Bare concrete adjustable combined type inner-outer wall steel die

A clear-faced concrete and adjustable technology, which is applied to the preparation of formwork/formwork components, formwork/formwork/work frames, and building components on site, and can solve the problems of difficulty in reaching standards, high costs, and waste of resources. Achieve the effects of improving pouring quality, simple construction and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Describe the present invention in detail below in conjunction with accompanying drawing:

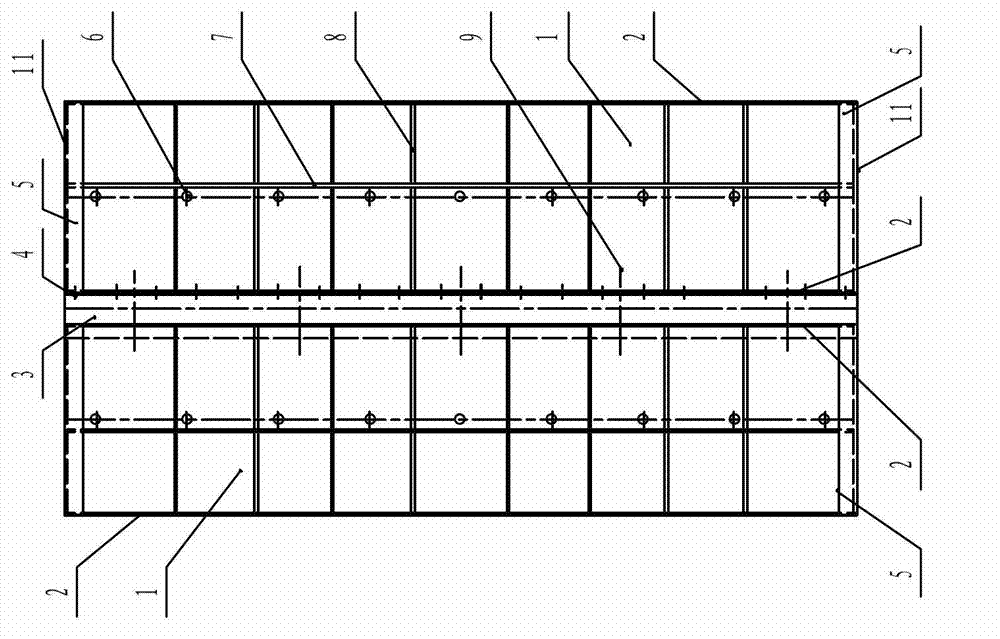

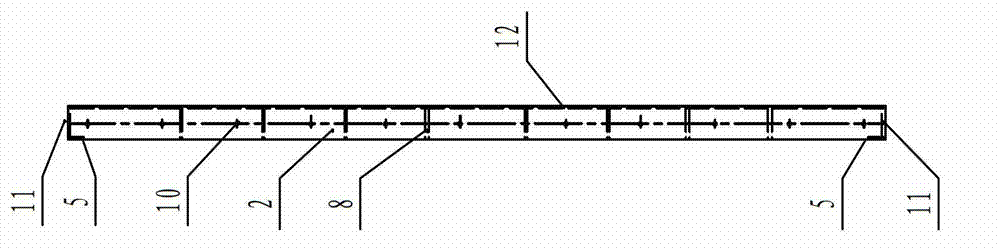

[0015] Such as Figure 1-4 As shown, the adjustable combined inner and outer wall steel form of fair-faced concrete includes several pieces of inner wall steel form 1 and outer wall steel form 18 respectively combined and spliced, and the inner and outer wall steel form includes panels 12, longitudinal ribs 2, and transverse sides Ribs 11, transverse ribs 8, longitudinal ribs 7, longitudinal ribs 2, transverse ribs 11, transverse ribs 8, and longitudinal ribs 7 are connected vertically and horizontally to form a rectangular frame, and the panels are fixed on the rectangular frame. 1. The vertical center line of the outer wall steel formwork 18 is provided with several opposite pull holes 6. The opposite draw holes 6 are symmetrical up and down on the inner wall steel formwork 1, centered left and right, and the inner wall steel formwork 1 and the outer wall steel formwork 18 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com