Exhaust and detection method of hydraulic brake circuit of brake-by-wire system

A hydraulic brake and brake-by-wire technology, applied in the direction of brake safety system, brake, brake components, etc., can solve problems such as increased workload, vehicle brake safety accident, brake risk, etc., to simplify exhaust The effect of operation, improving the pressure building capacity, and improving the exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

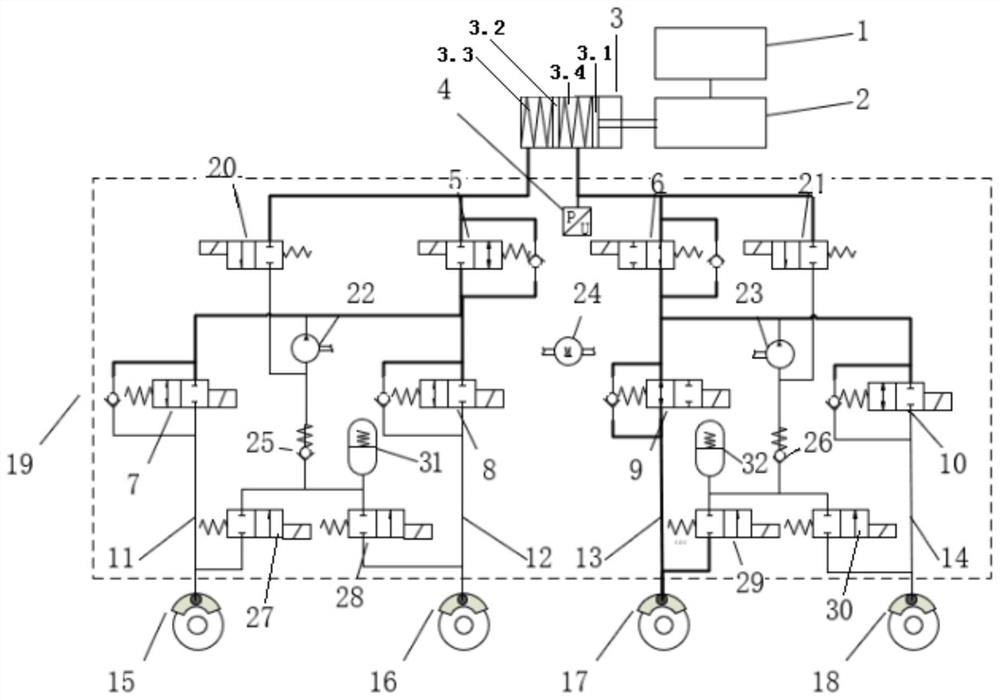

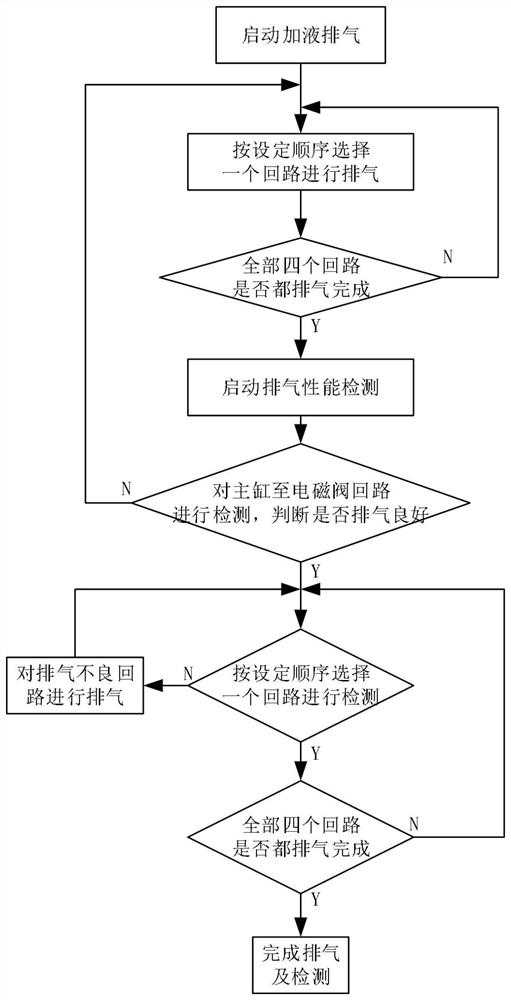

[0019] Such as figure 1 As shown in -2, the exhaust and detection method of the hydraulic brake circuit of the brake-by-wire system is: after the vehicle is started to add fluid and exhaust, first pressurize the left front wheel pipeline (the third brake pipeline 13) exhaust.

[0020] The ESC controller controls the first pressure limiting valve 5 to close, the second pressure limiting valve 6 to open, the first boost valve 7 to close, the second boost valve 8 to close, the third boost valve 9 to open, and the fourth boost valve 10 closure. Brake fluid cannot enter the first brake pipeline 11 , the second brake pipeline 12 and the fourth brake pipeline 14 . The electric power-assisted driving mechanism pushes the first piston 3.1 of the brake master cylinder 3 to move forward, and the brake fluid is discharged from the liquid outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com