Novel reaction vessel

A reactor and a new type of technology, applied in the field of new reactors, can solve problems such as affecting the purity of the output product, and achieve the effect of increasing the coverage and ensuring the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is further elaborated:

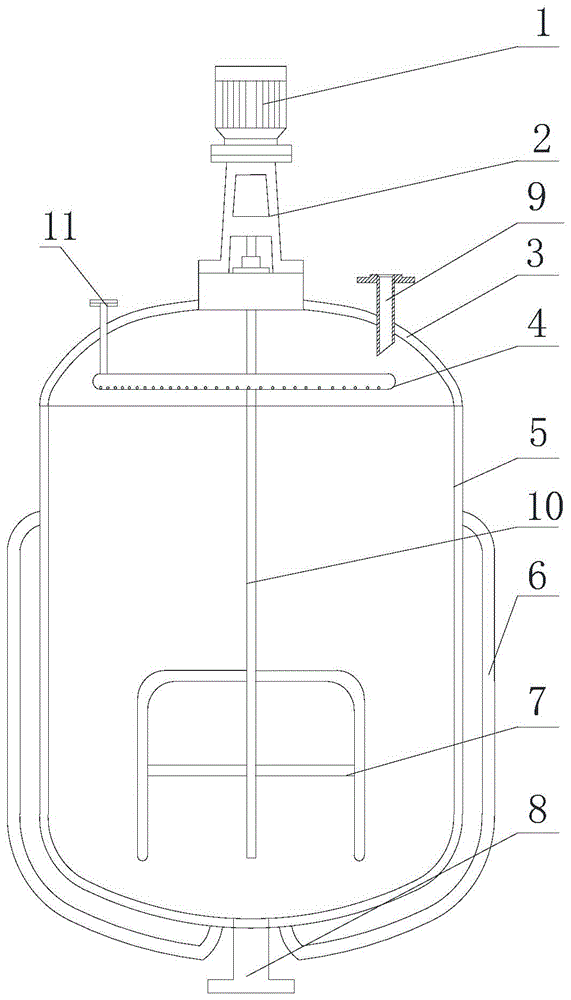

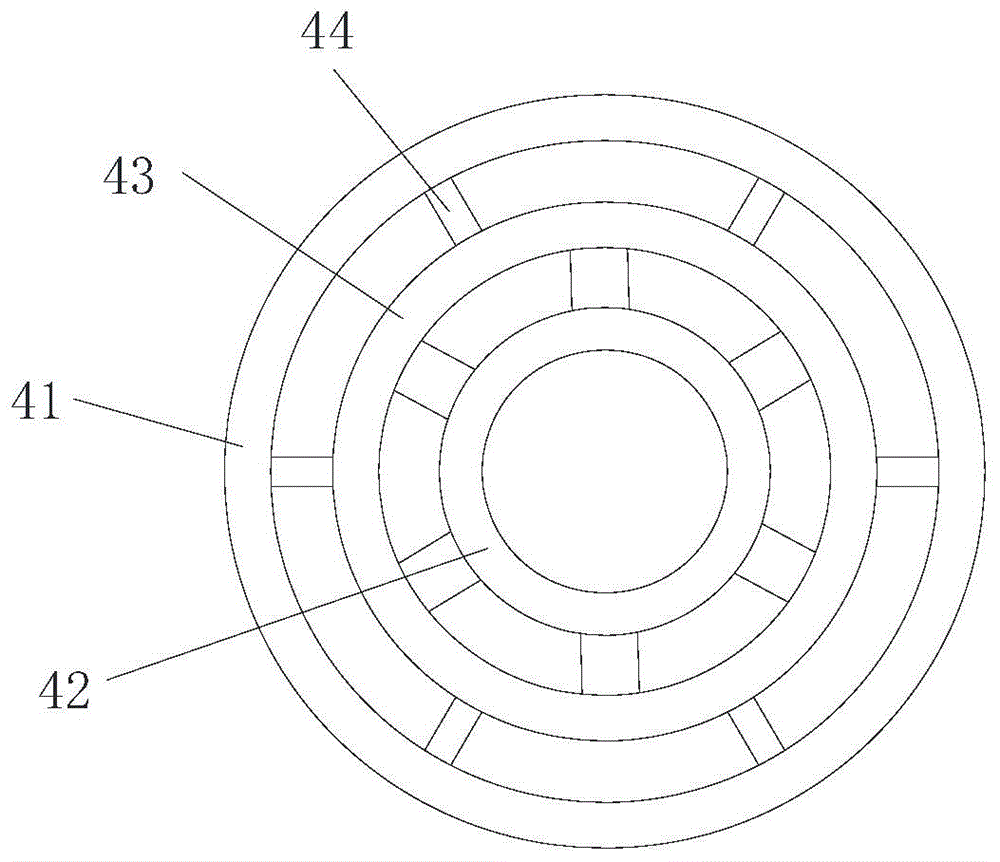

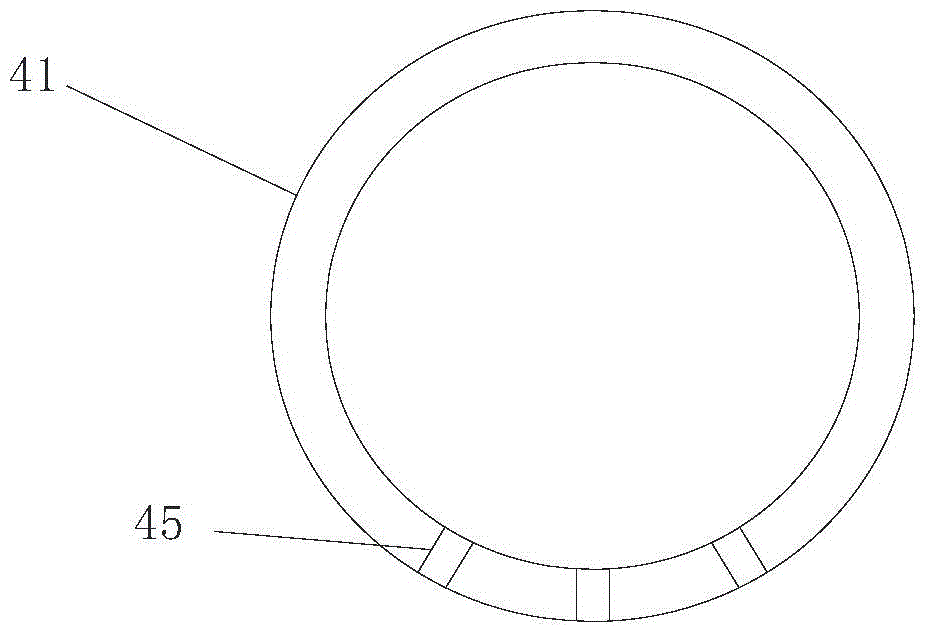

[0014] Such as figure 1 The novel reaction kettle shown comprises a still body 5, the lower end of the still body 5 is provided with a discharge port 8, the periphery of the still body 8 is provided with a jacket 6, the top of the still body 5 is connected with a still cover 3, the still body The cover 3 is provided with a feed inlet 9, and a support 2 is provided at the center of the kettle cover 3, and the top of the support 2 is connected with a stirring motor 1, and the stirring motor 1 is connected with a stirring shaft 10 extending into the kettle body. The shaft 10 is provided with an agitator 7, and it is characterized in that: the top inside the kettle body is provided with a gas defoaming pipe 4, and the gas defoaming pipe includes an outer ring pipe 41, a middle ring pipe 43 and an inner ring pipe 42 , the connecting pipe 44 is arranged between the outer ring pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com