Die and die supporting mechanism thereof

A support mechanism and mold technology, applied in the field of injection molds, can solve problems such as waste, large limitations, and consumption, and achieve the effects of saving mold space, strong support, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

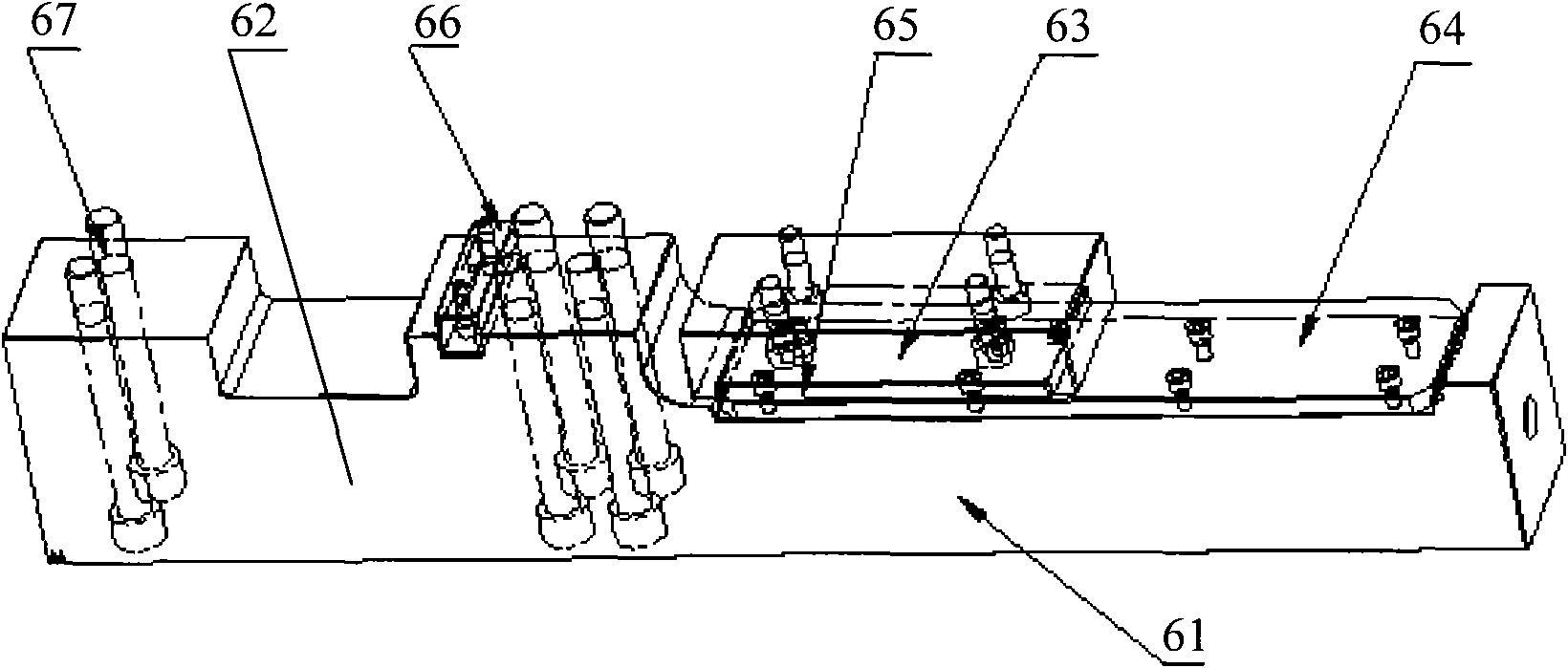

[0031] Embodiments of the present invention provide a mold support mechanism, such as figure 2 As shown, the mold support mechanism 6 includes: a support beam 61 for supporting the mold middle template; a fixing part 62 for fixing the mold front template or the mold rear template; a cushion block for fixing the mold middle template 63, set on the support beam 61.

[0032] The mold support mechanism provided in this embodiment is applied in a double-layer mold or a multi-layer mold to provide support for the middle template of the mold. Specifically, the affixed part 62 is affixed to the bottom of the mold front template or the mold rear template, The spacer 63 is fixedly connected to the middle formwork of the mold, so that the support beam 61 is under the middle formwork of the mold to provide support for the middle formwork of the mold. When the mold is opened and closed, the spacer 63 and the support beam 61 slide relative to each other to realize Support for the formwork...

Embodiment 2

[0036] On the basis of Example 1, as figure 1 As shown, during the mold opening and closing process, the cushion block 63 and the support beam 61 slide relative to each other, thereby causing the wear of the support beam 61. Therefore, further, the support beam 61 is provided with a first wear-resistant plate 64 . The first wear plate 64 has good wear resistance, and can effectively reduce wear and tear of the support beam 61 .

[0037] Still further, the first wear-resistant plate 64 may be fixedly connected to the support beam 61 through screws 67 or the like. The first wear-resistant plate 64 can be disassembled and replaced. When the first wear-resistant plate 64 is worn to the extent that it needs to be replaced, the first wear-resistant plate 64 can be replaced, which increases the service life of the entire mechanism.

[0038] Furthermore, since the cushion block 63 and the support beam 61 slide relative to each other during the mold opening and closing process, lubri...

Embodiment 3

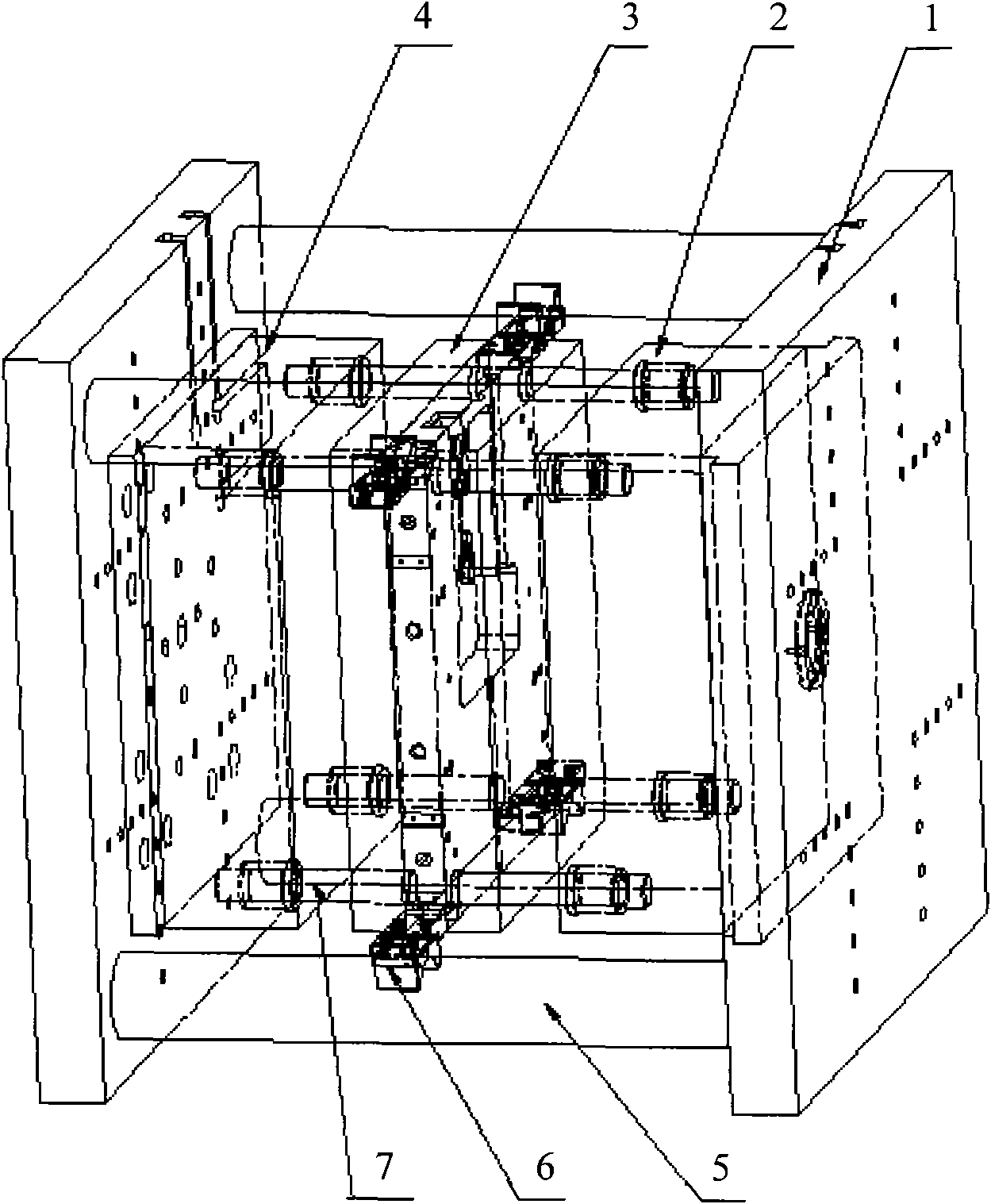

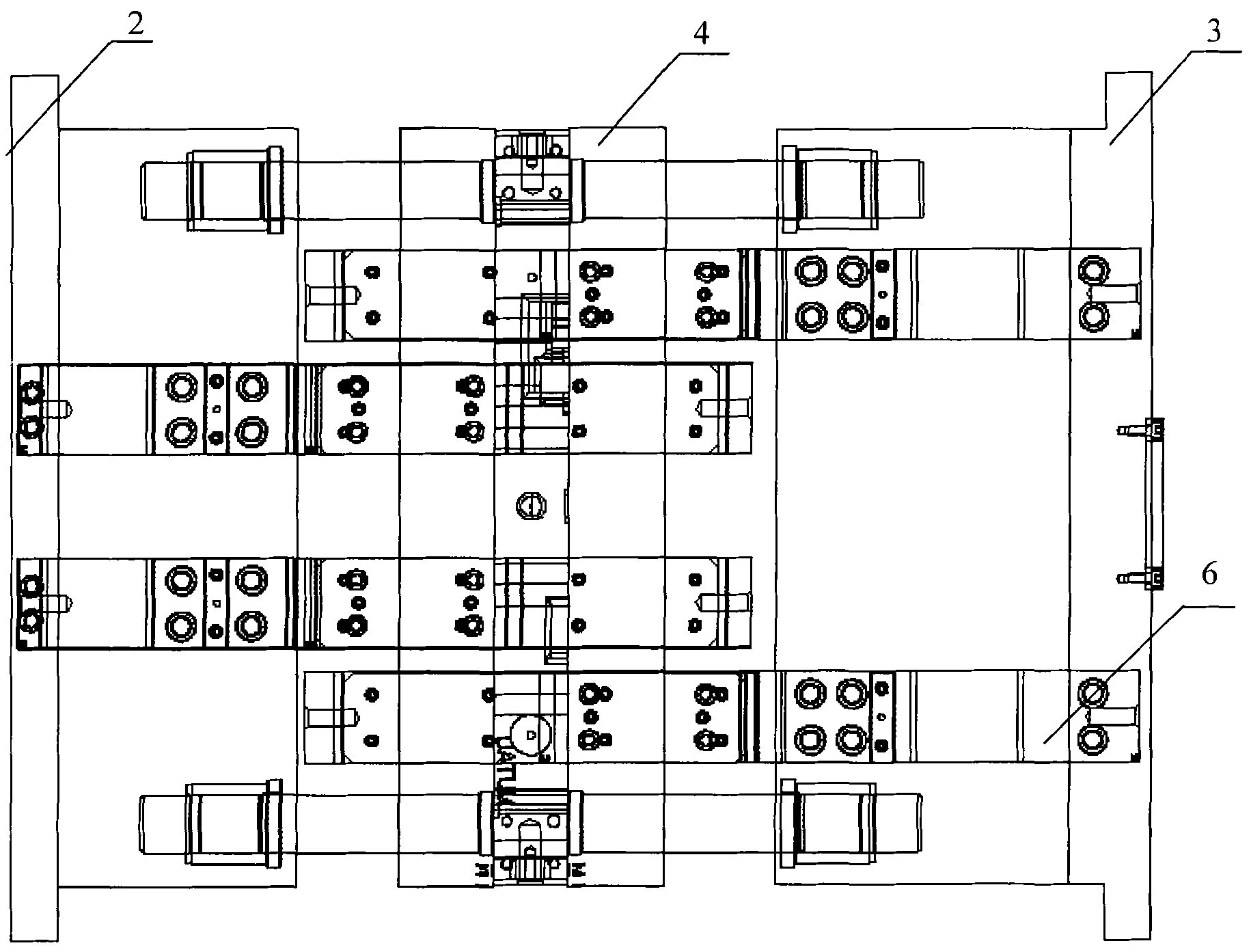

[0046] Embodiments of the present invention provide a mold, such as image 3 As shown, it includes: a mold front template 2, a mold rear template 3 and at least one mold middle template 4, and at least one mold support mechanism 6 is affixed to the mold, and the mold support mechanism includes: for supporting the middle of the mold The supporting beam of the template 4; the fixing part for fixing the front template 2 of the mold or the rear template 3 of the mold; the pad for fixing the middle template 4 of the mold is arranged on the supporting beam.

[0047] The mold provided in this embodiment is a double-layer mold or a multi-layer mold, and a mold support mechanism 6 is used to provide support for the middle template 4 of the mold. Specifically, the fixed part of the mold support mechanism 6 is fixed on the front template 2 or Below the mold rear formwork 3, the cushion block is fixedly connected with the mold middle formwork 4, so that the support beam is under the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com