Aqueous inkjet transfer printing method for personalized printing of textiles

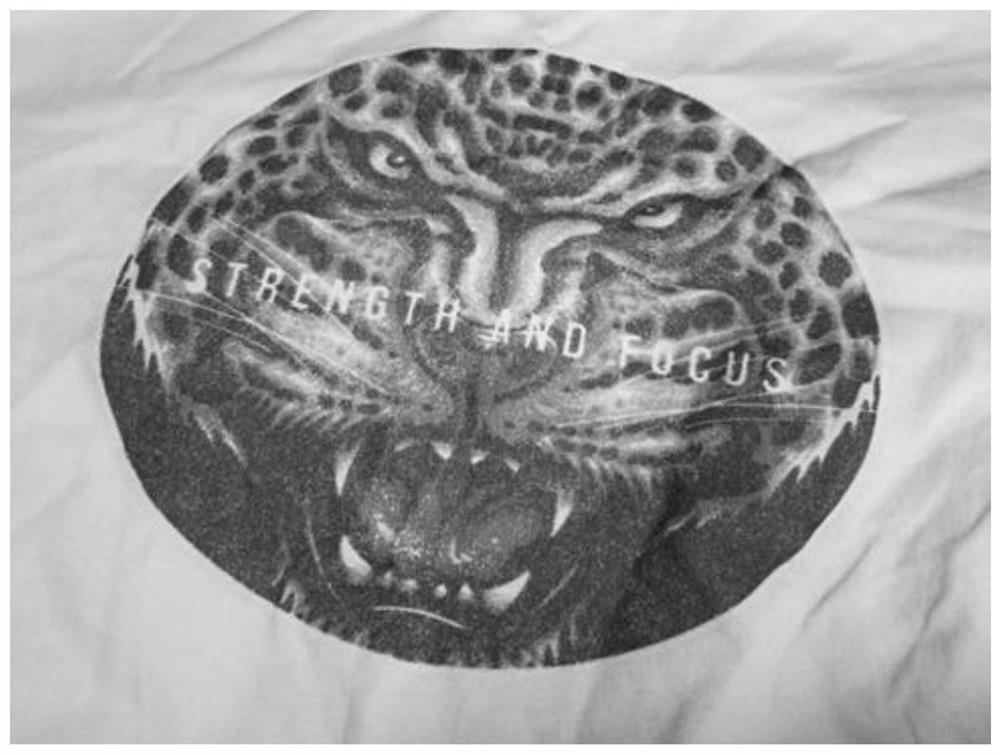

A textile and water-based technology, which is applied in the post-processing of printing, printing, ink transfer from original manuscript, etc. It can solve problems such as poor color reproduction, poor flatness, and color fading, and achieve stable surface tension, improved weather resistance, and increased water resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

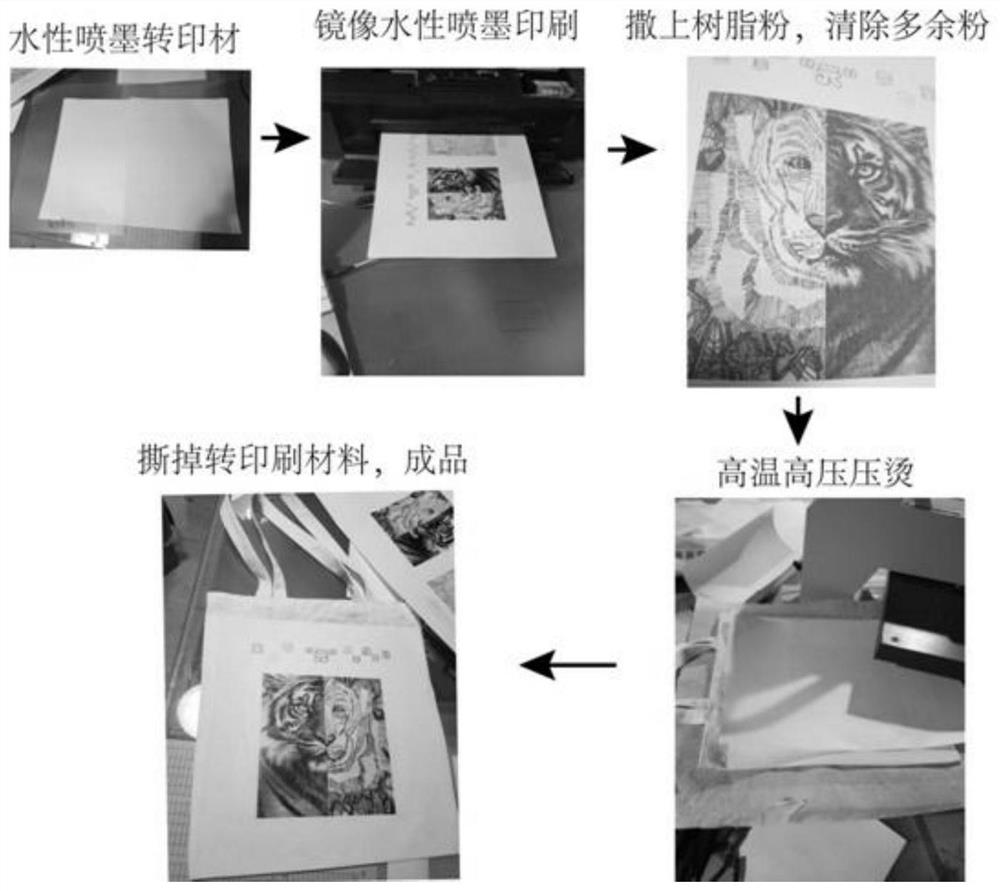

Method used

Image

Examples

Embodiment 1

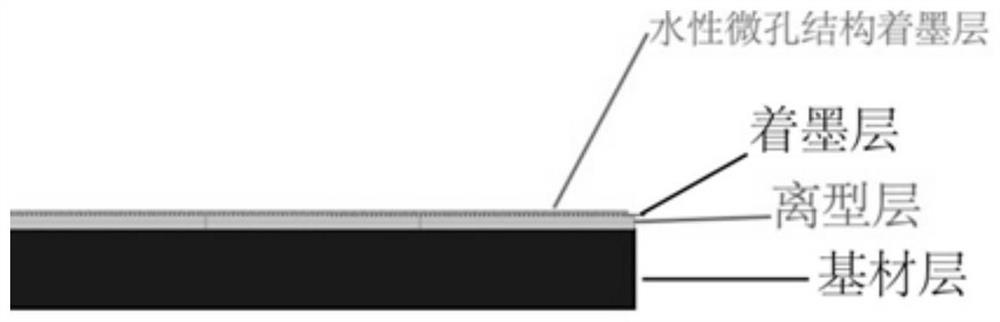

[0056] The water-based inkjet transfer printing material used in the water-based inkjet transfer printing method for personalized printing of textiles includes a substrate layer, a release layer and an ink layer in sequence, wherein the release layer is a PP release layer, and the ink layer consists of deionized 50 parts of water, nano-SiO with a solid content of 20% to 48% 2 It is prepared by mixing 1 part of emulsion, 0.1 part of sodium alginate, DYNOL604 607 and SURFYNOL 420 440 4650.1 parts.

Embodiment 2

[0058] The water-based ink-jet transfer printing method used in the personalized printing of textiles adopts a water-based ink-jet transfer printing material that sequentially includes a substrate layer, a release layer and an ink layer, wherein the release layer is a PP release layer, and the ink layer consists of deionized 55 parts of water, nano-SiO with a solid content of 20% to 48% 2 It is made by mixing 5 parts of emulsion, 1 part of sodium alginate, and 0.5 part of SURFYNOL 420 440 465.

Embodiment 3

[0060] The water-based ink-jet transfer printing method used in the personalized printing of textiles adopts a water-based ink-jet transfer printing material that sequentially includes a substrate layer, a release layer and an ink layer, wherein the release layer is a PP release layer, and the ink layer consists of deionized 60 parts of water, nano-SiO with a solid content of 20% to 48% 2 It is made by mixing 10 parts of emulsion, 2 parts of sodium alginate, 1 part of DYNOL604 607 and 1 part of SURFYNOL 420 440 465.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com