Roofing Products Having Receptor Zones and Photovoltaic Roofing Elements and Systems Using Them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

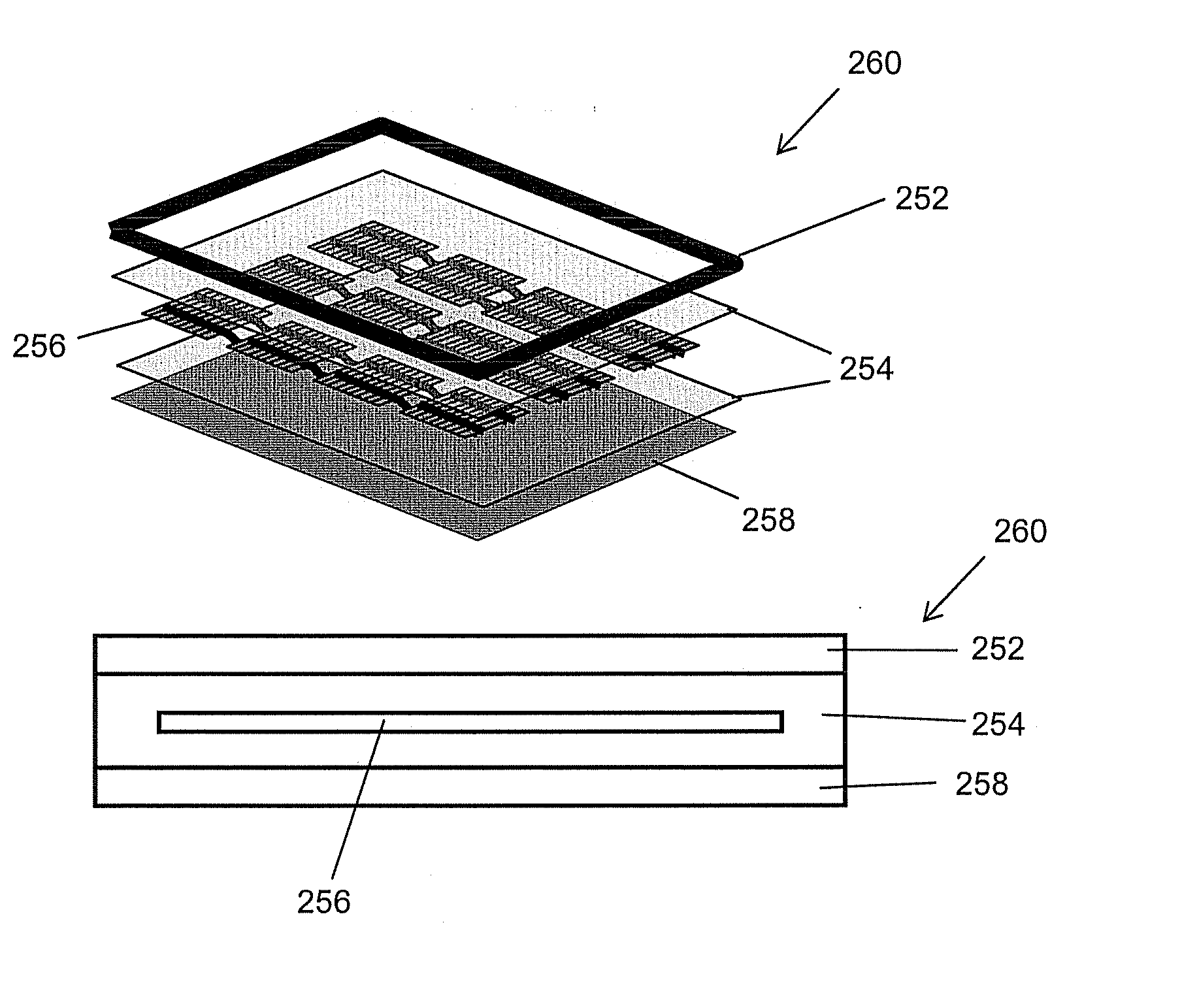

[0043]One embodiment of a roofing product according to the present invention is shown in schematic perspective view in FIG. 1. Roofing product 100 comprises a flexible roofing substrate 110 having a top surface 112. One or more (in this embodiment, six) receptor zones 120 are on the top surface 112 of flexible roofing substrate 110. Each receptor zone 120 is adapted to receive one or more photovoltaic elements, and has a different surfacing than the area 122 of the top surface adjacent to the receptor zone 120. The sizes and shapes of the one or more receptor zones can, for example, be selected based on the sizes and shapes of the photovoltaic elements envisioned for use therewith. For example, certain photovoltaic elements available from Uni-solar Ovonic have dimensions of about 12 cm×18 cm (T-Cells); about 24 cm×36 cm (L-Cells); or about 40 cm×5 m (strip).

[0044]In some embodiments, the receptor zone has dimensions that are somewhat larger than (e.g., in the range of 101-120% of, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com