Flow injection analysis device with exhaust function and exhaust method during flow injection analysis

A technology of flow injection and analysis device, applied in the direction of analysis materials, instruments, etc., can solve the problems of cumbersome operation, unfavorable analysis efficiency, limited application scope, etc., to ensure the defoaming effect, simplify the exhaust operation, and achieve a good exhaust effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

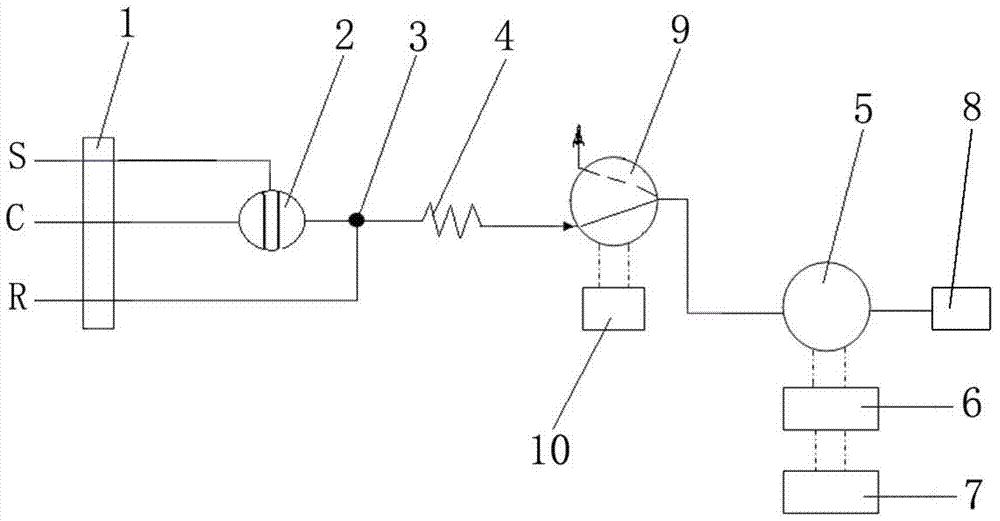

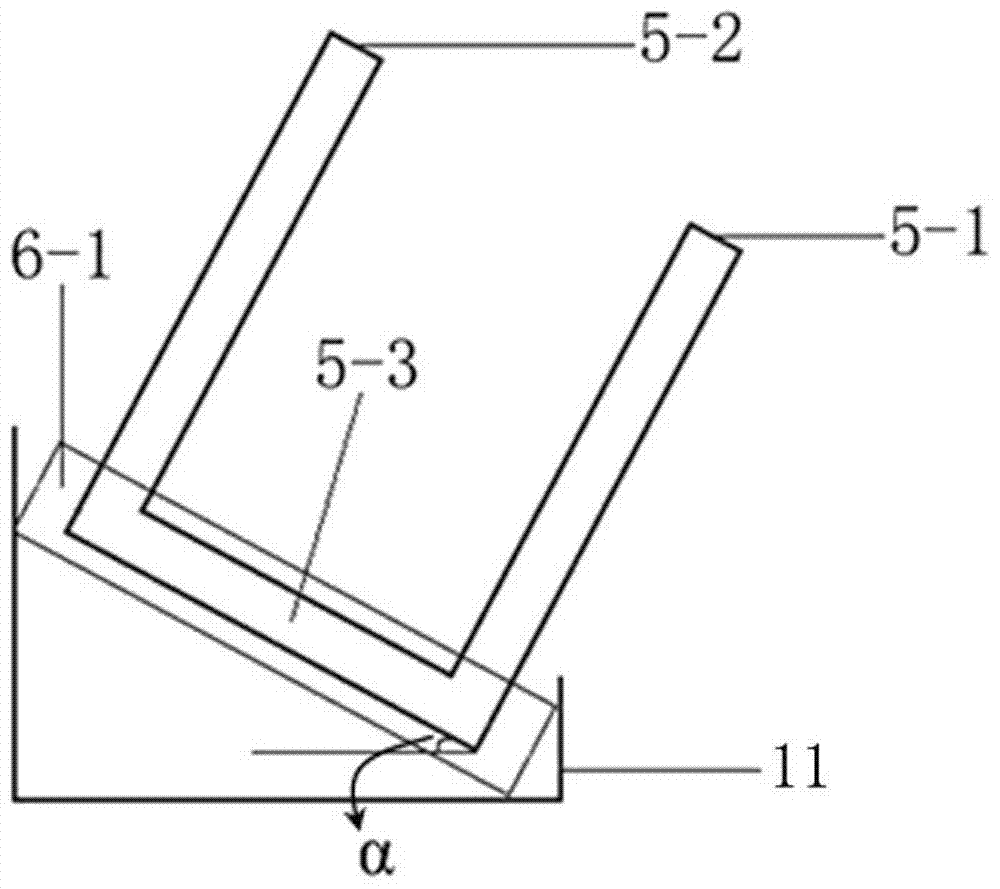

[0038] In this embodiment, the structure of the flow injection analysis device with exhaust function is as follows figure 1 As shown, it includes a low-pressure pump 1, a six-way sampling valve 2, a first mixer 3, a reactor 4, an optical flow cell 5, an optical detector 6, a computer processing system 7 and a waste liquid container 8, and the optical flow cell 5 is a U-shaped optical flow cell, including an optical detection channel 5-3, a liquid inlet channel 5-1 and a liquid outlet channel 5-2 communicated with the optical detection channel, and the optical detector 6 includes an optical system box 6-1 and an optical Signal acquisition and processing system, the optical detection channel 5-3 of the optical flow cell is installed in the optical path system box of the optical detector, the detection light path of the optical detector passes through the optical detection channel 5-3 of the optical flow cell and is connected with the optical flow cell The optical detection chann...

Embodiment 2

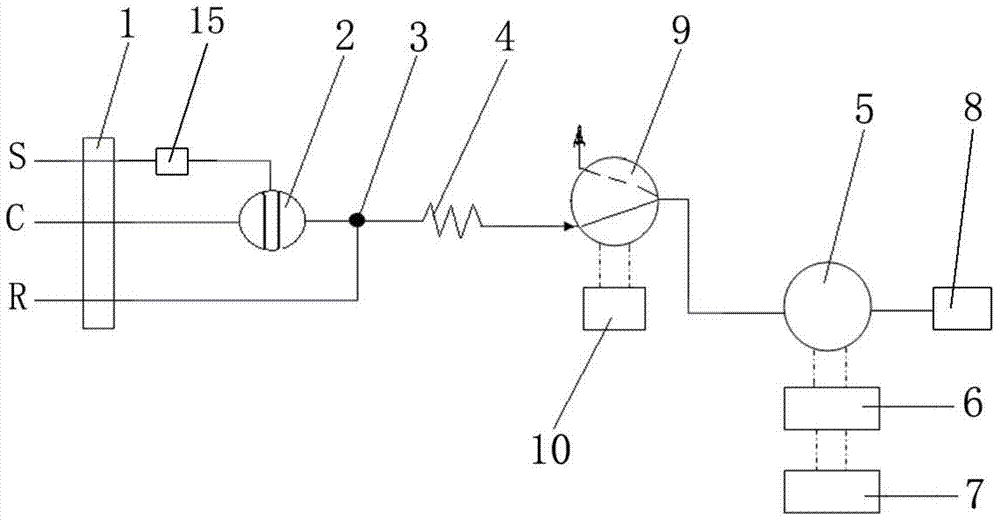

[0044] In this embodiment, the structure of the flow injection analysis device with exhaust function is as follows image 3 As shown, it includes a low-pressure pump 1, a six-way sampling valve 2, a first mixer 3, a reactor 4, an optical flow cell 5, an optical detector 6, a computer processing system 7 and a waste liquid container 8, and the optical flow cell 5 is a U-shaped optical flow cell, including an optical detection channel 5-3, a liquid inlet channel 5-1 and a liquid outlet channel 5-2 communicated with the optical detection channel, and the optical detector 6 includes an optical system box 6-1 and an optical Signal acquisition and processing system, the optical detection channel 5-3 of the optical flow cell is installed in the optical path system box of the optical detector, the detection light path of the optical detector passes through the optical detection channel 5-3 of the optical flow cell and is connected with the optical flow cell The optical detection chann...

Embodiment 3

[0049] In this embodiment, the structure of the flow injection analysis device with exhaust function is as follows Figure 5 As shown, it includes a low-pressure pump 1, a six-way sampling valve 2, a first mixer 3, a reactor 4, an optical flow cell 5, an optical detector 6, a computer processing system 7 and a waste liquid container 8, and the optical flow cell 5 is a U-shaped optical flow cell, including an optical detection channel 5-3, a liquid inlet channel 5-1 and a liquid outlet channel 5-2 communicated with the optical detection channel, and the optical detector 6 includes an optical system box 6-1 and an optical Signal acquisition and processing system, the optical detection channel 5-3 of the optical flow cell is installed in the optical path system box of the optical detector, the detection light path of the optical detector passes through the optical detection channel 5-3 of the optical flow cell and is connected with the optical flow cell The optical detection chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com