High-efficiency defoaming agent and preparation method thereof

A defoamer and high-efficiency technology, applied in the field of high-efficiency defoamer and its preparation, can solve the problems of harsh preparation equipment, potential safety hazards in the preparation process, and low defoaming efficiency, so as to achieve low equipment requirements and safe production process , good defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A high-efficiency defoamer proposed by the present invention includes the following raw materials in parts by weight: 3 parts of organosiloxane, 15 parts of simethicone oil, 6 parts of hexenyl bis stearamide, 3 parts of monoglyceride stearate 2 parts, molybdenum disulfide 2 parts, montmorillonite powder 2 parts, metal oxide 3 parts, charcoal powder 4 parts, inorganic salt 4 parts, surfactant 2 parts, polyvinyl ether 25 parts.

[0023] Its preparation method comprises the following steps:

[0024] S1. Weigh the corresponding weight parts of simethicone and polyvinyl ether, and mix them evenly to obtain the mixed liquid A. Put the corresponding weight parts of organosiloxane into the dropping funnel, and mix it with 800r / min Stir the mixed solution A at a high speed, and at the same time add the organosiloxane in the dropping funnel dropwise to the mixed solution A, and the dropping time of the organosiloxane is 15min / L, and continue to stir after the organosiloxane is ad...

Embodiment 2

[0028] A high-efficiency defoamer proposed by the present invention includes the following raw materials in parts by weight: 2 parts of organosiloxane, 15 parts of simethicone, 5 parts of hexenyl bis stearamide, 3 parts of monoglyceride stearate 3 parts, molybdenum disulfide 3 parts, montmorillonite powder 2 parts, metal oxide 3 parts, charcoal powder 3 parts, inorganic salt 6 parts, surfactant 3 parts, polyvinyl ether 25 parts.

[0029] Its preparation method comprises the following steps:

[0030] S1. Weigh the corresponding weight parts of simethicone oil and polyvinyl ether, and mix them evenly to obtain the mixed solution A. Put the corresponding weight parts of organosiloxane into the dropping funnel, and use 1000r / min Stir the mixed solution A at a high speed, and at the same time add the organosiloxane in the dropping funnel dropwise to the mixed solution A, and the dropping time of the organosiloxane is 20min / L, and continue to stir after the organosiloxane is added d...

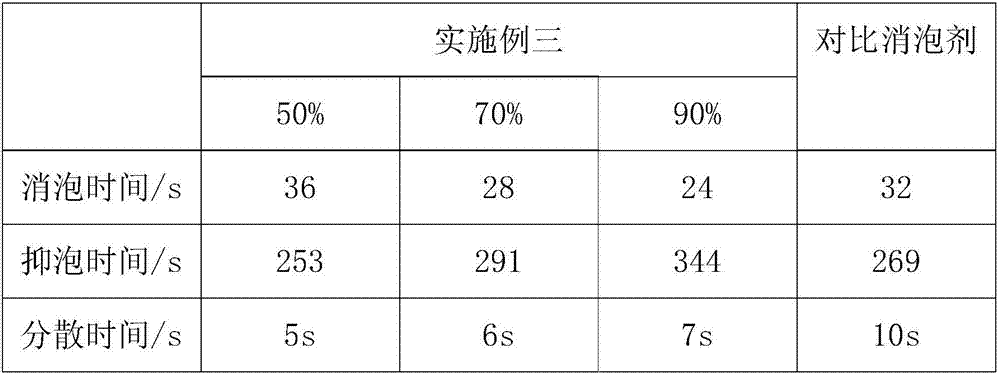

Embodiment 3

[0034] A high-efficiency defoamer proposed by the present invention includes the following raw materials in parts by weight: 4 parts of organosiloxane, 20 parts of simethicone oil, 6 parts of hexenyl bis stearamide, 3 parts of monoglyceride stearate 2 parts of molybdenum disulfide, 1 part of montmorillonite powder, 4 parts of metal oxide, 4 parts of charcoal powder, 6 parts of inorganic salt, 1 part of surfactant, and 25 parts of polyvinyl ether.

[0035] Its preparation method comprises the following steps:

[0036] S1. Weigh the corresponding weight parts of simethicone and polyvinyl ether, and mix them evenly to obtain the mixed liquid A. Put the corresponding weight parts of organosiloxane into the dropping funnel, and mix it with 800r / min Stir the mixed solution A at a high speed, and at the same time add the organosiloxane in the dropping funnel dropwise to the mixed solution A, and the dropping time of the organosiloxane is 20min / L, and continue to stir after the organo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com