A dual-chamber flow cell turbidity measurement system and its control method

A measurement system and flow cell technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problem of measurement accuracy, timeliness, and system miniaturization. Content, turbidity change measurement environment and other issues, to avoid adverse effects, take into account the measurement accuracy, and ensure the effect of defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The dual chamber flow cell turbidity measurement system of the present invention will be further described below with reference to the drawings and specific embodiments.

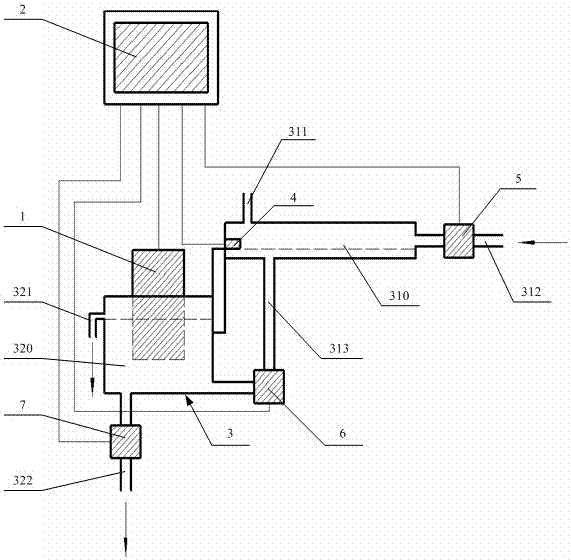

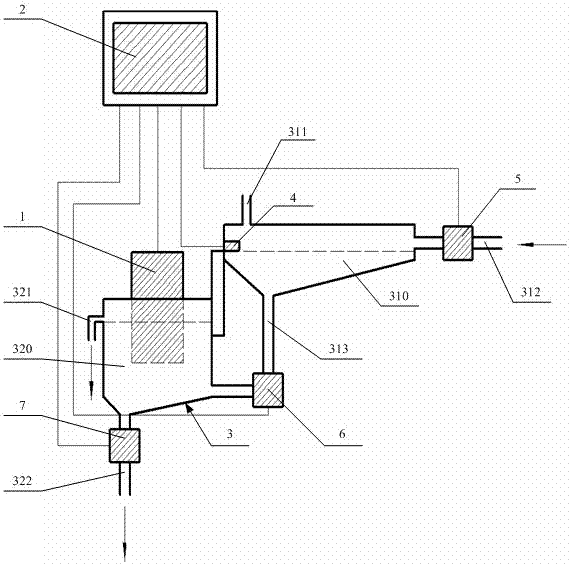

[0070] figure 1 A schematic structural diagram of an implementation of the dual-chamber flow cell turbidity measurement system of the present invention is shown. Such as figure 1 As shown, the dual-chamber flow cell turbidity measurement system of the present invention includes a turbidity sensor 1 , a controller 2 , and what is particularly different is that it also includes a dual-chamber flow cell 3 . The double-chamber flow cell includes a defoaming chamber 310 and a measuring chamber 320 . Wherein, the top of the defoaming cavity 310 is provided with an exhaust hole 311; the side wall in the defoaming cavity 310 is provided with a liquid level sensor 4 at the position of the preset defoaming water level, and the preset value in the defoaming cavity is The water capacity corresponding to the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com