PU (Polyurethane) composite leather and preparation method thereof

A leather and lamination technology, applied in the direction of coating, textiles and papermaking, etc., can solve the problems of poor surface quality, etc., and achieve the effects of improving uneven coating, improving product life, no air bubbles and excellent abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

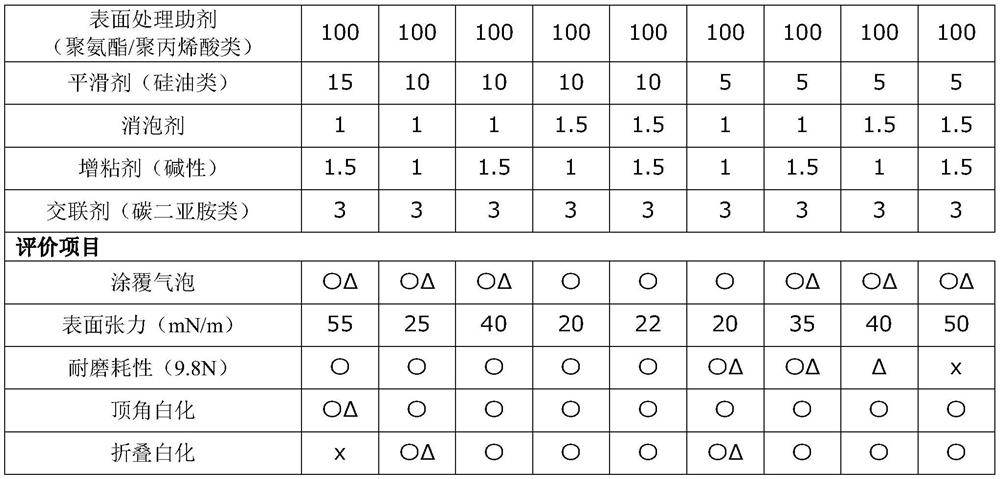

Examples

preparation example Construction

[0039] The present invention also provides a preparation method for preparing the synthetic leather, the preparation method comprising the following steps:

[0040] S1 surface layer production, surface layer 3 production includes preparation of surface layer solution, surface layer solution defoaming treatment, surface layer solution coating process and surface layer drying molding to obtain surface layer 3; the stirring speed of the prepared surface layer solution is 350rpm ~450rpm, the stirring time is 60min~65min, the viscosity of the surface layer solution is 2000cps~3000cps.

[0041] The treatment time for the degassing treatment of the surface layer solution in step S1 is 60 minutes to 65 minutes. The prepared surface layer solution is defoamed with a circulating defoaming machine to fully ensure the defoaming effect, so that air can be prevented from entering the surface layer solution during the transportation process during recycling, so as to improve the coating qual...

Embodiment 1

[0049] The preparation method of a PU synthetic leather provided in this embodiment: first prepare the release paper mold and the base cloth layer; the production environment temperature is 0° C. to 40° C., and the production environment humidity is 20% to 80%.

[0050] S1 surface layer is made, according to each material component of this surface layer 3, select mass percent to be 57.4% polyurethane, 13.9% inorganic pigment iron oxide and carbon black, the surplus is the dissolution medium MEK and DMF to prepare surface layer solution; The prepared surface The stirring speed of the layer solution is 350rpm-450rpm, the stirring time is 60min-65min, and the viscosity of the surface layer solution is 2000cps-3000cps; the surface layer solution is fully defoamed, and the treatment time is 60min-65min; the surface layer solution coating process The speed is 9m / min, and the usage is 35g / m 2 ~45g / m 2 ; The surface layer is dried and molded at a temperature of 100°C to 125°C for 3 m...

Embodiment 2

[0058] Another kind of PU synthetic leather provided in this embodiment and its preparation method differ from Embodiment 1 in that:

[0059] S1 surface layer is made, according to each material component of this surface layer 3, select mass percentage to be 50.4% polyurethane, 1.7% bridging agent carbodiimide, 8.0% basic tackifier, 16.5% inorganic pigment iron oxide and carbon black, the balance is the dissolution medium MEK and DMF to prepare the surface layer solution; the stirring speed of the prepared surface layer solution is 350rpm~450rpm, the stirring time is 60min~65min, and the viscosity of the surface layer solution obtained is 2000cps~3000cps; the surface layer solution is Sufficient defoaming treatment, the treatment time is 30min~35min; the speed of surface layer solution coating processing is 10m / min, and the usage amount is 30g / m 2 ~35g / m 2 ; The surface layer is dried and molded at a temperature of 100°C to 125°C for 3 minutes.

[0060] S2 Adhesive Layer Pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com