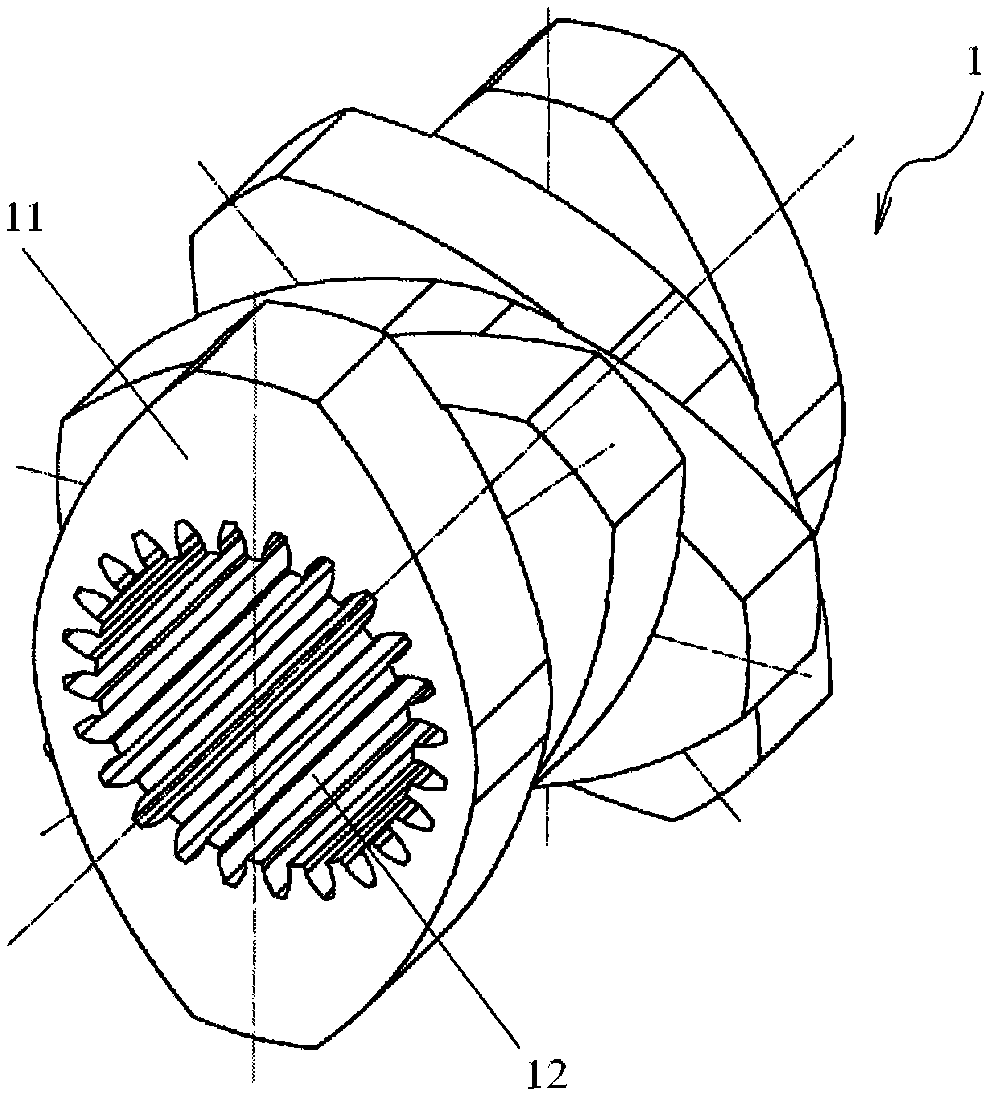

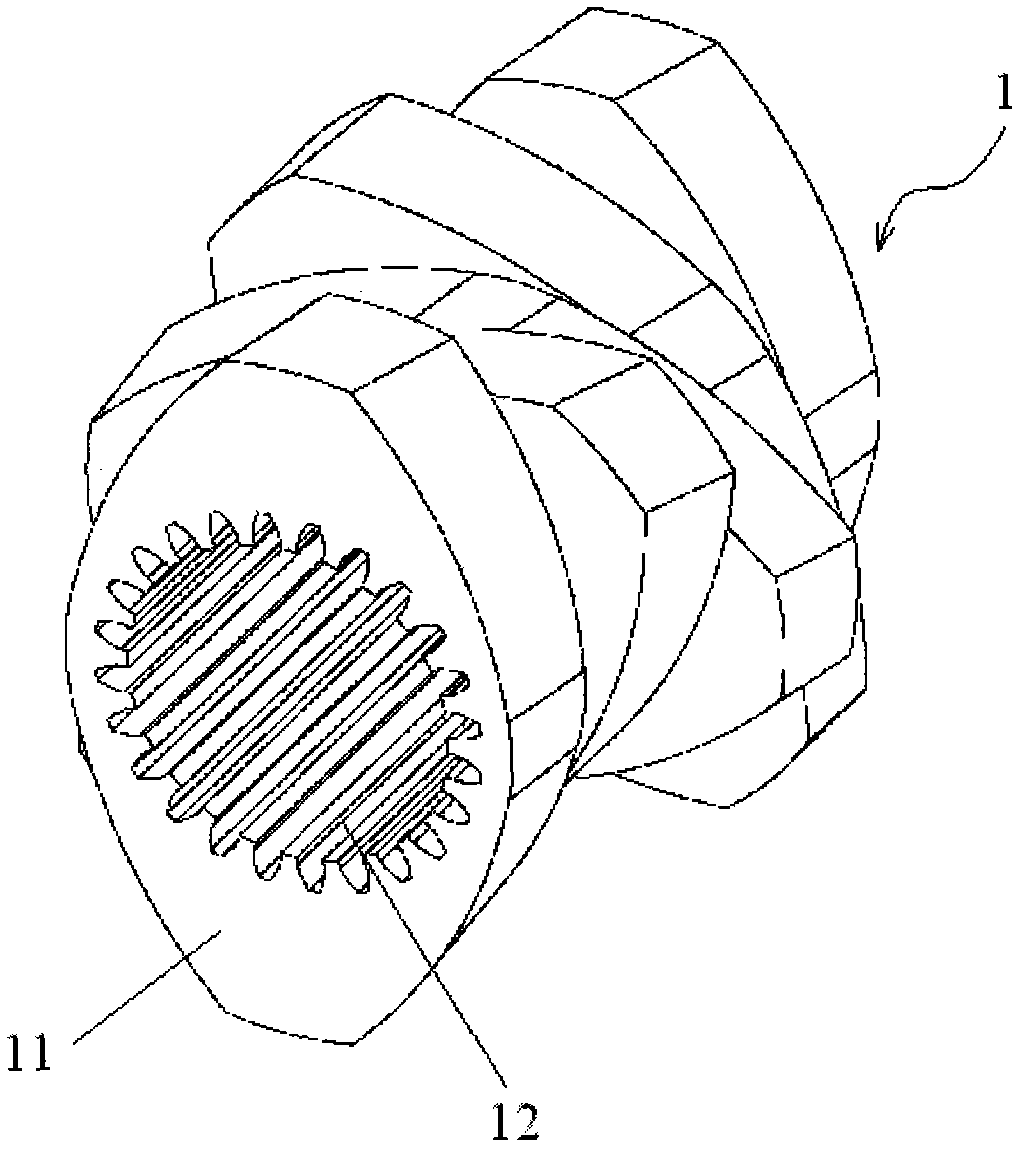

Twin-screw extruder and meshing disk element therefor

A twin-screw extruder and meshing disc technology, which is used in the fields of plastic processing machinery and twin-screw extruders, can solve the problems that cannot be adjusted again, the function is single, and the mixing quality of meshing disc element 1 decreases, and achieves good mixing. The effect of refining quality and conveying capacity or pressure building capacity, improving conveying capacity and improving mixing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

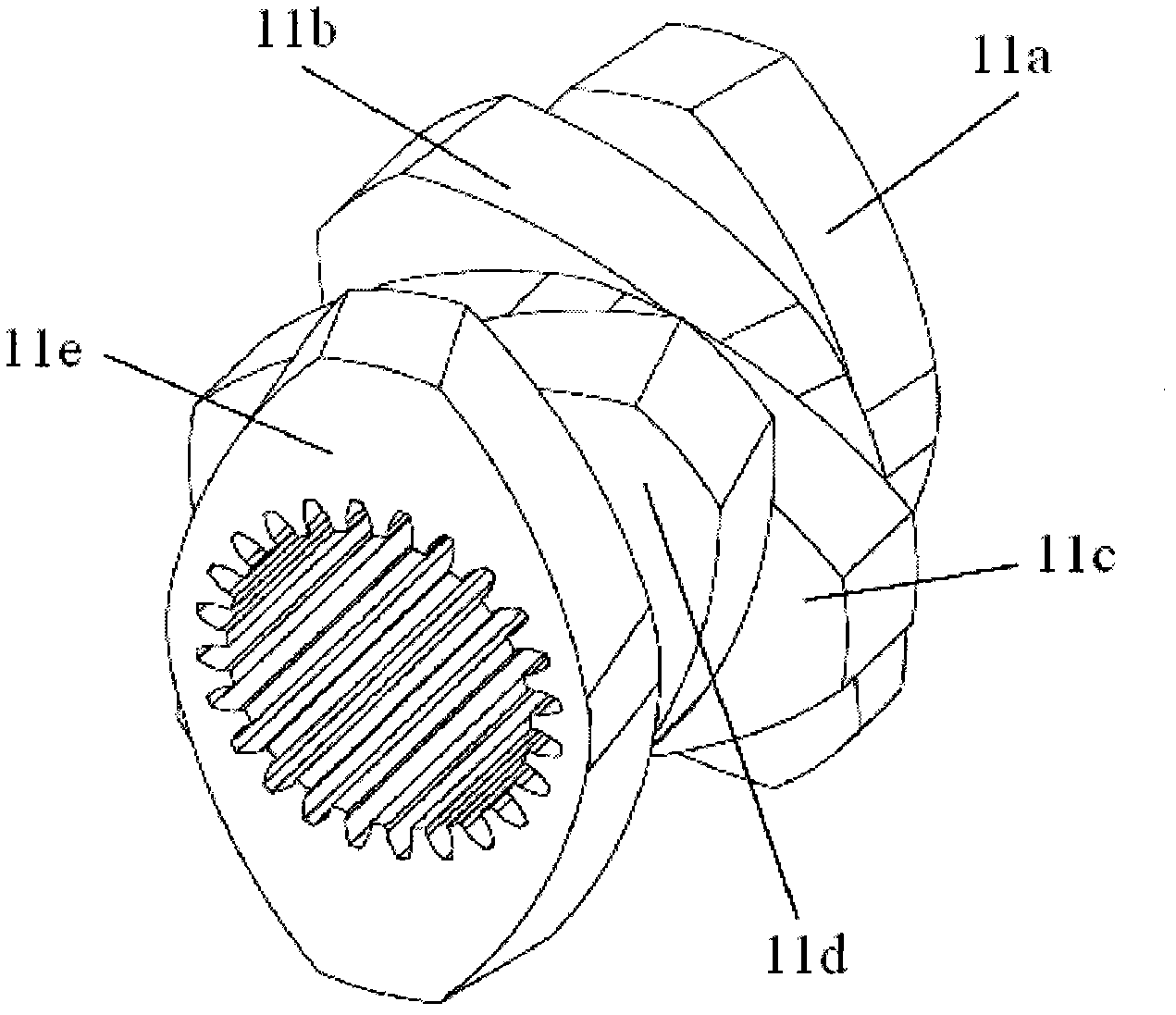

[0031] In order for those skilled in the art to better understand the technical solution of the present invention, the intermeshing disk element for the twin-screw extruder and the twin-screw extruder provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0032] In order to facilitate the description of the technical solution of the present invention, in this embodiment, the torsion angle refers to the included angle at which the two end surfaces of the engaging block rotate and stagger around the axis of the engaging disc element. The staggered angle refers to the included angle at which the contacting end surfaces of adjacent engaging blocks are rotated and staggered around the axis of the engaging disc element. The rotation direction of the meshing block is observed from the extrusion direction, "-" means left-handed, "+" means right-handed. The front end of the engaging disc element (engaging block) refers to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com