Automatic mucilage glue temperature control system

An automatic control system, viscose technology, applied in filament forming processing, textile and papermaking, fiber processing, etc. problems, to avoid output and quality loss, stabilize the flow and quality of glue supply, and achieve cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

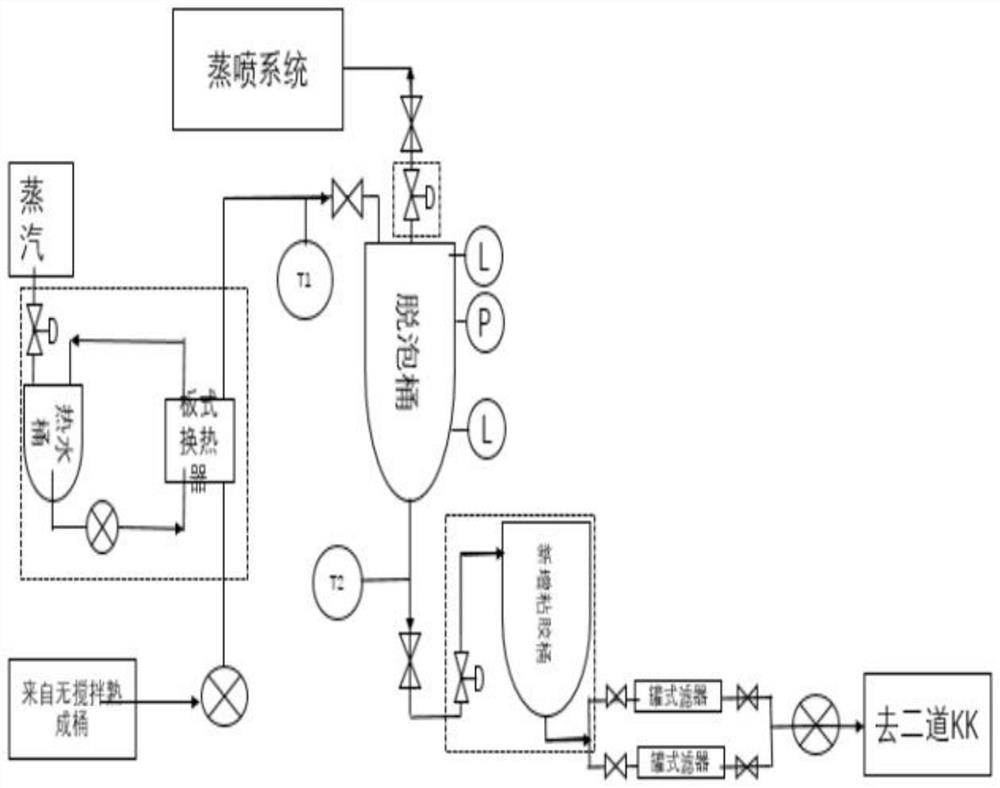

[0016] like figure 1 As shown, a viscose temperature automatic control system includes a viscose heat exchange system. The viscose must pass through the viscose heat exchange system before entering the defoaming barrel after the aging process. The viscose heat exchange system consists of a hot water bucket, a plate heat exchange Composed of a water heater and a hot water circulation pump, the hot water inside the hot water bucket is heated by an external steam pipeline, and the flow rate of the steam pipeline is controlled by an automatic control valve according to the set glue temperature and water temperature. And through the hot water circulation pump, the hot water circulates between the hot water tank and the plate heat exchanger to achieve the effect of heating up the viscose and ensure that the temperature of the glue entering the degassing tank reaches the standard; the viscose temperature automatic control system, the degassing tank vacuum The system regulating valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com