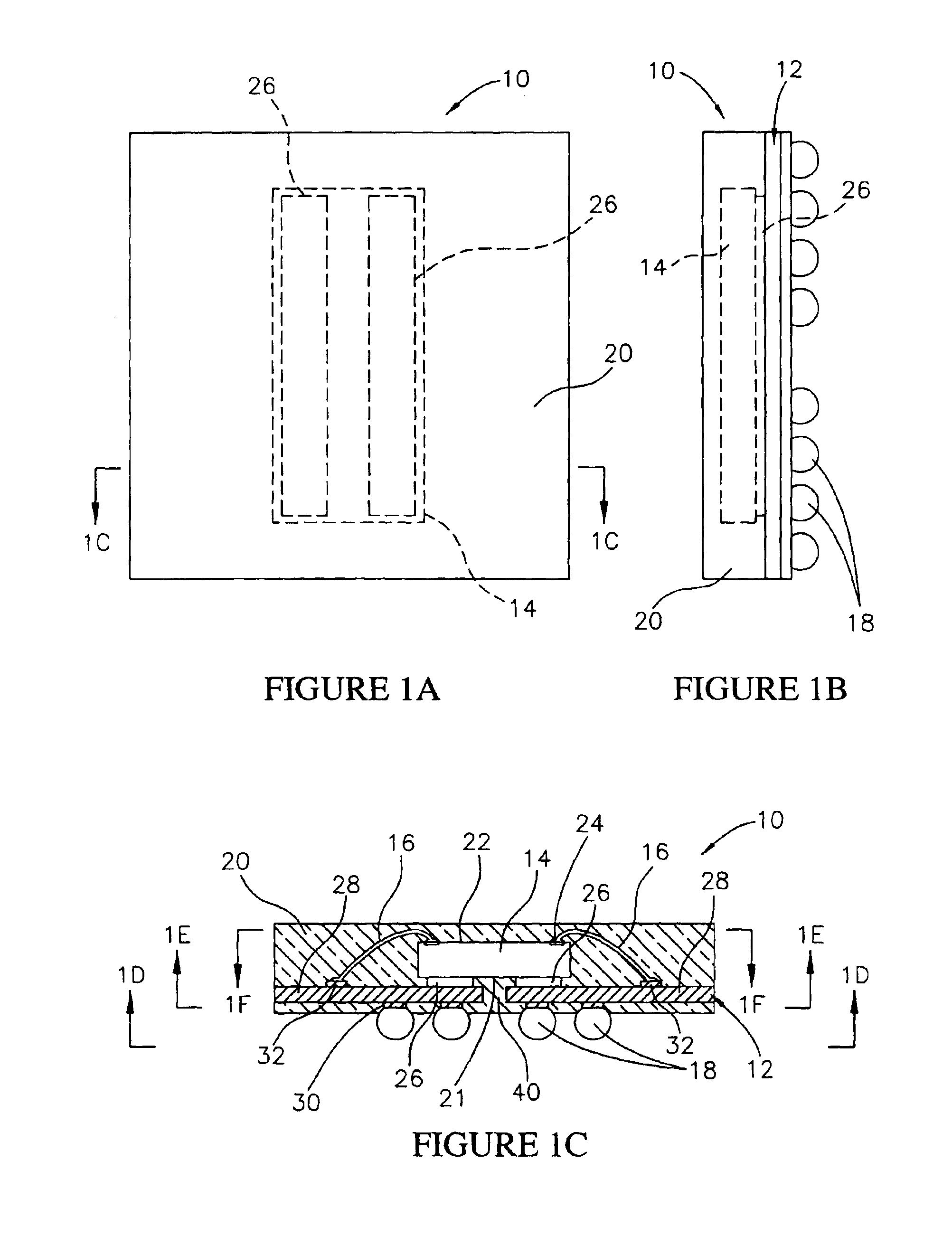

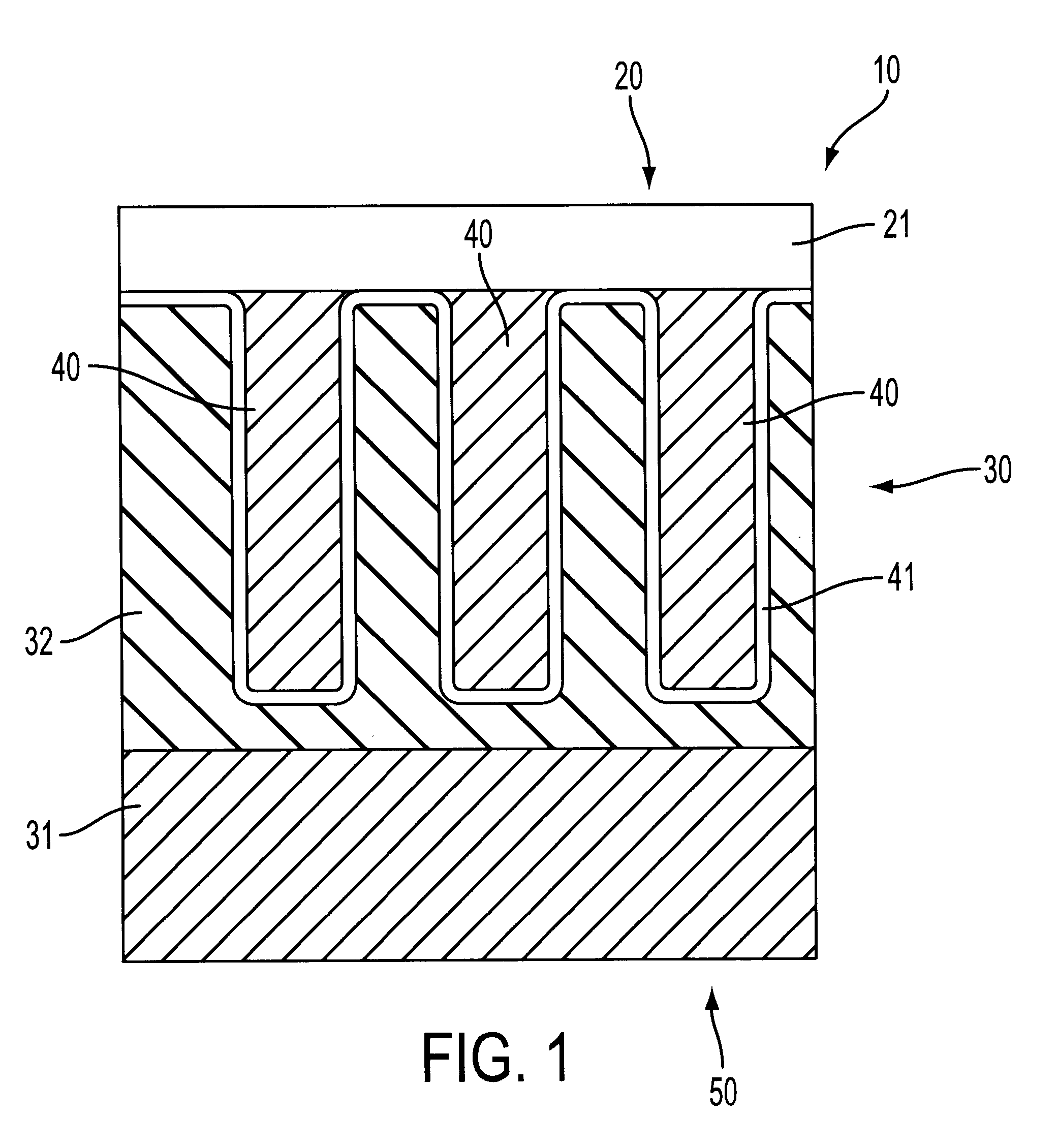

Heater chips with silicon die bonded on silicon substrate and methods of fabricating the heater chips

InactiveUS20090256891A1Reduce necessityAvoid loopsWriting implementsMetal-working apparatusPartial alignmentDying back

A heater chip has a substrate and at least one die, made of silicon, and a bond non-adhesively attaching them. The substrate, thick enough to resist bowing, has ink supply vias from back to front surfaces. The die has ink flow vias from back to front surfaces and circuitry including heater elements adjacent the front surface interspersed with ink flow vias. The at least one die is superimposed on the substrate such that ink supply vias of the substrate align with ink flow vias of the die and portions of substrate front surface and die back surface are aligned, disposed adjacent and facing one another. The bond formed between substrate and die facing surface portions is hermetic and equal in strength to a Si—O bond. By separate processing of carrier and device wafers, size and features of substrate and die can be tailored to provide a desired heater chip construction.

Owner:FUNAI ELECTRIC CO LTD

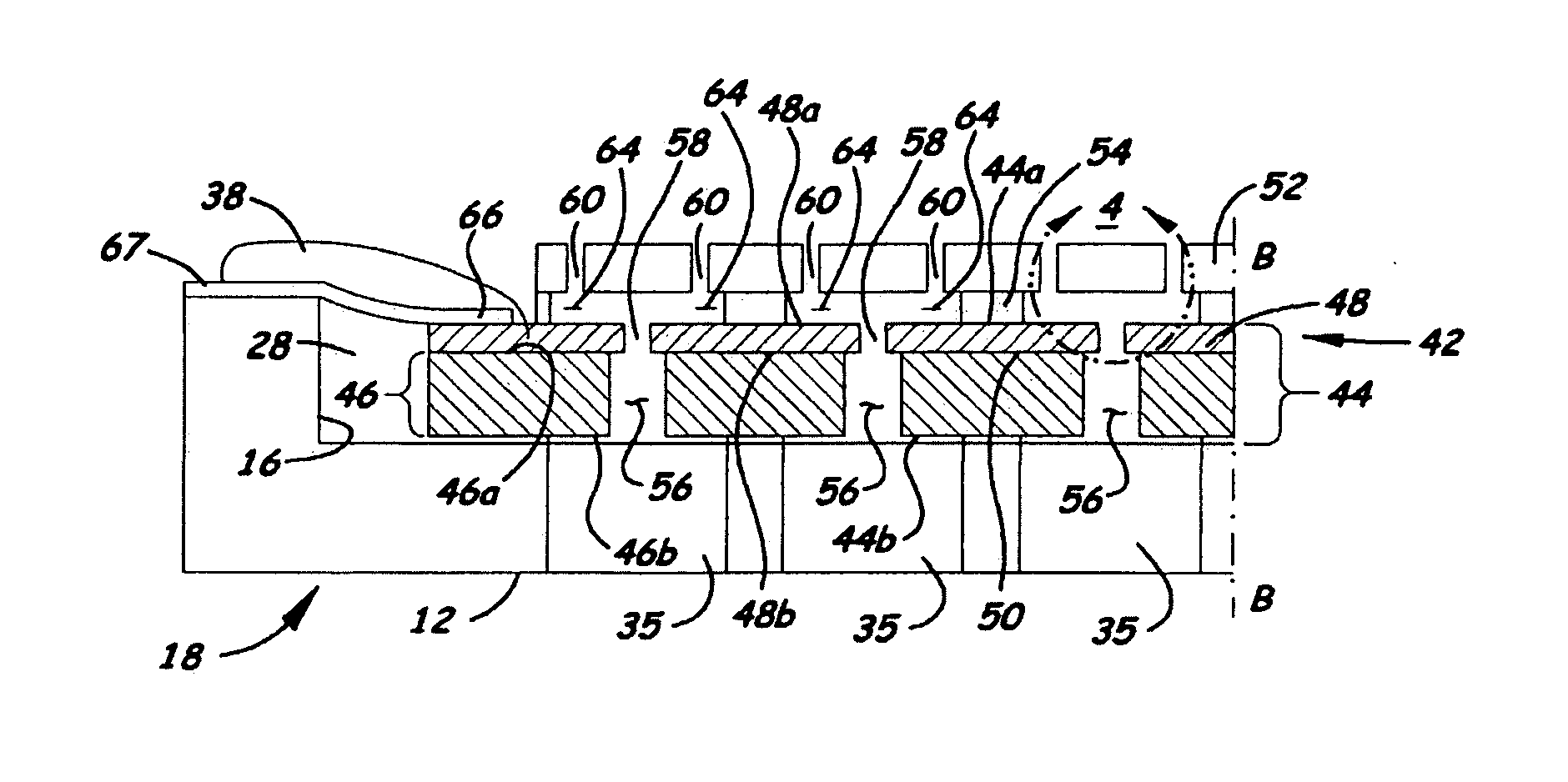

Semiconductor component having chip on board leadframe

A semiconductor component includes a chip on board leadframe, a semiconductor die back bonded and wire bonded to the leadframe, an encapsulant on the die and an area array of terminal contacts on the leadframe. The leadframe includes leadfingers, interconnect bonding sites for wire bonding the die, terminal bonding sites for the terminal contacts, and bus bars which electrically connect selected leadfingers to one another. The interconnect bonding sites are located on the leadframe relative to the bus bars such that shorting to the bus bars by wire interconnects is eliminated. A method for fabricating the component includes the steps of attaching the die to the leadframe, bonding the wire interconnects to the die and to the interconnect bonding sites, forming the encapsulant, and then forming the terminal contacts on the terminal bonding sites.

Owner:MICRON TECH INC

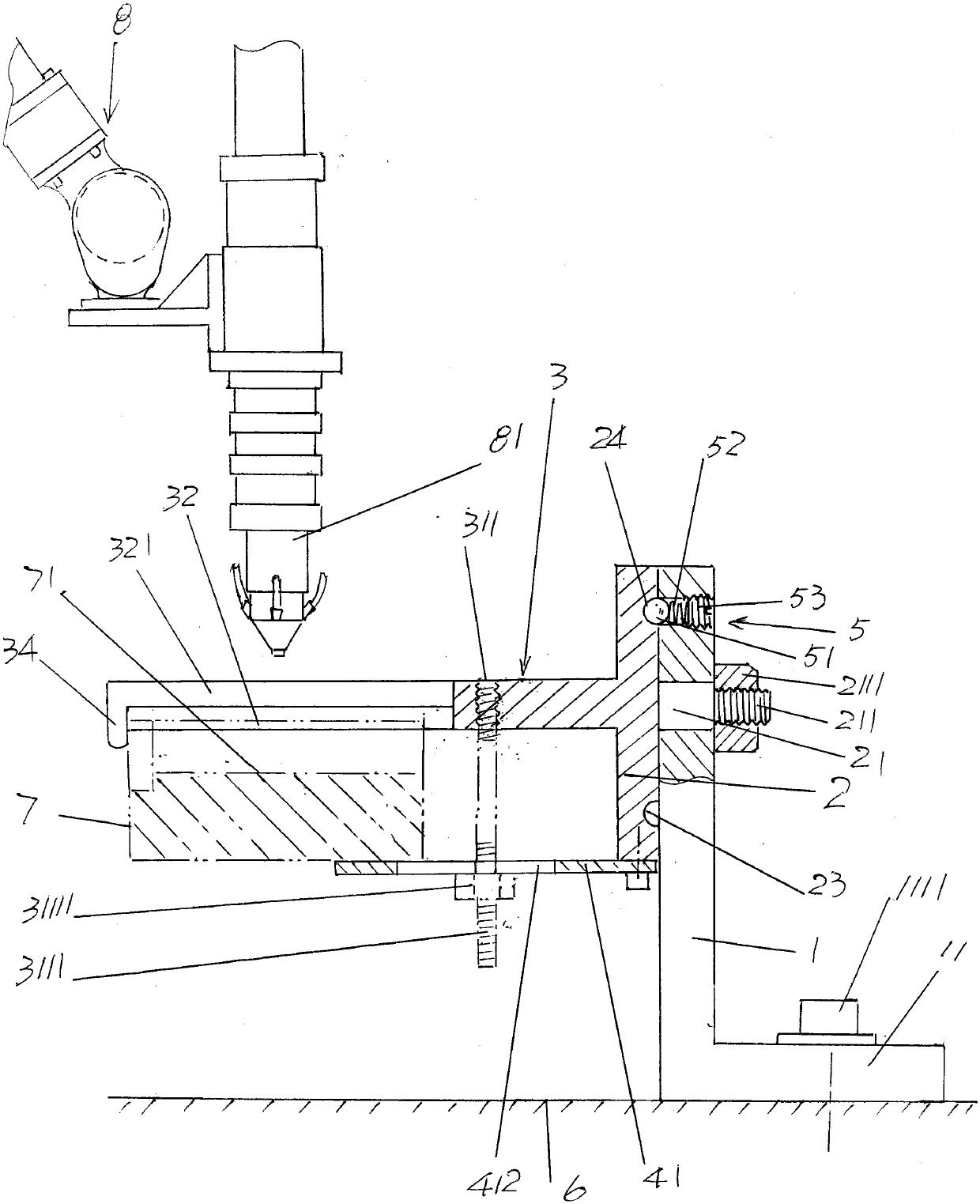

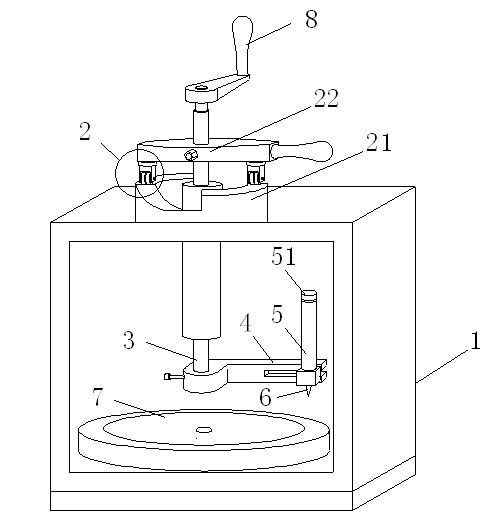

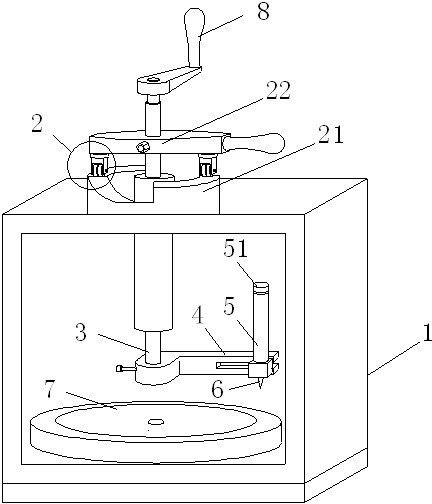

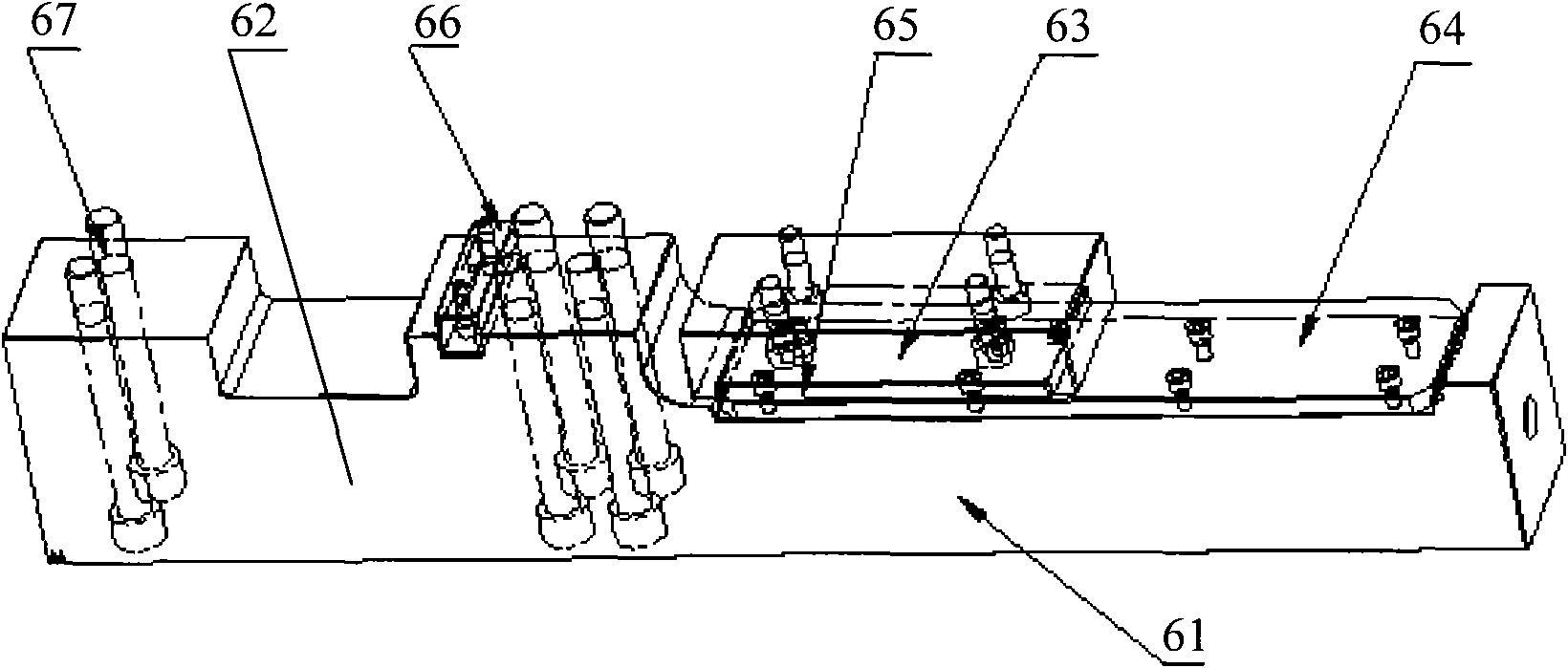

Clamp structure for spraying welding of mouth mold cavity of glass mold

PendingCN107900594AIdeal levelImprove levelWelding/cutting auxillary devicesAuxillary welding devicesWear resistantAlloy

The invention discloses a clamp structure for spraying welding of a mouth mold cavity of a glass mold and belongs to the technical field of tool clamps. The clamp structure comprises a supporting frame, a rotating disk, a mouth mold bearing table, a mouth mold back positioning mechanism and a mouth mold bearing table horizontal keeping mechanism, wherein the position, corresponding to the left side of the upper portion of the supporting frame, of the rotating disk is connected with the supporting frame; the mouth mold bearing table is fixed to the side, backing onto the supporting frame, of the rotating disk in a horizontal cantilever state; the mouth mold back positioning mechanism is connected to the rotating disk and stretches in the direction of the mouth mold bearing table in the horizontal cantilever state; and the mouth mold bearing table horizontal keeping mechanism is arranged on the supporting frame and is matched with the side, facing the supporting frame, of the rotating disk. The overall structure is very simple, and manufacturing is facilitated and convenient; the clamping speed can be easily increased so as to shorten the waiting time of a spraying welding machine, and improve the spraying welding efficiency of the spraying welding machine; and the thickness uniformity of the spraying welding machine on an abrasion-resistant hard alloy material layer for sprayingwelding of the mouth mold cavity is guaranteed.

Owner:CHANGSHU JIANHUA MOLD TECH

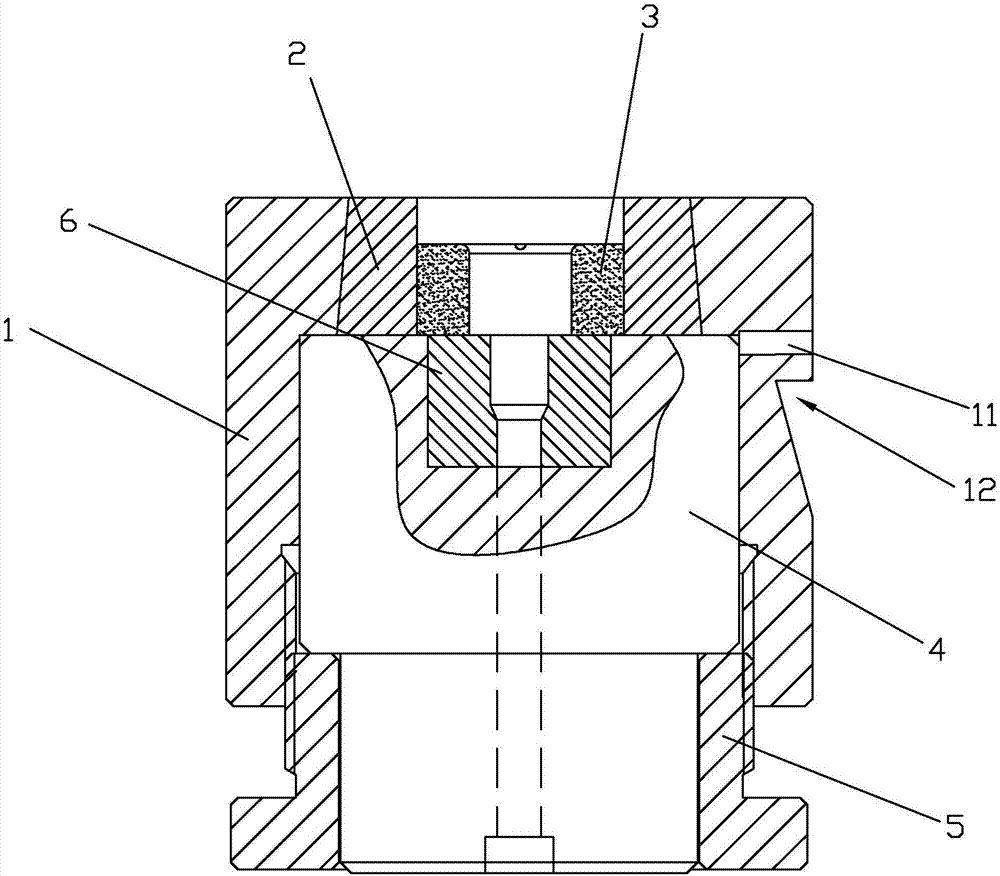

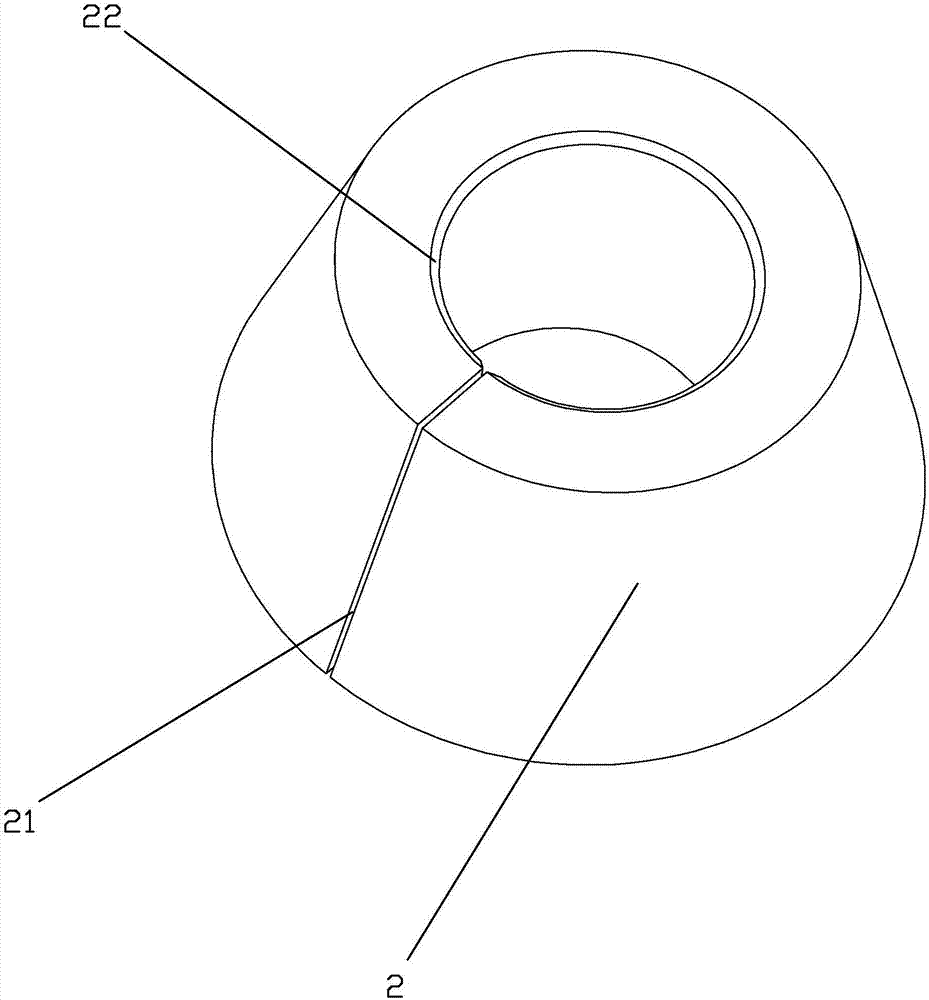

Cold upsetting die and machining technology thereof

InactiveCN106955960AExtended useful lifeGuaranteed accuracyForging/hammering/pressing machinesDying backEngineering

The invention discloses a cold upsetting die and a machining technology thereof. The cold upsetting die comprises a shell and an inner die; the shell comprises a die shell, a ladder hole penetrating the two end faces of the die shell is formed in the die shell, a conical segment is arranged at the small end of the ladder hole, the conical segment is located on the upper surface of the die shell, the large end of the ladder hole is located on the lower surface of the die shell, the inner die comprises a conical reinforcing ring matched with the inner wall of the conical segment, an inner die core is arranged in the reinforcing ring, an axial cutting opening penetrating the inner surface and the outer surface of the reinforcing ring is formed in the side face of the reinforcing ring, an inner die back pad abutting against the lower end of the inner die is arranged in the position, below the inner die, in the ladder hole, a thread part in threaded connection with the shell is arranged below the inner die back pad, and the thread part abuts against the inner die back pad so as to enable the reinforcing ring to shrink and clamp the inner die core. The cold upsetting die can conveniently achieve detaching and assembling of the die core and die shell, meanwhile, the higher precision is achieved, the machining technology of the die can conveniently machine the components of the die, and the service life of the die is longer.

Owner:SANMEN TONGSHUN RIVET

Method for removing polished section crystal round edge used for IGBT (insulated gate bipolar transistor) in a row grinding manner

ActiveCN102437043AControl concentrationDosage controlSemiconductor/solid-state device manufacturingDying backElectric power

The invention relates to a method for removing a polished section crystal round edge used for an IGBT (insulated gate bipolar transistor) in a row grinding manner. The method is characterized in that a special cutting edge machine is applied to a polished section crystal round edge oxide film treatment process, and firstly, a package plastic blue film is adhered on a silicon die back surface through a pyrocondensation machine; the special cutting edge machine marks different sizes of roundness incisions on the plastic blue film adhered on the silicon die back surface according to different specification of a silicon slice, the annular roundness plastic blue film required to be corroded is torn up along the incisions, thereby protecting the part of which a back sealed Si02 film is not required to remove; the row ground type cutting edge technology can be used for preparing a raw material substrate of an epitaxial wafer used for electric power electron devices such as IGBT and the like;and the method provided by the invention has the advantages of simple operation, low cost, high production efficiency, strong practicability, and is technology which is suitable for removing the backSi02 film in large-scale industry production.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

Module assembly for multiple die back-illuminated diode

InactiveUS7439516B2Solid-state devicesMaterial analysis by optical meansElectrical conductorDying back

Owner:GENERAL ELECTRIC CO

Method of preparing for structural analysis a deep trench-type capacitor and method of structural analysis therefor

InactiveUS6403439B1Easy to checkOvercome deficienciesSemiconductor/solid-state device testing/measurementSolid-state devicesChemical treatmentDying back

A method of preparing for structural analysis a deep trench-type capacitor formed in a die employs a combination of mechanical and chemical action to expose the trench-type capacitors. The method of preparing the die includes the steps of (a) mechanically treating the die back side so as to remove a first portion of the substrate and leave intact a second portion of the substrate; (b) mounting the mechanically treated die by affixing the die by its top side to a mount; and (c) chemically treating the mounted die so as to remove the substrate second portion and provide a chemically treated die. By exposing the deep trench capacitors, the method facilitates the inspection of the device for the detection of possible structural defects such as metal shorts, capacitor holes, and particle failures. The method further overcomes the deficiencies associated with conventional methods of substrate removal, and facilitates inspection by a variety of methods. The method facilitates, for example, the detection of residual arsenic glass, and deep trench deformities, such as those associated with deep trench length and the thickness of the deep trench ON layer.

Owner:PROMOS TECH INC

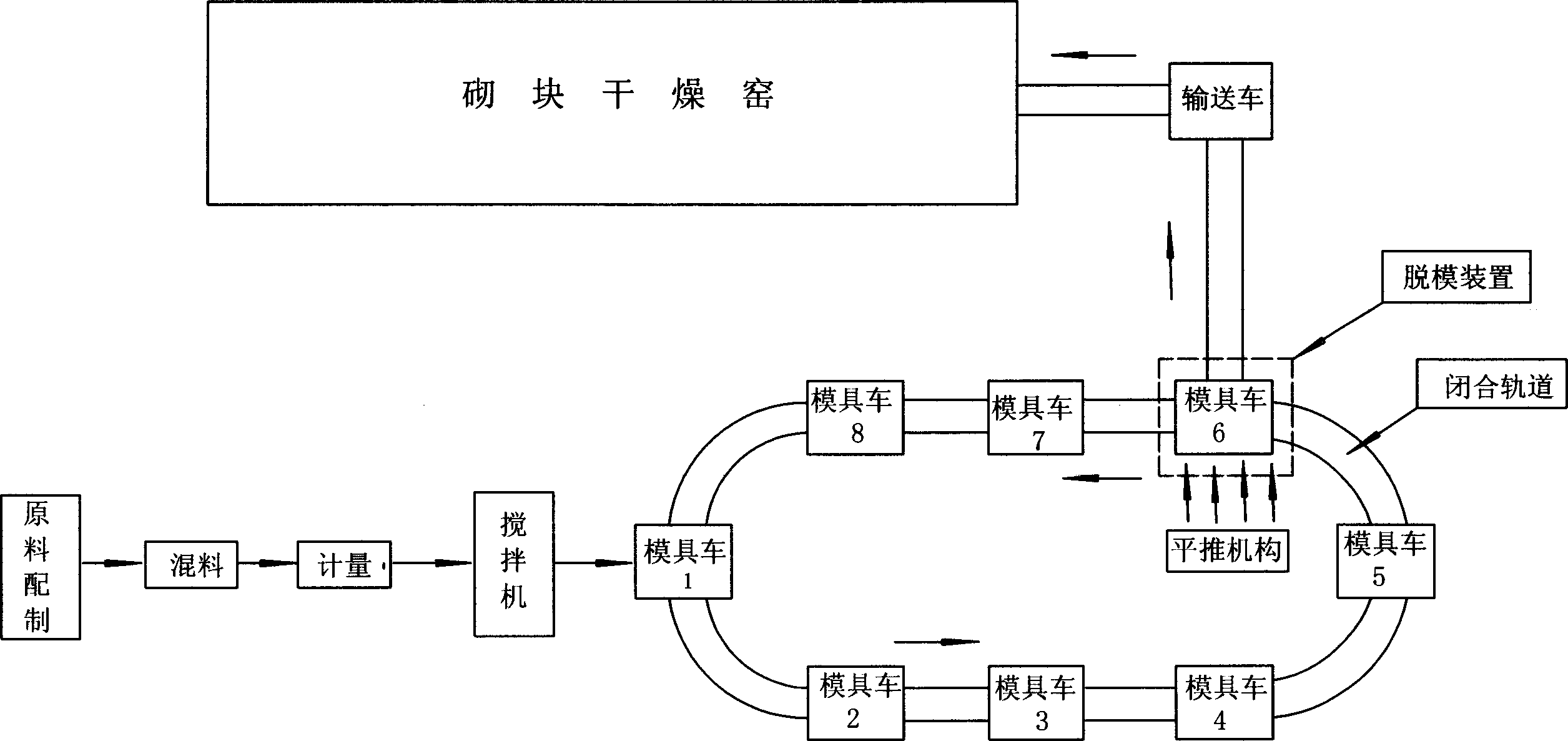

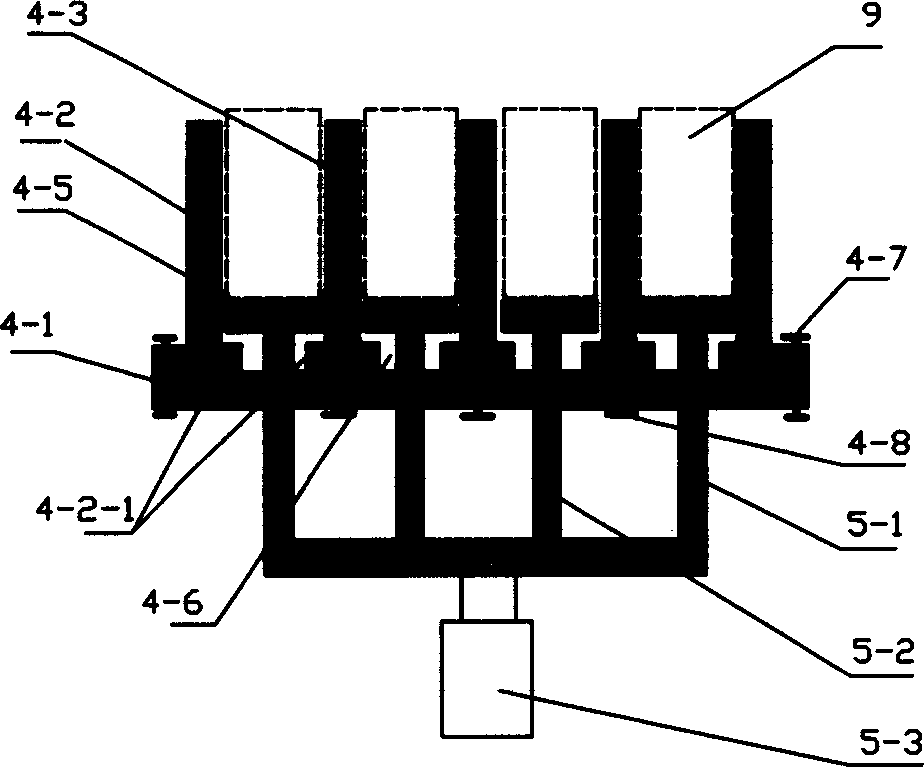

Gypsum block continuous production apparatus capable of adjusting thickness

InactiveCN1850470AIncrease productivityReduce manufacturing costDischarging arrangementMouldsProcess systemsEngineering

The invention discloses a continuous process system of the plaster block which can adjust the thickness. The present device can not adjust the die and when the plaster is out of the die, the die back plate should be opened. The die is made up of the external dummy plate, the inner dummy plate, the back plate and the die base plate. The stripper device includes the liftout shelf which can extend to the hollow from the bottom of the die car. The liftout plate is contacted to the base plate. The invention can make the process of pouring, solidifying and stripping independent. The space of the die dummy plate can be adjusted, so it can be used for many type of the plaster block.

Owner:张继忠 +1

Process for producing resonant tag

InactiveUS20020171528A1Easy to manufactureStable resonant characteristicWave amplification devicesElectrical connection printed elementsMetal foilAdhesive

A process for producing a resonant tag, wherein a metal foil having a thermal adhesion adhesive applied to at least one face thereof is stamped out into a circuit-like shape and is adhered to a base sheet, the process comprising: stamping out the metal foil into a predetermined shaped metal foil portion (4c) while being passed through a die roll (1) having thereon a stamping blade with a predetermined shape and a transfer roll (2) in contact with the die roll (1) which functions also as a die back-up roll; holding this metal foil portion obtained by the stamping-out operation onto the surface of the transfer roll by suction holes formed in the transfer roll; and thermally adhering the stamped metal foil portion to the base sheet (7) in contact with the transfer roll (2) at its another face by an adhesive roll (3) in contact with the transfer roll through the base sheet. The present invention has such advantages as no damage to the base sheet since the stamping-out operation for the metal foil and the thermal adhesion operation thereof to the base sheet are carried out in separate positions, and no requirement of carrier sheet because the resultant metal foil portion obtained by the stamping-out operation is sucked and held onto the surface of the transfer roll.

Owner:NOVATRON ELECTRONICS HANGZHOU

Cold-forging technology for safety belt transmission shaft and die structure of molded transmission patterned tooth

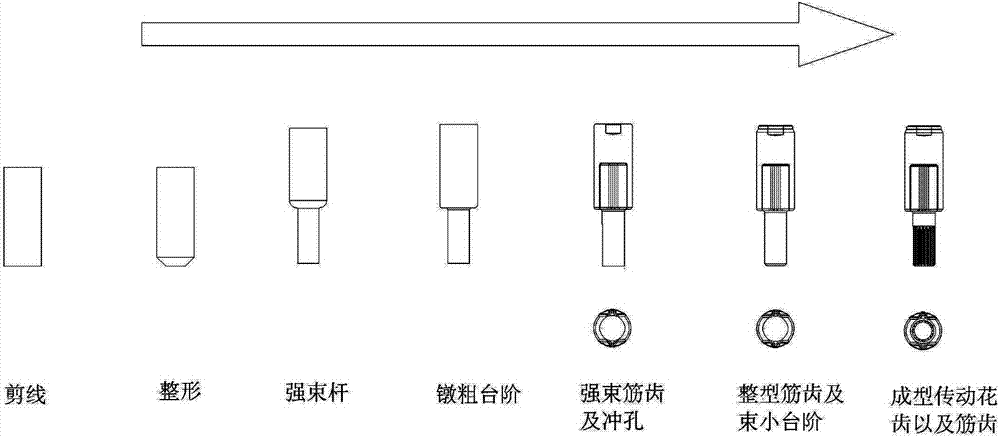

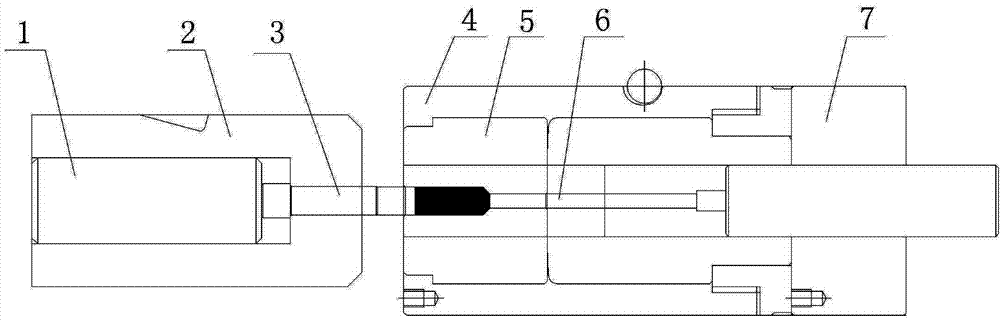

ActiveCN104493061AHigh strengthStreamline completeForging/hammering/pressing machinesEngine componentsWire rodPunching

The invention relates to a cold-forging technology for a safety belt transmission shaft and a die structure of a molded transmission patterned tooth. The process comprises the following steps: S1, trimming a wire rod; S2, shaping; S3, intensifying a rod part; S4, upsetting a step; A5, intensifying a tenon tooth and punching; S6, shaping the tenon tooth and intensifying a small step; S7, molding the transmission patterned tooth. The die structure comprises a master die unit and a punching unit, wherein the master die unit comprises a master die cover and a master die back base plate; the punching unit comprises a punching cover and a moulding cover, wherein the master die cover is internally provided with a master die upper section, a master die middle section and a master die lower section, and a master die ejector pin is arranged in the middle of the master die cover; the punching cover is internally provided with an upper punching die cushion block, a middle punching die cushion block and a lower punching die cushion block, a punching pin is arranged in the middle of the punching cover, a blind hold is formed in the middle of the middle punching die cushion block, a small cushion block is arranged in the blind hold, and a spring is arranged at the bottom of the small cushion block. All sizes of the products are accomplished by virtue of the cold-forging technology and the molded product is complete in streamline and high in strength of spare parts, so that the production efficiency of the product can be improved.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

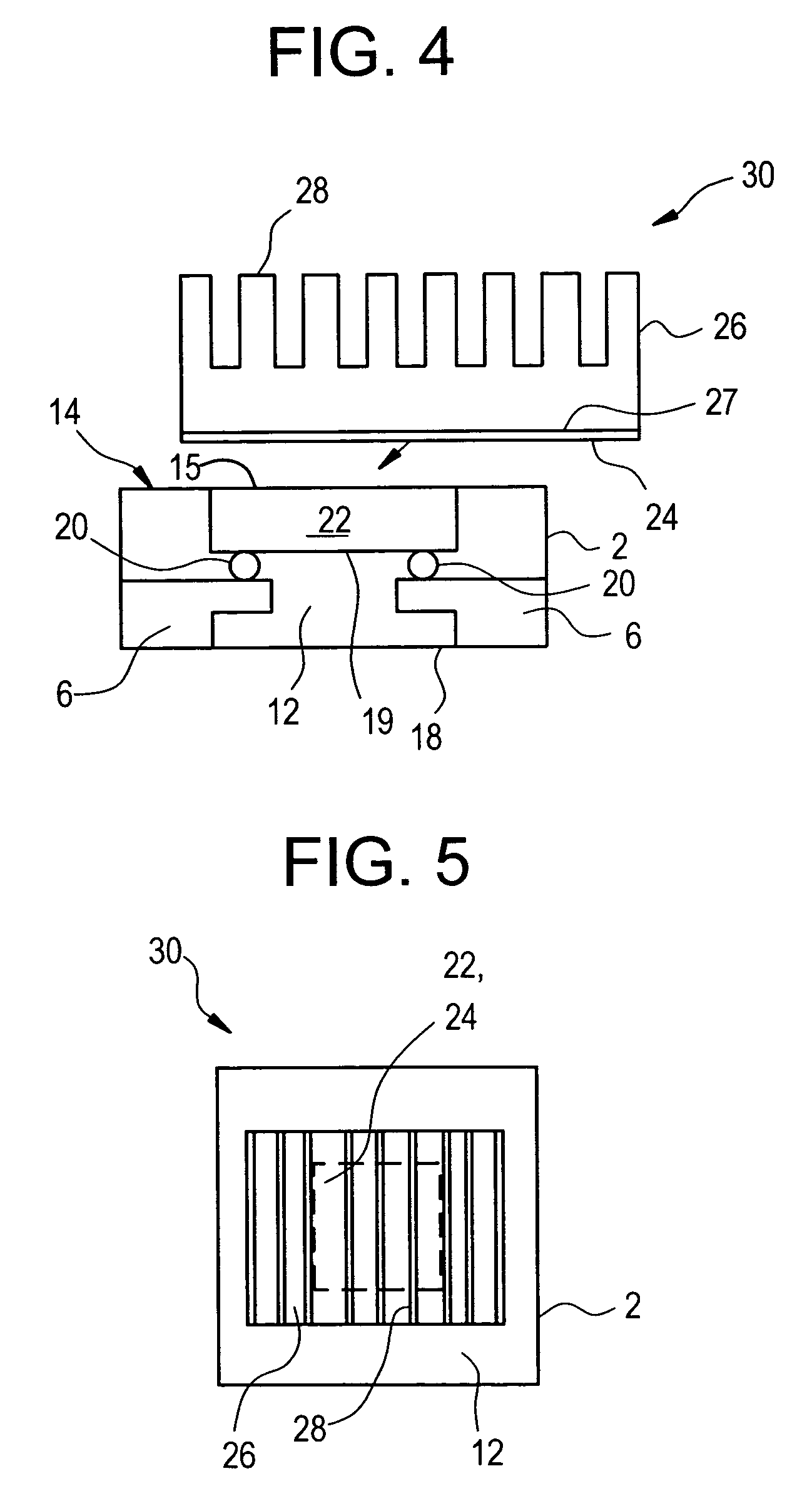

Drop-in heat sink and exposed die-back for molded flip die package

A system and method for modifying a molded flip die (MFD) integrated circuit package that includes an integrated circuit die to include a heat sink such that the heat sink is thermally coupled to either a top or bottom portion of the integrated circuit die and can then dissipate heat to ambient air. The system and method presented herein modify the MFD package by either removing portions of a molding material and attaching the heat sink directly to the die, or thermally coupling the heat sink to the die prior encapsulation of the integrated circuit die and heat sink.

Owner:MARVELL ASIA PTE LTD

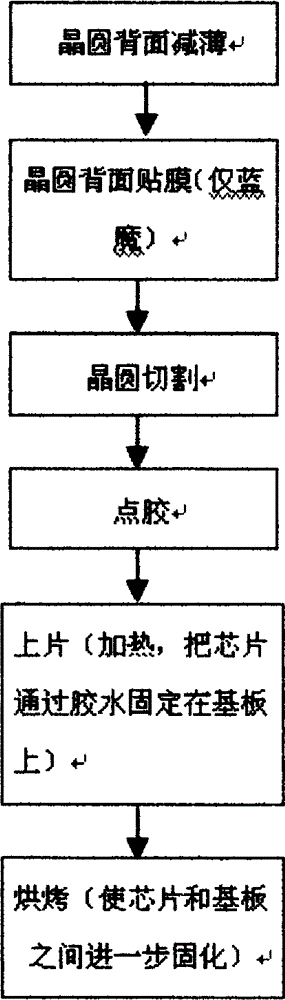

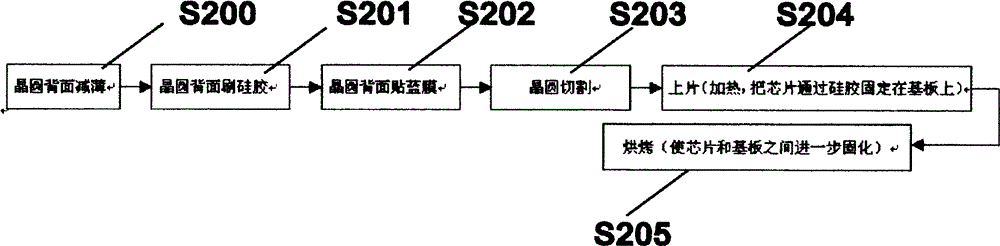

Die back surface silicone printing encapsulation method

InactiveCN105895540AChange dependenciesLow costSemiconductor/solid-state device manufacturingDying backEngineering

The invention discloses a die back surface silicone printing encapsulation method, which adopts a die, a silicone layer and a substrate, and is used for carrying out thinning, silicone brushing, blue film adhering, cutting, die attaching and baking processes on the whole die. The die back surface silicone printing encapsulation method comprises the steps of thinning the back surface of the die, brushing the silicone on the back surface of the die, adhering the blue film on the back surface of the die, cutting the die, attaching the die and baking. The die back surface silicone printing encapsulation method is characterized in that: the die which is subjected to silicone brushing and blue film adhering on the back surface is cut into single die particles, the dependence of the die on the DAF film is changed, and direct material cost of die bonding is greatly reduced; and silicone layer cavities formed by uneven silicone dispersing process are avoided, reliability of the encapsulation technology is improved, and chip flatness after die bonding is increased, thereby being conductive to stabilizing a wire bonding process, reducing cost without increasing complexity of the processes, and improving bonding quality of the die and the substrate.

Owner:TEKISM

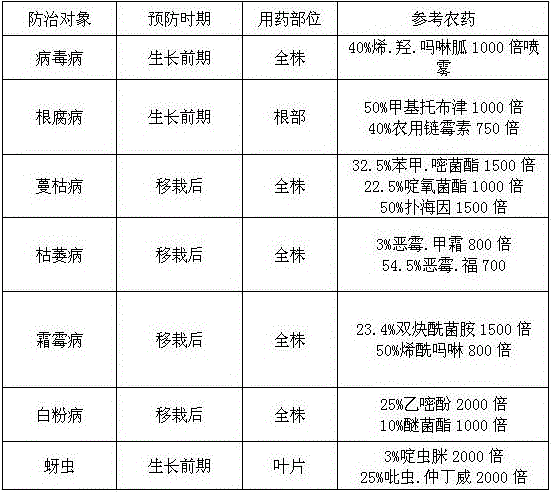

Cantaloupe cultivation method in clay region

The invention provides a cantaloupe cultivation method in clay regions; the method comprises the following steps: 1, planting soil selection; 2, cantaloupe variety selection; 3, ridging and soil working; 4, colonization; 5, vine hanging and cultivation; 6, dual-vine pruning; 7, post-planting management; 8, fruit management; 9, maturation and harvesting. The method uses connecting greenhouse to provide warming and rainproof effects, uses high ridging to provide waterproof and waterlogging preventing effects, uses biological bacterial manure to improve soil bacterium colony composition, uses dual-vine hanging to enhance planting vigor, thus effectively reducing gummy stem blight, die-back, downy mildew and powdery mildew diseases, so the cantaloupe can grow in local regions with health, thus realizing high yield and high quality effects.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST

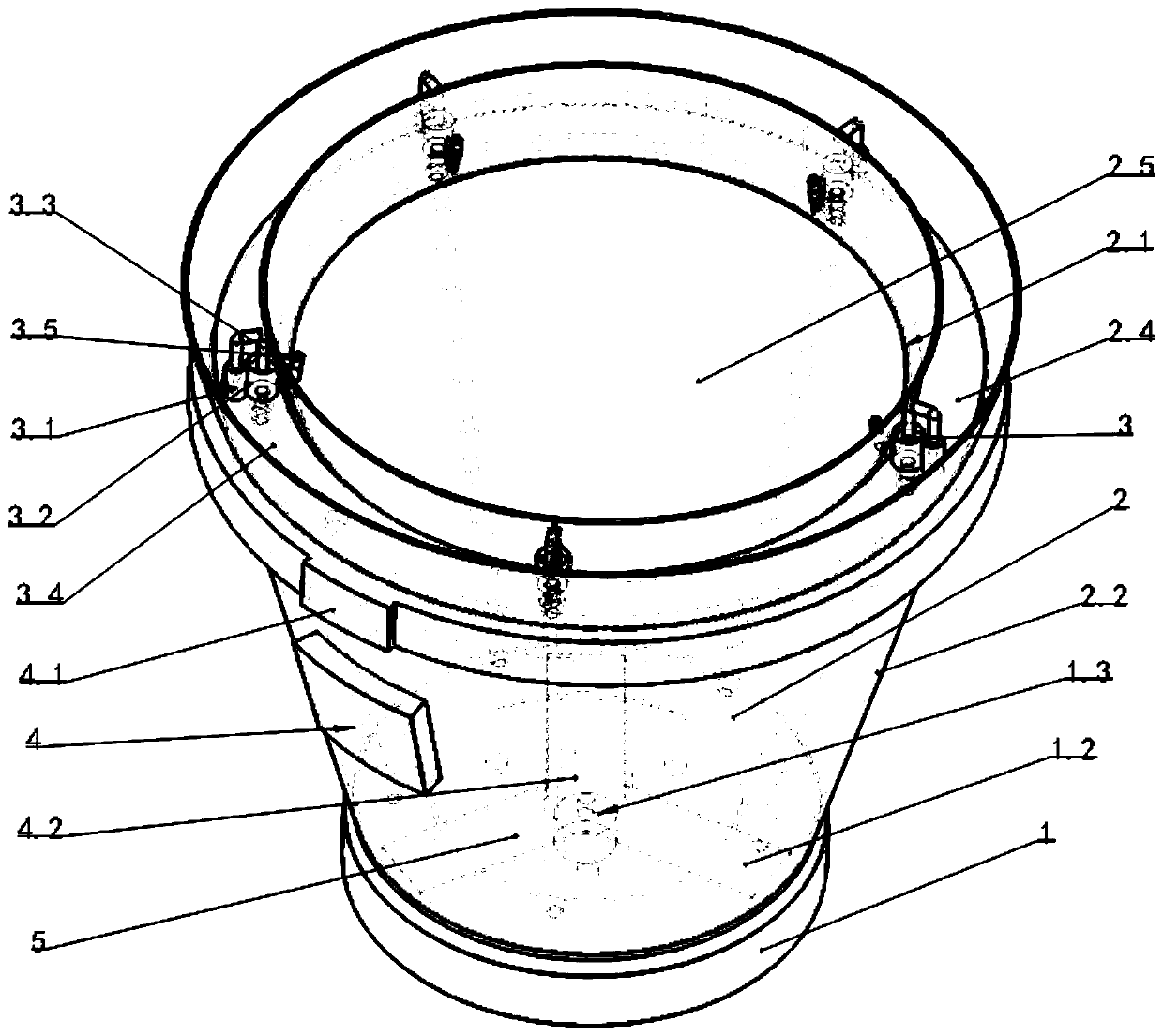

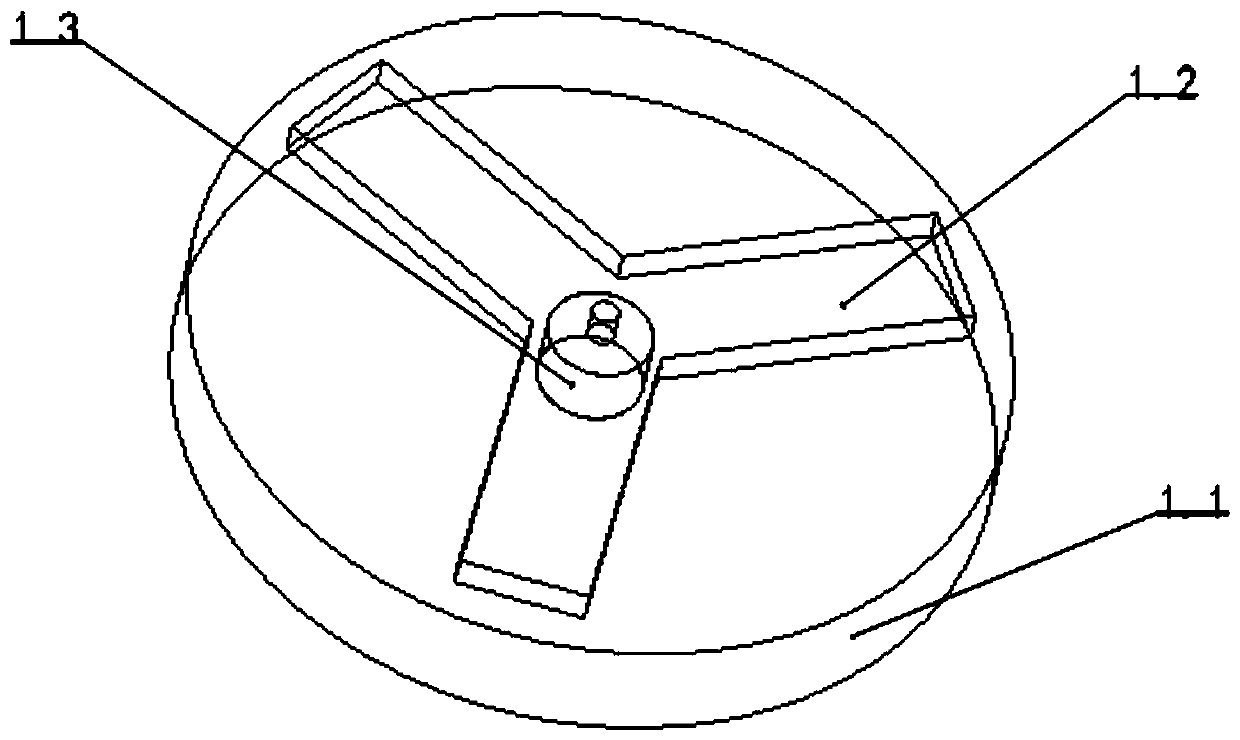

Solar intelligent care flowerpot

PendingCN110073839AHigh degree of intelligenceSimple structureSelf-acting watering devicesSaving energy measuresDying backEngineering

The invention discloses a solar intelligent care flowerpot. The flowerpot is used for performing intelligent caring on potted plants under the unmanned condition. The solar intelligent care flowerpotcomprises a rotating base, a pot body, a solar panel, a controller, a humidity sensor, illumination sensors and a water spraying device, wherein the rotating base is positioned under the flowerpot, and is used for plant intelligent illumination; the pot body is positioned above the rotating base; the solar panel is positioned on the outer surface of the pot body; the controller is positioned in the middle position of the outer side of the pot body; the humidity sensor is positioned in the center of the bottom of the inner side of the pot body; the illumination sensor is positioned on the upperedge of the outer wall of the pot body; the two illumination sensors are in symmetrical arrangement; the water spraying device is positioned on the upper edge of a pot body cavity, and is used for intelligently watering plants. Compared with a conventional flowerpot, the solar intelligent care flowerpot has the advantages that the intelligence degree is high; the structure is simple; the operation is convenient; the problem that the plants cannot be regularly watered by people when people go out for a long time or forget, so that the plant withering, or even dying back is caused can be effectively solved.

Owner:ANHUI UNIV OF SCI & TECH

Biocontrol bacterial strain SM16 for preventing pear die-back

InactiveCN101864377AConducive to pollution-free productionFavorable export tradeBiocideBacteriaPEARMicrobiology

The invention relates to a biocontrol bacterial strain SM16 for preventing pear die-back, belonging to the technical field of plant protection. The strain is bacillus subtilis prepared by the following steps of: vaccinating the strain in culture liquid; fermenting at 30 DEG C and 250 rpm for 20-24 h; then, centrifuging at 6000 rpm for 10 min; and preparing a bacterial agent from wet bacteria and a cell preservation solution in a ratio of 1:40 (g / ml), wherein the total concentration of live viable bacteria in a finished product is 1*109-1*1012 cfu / ml. When the biocontrol bacterial strain SM16 for preventing pear die-back is used in a fruit garden and 25 percent and 75 percent of pear flowers are blossomed, the bacterial agent is diluted into 1*108 cfu / ml by adding water and sprayed on the flower surfaces and has the pear die-back prevention effect over 57-68 percent.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for fabricating semiconductor component with chip on board leadframe

A semiconductor component includes a chip on board leadframe, a semiconductor die back bonded and wire bonded to the leadframe, an encapsulant on the die and an area array of terminal contacts on the leadframe. The leadframe includes leadfingers, interconnect bonding sites for wire bonding the die, terminal bonding sites for the terminal contacts, and bus bars which electrically connect selected leadfingers to one another. The interconnect bonding sites are located on the leadframe relative to the bus bars such that shorting to the bus bars by wire interconnects is eliminated. A method for fabricating the component includes the steps of attaching the die to the leadframe, bonding the wire interconnects to the die and to the interconnect bonding sites, forming the encapsulant, and then forming the terminal contacts on the terminal bonding sites.

Owner:MICRON TECH INC

Sterilization composition containing fluoxastrobin and antibiotics

InactiveCN103238608ANot easy to produceThe production is convenientBiocideFungicidesDiseaseDying back

The invention provides a sterilization combination containing fluoxastrobin and antibiotics, comprising an active component A and an active component B, wherein the active component A is selected from fluoxastrobin, the active component B is selected from any one of the following bactericides: validamycin, polyoxin and kasugamycin, and a mass ratio of the active component A to the active component B is 60:1-1:40. The composition of the invention can be used for controlling various crop diseases, has an obvious synergy effect, enlarges a sterilization spectrum, and has high activity on rust disease, septoria nodorum, net blotch, powdery mildew, downy mildew, sheath blight, rice blast, Bacterial Angular Leaf Spot, rice bacterial leaf blight, virus disease, soft rot disease, leaf mold, die-back, downy mildew, bakanae disease, banana leaf spot disease and apple rot; pesticide dose is reduced, pesticide residual quantity on crops is reduced, and environment pollution is mitigated.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

Die and die supporting mechanism thereof

The embodiment of the invention discloses a die and a die supporting mechanism thereof, relating to the field of injection molding dies. The die and the die supporting mechanism have simple structures and large bearing force, and are easy to assemble and disassemble. The die supporting mechanism comprises a supporting beam, a fixedly-connected part and a cushion block, wherein the supporting beam is used for supporting a die middle template; the fixedly-connected part is fixedly connected with a die front template or a die back template; and the cushion block is fixedly connected with the die middle template, and is arranged on the supporting beam. The die comprises a die front template, a die back template and at least one die middle template, wherein the die is fixedly connected with at least one die supporting mechanism; and the die supporting mechanism comprises the supporting beam which is used for supporting the die middle template, the fixedly-connected part which is fixedly connected with the die front template or the die back template, and the cushion block which is fixedly connected with the die middle template, and is arranged on the supporting beam. The die supporting mechanism is applied to double-layer dies or multi-layer dies.

Owner:QINGDAO HAIER MOLDS

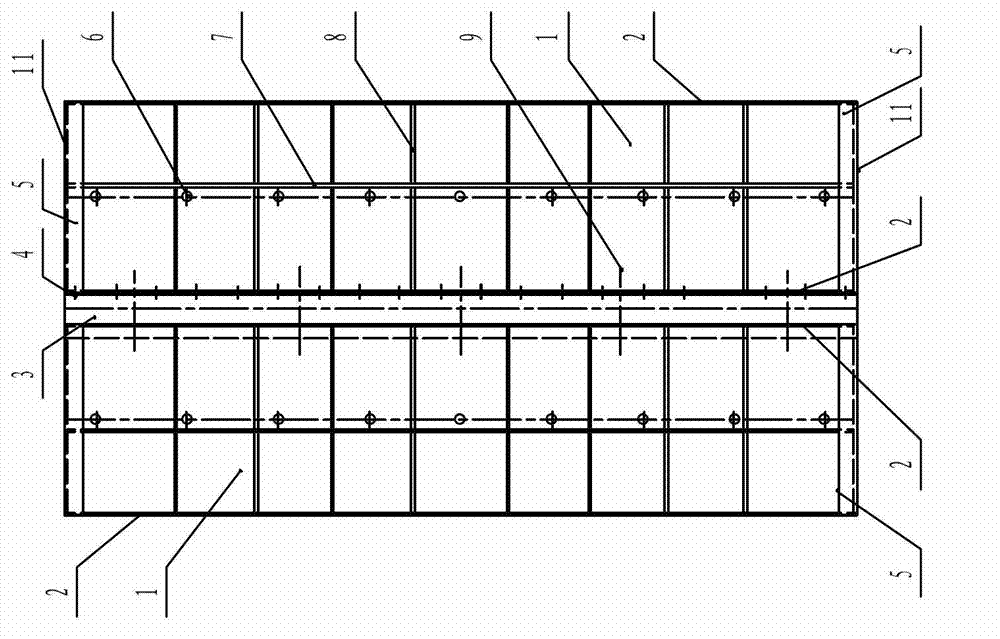

Bare concrete adjustable combined type inner-outer wall steel die

InactiveCN102817471AEasy constructionAvoid deformationForms/shuttering/falseworksForming/stuttering elementsFloor slabInverted-T shape

The invention relates to a bare concrete adjustable combined type inner-outer wall steel die, which is characterized in that a plurality of corresponding opposite-push holes are arranged in a vertical center line of the inner-outer wall steel die; the length of the inner-outer wall steel die is equal to a difference between the height of an inner wall of a bare concrete residential building and a height of a 30-mm lime-sand mortar cushion layer at the bottom; the length of an outer wall steel die is equal to the sum of the height of a corresponding floor and a 30-mm outer wall steel die back table, and includes the thickness of a cast-in-place floor board; adjusting dies are respectively corresponding assorted among a plurality of the inner and the outer wall steel dies according to the demands, and are inverted T-shaped; the height of vertical ribs is the same as the thickness of the steel dies; a panel is 30-70 mm wide; the lengths of the adjusting dies are respectively the same as the length of the assorted inner and outer wall steel dies; and a plurality of assembly holes with the same vertical rib hole distance and aperture are arranged on vertical ribs. A manual marking positioning step on the height aspect is eliminated by a template, so that the simple construction is realized; the bare concrete adjustable combined type inner-outer wall steel die can be manually moved; and the bare concrete adjustable combined type inner-outer wall steel die can be combined with the other steel dies of a building, so that accurate adjustment, positioning, fixation and one-step pouring formation can be realized.

Owner:刘其标

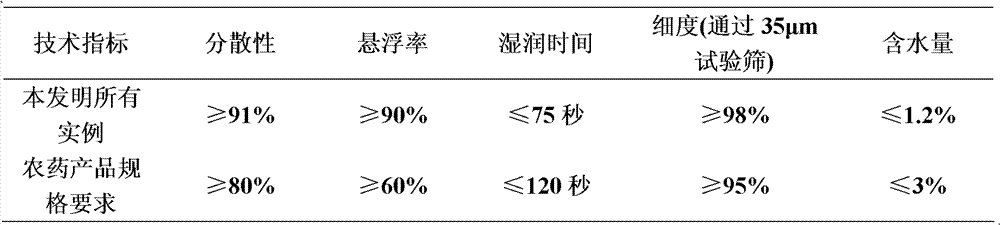

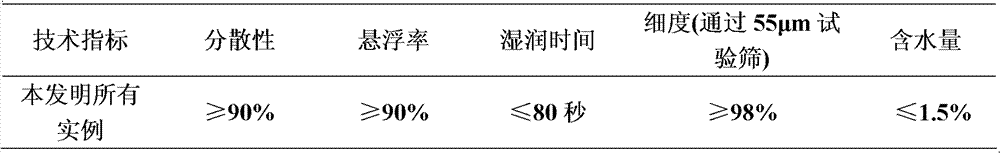

Sterilization composition containing copper quinolate and zhongshengmycin

InactiveCN105010367ASynergistic effect is obviousDelay key drug resistanceBiocideFungicidesSuspending AgentsDying back

A sterilization composition containing copper quinolate and zhongshengmycin is disclosed. The effective compositions copper quinolate and zhongshengmycin are subjected to two-composition combination, and the rest is auxiliary compositions. The mass ratio of copper quinolate to zhongshengmycin in the pesticide composition is 1-50:50-1, the mass proportion of the effective compositions copper quinolate and zhongshengmycin in the preparation is 1%-80%, and the rest is acceptable auxiliary compositions allowed to be used in pesticide. The dosage forms of the pesticide composition are missible oil, a suspending agent, a wettable powder, a water dispersable granule, an emulsion in water, a micro emulsion, a granule and a micro capsule. The sterilization composition is mainly applied to control fruit tree rot disease, Alternaria Leaf Spot, rice blast, soybean root rot, cucurbits die-back, cotton verticillium wilt, jujube tree rust, grape white rot, panax notoginseng black spot, exobasidium vexans Ma-ssee, forest tree rot disease, canker, gummosis, leaf cast, tree seedling stage damping-off, erwinia carotovora, Pseudomonas syringae pv.lachrymans, xanthomonas oryzae pv.Oryzae, botryospuaeria berengeriana de Not .t .sp .Piricola, fusarium graminearum and the like.

Owner:HAILIR PESTICIDES & CHEM GRP

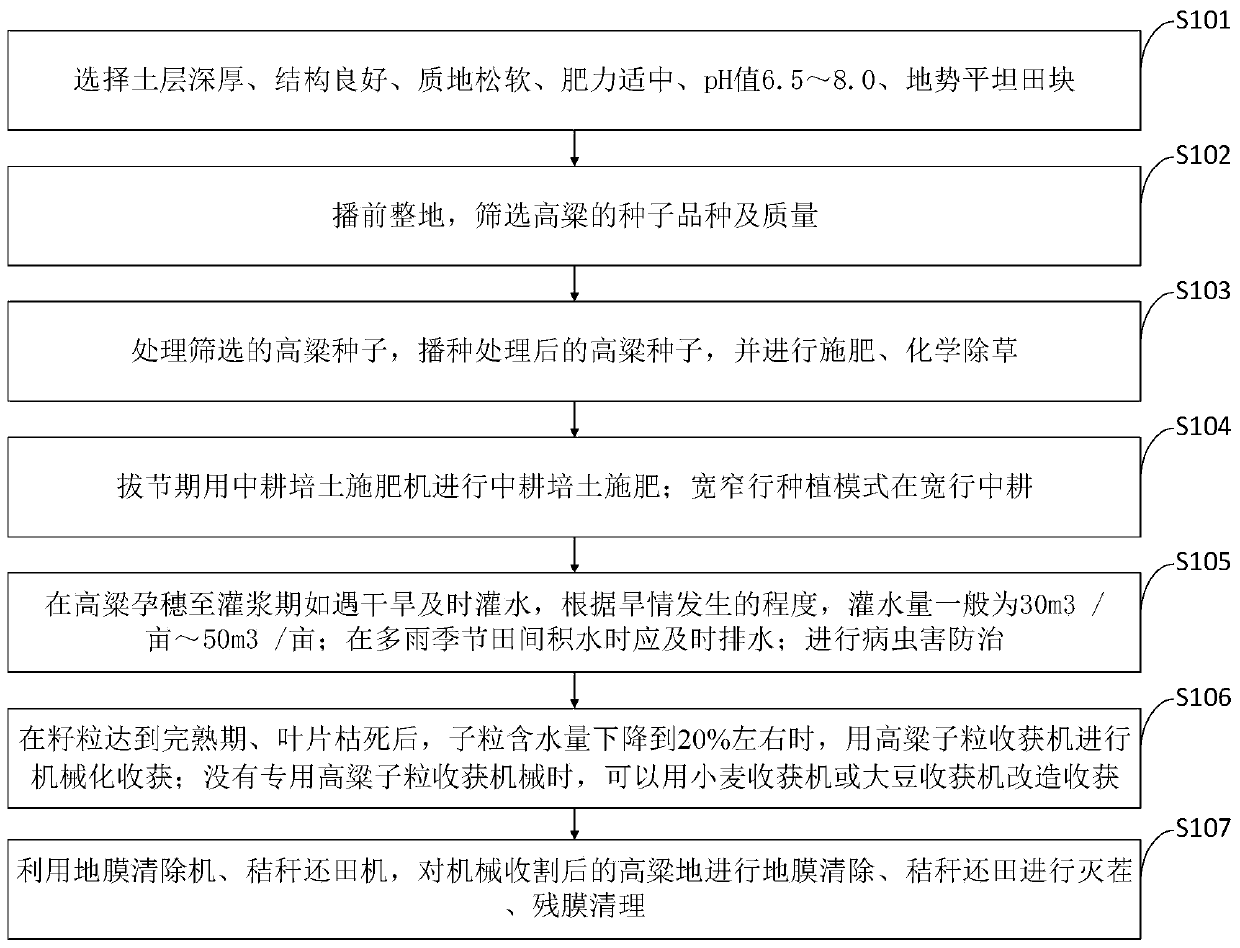

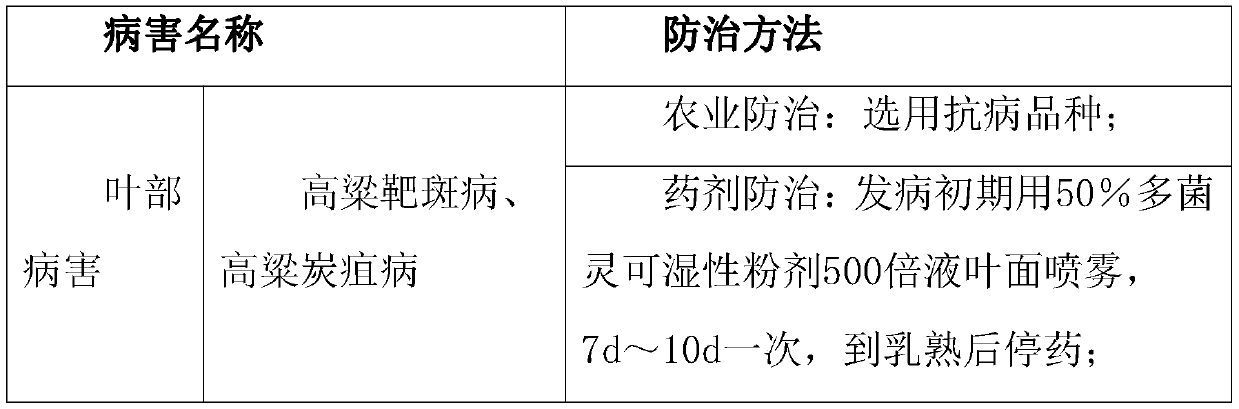

Mechanical mulching-film cultivation method for sorghum

InactiveCN110249934AReduce the impactIncrease moistureClimate change adaptationCereal cultivationPlastic mulchDying back

The invention belongs to the technical field of mechanical agricultural planting, and discloses a mechanical mulching-film cultivation method for sorghum. The mechanical mulching-film cultivation method for the sorghum comprises the specific steps that a mass of land is selected; land preparation before seeding is conducted, wherein the variety and quality of sorghum seeds are selected; the selected sorghum seeds are treated and sowed, and fertilization and chemical weeding are conducted; intertillage, hilling and fertilization are conducted by using an intertillage, hilling and fertilization integrated machine in the elongation stage; intertillage is conducted in wide lines through wide-narrow line planting; irrigation and drainage are conducted; pest and disease control is conducted; after grains completely ripen and leaves die back, when the water content of the grains is reduced to about 20%, mechanical harvesting is conducted by using a sorghum grain harvesting machine; when there is no special sorghum grain harvesting machine, modified harvesting can be conducted by using a wheat harvesting machine or a soybean harvesting machine; by using a mulching film removal machine and a straw returning machine, the sorghum land obtained after mechanical harvesting is subjected to mulching film removal, straw returning, and stubble cleaning and film residue cleaning are conducted.

Owner:平凉市农业科学院

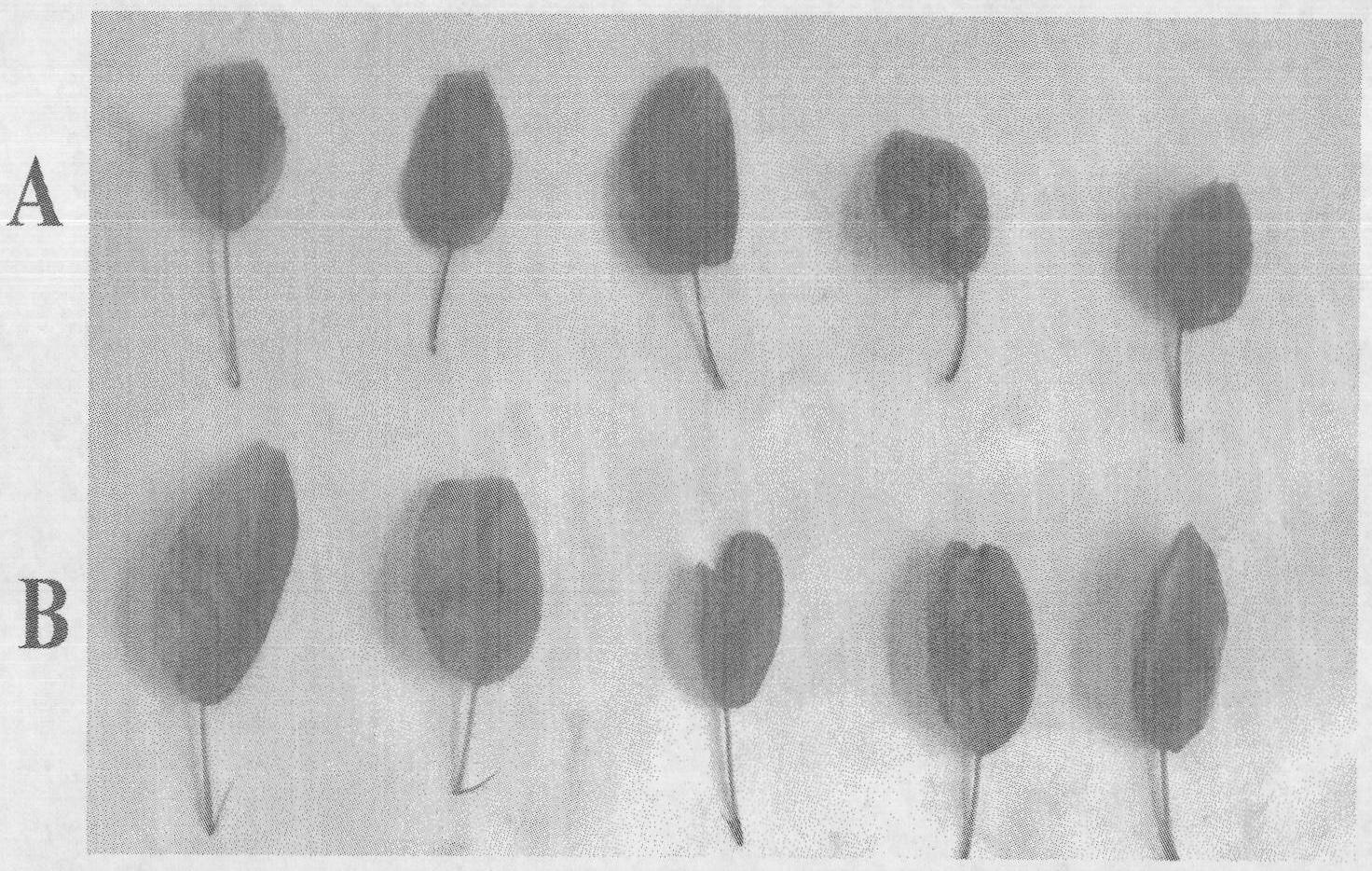

Interspecific cross breeding method for cucurbit (melon rootstock)

InactiveCN102204508ANot easy to growNot easy to hollowPlant genotype modificationHigh resistanceDying back

The invention belongs to the technical field of breeding of cucurbitaceae vegetable. An interspecific hybrid F1 (Yong rootstock No. 6) of cucurbit (a melon rootstock) is obtained by hybridizing a female parent of a stable inbred line J03-2-3-2-1-5-7-4 by multi-generation of directed autocopuation screening of cucurbit materials originated from Japan and a male parent of a stable inbred line YH2-3-3-2-1-4-2-6 by multi-generation of directed autocopuation screening of local Lagenaria species produced in Ningbo. The melon rootstock selectively bred with the method provided in the invention meets objectives of breeding and has moderate growth potential, high resistance to die-back and root rot, well-developed roots, strong stalks, strong ability in absorbing nutrient, low degree of vain growth and robust hypocotyls which are not easy to become hollow, and therefore the melon rootstock is favorable for grafting. The melon rootstock has good grafting affinity and strong symbiosis affinity, and a survival rate over 95% is obtained for the grafting of the rootstock onto the watermelon specie ''Zaojia'' (8424). The engrafted melon rootstock is low temperature-resistant, moisture-resistant and barren-resistant; after field planting, the root and overground part of a grafted seedling grows fast and has sound growth potential, and the period of first harvest of the grafted seedling is 5 days earlier than that of a self-rooted seedling, the fruition rate is high and stable, weight of single fruit and fruit shape can substantially maintain the same, melon skin is not thickened, sugar degree of the grafted seedling is higher than that of the self-rooted seedling, sugar degree gradient is small, quality of the watermelon is not affected, and good adaptability is obtained.

Owner:NINGBO ACAD OF AGRI SCI

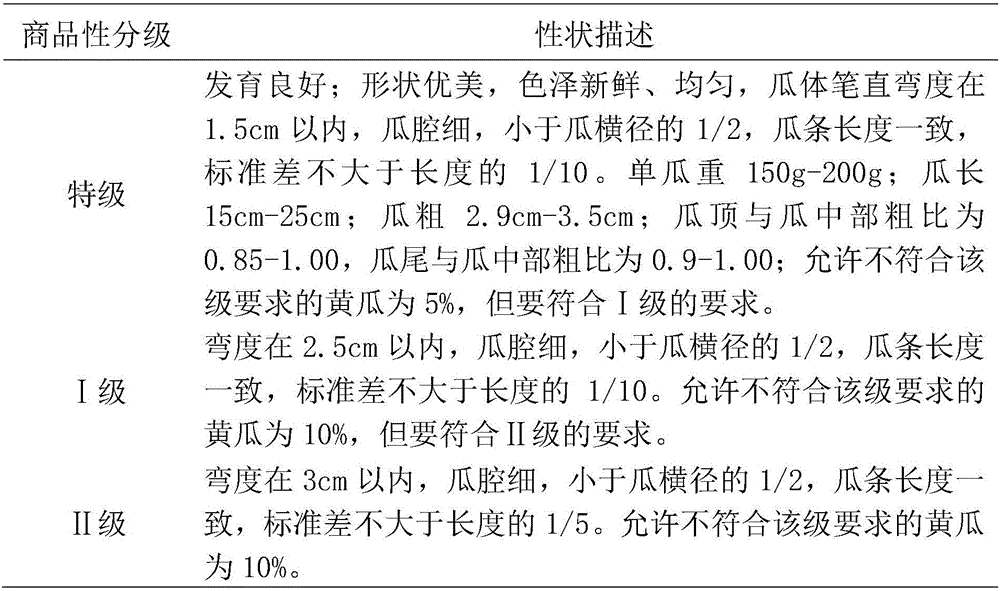

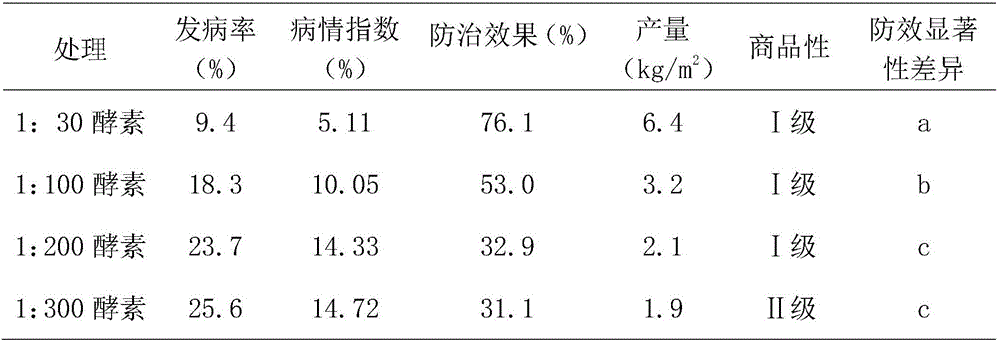

Method using environmental protection ferment to control cucumber die-back disease

InactiveCN105961093AControl Fusarium WiltLow costPlant cultivationCultivating equipmentsDying backThinning

The invention discloses a method for the prevention and treatment of cucumber wilt, which comprises the following steps: 1) deep plowing of the furrows: deep plowing is performed on the fields to be planted with cucumbers, and then the furrows are raised; Apply organic fertilizer co-fermented with environmentally friendly enzymes and chicken manure in the planting line as base fertilizer, and cover with soil after fertilization; 3) Seed soaking: choose bright and plump seeds, soak them in environmentally friendly enzyme water before sowing, remove and drain after soaking; 4) planting: plant in the planting line; 5) thinning and replenishing seedlings: after 7-8 days, carry out thinning for the first time, remove some weaker seedlings, when growing to 3-4 true leaves, carry out thinning and replenishing seedlings, each hole Only one strong seedling is left; 6) Disease control: when the cucumber grows 5-6 true leaves, spray it twice a week with environmentally friendly enzyme water to prevent the occurrence of Fusarium wilt; when a disease occurs, use environmentally friendly enzyme water Spray the plants and borders evenly in the morning and evening, and take the plants as the standard.

Owner:防城港市农产品质量安全检测中心

Independent die cutting apparatus for liquid filling machine

InactiveCN1923626AQuality assuranceSimple structurePackagingMetal working apparatusPunchingDrive shaft

An independent punching device for a hydraulic bottle filler, comprises of a body's major drive shaft that has a set of punching cams, whose both sides have a moving shaft and a support shaft, and the left of the said moving shaft equipped a connecting plate, the right of the support shaft connected to a cross beam, whose both ends connect to drive shafts and who connects with the connecting plate through an extension spring, and it features in the punch die of the punch back board, which fastened on the left of the connecting plate, and the left of the said drive shaft led out by the punch back board and connects with the cavity die back board at the left of the drive shaft, with the inner side of the cavity back board equipped with a cavity die plate, which are connected with each other through a guide component.

Owner:锦州春光包装机械有限公司

Process for producing resonant tag and resonant tag

InactiveCN1564648AEasy to manufactureStable resonance characteristicsLayered productsPrinted electric component incorporationAdhesiveMetal foil

A process for producing a resonant tag, wherein a metal foil having a thermal adhesion adhesive applied to at least one face thereof is stamped out into a circuit-like shape and is adhered to a base sheet, the process comprising: stamping out the metal foil into a predetermined shaped metal foil portion (4c) while being passed through a die roll (1) having thereon a stamping blade with a predetermined shape and a transfer roll (2) in contact with the die roll (1) which functions also as a die back-up roll; holding this metal foil portion obtained by the stamping-out operation onto the surface of the transfer roll by suction holes formed in the transfer roll; and thermally adhering the stamped metal foil portion to the base sheet (7) in contact with the transfer roll (2) at its another face by an adhesive roll (3) in contact with the transfer roll through the base sheet.

Owner:NOVATRON ELECTRONICS HANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com