A kind of water-soluble polyether modified silicone defoamer and its preparation and compounding method

A silicone defoamer and water-soluble polyether technology, applied in the field of coatings and water-based inks, can solve the problems of poor alkali resistance, insoluble in water, unsatisfactory defoaming speed and foam suppression time, etc. Compatibility, improve product quality, improve the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

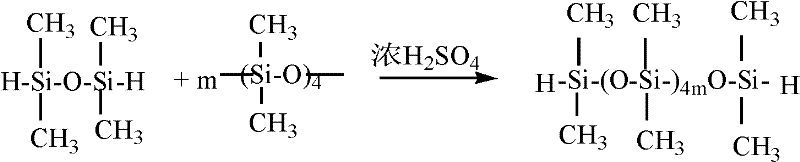

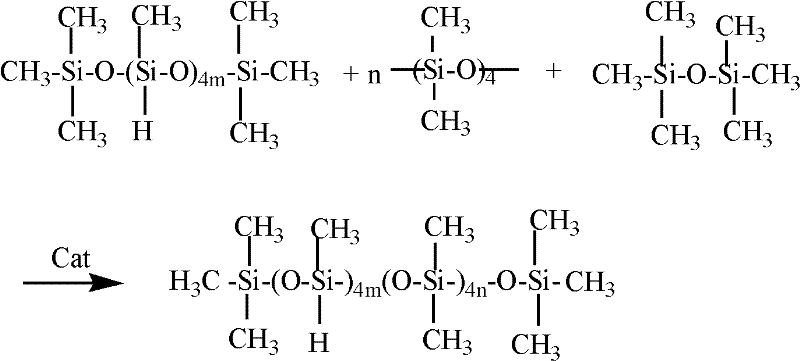

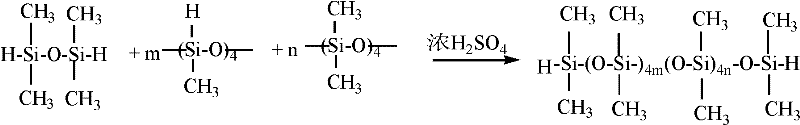

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of water-soluble polyether modified silicone defoamer, comprising the following steps:

[0035] a. Add allyl-terminated polyoxyalkylene ether into the container for stirring, and vacuum distill to remove water until the water content reaches 0.5-1‰. Adding a solvent when removing water will have a better effect of removing water, but the subsequent treatment will be more troublesome. The reason why allyl-terminated polyoxyalkylene ethers need to be strictly dewatered: Even a small amount of water can hydrolyze the Si-H group in the low-hydrogen silicone oil and further shrink and cross-link, which greatly increases the molecular weight of the product and has a more structured structure. Complex, which makes it easier to form gel insoluble matter.

[0036] b. Then add solvent and low-hydrogen-containing silicone oil to the system in step a and stir, control the amount and adding speed of low-hydrogen-containing silicone oil, slowly add the reaction ...

Embodiment 1

[0060] Embodiment 1, the preparation of polyether modified silicone defoamer

[0061] a. Add allyl-terminated polyoxyalkylene ether and toluene accounting for 20% of the total mass of allyl-terminated polyoxyalkylene ether and low hydrogen-containing silicone oil into the container for stirring, and vacuum distill to remove water until the water content reaches 0.5‰.

[0062] b. Then add low-hydrogen-containing silicone oil to the system in step a and stir, control the amount and adding speed of low-hydrogen-containing silicone oil, slowly add to the reaction system drop by drop, and stir at a uniform speed. The ratio of the amount of the C=C group substance of the terminal allyl polyoxyalkylene ether to the amount of the low hydrogen-containing silicone oil Si-H group substance is 1.1:1.

[0063] C, then add the isopropanol solution of chloroplatinic acid as catalyzer, install reflux condenser, in N 2 Under the atmosphere, stir and heat to 90°C for 4 hours, and keep warm unt...

Embodiment 2

[0071] Embodiment 2, the preparation of polyether modified silicone defoamer

[0072] a. Add allyl-terminated polyoxyalkylene ether and xylene accounting for 35% of the total mass of allyl-terminated polyoxyalkylene ether and low-hydrogen-containing silicone oil into the container for stirring, and vacuum distill to remove water until the water content reaches 1‰ .

[0073] b. Then add low-hydrogen-containing silicone oil to the system in step a and stir, control the amount and adding speed of low-hydrogen-containing silicone oil, slowly add to the reaction system drop by drop, and stir at a uniform speed. The ratio of the amount of the C=C group substance of the terminal allyl polyoxyalkylene ether to the amount of the low hydrogen-containing silicone oil Si-H group substance is 1.4:1.

[0074] C, then add the isopropanol solution of chloroplatinic acid as catalyzer, install reflux condenser, in N 2 Under the atmosphere, stir and heat to 120° C. for 6 hours, and keep warm u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com