Cold upsetting die and machining technology thereof

A processing technology and mold technology, applied in the field of cold heading die and its processing technology, can solve the problems affecting the product quality of cold heading forming, affecting the assembly accuracy and service life between the mold core and the mold sleeve, and the damage of the mold sleeve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

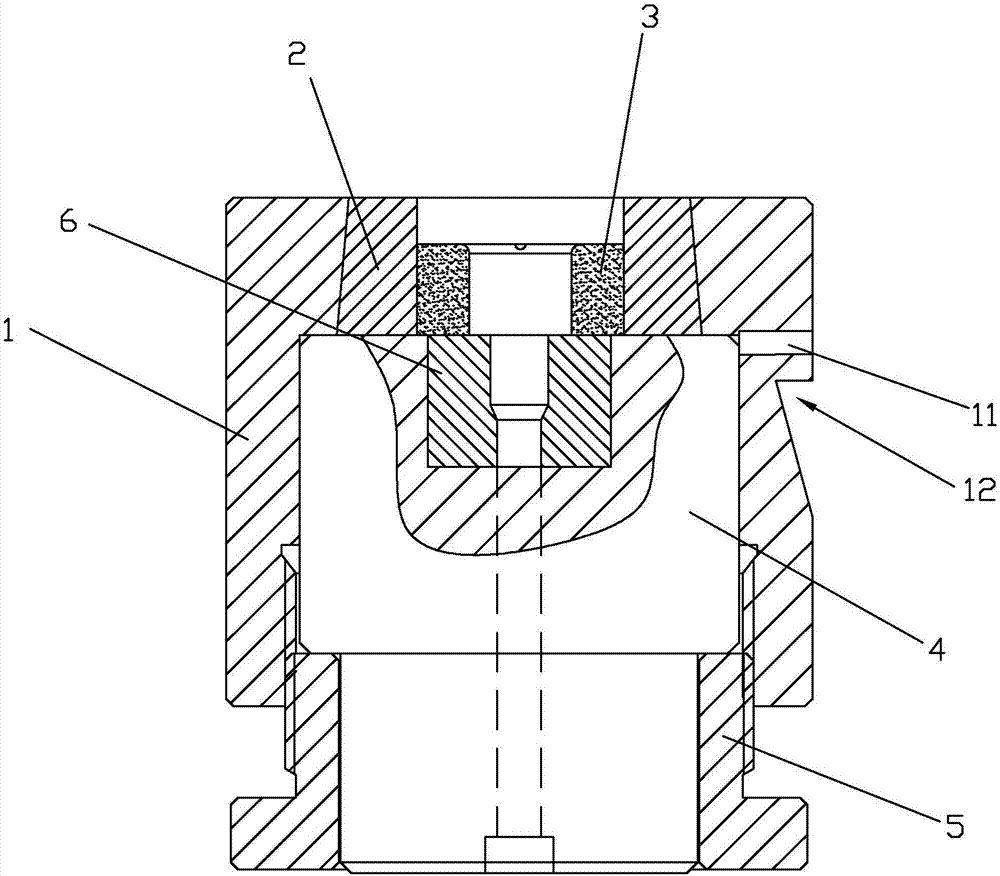

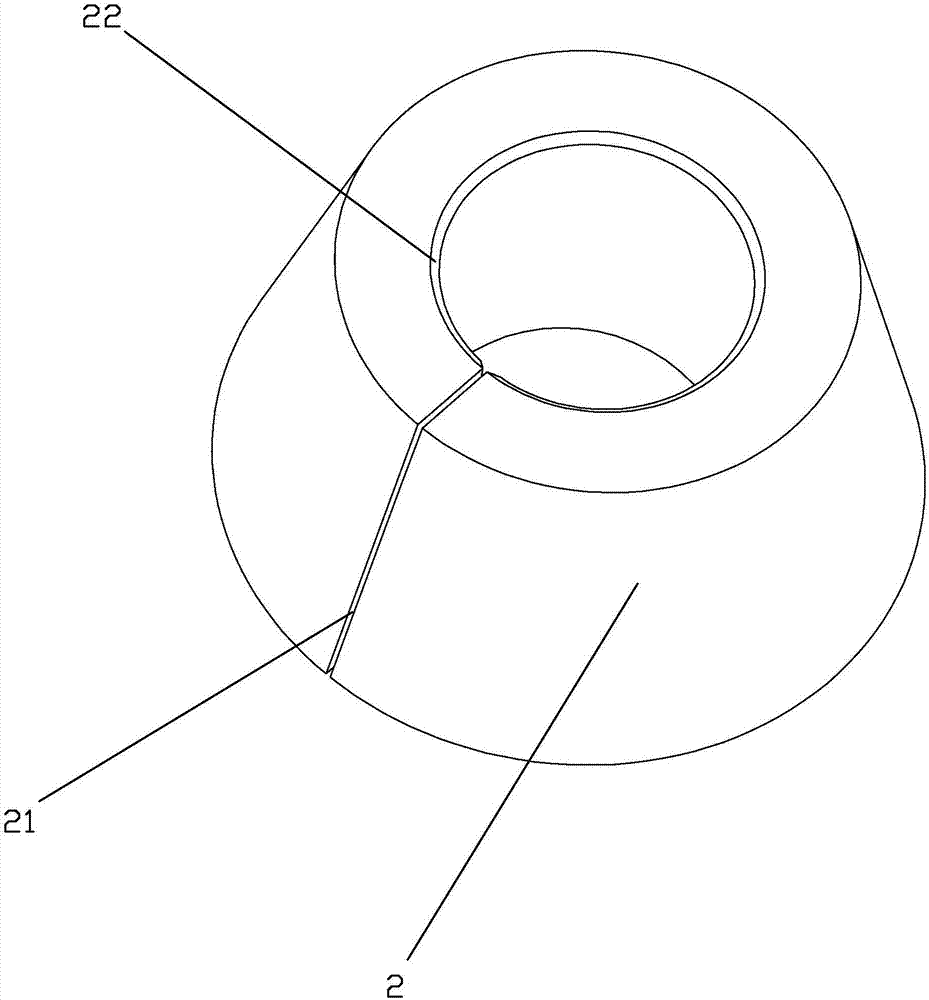

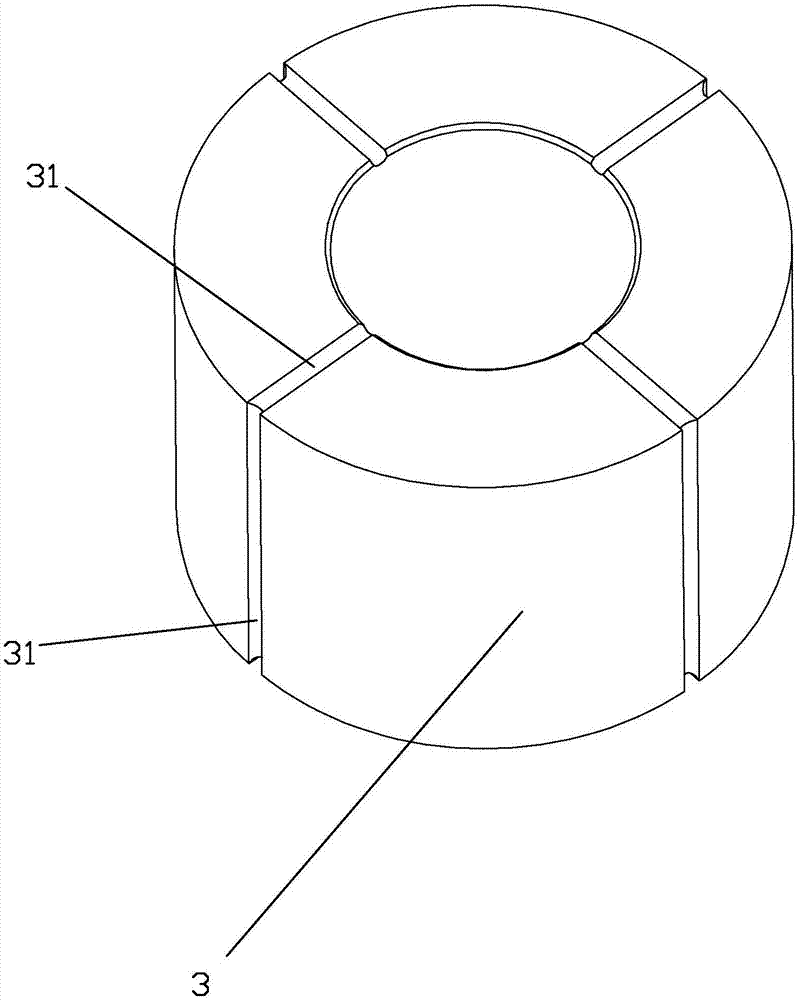

[0058] Embodiment one, a kind of cold heading mold,

[0059] Such as Figure 1 to Figure 3 As shown, a cold heading die includes a cylindrical formwork 1, the outer surface of the formwork 1 is provided with a positioning groove 12, the positioning groove 12 is cut by wire cutting, and the positioning groove 12 includes a shaft with the formwork 1 To a vertical face and an inclined plane, the angle between the inclined plane and the axis of the formwork 1 is 15°. The setting of the positioning groove 12 can cooperate with the fiber parts on the cold heading machine to prevent the mold from rotating after being loaded into the cold heading machine. There is an axial stepped hole in the formwork 1, the stepped hole runs through the upper and lower end surfaces of the formwork 1, the small end of the stepped hole is a tapered section, and communicates with the upper end surface of the formwork 1, the axial section of the tapered section is conical ; The big end of the stepped h...

Embodiment 2

[0065] Embodiment two, a kind of cold heading abrasive tool,

[0066] Such as Figure 4 As shown, the difference between the second embodiment and the first embodiment lies in the mold shell 1 and the inner mold core 3 . The middle part of the outer surface of the formwork 1 in the second embodiment is provided with a ring of fixing rings 13, and the fixing ring 13 and the formwork 1 are integrated. A plurality of screw holes 14 are provided on the fixing ring 13 to facilitate fixing the formwork 1 to the cold heading machine. At the same time, an annular groove 15 is provided between the conical section and the cylindrical section of the stepped hole inside the formwork 1 , and the exhaust hole 11 is located on the annular groove 15 . After the mold installation was completed, the lower end surface of the inner mold and the upper end surface of the rear pad 4 of the inner mold were all in the annular groove 15. During cold heading, the air on the inner hole of the inner mo...

Embodiment 3

[0068] Simultaneously in embodiment two also can also be set with inner mold rear pad 4 and threaded part 5 integrally, when reprocessing screwed part 5, directly the inner mold back pad 4 is integrally manufactured on the screwed part 5 upper end, on the one hand reduces processing procedure, on the other hand On the one hand, the mold structure is further simplified. Embodiment three, a kind of processing procedure of cold forging die,

[0069] The invention relates to a processing procedure of a cold forging die, which includes the processing technology of the mold shell, the processing technology of the reinforcing ring, the processing technology of the inner mold core, the processing technology of the rear pad of the inner mold and the processing technology of the screw parts.

[0070] The processing technology of the mold shell includes:

[0071] S1, blanking: select the forged round steel with the grade of SKD61, and use a large cutting machine to cut the material.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com