Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Guaranteed defoaming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

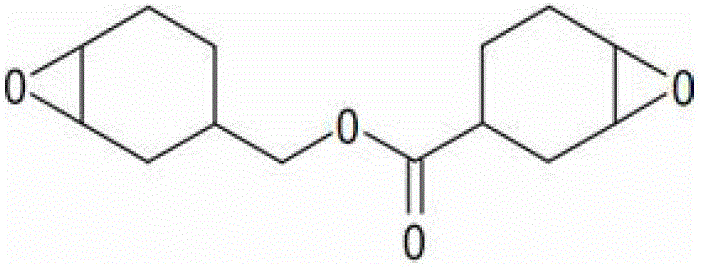

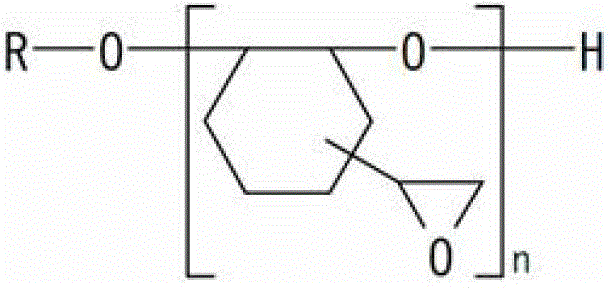

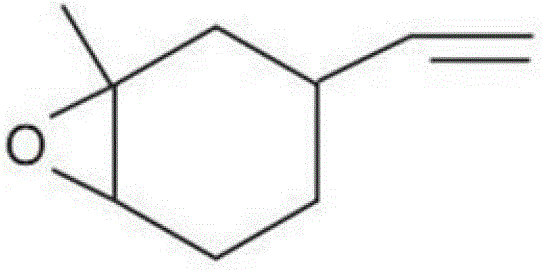

LED-packaging epoxy resin composition

InactiveCN102746487AGuaranteed crack resistanceGuaranteed craftsmanshipNon-macromolecular adhesive additivesEpoxy resin adhesivesPhosphonium saltPhosphate

The invention discloses a method for improving the performance of a large-power high-light-transmittance LED packaging epoxy resin composition. The composition is composed of a component A and a component B. The composition has excellent UV resistance and yellowing resistance. The composition is advantaged in good manufacturability, good light transmittance, and low light failure. The composition can be used in white-light and blue-light LED packaging. Compared with organosilicon, the composition is advantaged in low price. Innovatively, the component A of the composition is composed of liquid cycloaliphatic epoxy resin, solid cycloaliphatic epoxy resin, and hydrogenated bisphenol A epoxy resin. An anti-forming agent, a color complementary agent, and a dispensing agent are adopted in auxiliary. The system does not contain benzene ring, and yellowing is not easy to occur. The component B is prepared through the steps that: methyl hexahydrophthalic anhydride and hexahydrophthalic anhydride are subjected to a polymerization reaction with promoting agents or cationic initiators such as quaternary phosphonium salt, quaternary ammonium salts, DBU salt, and imidazole; with added phosphate antioxidant, a thermal yellowing capacity is improved. With the applications of an ultraviolet absorber and a light stabilizer, a UV yellowing resisting effect is further improved.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS +1

Organosilicone composition, preparation method and application thereof

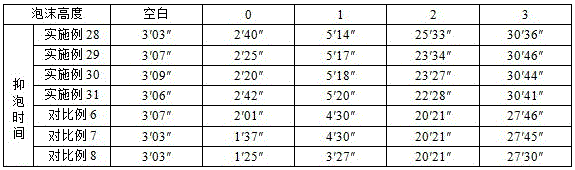

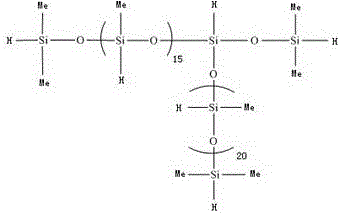

ActiveCN104274998AGood defoamingGood anti-foam performanceFoam dispersion/preventionPolymer scienceUnsaturated hydrocarbon

The present invention relates to a crosslinked network polymer obtained on the basis of an addition reaction of a hydrogen-containing polyorganosiloxane, an organic silicon resin and an unsaturated hydrocarbon, followed by the process of adding a crosslinking agent containing an active group and silicon dioxide; the polymer has an improved defoaming performance, good anti-foaming effect, and is easy to handle and process, and the addition of an emulsifier does not reduce the anti-foaming effect. The polymer has a good anti-foaming performance with no decay, and the polymer formed therefrom can easily be processed.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

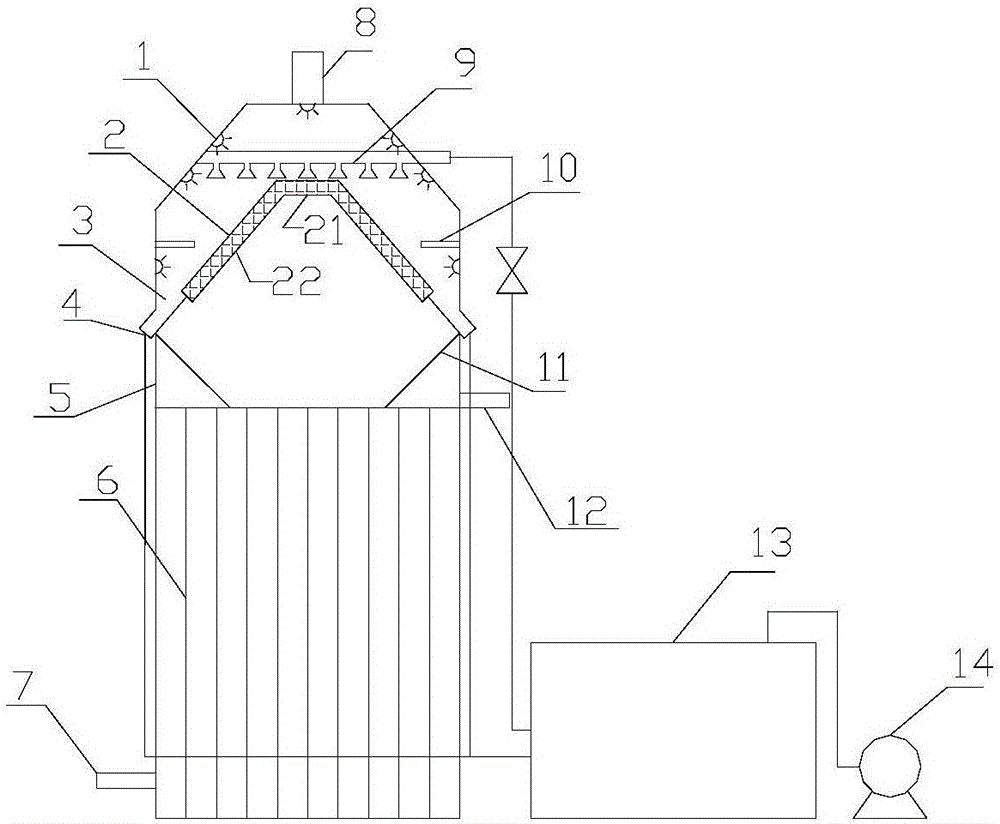

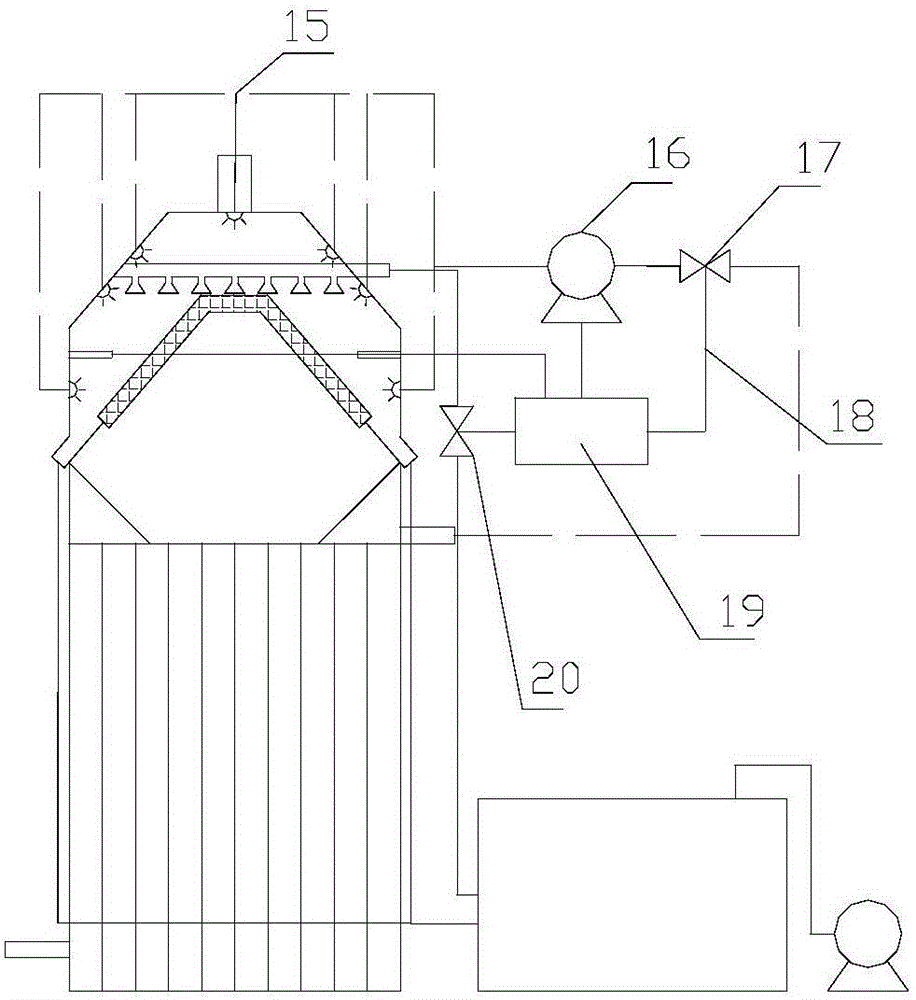

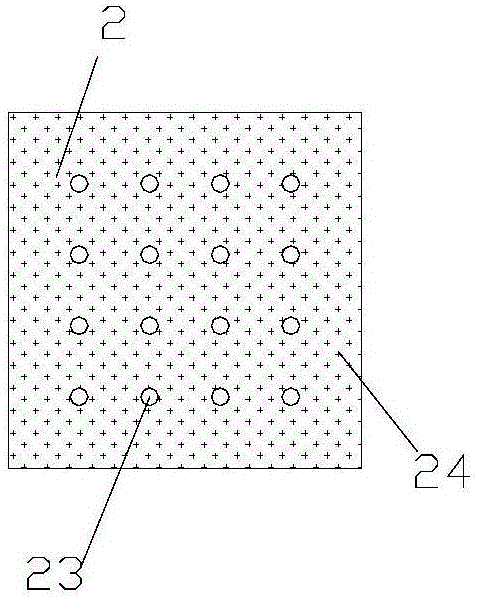

Defoaming device and method for electrochemical wastewater treatment system

ActiveCN106430389AIncrease contact areaEasy to remove foamWater/sewage treatment by degassingFoam dispersion/preventionChemical treatmentSlag

The invention discloses a defoaming device and method for an electrochemical wastewater treatment system. The defoaming device comprises an electrolytic tank, wherein the electrolytic tank is connected with a water inlet pipe and a water outlet pipe; the defoaming device further comprises a defoaming baffle plate inverted above the electrolytic tank, a gas collecting cover arranged above the defoaming baffle plate in a covering manner, a plurality of spray nozzles distributed on an inner wall of the gas collecting cover, and a slag discharging opening which is connected with a bottom edge of the defoaming baffle plate and extends out of the electrolytic tank; a plurality of through holes are formed in the defoaming baffle plate; a plurality of barbs are arranged on one surface, facing the electrolytic tank, of the defoaming baffle plate; the top of the gas collecting cover is connected with an exhaust pipe; the spray nozzles are connected with a high pressure water pump through a pipeline; the slag discharging opening is connected with a foam collecting pool through the pipeline. The defoaming device and method provided by the invention convert part of foam into liquid by utilizing diversion and interception effects of the baffle plate; foam overflowing from the baffle plate is broken by water drops sprayed by high pressure nozzles; the foam and defoamed liquid return to the electrolytic tank along with water flow; a defoaming agent can be added to the electrolytic tank for treatment.

Owner:SUZHOU INDAL TECH RES INST OF ZHEJIANG UNIV +2

Ink and preparation method thereof

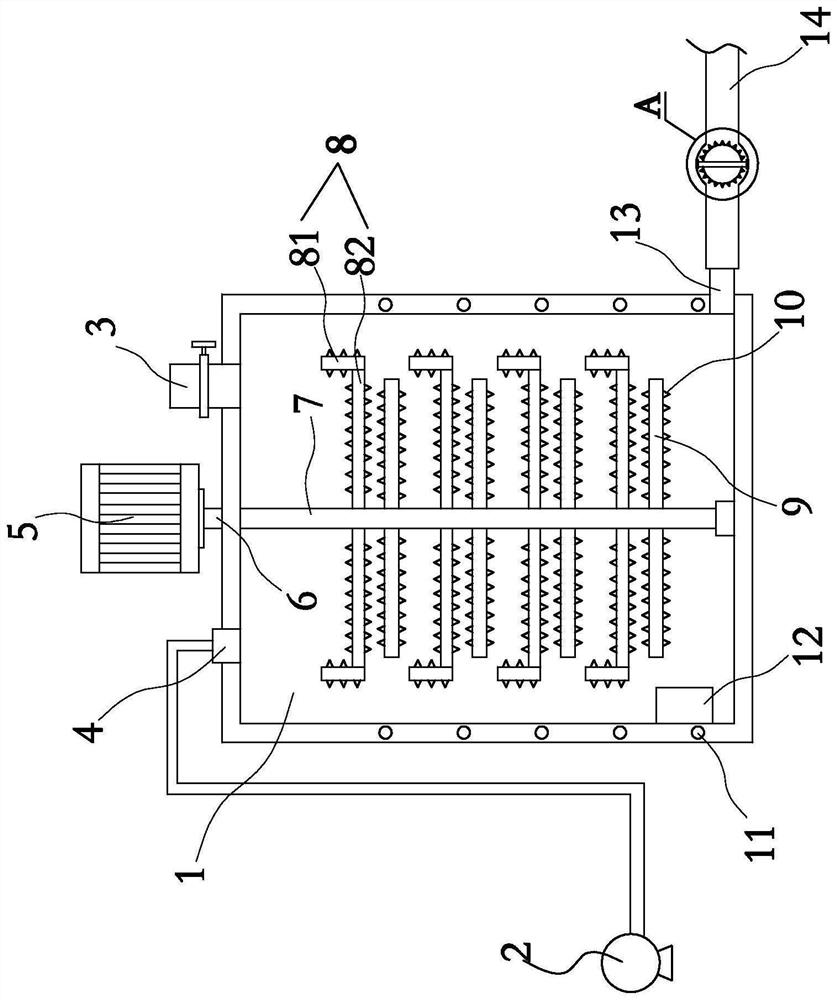

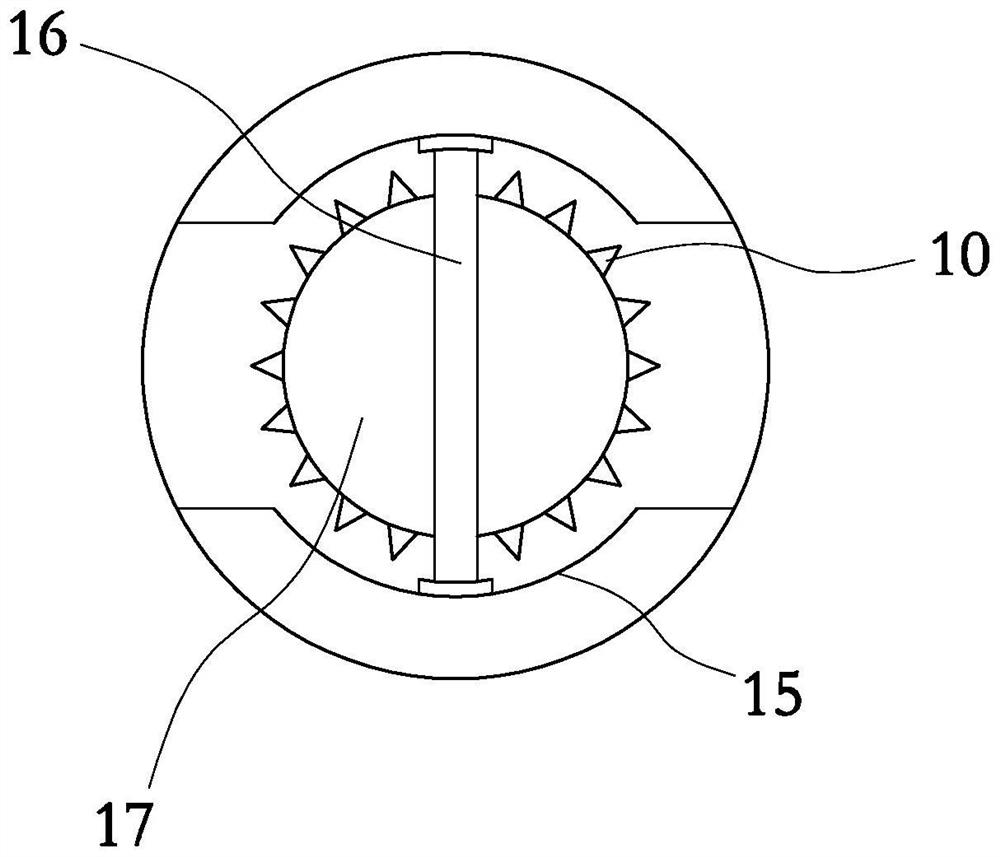

InactiveCN112011220AGood dispersionImprove uniformityLiquid degasificationMixing methodsDeinkingElectric machinery

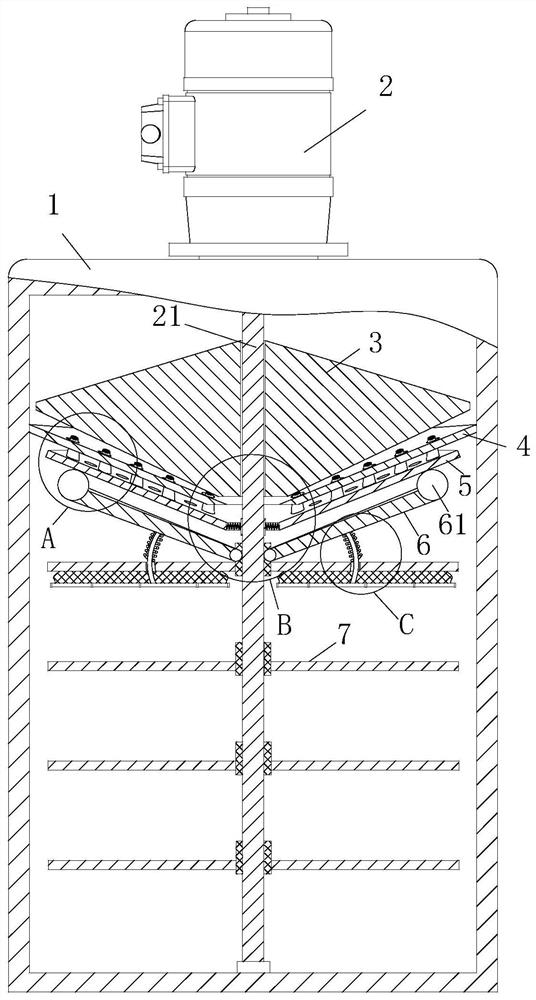

The invention relates to the technical field of ink, and especially relates to an ink and a preparation method thereof. Adopted stirring equipment comprises a stirring tank, a feeding port communicated with the inner cavity of the stirring tank is formed in one side of the upper end of the stirring tank, a motor is fixedly arranged in the middle of the upper end of the stirring tank, the output end of the motor is connected with a rotating shaft, and the rotating shaft penetrates through the upper end of the stirring tank and extends downwards to the inner cavity of the stirring tank. A plurality of groups of stirring rods are arranged on the rotating shaft at the lower part in the stirring tank at intervals. Through the arrangement of a grinding block and a grinding disc, particles of rawmaterials can be smaller, dispersion of the raw materials during subsequent stirring and emulsifying is facilitated, the uniformity of substances in the ink is improved, the overall viscosity is better, then the adhesive force of the ink is enhanced, and the problems of uneven printing and deinking are avoided.

Owner:张姣

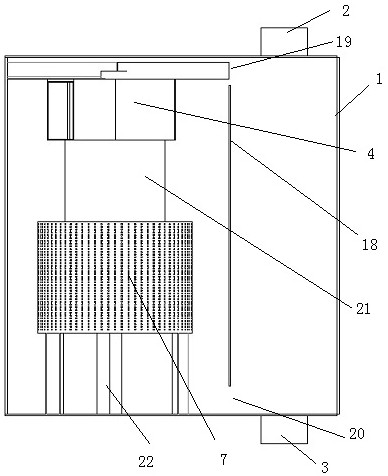

Paint defoaming device

The invention relates to the technical field of paint production equipment, and discloses a paint defoaming device. The paint defoaming device comprises a barrel, wherein the bottom of the barrel is of a conical structure; a plurality of supporting legs are fixedly connected to the bottom of the barrel; the top of the barrel is fixedly connected with a vacuum pump through a bracket; the input endof the vacuum pump is fixedly connected with an exhaust pipe; the bottom end of the exhaust pipe is rotationally connected with a rotating pipe through a first sealing bearing; the other end of the rotating pipe penetrates through the center of the top of the barrel and extends downwards to fixedly communicate with a transverse pipe; the lower surface of the transverse pipe communicates with a plurality of evenly-distributed extraction openings; the rotating pipe is rotationally connected with the top of the barrel through a second sealing bearing; a supporting plate is fixedly connected to the outer side wall, close to the top, of the barrel; a driving motor is fixedly installed on the supporting plate; and an output shaft of the driving motor is fixedly connected with a driving chain wheel. According to the paint defoaming device, paint can be conveniently, comprehensively and fully stirred, so the defoaming effect of paint is effectively guaranteed.

Owner:马鞍山采石矶涂料有限公司

Waterborne polyurethane composite leather and preparation method thereof

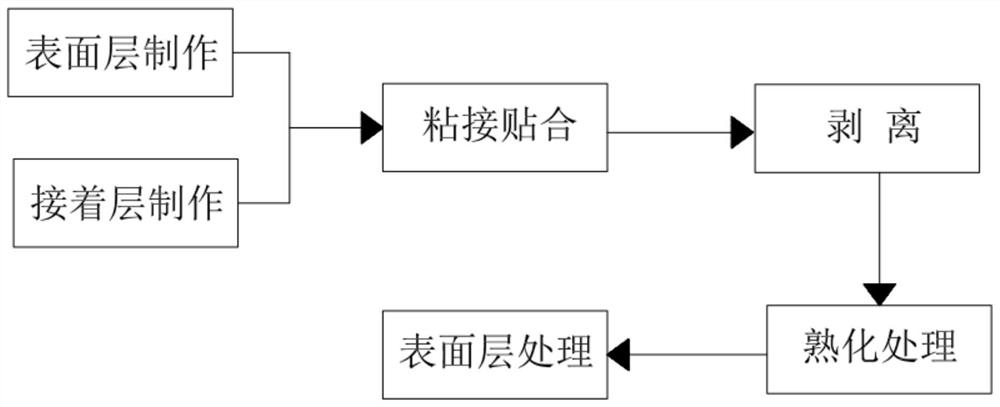

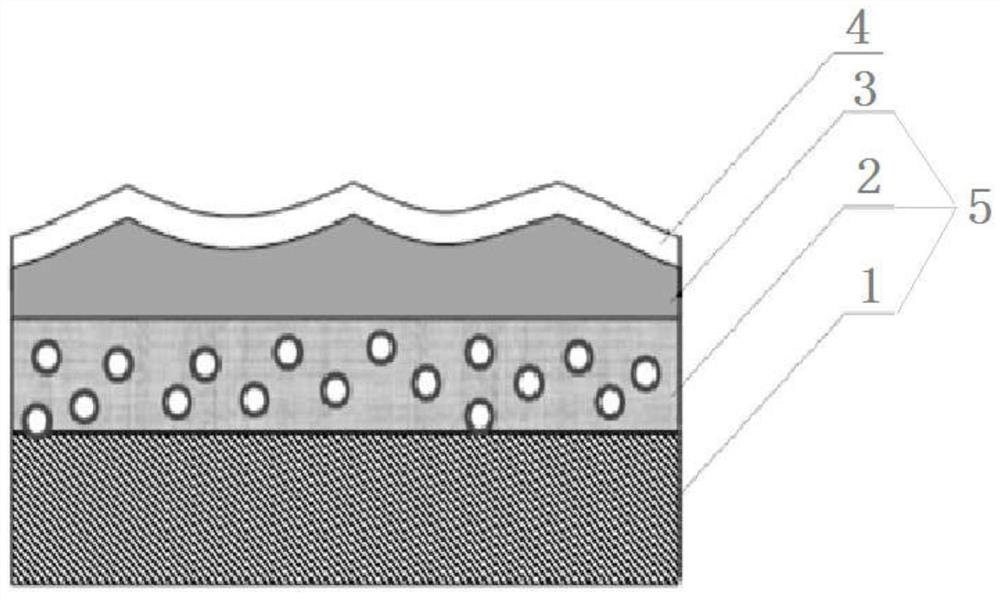

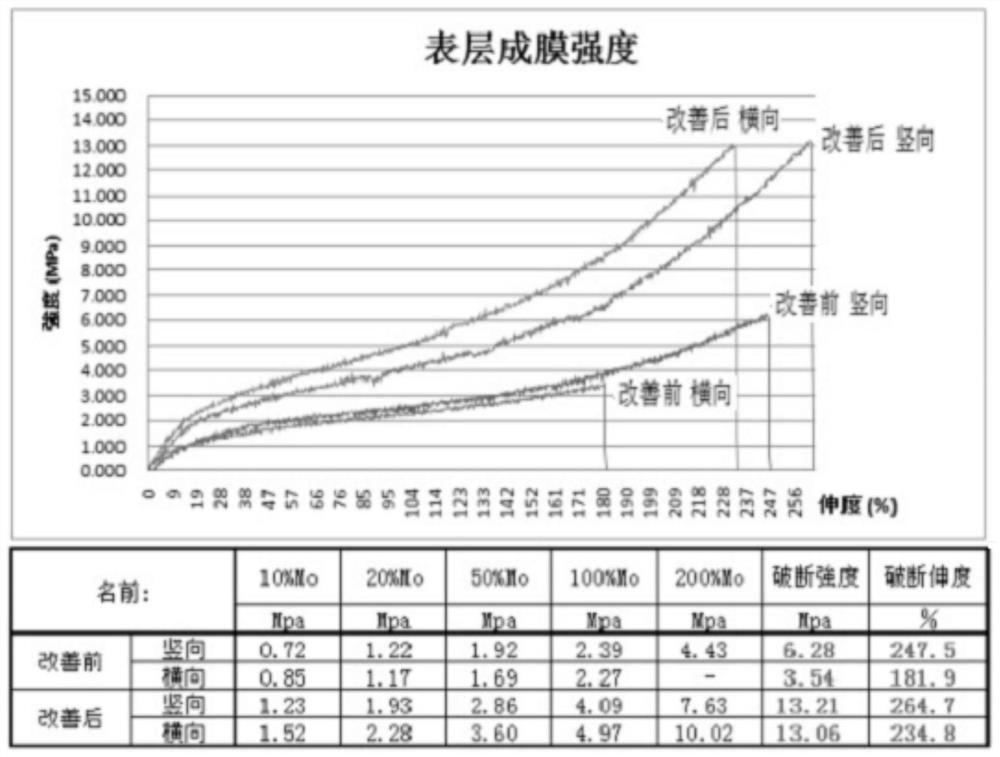

PendingCN111809404AExcellent light aging resistanceExcellent abrasion resistanceTextiles and paperPolymer scienceTackifier

The invention provides waterborne polyurethane composite leather. The waterborne polyurethane composite leather comprises a base cloth layer, an adhesion layer, a surface layer and a surface treatmentlayer, wherein the surface treatment layer comprises polyurethane, a bridging agent, a tackifier and a smoothing agent, the surface layer comprises polyurethane, a bridging agent, a tackifier, a pigment and a dissolving medium, and the adhesion layer comprises polyurethane, a hardening agent, a catalyst, a solvent, a flame retardant and a pigment. The invention further provides a preparation method of the composite leather. The preparation method comprises the steps of manufacturing the surface layer, manufacturing the adhesion layer, bonding the surface layer, the adhesion layer and the basecloth layer together, carrying out stripping, carrying out curing treatment, treating the surface layer and the like. According to the waterborne polyurethane composite leather and the preparation method thereof, the surface layer of the waterborne polyurethane composite leather can enhance surface film formation, abrasion resistance and flexibility by improving the components of all the layers and adopting the preparation method; and meanwhile, various strengths such as abrasion resistance, breaking property, tension and cracking of the waterborne polyurethane composite leather are enhanced,and the phenomena of peeling, cracking and the like of a product after long-term solarization are avoided.

Owner:SEIREN SUZHOU CO LTD

Processing method of bean curd, tender bean curd and refreshment made from bean milk

ActiveCN107348012AMeet the requirements of defoaming effectMeet usage limitsCheese manufactureFood scienceCompound organicFiltration

The invention discloses a processing method of bean curd, tender bean curd and refreshment made from bean milk and belongs to the technical field of processing of soya bean products. The processing method comprises the steps of material selection, soaking, smashing, separation, milk filtration and milk boiling, wherein the milk boiling temperature is 30-105 DEG C, the milk boiling time is 12-16 minutes, and a defoaming agent is added in the milk boiling process and is prepared by compounding organic silicone oil, modified soyabean lecithin, soybean oil and water. The defoaming effect in the bean curd processing process can be effectively improved by optimizing compounding of the components of the defoaming agent and optimizing the design of a bean curd processing technology, the usage amount of the defoaming agent is small, and the limited requirement for the use amount of polydimethylsiloxane in the national standard can be met.

Owner:JINCAIDI FOOD CO LTD

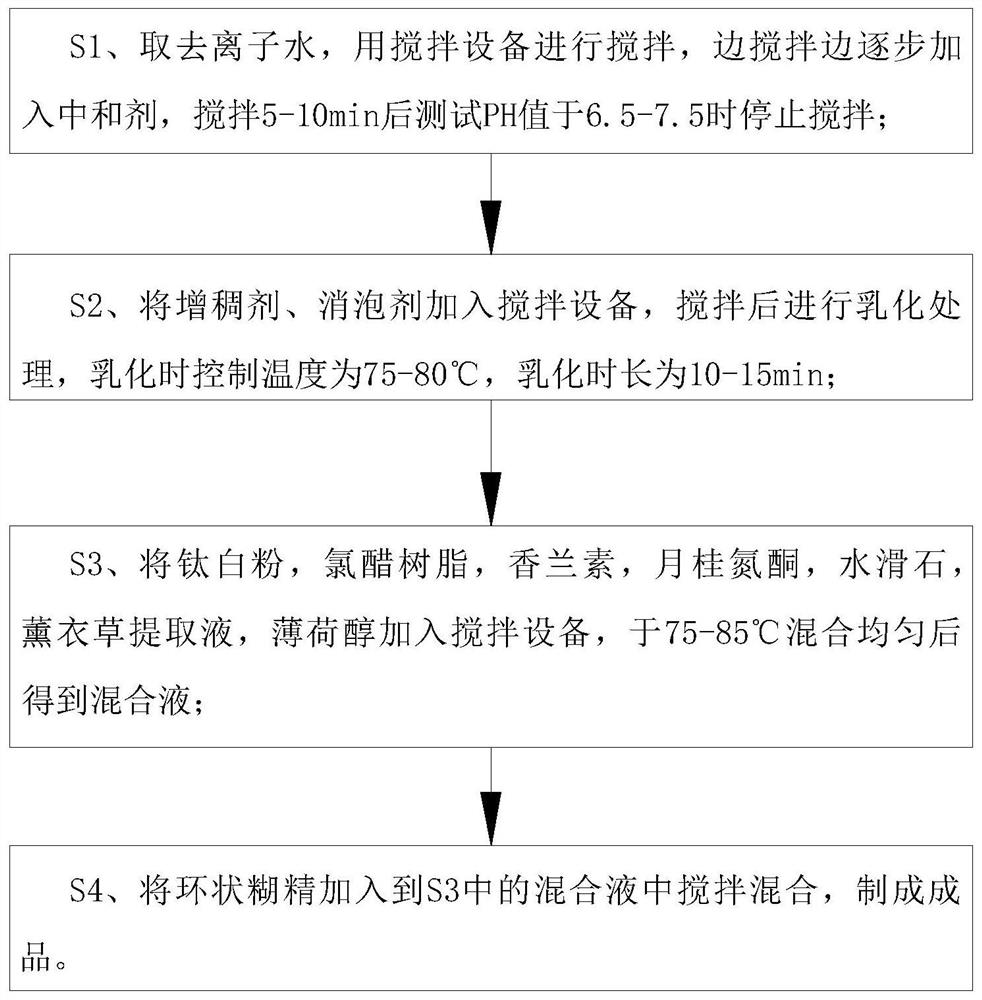

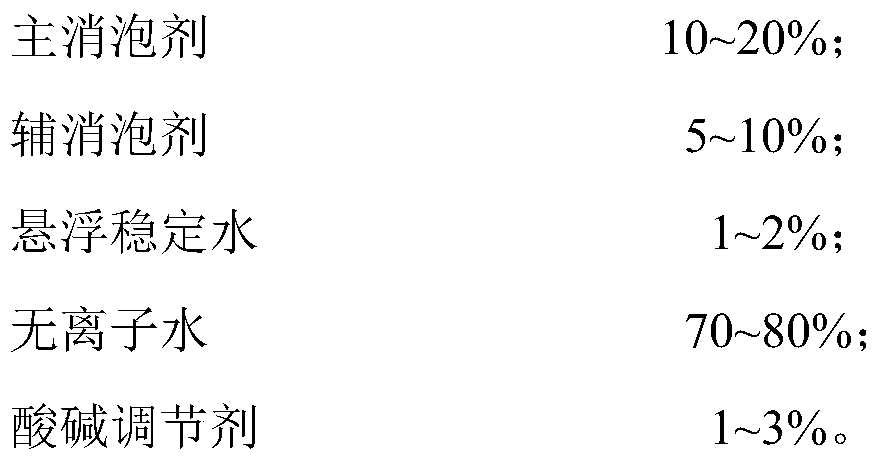

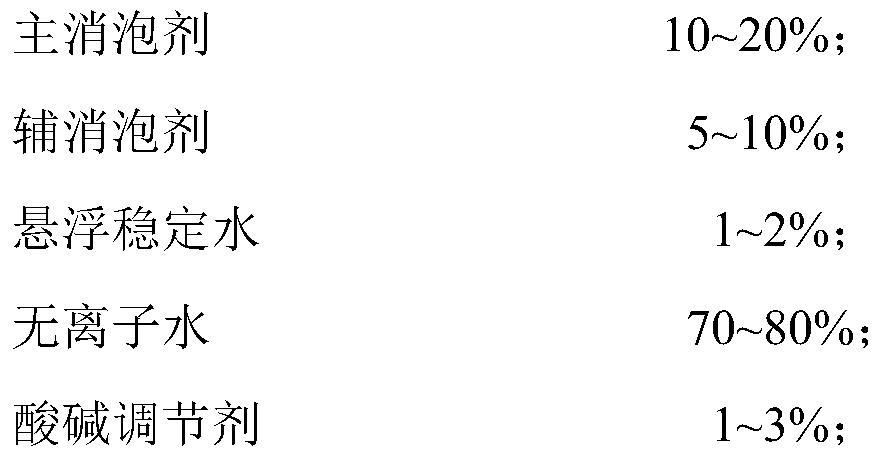

Organic silicone defoaming agent for PVC and preparation method thereof

ActiveCN110013690AImprove stabilityExtended storage timeFoam dispersion/preventionEtherWater soluble

The invention discloses an organic silicone defoaming agent for PVC and a preparation method thereof, and relates to industrial defoaming agents. The organic silicone defoaming agent comprises the following components in percent by mass: 10-20% of a main defoaming agent; 5-10% of an auxiliary defoaming agent; 1-2% of suspended stable water; 70-80% of deionized water; and 1-3% of an acid-base regulator. The preparation method comprises the following steps: firstly adding a stable water mother liquid to the deionized water, performing stirring for 15-20 minutes, adding the acid-base regulator, slowly regulating the pH of the stable water to be 6-7, then adding the main defoaming agent of modified silicon and the auxiliary defoaming agent of water-soluble ether when the stable water pH is stable and the solution is transparent, performing stirring for 25-30 minutes, and finally performing shearing treatment to obtain the organic silicone defoaming agent. The organic silicone defoaming agent for PVC can make the defoaming agent have good antifoaming effects under high temperature conditions, the production process of the organic silicone defoaming agent is simple, and the storage of the organic silicone defoaming agent is stable.

Owner:乌鲁木齐市华泰隆化学助剂有限公司

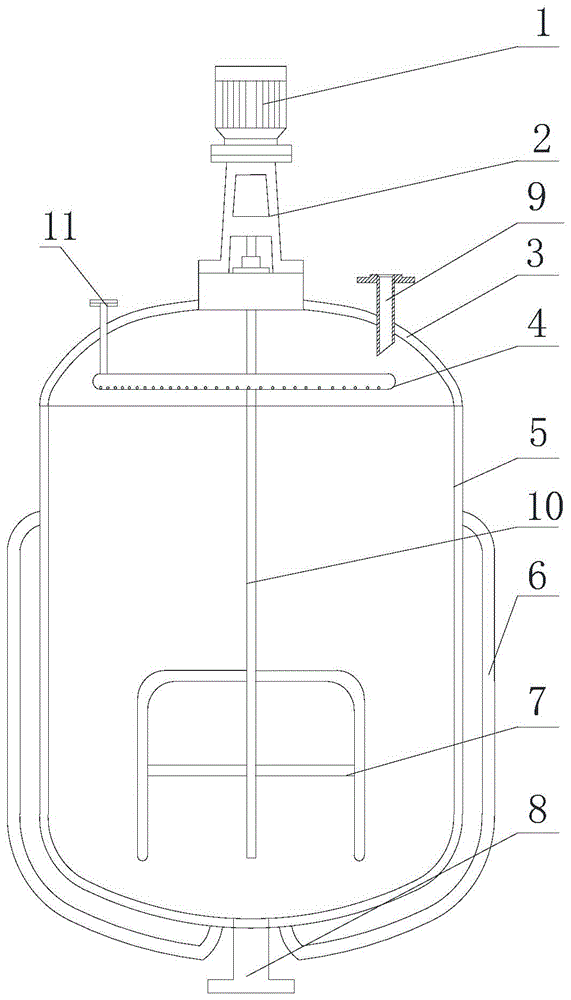

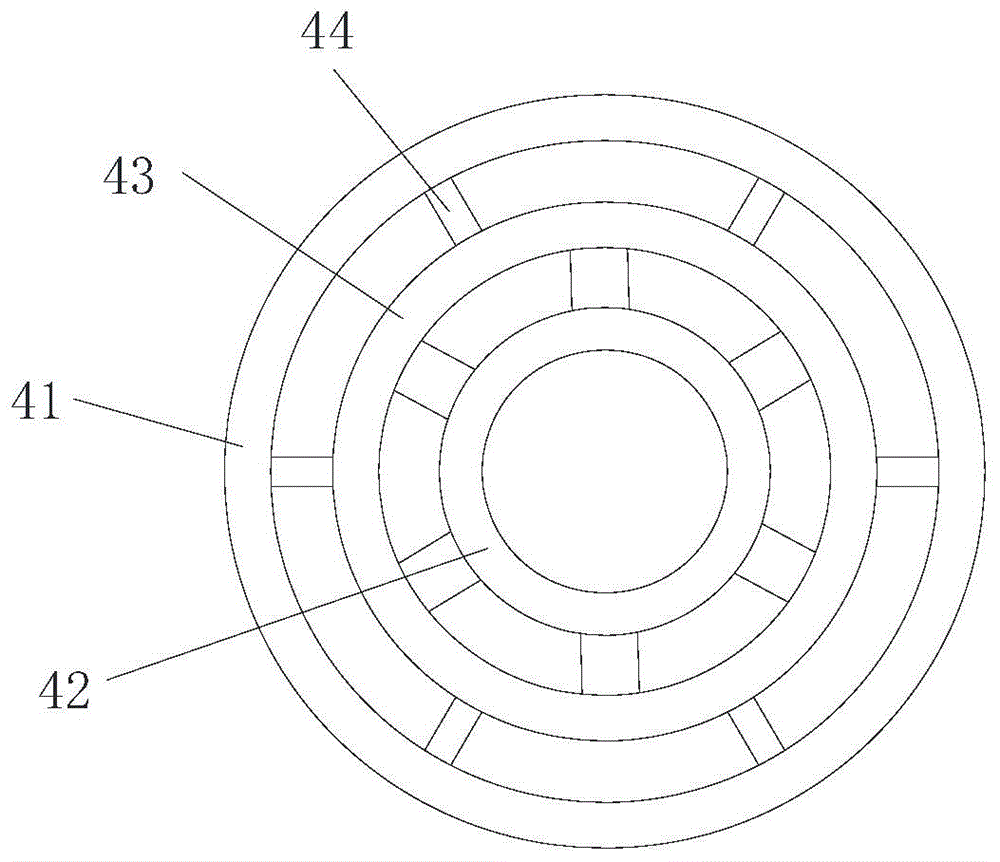

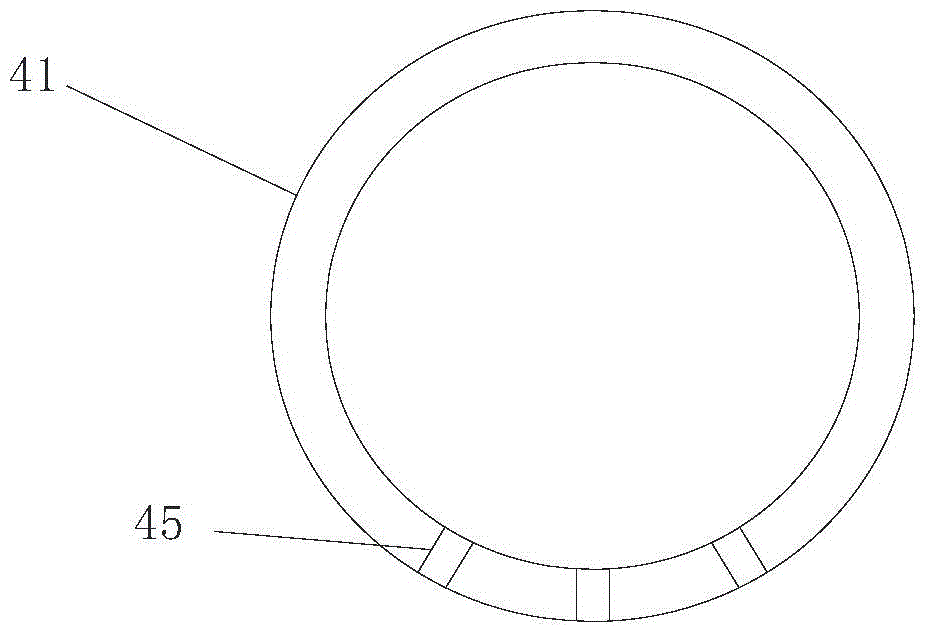

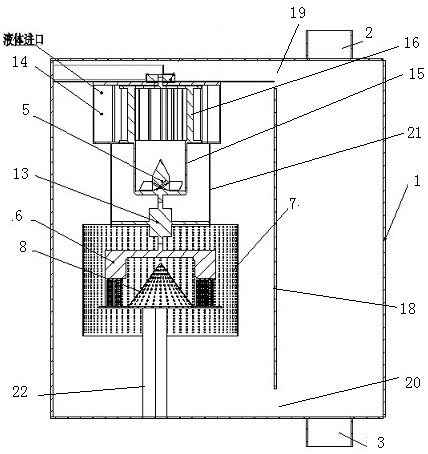

Novel reaction vessel

InactiveCN104587937AExpand coverageGuaranteed effectProcess control/regulationChemical/physical/physico-chemical stationary reactorsEngineering

The invention relates to reaction vessels, and especially relates to a n novel reaction vessel employing a gas for removing foams. The novel reaction vessel comprises a vessel body, the lower end of the vessel body is provided with a material outlet, the periphery of the vessel body is encircled by a jacket, and the top of the vessel body is connected with a vessel cover; the vessel cover is provided with a material inlet, and the center of the vessel cover is provided with a support; the top of the support is connected with a stirring motor; the stirring motor is connected with a stirring shaft stretching into the vessel body; the stirring shaft is provided with a stirrer; and the novel reaction vessel is characterized in that the top part in the vessel body is provided with a gas foam-removal pipe; the gas foam-removal pipe comprise an outer annular pipe, a medium annular pipe and an inner annular pipe; connection pipes are arranged between the outer annular pipe and the medium annular pipe, and between the medium annular pipe and the inner annular pipe; the lower surfaces of the outer annular pipe, the medium annular pipe and the inner annular pipe are uniformly provided with spray holes; and the vessel body is provided with a gas inlet pipe connected with the gas foam-removal pipe.

Owner:YADENG OPTOELECTRONICS TECH JIANGSU

Preparation method of 996 aluminum oxide ceramic substrate

ActiveCN114538899APromote densificationPromote growthAuxillary shaping apparatusClay mixing apparatusOxide ceramicSlurry

The invention relates to the technical field of ceramic substrates, and provides a preparation method of a 996 aluminum oxide ceramic substrate, which comprises the following steps: (1) preparing a sintering aid; (2) preparing slurry; (3) tape casting and stamping; (4) discharging glue; and (5) sintering. The formula and the process of the aluminum oxide ceramic are optimized, the content of aluminum oxide is increased to 99.6%, and the sintering temperature is reduced while the electrical property and the mechanical property of the aluminum oxide ceramic are improved. The problems that 99 porcelain products produced in the prior art are poor in quality stability and the sintering porcelain forming temperature is too high are solved.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

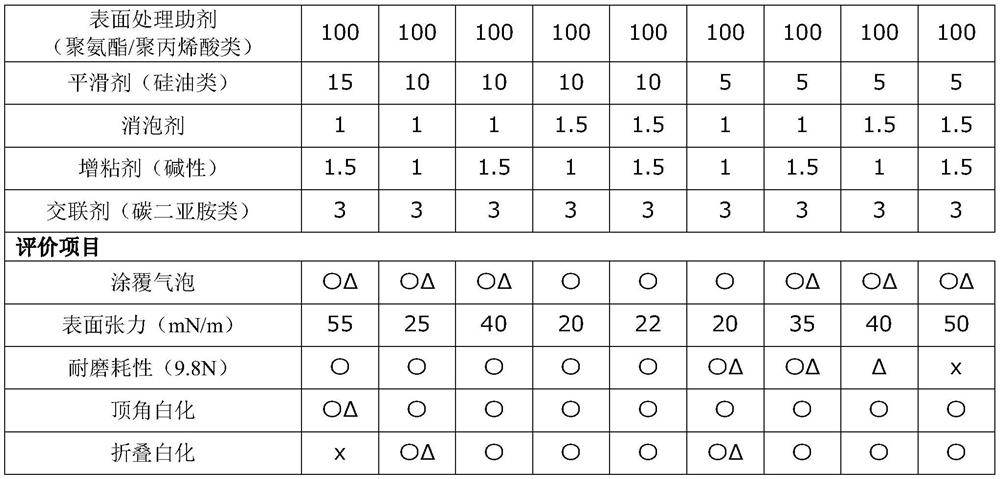

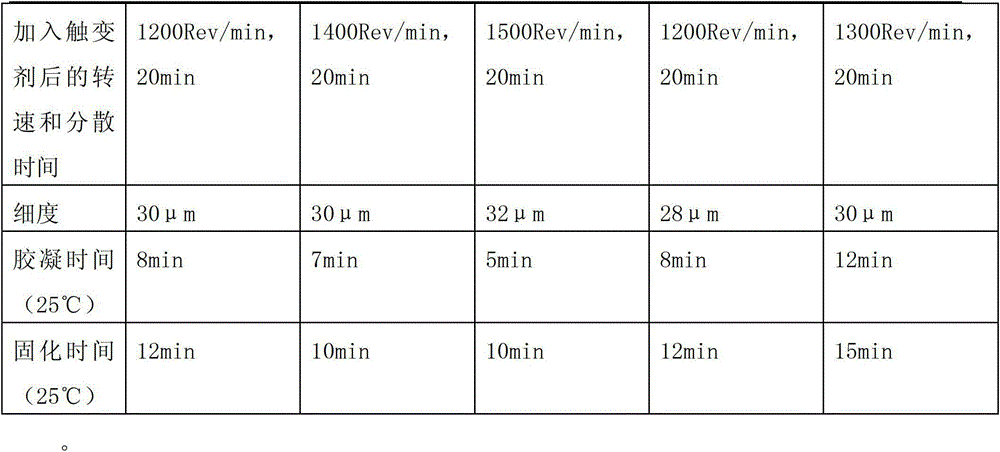

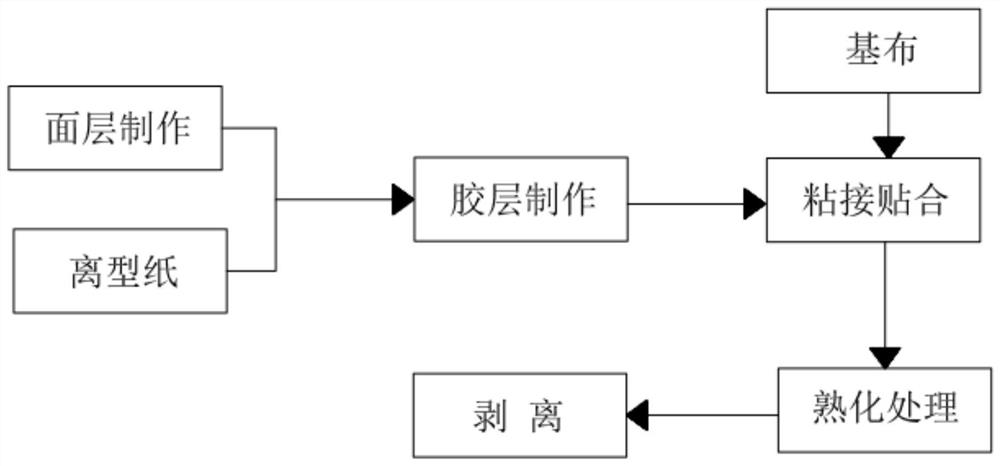

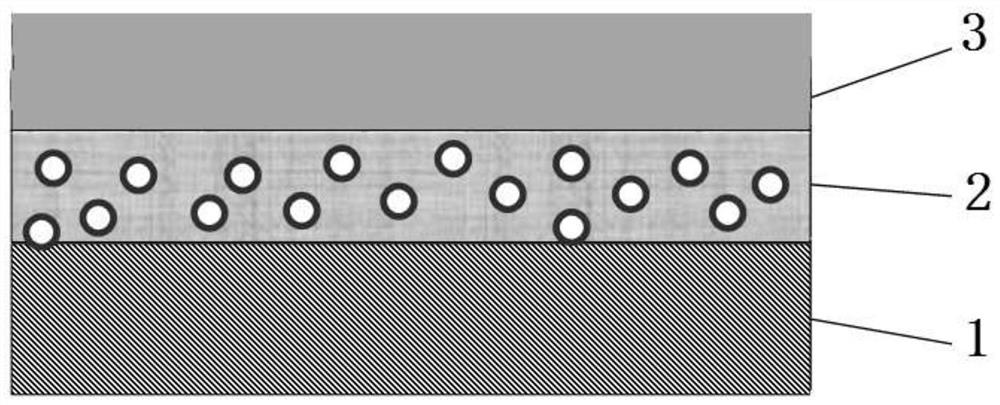

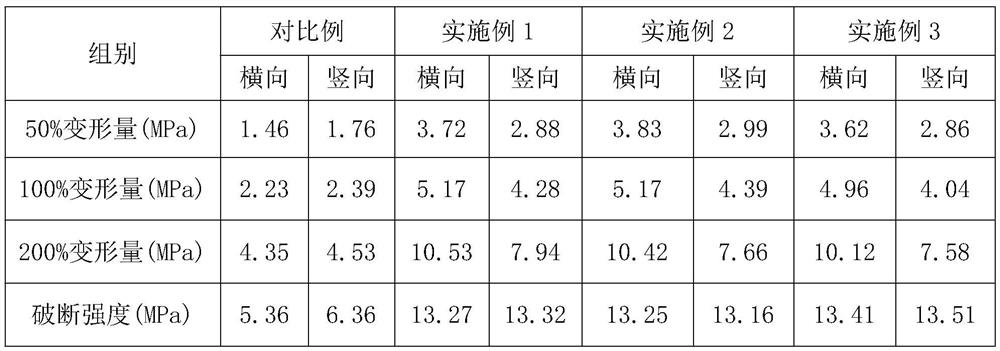

PU (Polyurethane) composite leather and preparation method thereof

PendingCN113605107AStable surface tensionExcellent abrasion resistanceCoatingsTextiles and paperPolymer scienceFire retardant

The invention provides PU (polyurethane) composite leather which comprises a leather blank and a surface treatment layer. The components of the surface treatment layer comprise polyurethane, a bridging agent, a tackifier and a smoothing agent; the leather blank comprises a base cloth layer, a bonding layer and a surface layer; and the material components of the blank comprise polyurethane, a dissolving medium, a hardening agent, a catalyst, a solvent, a flame retardant, a pigment and the like. The invention also provides a preparation method of the composite leather. The preparation method comprises the following steps of preparing the surface layer, preparing the bonding layer, bonding the surface layer, the bonding layer and the base cloth layer together, stripping, curing and treating the surface layer. According to the PU composite leather obtained through the preparation method, the dispersity and the leveling property of the raw materials are fully exerted, the mesh surface of the product is free of black spots and uneven coating, a hand feeling agent is evenly dispersed and free of bubbles, the abradability is excellent, and then the flatness and the high yield of the product are achieved.

Owner:SEIREN SUZHOU CO LTD

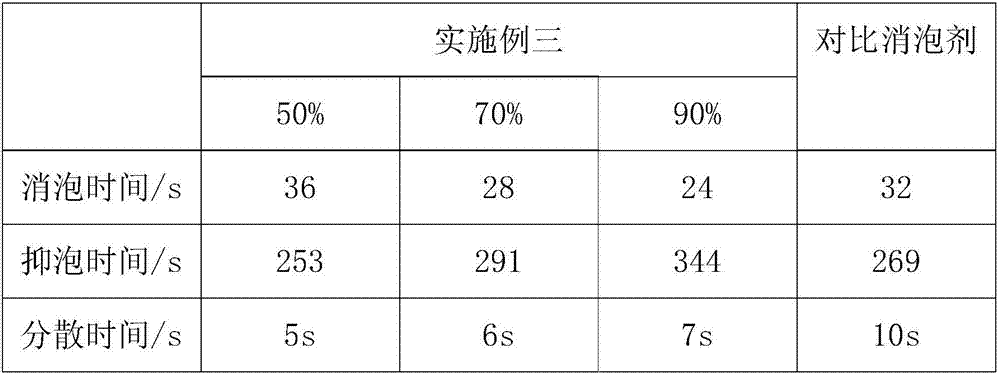

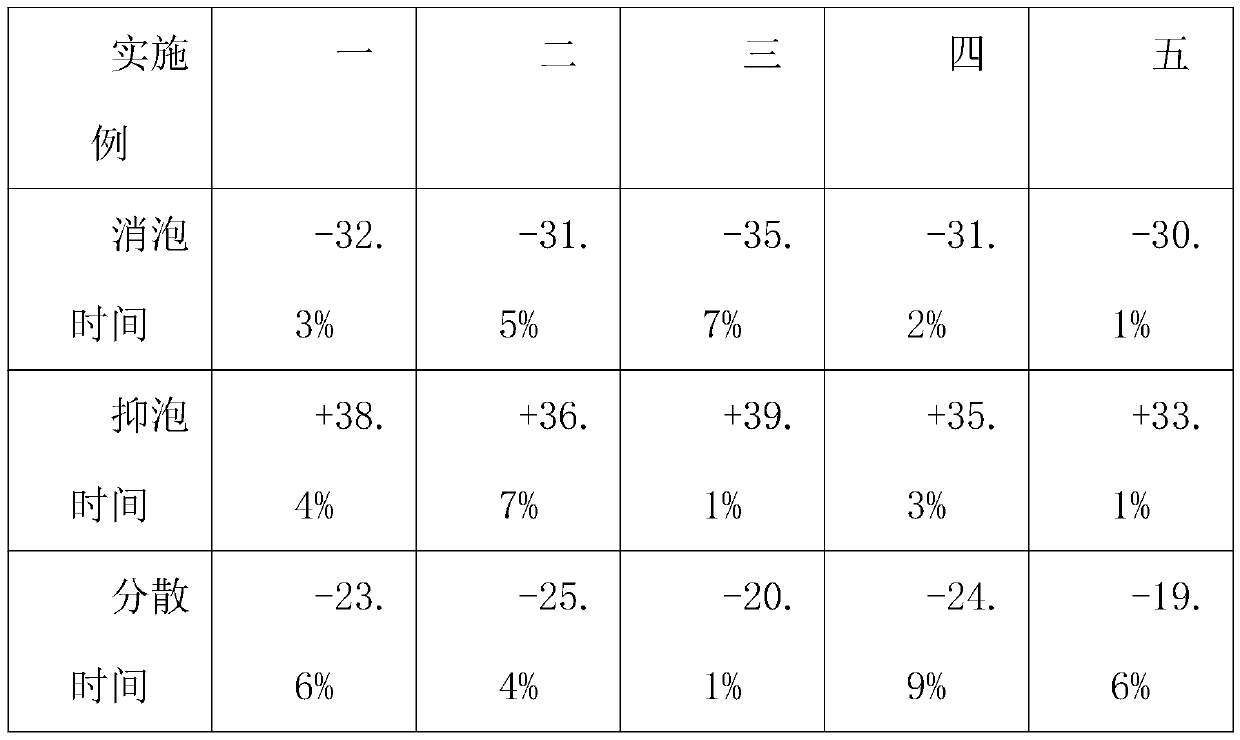

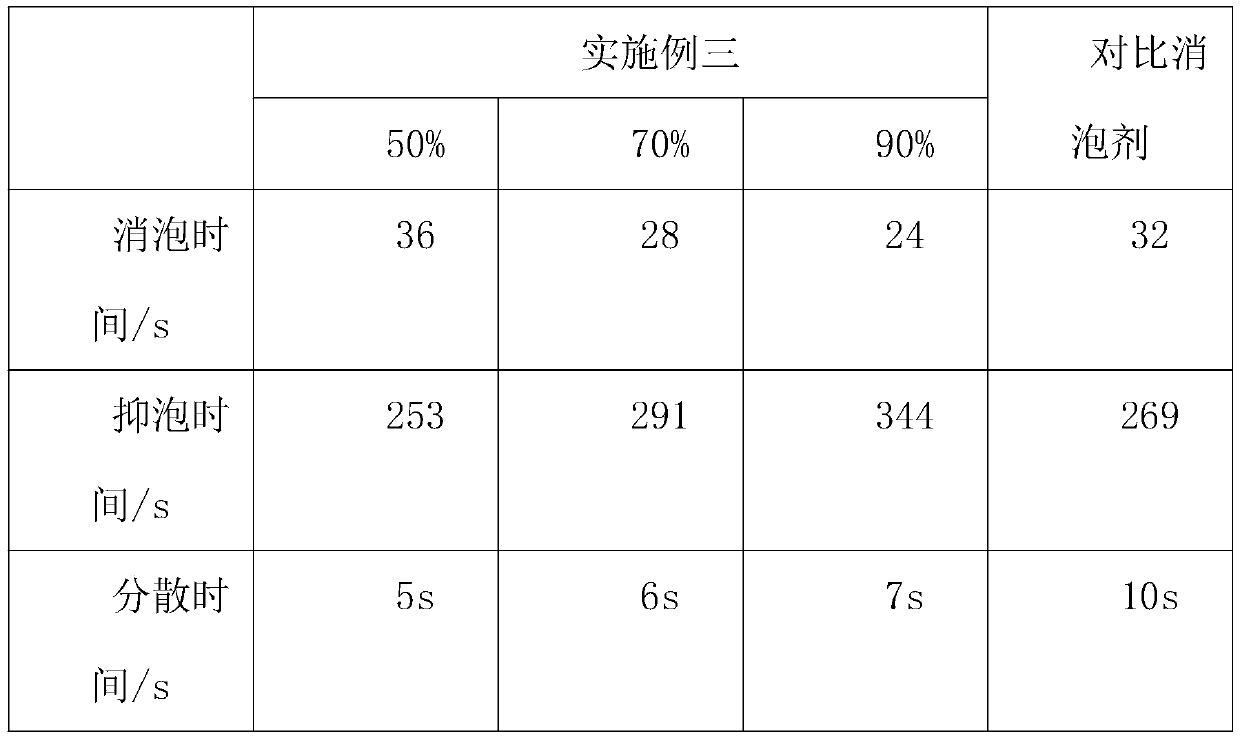

High-efficiency defoaming agent and preparation method thereof

ActiveCN107497140AStable in natureGood defoaming effectFoam dispersion/preventionDefoaming AgentsGlycerol monostearate

The invention belongs to the technical field of chemical preparations, and particularly relates to a high-efficiency defoaming agent and a preparation method thereof, which solves the problems in the prior art that the defoaming efficiency is low, the requirement on preparation equipment is strict, and the preparation process has safety potential hazard. The high-efficiency defoaming agent is prepared from the following raw materials: organosiloxane, dimethicone, hexenyl distearic amide, glycerol monostearate, molybdenum disulfide, montmorillonite powder, metal oxide, charcoal powder, inorganic salt, surfactant and polyvinylether. The preparation method comprises the following steps: S1, mixing dimethicone and polyvinylether, and adding organosiloxane; S2, slowing down, adding the hexenyl distearic amide, glycerol monostearate and surfactant, speeding up, adding the montmorillonite powder, molybdenum disulfide, charcoal powder and inorganic salt, then adding a 4A molecular sieve and metal oxide, thus obtaining the high-efficiency defoaming agent. The defoaming agent disclosed by the invention is stable in performance, good in defoaming effect, small in consumption amount, simple in preparation method, low in equipment requirement and safe in production process.

Owner:NINGBO SHUNZE RUBBER

Water wheel centrifugal defoaming device

ActiveCN111841085BPrevent splashAffect the separation effectLiquid degasification by filtrationWater wheelEngineering

Owner:AVIC WEIHAI SHIPYARD

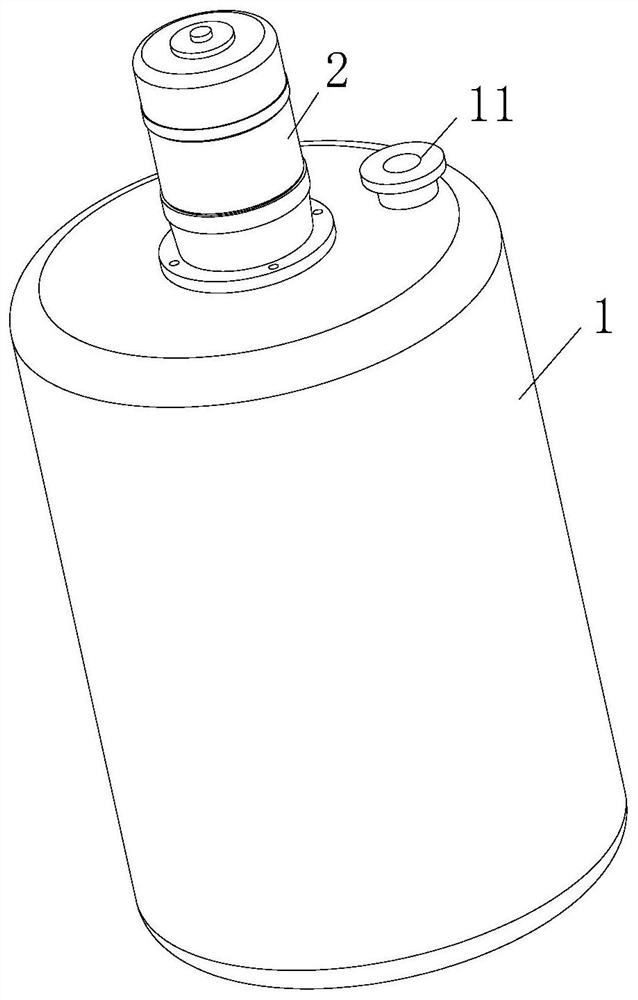

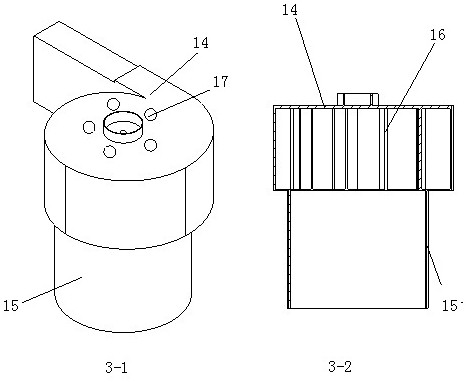

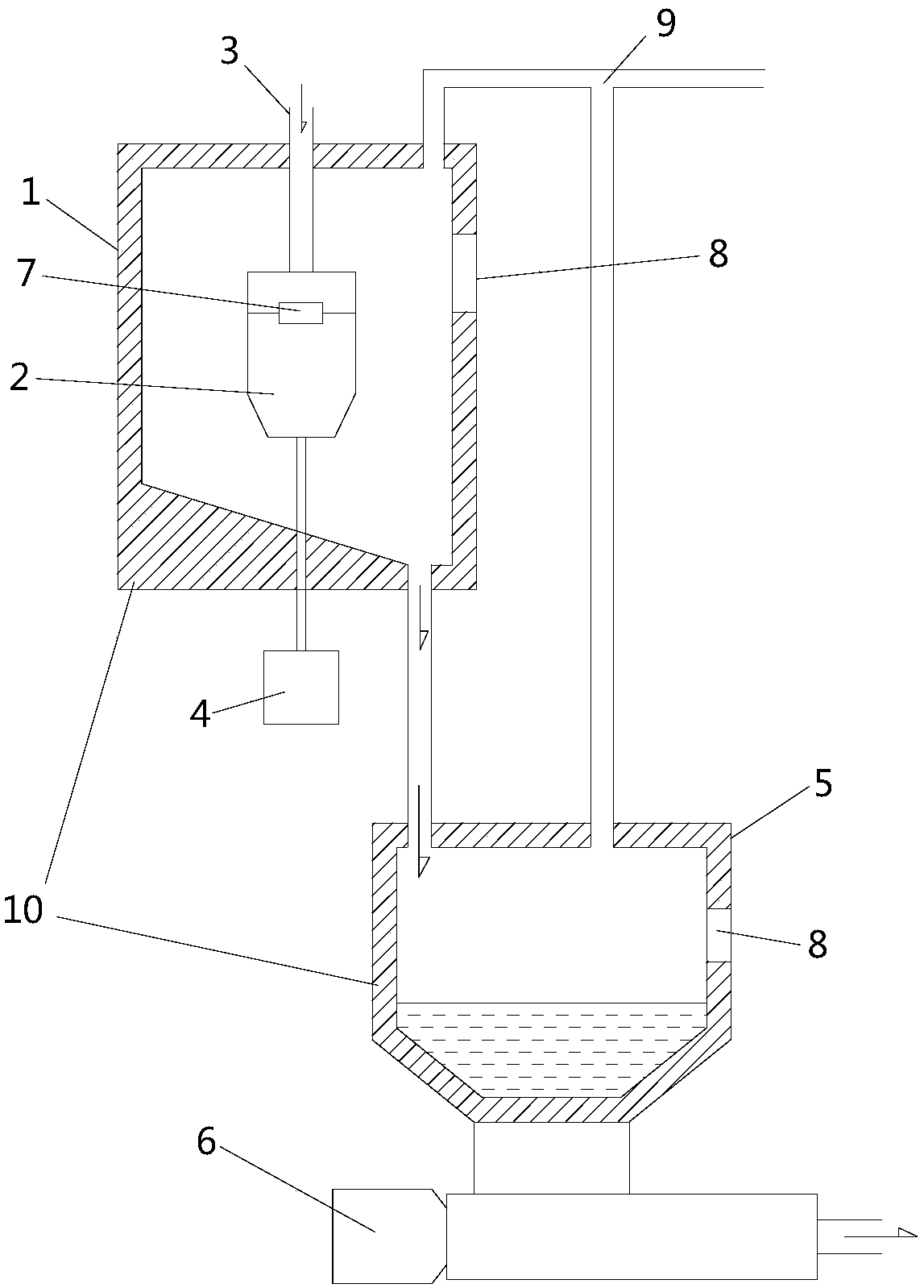

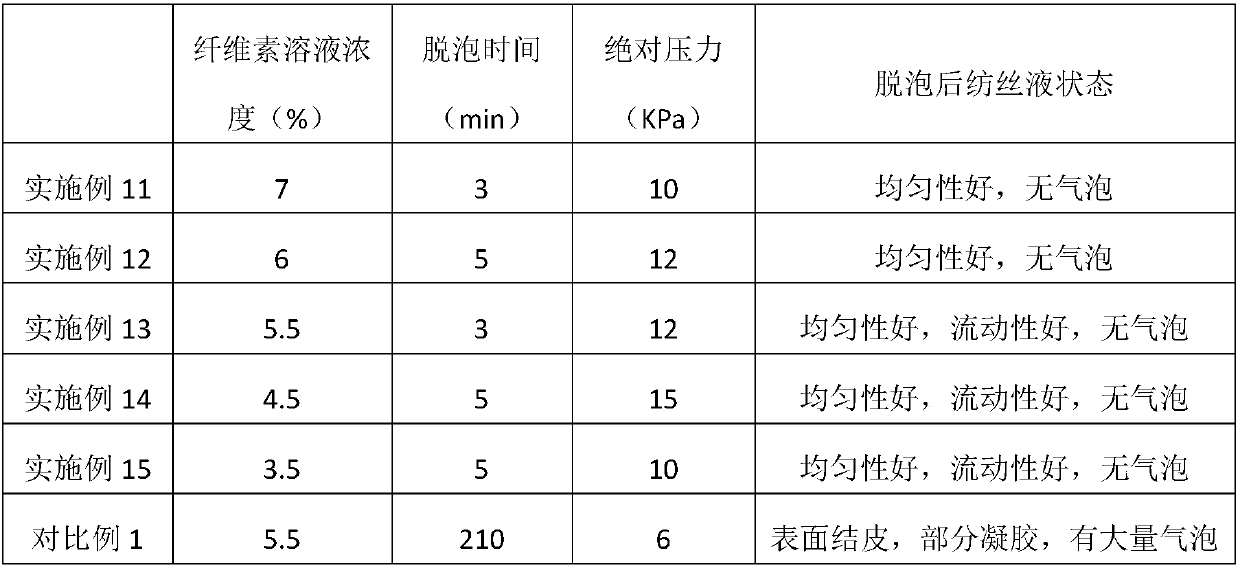

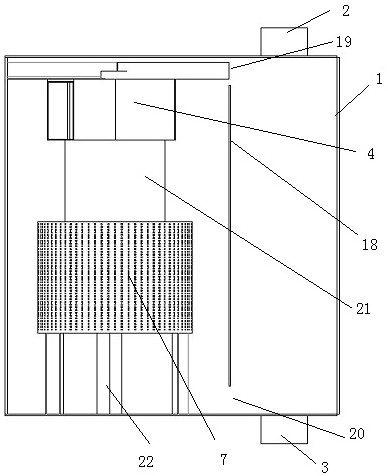

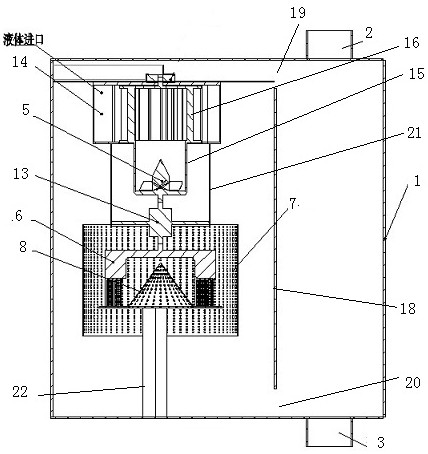

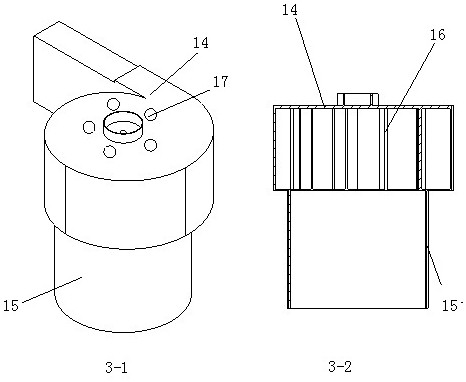

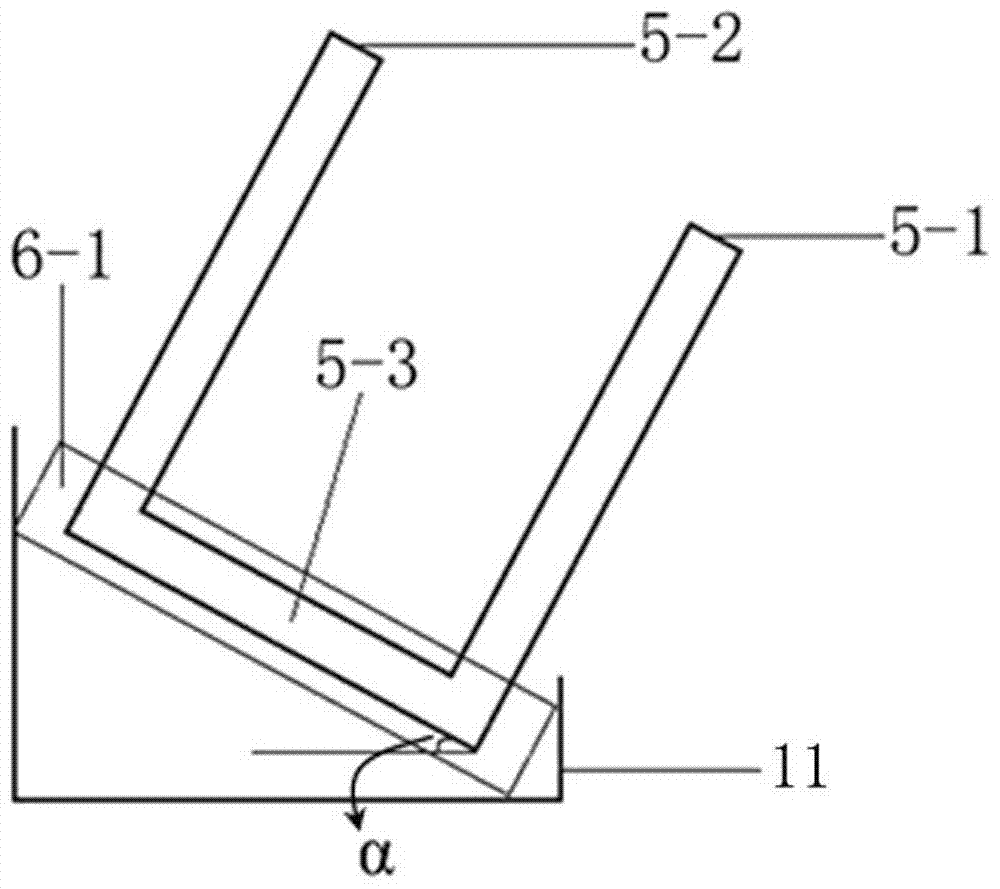

Defoaming device for cellulose solution, and defoaming method of defoaming device

PendingCN109957844AAvoid destructionImprove defoaming efficiencySpinning solution filteringCelluloseEngineering

The invention discloses a defoaming device for a cellulose solution, and a defoaming method of the defoaming device. The defoaming device comprises an outer barrel, a material barrel, a speed regulation device, a liquid inlet pipe and a material storage device, wherein the outer barrel is configured into a main body of the defoaming device; a liquid outlet is formed in the bottom of the outer barrel; the material barrel is arranged in the outer barrel and is provided with a through hole; the speed regulation device is used for driving the material barrel to make centrifugal movement; the liquid inlet pipe passes through the outer barrel and feeds a solution into the material barrel; the material storage device is communicated with the liquid outlet formed in the bottom of the outer barrel,and is arranged at the position lower than the outer barrel; a discharge device is arranged at the bottom of the material storage device. The defoaming device, which is simple in structure and easy to operate, for the cellulose solution has the characteristics of being high in defoaming efficiency, realizing continuous defoaming, and guaranteeing the continuous proceeding of the subsequent spinning; material conveying is not affected by a defoaming process, and efficient defoaming and continuous production are carried out at the same time; furthermore, the defoaming method is good in effect;the defoaming device for the cellulose solution can be used for producing a spinning solution with good stability and evenness, and does not produce gel.

Owner:CHINESE TEXTILE ACAD

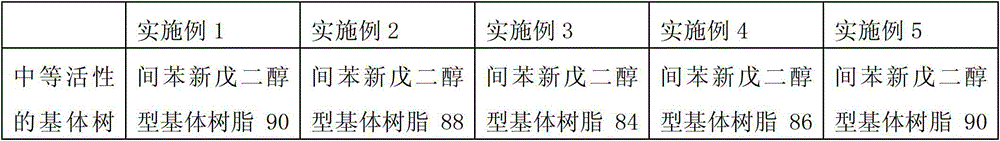

Color gel coat for sanitary ware and preparation method thereof

ActiveCN103013306BRich in colorImprove thermal shock resistancePolyester coatingsMulticolor effect coatingsPolyresinGelcoat

The invention discloses a colored gel coat for sanitary ware and a manufacturing method of the colored gel coat. The colored gel coat for the sanitary ware is manufactured by components including, by weight, 100 parts of matrix resin, 8-20 parts of styrene, 10-30 parts of functional filler, 2-3 parts of thixotropic agent, 0.12-0.2 part of thixotropic stabilizer, 0.6-1.2 parts of surface auxiliaries, 10-20 parts of color paste and 0.1-0.4 part of accelerator. The manufacturing method includes weighing the components for use according to formula; firstly placing the matrix resin into a dispersing reactor, adding the functional filler with stirring, dispersing after adding, adding the thixotropic stabilizer, adding the thixotropic agent with stirring, dispersing after adding and obtaining the matrix gel coat; adding the color paste, the styrene, the surface auxiliaries and the accelerator into the gel coat, and uniformly stirring to obtain the colored gel coat for the sanitary ware. The colored gel coat for the sanitary ware is colorful and has excellent resistance to heat and cod impact.

Owner:CHANGZHOU ZHONGJIE COMPOSITES

Soft transparent polyurethane surface film and preparation method thereof

PendingCN111979789AExcellent light aging resistanceExcellent abrasion resistanceTextiles and paperPhoto agingPolymer science

The invention provides a soft transparent polyurethane surface film. The surface film comprises base cloth, an adhesive layer and a surface layer, wherein the adhesive layer is arranged between the base cloth and the surface layer, and the base cloth and the surface layer are bonded together through the adhesive layer, and each of the surface layer and the adhesive layer contains polyurethane, a bridging agent, a thickener, a leveling agent and a defoamer; and meanwhile, the invention further provides a preparation method of the light, thin and flexible polyurethane surface film, wherein the method comprises the steps of manufacturing the surface layer, manufacturing the adhesive layer, bonding the adhesive layer and the base cloth together, curing and stripping, and by improving components of all the layers, the abrasion resistance, the breaking resistance and the transparency of the surface film are enhanced. In addition, the surface film also has an excellent light aging resistanceeffect, so that the phenomena of aging, peeling, cracking and the like of a product after long-term solarization are avoided.

Owner:SEIREN SUZHOU CO LTD

Water wheel centrifugal defoaming device

ActiveCN111841085AGuaranteed defoaming effectPrevent splashLiquid degasification by filtrationEnvironmental geologyWater wheel

The invention relates to the technical field of marine defoaming, in particular to a water wheel centrifugal defoaming device. The water wheel centrifugal defoaming device is provided with a shell, anair outlet and a liquid outlet are formed in the upper side and the lower side of the shell respectively, and the water wheel centrifugal defoaming device is characterized in that a defoaming assembly is arranged in the shell and comprises a volute flow guide cover, a water wheel rotor, a bubble capturing screen, a bubble filtering screen and a bubble collecting screen; the bubble capturing screen comprises a screen rod and an arc-shaped screen plate, the bubble collecting screen comprises a conical screen and an annular screen, liquid mixed with gas is defoamed three times through the voluteflow guide cover, the bubble capturing screen and the bubble filtering screen, and the water wheel centrifugal defoaming device has the advantages of being simple in structure, convenient to use, capable of saving energy, good in defoaming effect and the like.

Owner:AVIC WEIHAI SHIPYARD

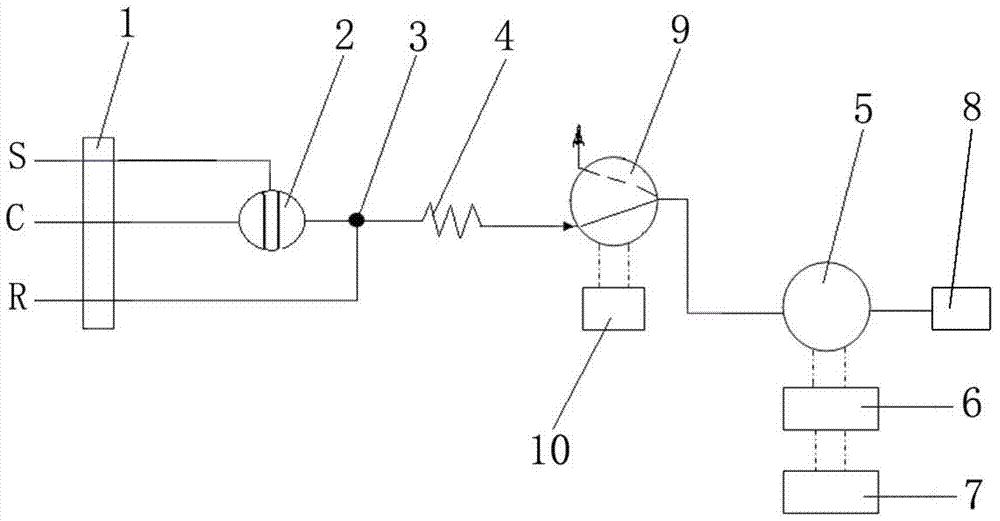

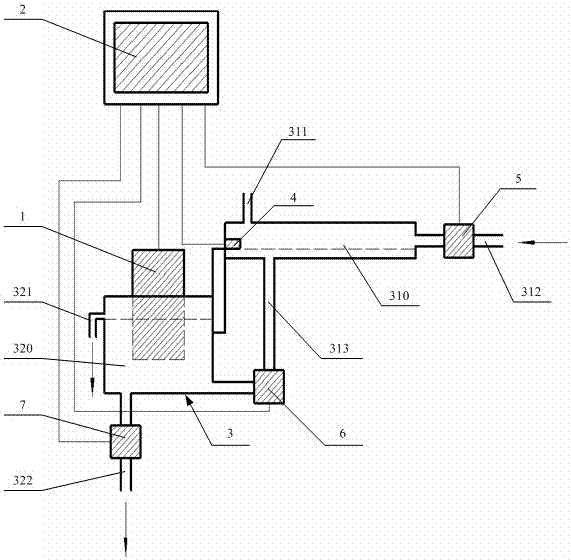

Flow injection analysis device with exhaust function and exhaust method during flow injection analysis

InactiveCN105445484BSimplified exhaust operationImprove the exhaust effectMaterial analysisSolenoid valveOptical flow

The invention provides a flow injection analysis apparatus with exhausting function. The apparatus comprises a low pressure pump, a six-way injection valve, a first mixer, a reactor, an optical flow cell, an optical detector, a computer processing system, a waste liquid container, a solenoid valve and a time relay which is matched with the solenoid valve. The invention also provides an exhausting method for flow injection analysis; the method is used for the flow injection analysis apparatus with exhausting function, and can be used for realizing hand-operated exhaust or automatic on-line exhaust during the flow injection analysis process; the exhaust operation is simple, the exhaust effect is good, and the analysis efficiency is improved.

Owner:SICHUAN UNIV

A kind of silicone defoamer for PVC and preparation method thereof

ActiveCN110013690BImprove stabilityExtended storage timeFoam dispersion/preventionFoaming agentEther

The invention discloses an organosilicon defoamer for PVC and a preparation method thereof, and relates to an industrial defoamer. The organosilicon defoamer of the present invention comprises the following components by mass percentage: 10-20% of the main defoamer; 5-10% of the auxiliary defoamer; 1-2% of suspended and stable water; 70-80% of deionized water ; Acid-base regulator 1 to 3%. The preparation method is as follows: first, add the stabilized jelly mother liquid into the ion-free water, stir for 15-20 minutes, add an acid-base regulator, slowly adjust the pH of the stabilized water to 6-7, and the solution becomes transparent when the pH of the stabilized water is stable , and then add the main defoamer modified silicon and the auxiliary defoamer water-soluble ether, stir for 25 to 30 minutes, and finally prepare the silicone defoamer through shearing treatment. The organosilicon antifoaming agent for PVC of the present invention can make the antifoaming agent have a good antifoaming effect under high temperature conditions, and the production process is simple and the storage is stable.

Owner:乌鲁木齐市华泰隆化学助剂有限公司

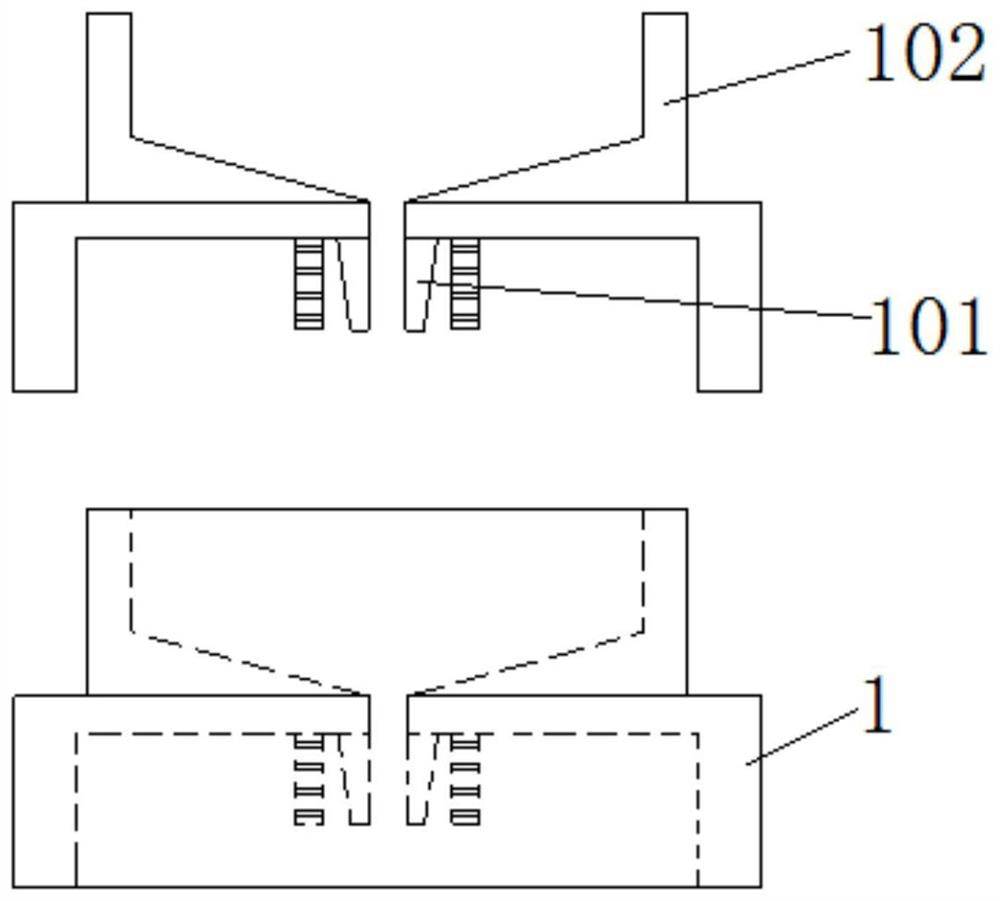

A defoaming, stirring and filling jig for conductive adhesive and its installation and use method

ActiveCN110215859BIncrease profitSpillover does not occurFlow mixersMixer accessoriesMechanical engineeringLuting agent

This application discloses a defoaming stirring and filling jig for conductive adhesive and its installation and use method. The base of the defoaming stirring and filling jig has a sealing mouth, and the sealing mouth has a tank connecting screw , There are bayonet pins and limit pins on the outer wall of the tank body, the middle part of the tank body is covered with a limit ring, and there is a card slot on the inner wall of the limit ring, the bayonet pin is in the slot, and the limit pin supports the bottom of the limit ring. The installation pin of the limit ring is set in the installation groove of the stirring device; there is a stirring sealing cover at the top opening of the tank body, and there is a knob on the top of the stirring sealing cover; there is a filling nozzle sealing cover on the sealing nozzle at the bottom of the base; The ring is set outside the tank; there is a propulsion rod inside the tank; it can solve the problems existing in the prior art, such as low fixture stirring efficiency, difficulty in mixing the glue evenly, low utilization rate of the glue, easy overflow and leakage of the glue, and glue Filling is inconvenient and easy to trap air, which will lead to problems such as deterioration of the defoaming effect.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

A kind of high-efficiency defoamer and preparation method thereof

ActiveCN107497140BStable in natureGood defoaming effectFoam dispersion/preventionDefoaming AgentsGlycerol monostearate

The invention belongs to the technical field of chemical preparations, and particularly relates to a high-efficiency defoaming agent and a preparation method thereof, which solves the problems in the prior art that the defoaming efficiency is low, the requirement on preparation equipment is strict, and the preparation process has safety potential hazard. The high-efficiency defoaming agent is prepared from the following raw materials: organosiloxane, dimethicone, hexenyl distearic amide, glycerol monostearate, molybdenum disulfide, montmorillonite powder, metal oxide, charcoal powder, inorganic salt, surfactant and polyvinylether. The preparation method comprises the following steps: S1, mixing dimethicone and polyvinylether, and adding organosiloxane; S2, slowing down, adding the hexenyl distearic amide, glycerol monostearate and surfactant, speeding up, adding the montmorillonite powder, molybdenum disulfide, charcoal powder and inorganic salt, then adding a 4A molecular sieve and metal oxide, thus obtaining the high-efficiency defoaming agent. The defoaming agent disclosed by the invention is stable in performance, good in defoaming effect, small in consumption amount, simple in preparation method, low in equipment requirement and safe in production process.

Owner:NINGBO SHUNZE RUBBER

A kind of processing method of hundred pages and vegetarian chicken

ActiveCN107439703BAdd lessImprove elimination effectCheese manufactureFoam dispersion/preventionBiotechnologySoybean product

The invention discloses a method for processing fenugreek and vegetarian chicken, and belongs to the technical field of bean product processing. The invention includes the steps of material selection, soaking, pulping, pulping, pulping, beating, pouring, pressing and molding, wherein, in the process of pulping, a defoamer is added, and the defoamer is composed of organic silicon oil, modified soybean lecithin , soybean oil and water. The present invention optimizes the compounding of the components of the defoamer, and at the same time optimizes the design of the processing technology of soy-based department store products such as Baiye or vegetarian chicken, thereby effectively improving the processing process of soybean-made department store products such as Baiye or vegetarian chicken. The antifoaming effect in the middle, and the usage amount of the defoaming agent is small, which can meet the limit requirement of the usage amount of polydimethylsiloxane in the national standard.

Owner:JINCAIDI FOOD CO LTD

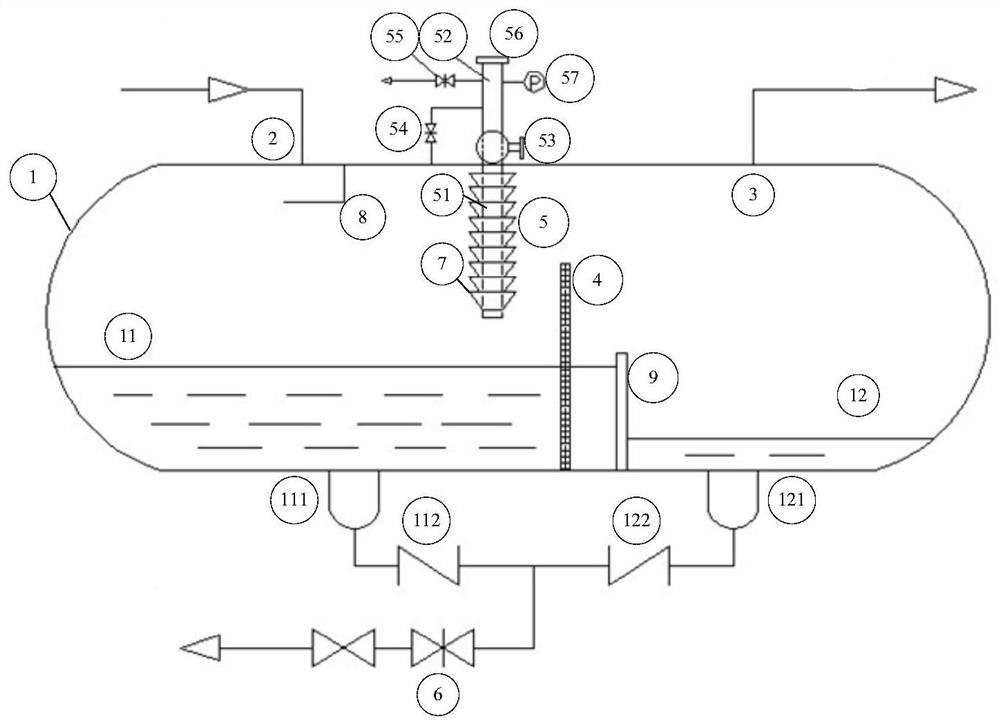

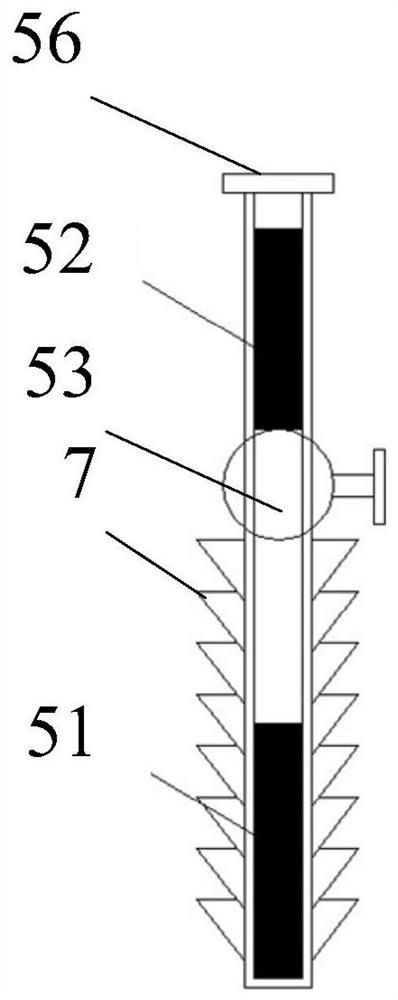

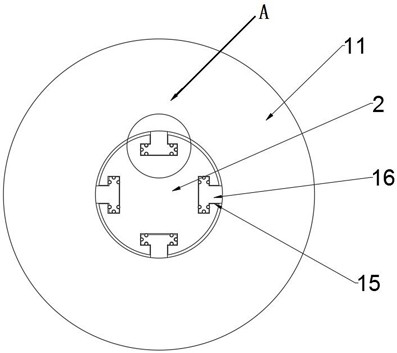

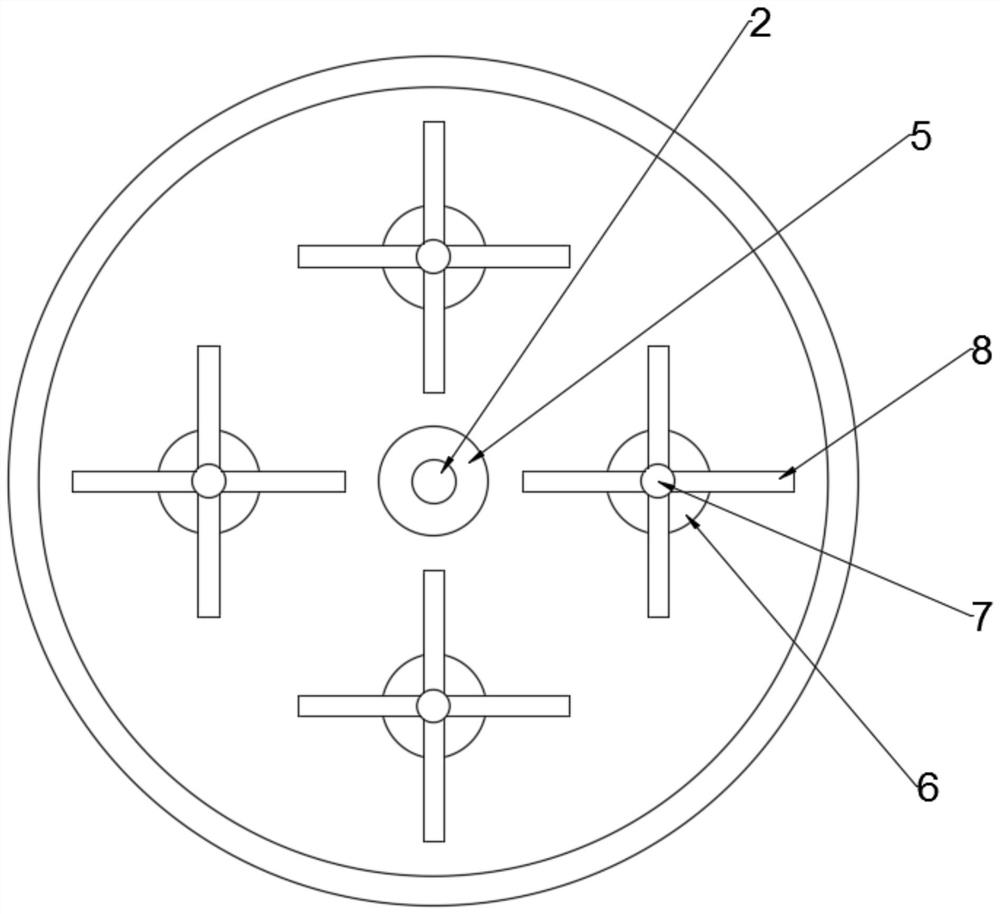

Defoaming device

The invention discloses a defoaming device, and belongs to the field of natural gas production. According to the defoaming device provided by the embodiment of the invention, when the natural gas passes through the defoaming device, the defoaming rod in the defoaming cylinder can perform chemical defoaming on the natural gas, the defoaming wire mesh can perform physical defoaming on the natural gas, and through mutual cooperation of physical defoaming and chemical defoaming, the defoaming effect on the natural gas is improved. Besides, the defoaming rod is placed in the defoaming cylinder, and the defoaming rod is naturally consumed along with the amount of foam in the natural gas, so that the defoaming effect is ensured, the use amount of the defoaming rod is reduced, and the cost is reduced. Moreover, when the defoaming rods are consumed, the technicians can also quickly add the defoaming rods into the defoaming barrel without stopping production, so that the adding efficiency of the defoaming rods is improved, and the yield loss caused by stop production of the added defoaming rods is reduced.

Owner:PETROCHINA CO LTD

Method for deaeration of cellulose ionic liquid solution

ActiveCN101787572BShort stayHigh purityArtificial filaments from cellulose solutionsFilament-forming treatmentCelluloseViscosity

Owner:潍坊欣龙生物材料有限公司

Floating liquid fertilizer preparation device

InactiveCN112495257AAvoid the phenomenonReduce productionShaking/oscillating/vibrating mixersTransportation and packagingElectric machineAgricultural engineering

The invention discloses a floating liquid fertilizer preparation device, belonging to the technical field of fertilizer production. The device comprises a cylinder body, wherein a driving rotating shaft is vertically arranged at the center of the interior of the cylinder body; a speed reducing motor is fixed at the center of the upper side of the cylinder body; the output end of the speed reducingmotor is fixedly connected with the driving rotating shaft; a waterproof cover is fixed to the outer wall of the driving rotating shaft; an annular electromagnet is fixed in the waterproof cover; anda plurality of waterproof bearing seats distributed annularly are fixed to the inner bottom of the cylinder body. Thus, attraction and repulsion effects generated by a magnetic field can be used fordriving stirring mechanisms on the periphery to conduct alternate stirring; the phenomenon that a large number of bubbles are generated due to shearing force generated by continuous rotation of a stirring rod in the prior art is effectively avoided; and the generation amount of the bubbles in a liquid fertilizer stirring process is effectively reduced, the bubbles can be eliminated in the stirringprocess, and the generation amount of the bubbles in the liquid fertilizer production process is greatly reduced.

Owner:陈小刚

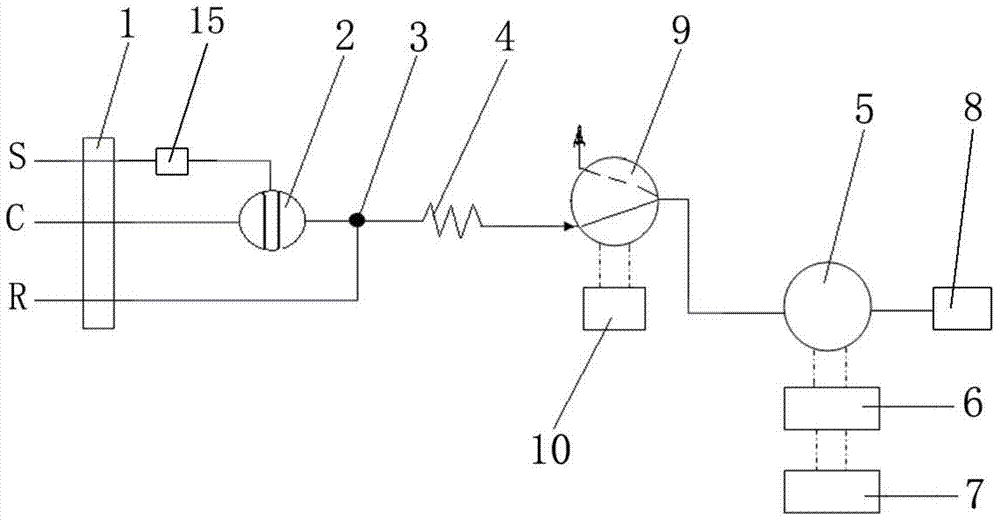

A dual-chamber flow cell turbidity measurement system and its control method

ActiveCN104807753BMiniaturizationTaking into account measurement accuracyMaterial analysis by optical meansControl flowFlow cell

The invention provides a dual-chamber flow cell turbidity measurement system and its control method. The dual-chamber flow cell turbidity measurement system adopts a double-chamber flow cell with a defoaming cavity and a measurement cavity, and the two can be independent of each other. It can effectively take into account the requirements of measurement accuracy, timeliness and system volume miniaturization. At the same time, it can have better adaptability to the measurement environment with large changes in bubble content and turbidity. It provides a new turbidity measurement system. Implementation scheme; at the same time, the measurement control method of the dual-chamber flow cell turbidity measurement system of the present invention has a simple control process, and while ensuring better measurement accuracy, the timeliness of system measurement is further improved; in addition, the present invention The dual-chamber flow cell turbidity measurement system can also realize self-cleaning control and clean the double-chamber flow cell to reduce the influence of the dirt deposited in the double-chamber flow cell on the accuracy of turbidity measurement and reduce false detection rate to improve measurement accuracy.

Owner:CHONGQING ACADEMY OF SCI & TECH

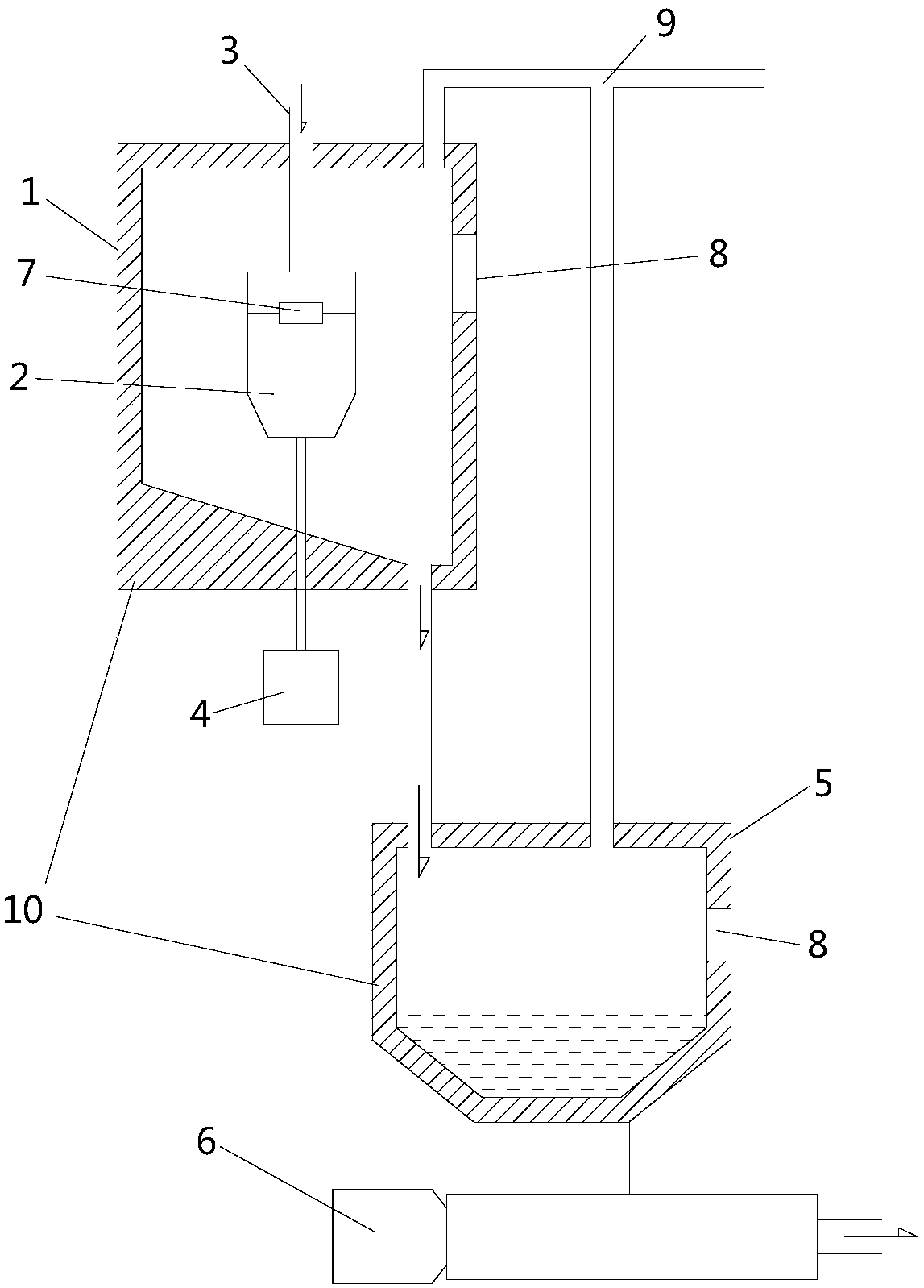

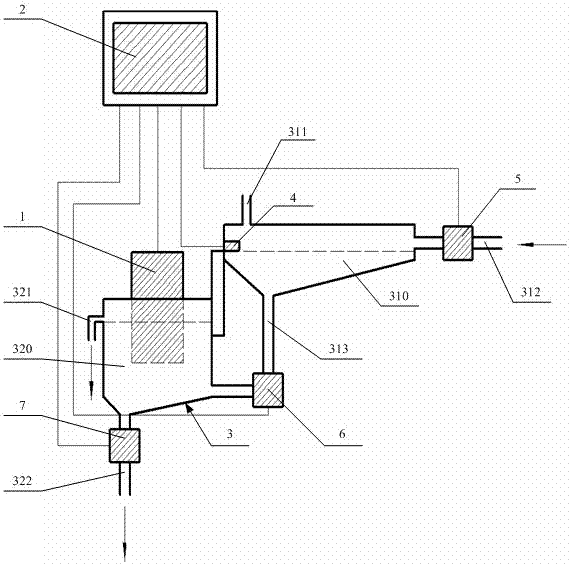

Automatic mucilage glue temperature control system

InactiveCN112111792AGuaranteed defoaming effectEasy to checkFilament-forming treatmentStationary plate conduit assembliesTemperature controlPlate heat exchanger

The invention provides an automatic mucilage glue temperature control system, and particularly relates to the field of automation devices. The automatic mucilage glue temperature control system comprises a mucilage glue heat exchange system, wherein mucilage glue passes through the mucilage glue heat exchange system before entering a defoaming barrel through a ripening process, the mucilage glue heat exchange system is composed of a hot water barrel, a plate heat exchanger and a hot water circulating pump, hot water in the hot water barrel is heated through an external steam pipeline, the hotwater circularly flows between the hot water barrel and the plate heat exchanger through the hot water circulating pump, and the opening degree of a steam valve is adjusted by setting the glue temperature output, the water temperature in the hot water barrel can be increased or decreased, and the constant glue temperature is guaranteed through heat exchange between water and glue in the plate heatexchanger. The gluing quality can be stabilized, the gluing temperature is guaranteed, gluing bubbles are reduced, and yield and quality losses are avoided.

Owner:赛得利(江苏)纤维有限公司

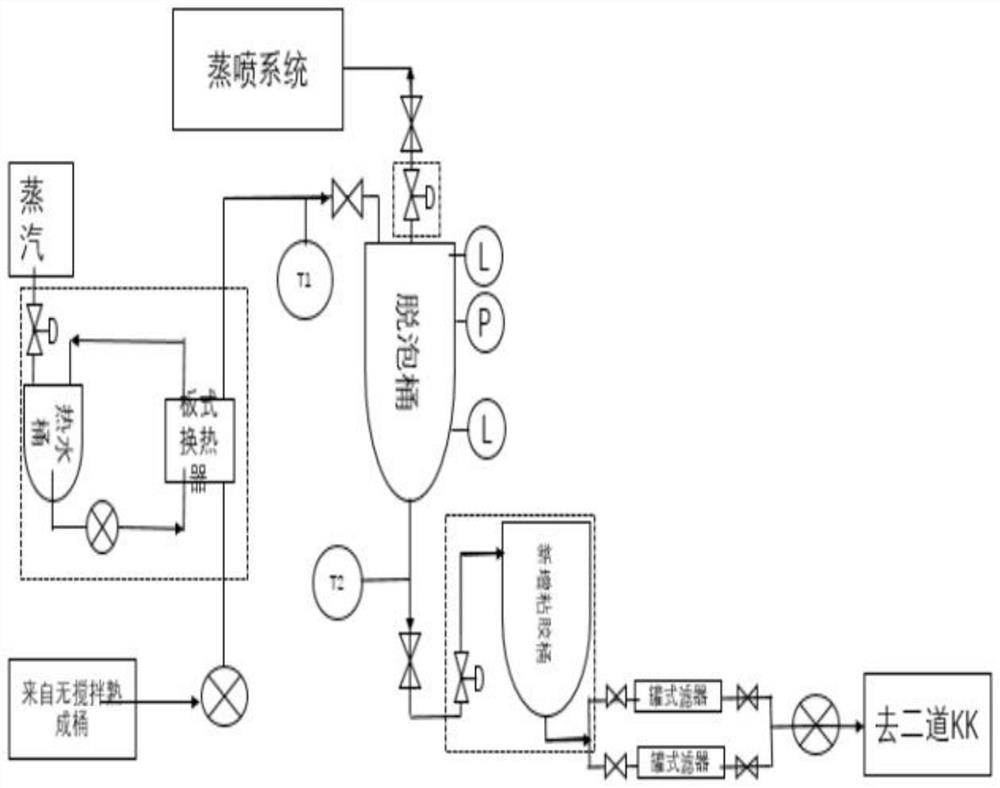

A kind of organosilicon composition, preparation method and application

ActiveCN104274998BGood defoamingGood anti-foam performanceFoam dispersion/preventionHydrogenPolymer science

The present invention relates to a crosslinked network polymer obtained on the basis of an addition reaction of a hydrogen-containing polyorganosiloxane, an organic silicon resin and an unsaturated hydrocarbon, followed by the process of adding a crosslinking agent containing an active group and silicon dioxide; the polymer has an improved defoaming performance, good anti-foaming effect, and is easy to handle and process, and the addition of an emulsifier does not reduce the anti-foaming effect. The polymer has a good anti-foaming performance with no decay, and the polymer formed therefrom can easily be processed.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

A kind of processing method of tofu, soft tofu and old tofu

ActiveCN107348012BMeet the requirements of defoaming effectMeet usage limitsCheese manufactureFood scienceSoybean productSoybean Phospholipids

Owner:JINCAIDI FOOD CO LTD

Self-drying black aluminum mirror coating and preparation method thereof

InactiveCN111363441AStrong adhesionGuaranteed quick dryingAnti-corrosive paintsPolymer scienceBenzoyl peroxide

The invention provides a self-drying black aluminum mirror coating. The self-drying black aluminum mirror coating comprises the following components in percentage by weight: 20-30% of an oil-based resin, 30 to 50 percent of a modified acrylic resin, 5-15% of a pigment, 25-48% of a filler, 3-5% of a 2# solvent and 2-5% of an aid. The substances are uniformly mixed, stirred and ground into the air-drying black aluminum mirror coating. The air-drying type black aluminum mirror coating prepared by the invention adopts an acrylic acid modified resin system, so that the quick drying property and thehigh corrosion resistance are ensured. Meanwhile, dimethylbenzene of benzoyl peroxide is added in the resin polymerization process, the coating has super-strong adhesive force, and in terms of colored paint formula design and pigment and filler selection, pigment and filler containing heavy metal are avoided, in terms of solvent selection, corresponding high-boiling-point and low-boiling-point solvents are adopted according to different temperature and humidity climate conditions, and auxiliaries which do not influence curtain coating are added, so that the defoaming property and leveling property in the construction process are guaranteed.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com