Process for producing resonant tag and resonant tag

A label and resonance technology, applied in the manufacture of resonance labels and the field of resonance labels, can solve the problems of disconnection, interconnection, bad circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiments of the present invention will be described below with reference to the drawings, but the present invention is not limited to these examples.

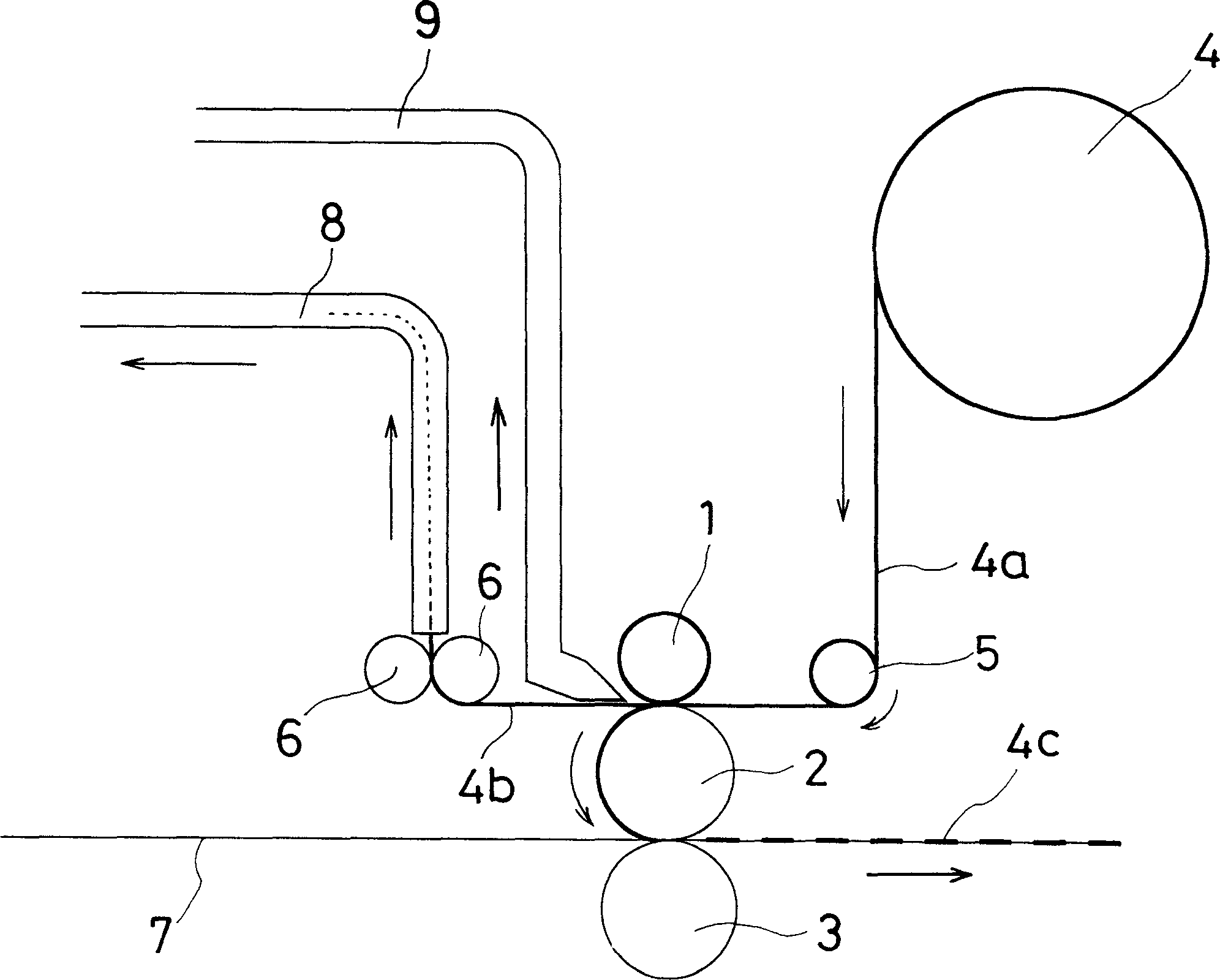

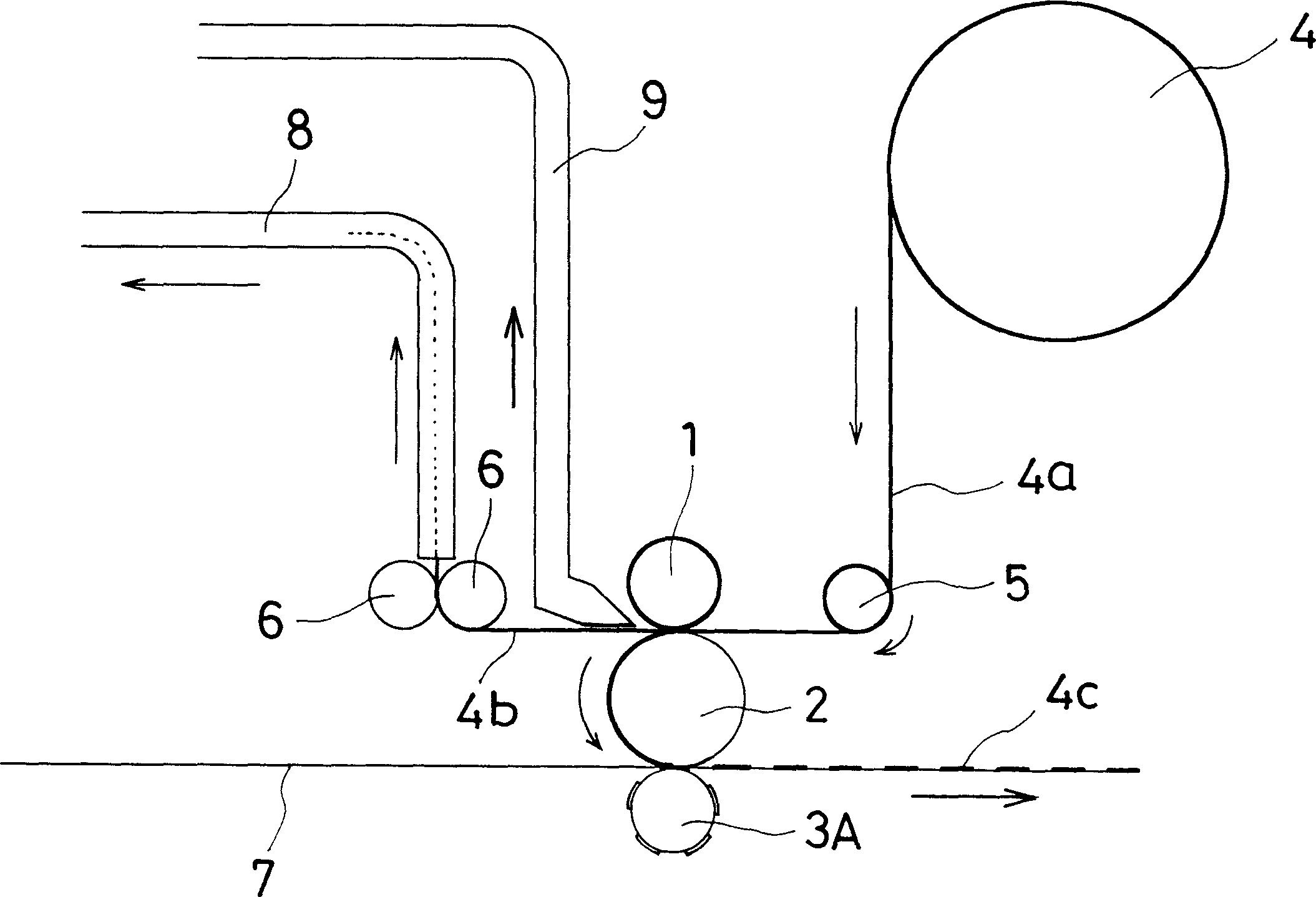

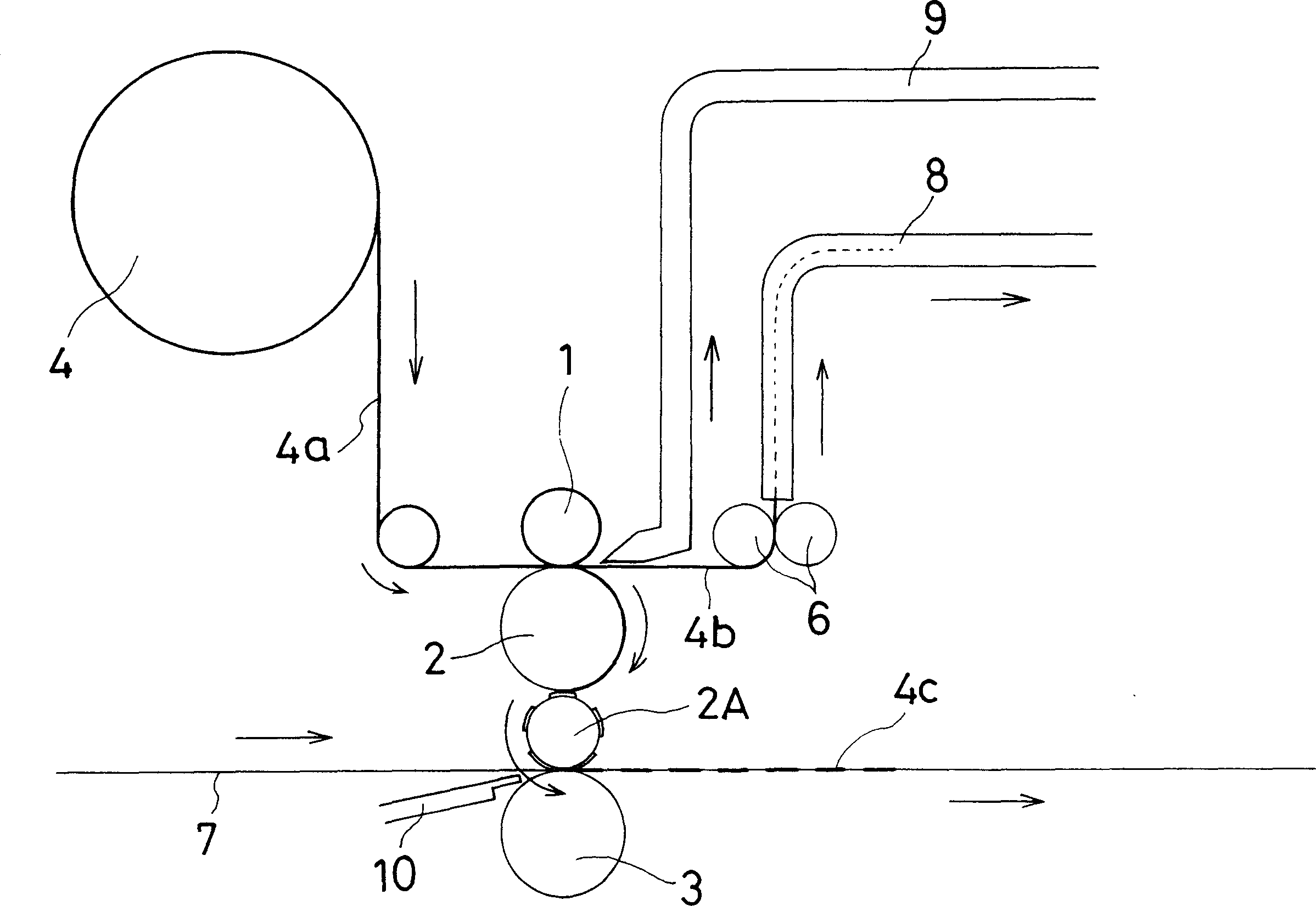

[0067] figure 1 It is a figure which shows an example of the basic method of this invention, 1 shows a die roll, 2 shows a transfer roll, and 3 shows a bonding roll. In practice, the metal foil 4a coated with a thermal adhesive resin is unwound from its roll 4, and fed between the die roll 1 and the transfer roll 2 via the guide roll 5 and punched into a predetermined shape. The die-cut metal foil 4c is held on the surface of the roller 2 by the suction hole (not shown) provided on the transfer roller 2, and sticks to the substrate flowing on the bonding roller 3 that is in contact with the lower side of the transfer roller 2. Sheet 7 on.

[0068] In the case of this example, the roller surfaces of the transfer roller 2 and the bonding roller 3 are flat, and the bonding roller 3 is a metal heating roller (heating r...

Embodiment 2

[0076] Embodiment 2 and comparative example

[0077] The size of the resonant tag: 40×40mm (the size of the circuit periphery)

[0078] Resonant frequency: 8.2MHz

[0079] Under the above conditions, a resonant tag of the present invention (Example) and a prior art resonant tag were produced and their performances were compared.

[0080] Embodiment is the resonant tag of the two-sided coil form shown in Fig. 4D, and comparative example is taken as Figure 7 in the form of a single-sided coil.

[0081] The composition and properties are shown in Table 1.

[0082] comparative example

Example

Coil

Material

Thickness (Front / Reverse)

Number of turns

Area / capacity

L (inductance)

coil length

coil resistance

Q calculated value

measured value

aluminum

50μm / 10μm

8

20μm polyethylene film

121mm 2 / 128pF

3.06μH

980mm

0.6860Ω

230 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonance | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com