A defoaming, stirring and filling jig for conductive adhesive and its installation and use method

An adhesive and conductive adhesive technology, applied in chemical instruments and methods, mixer accessories, packaging, etc., can solve problems such as difficulty in mixing glue evenly, low mixing efficiency of fixtures, easy overflow and leakage of glue, etc. foaming effect and quality, improving glue utilization, convenient and quick filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

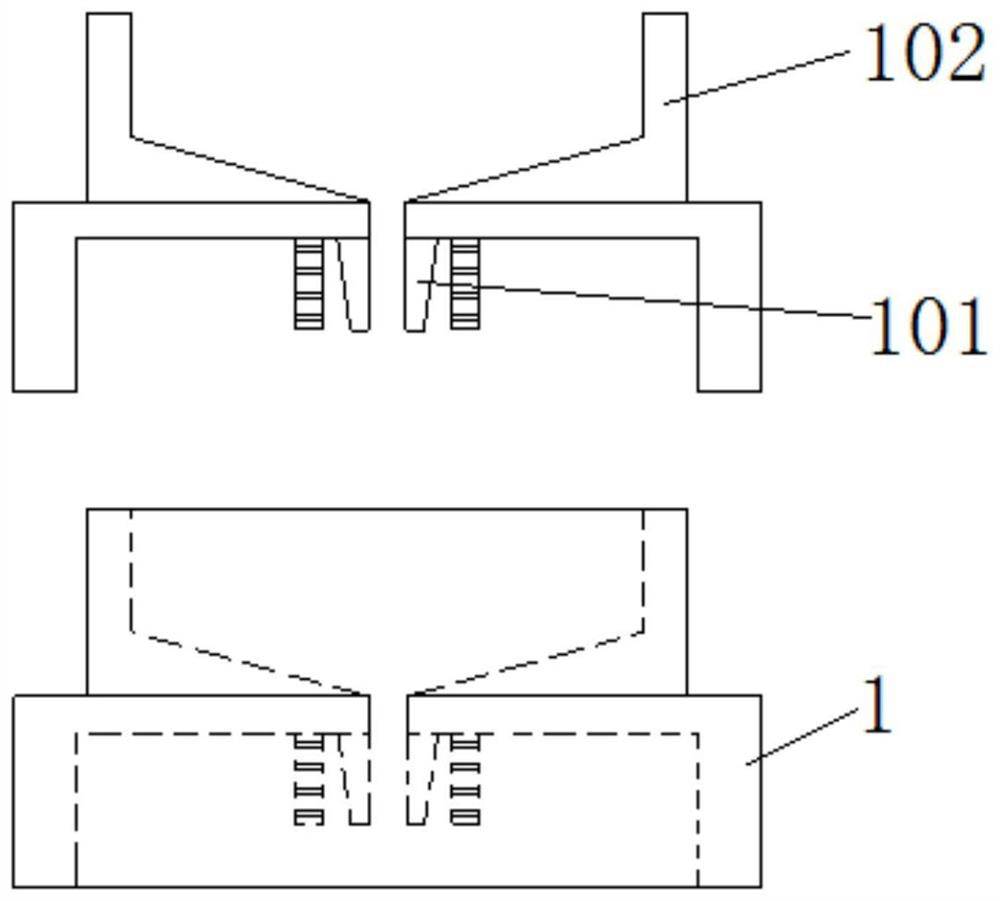

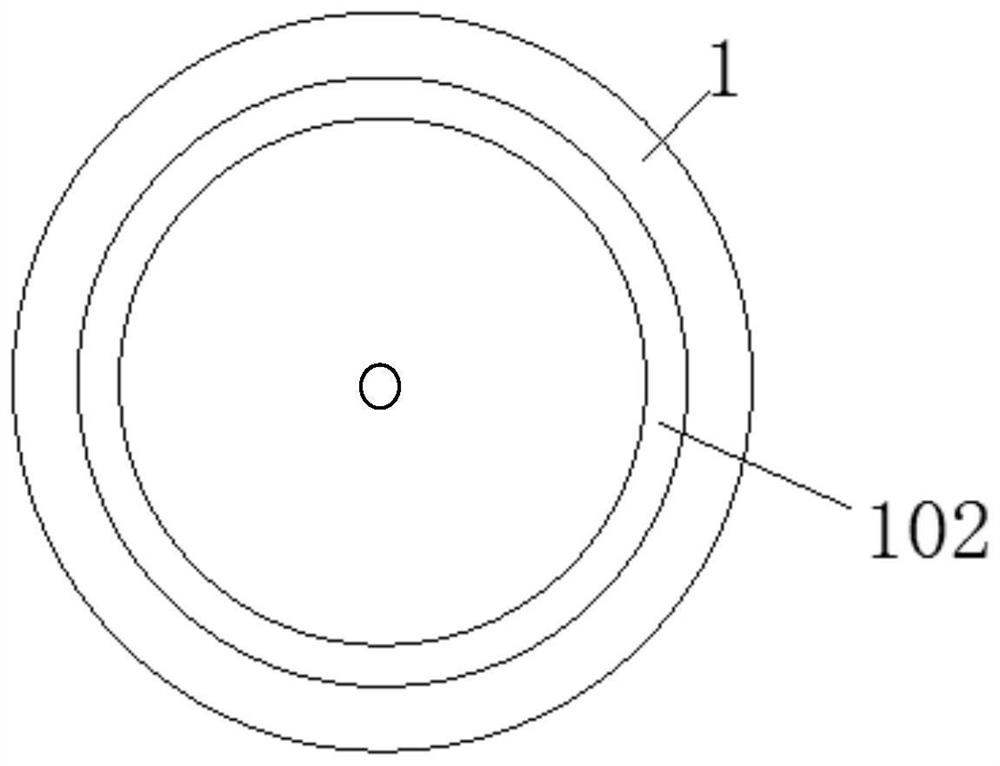

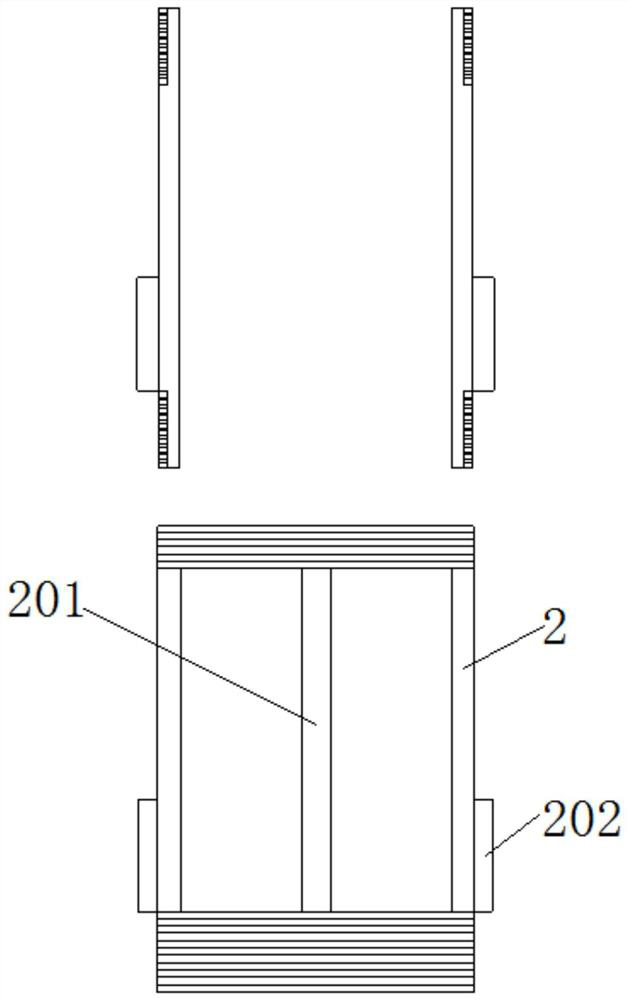

[0043] A defoaming stirring and filling jig for conductive adhesive, the defoaming stirring and filling jig includes a base 1, see figure 1 and figure 2 , the bottom of the base 1 is set as an open structure, the base 1 is provided with a sealing nozzle 101, and the sealing nozzle 101 is provided with a cylindrical tank connection screw 102, see image 3 and Figure 4 , the inner wall of the tank connection screw 102 is provided with a lower internal thread; the base 1 is provided with a longitudinal cylindrical tank body 2, and the lower outer wall of the tank body 2 is provided with a lower external thread, and the lower part of the tank body 2 passes through The lower external thread and the lower internal thread are connected to the tank connecting screw 102; the outer wall of the tank 2 is provided with two symmetrical longitudinally protruding bayonet pins 201 and two symmetrical longitudinally protruding stoppers Pin 202, the middle outer jacket of the tank body 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com