Metal foil treatment process, electrode plate and electrochemical device

A treatment process and electrode pole piece technology, applied in electrochemical generators, electrode carriers/collectors, battery electrodes, etc., can solve problems that affect the use of metal foil, unfavorable health of workers, and metal foil odor, etc., to reduce the impact , eliminate odor, stabilize surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

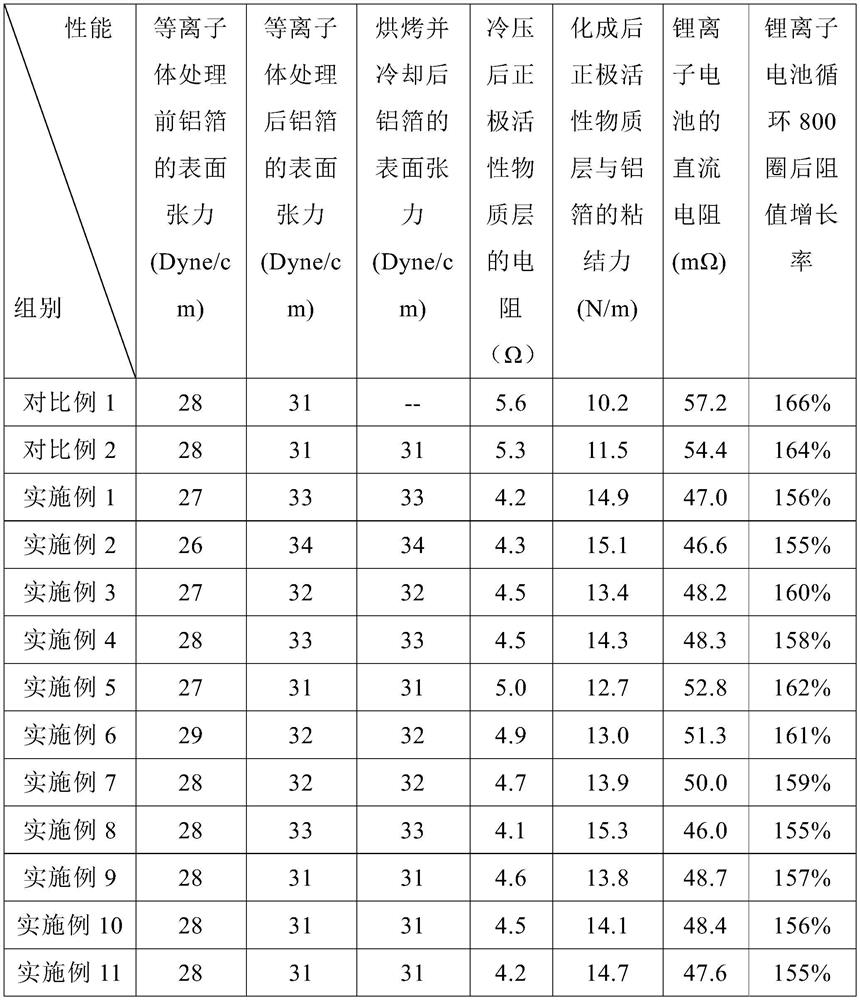

Embodiment 1

[0096] The aluminum foil is transported into the plasma treatment chamber by means of a conveyor belt for plasma treatment, and then rolled into rolls. Wherein, the plasma emission source is 2 cm away from the surface of the aluminum foil, the power of the plasma treatment is 55 kW, and the conveying speed of the aluminum foil is 120 m / min. Put the plasma-treated aluminum foil roll in a baking oven, let it stand still and raise the temperature from room temperature to 120 °C at a heating rate of 5 °C / min and keep it warm for 20 minutes, then take it out and naturally cool it to room temperature in the air. Aluminum foil is odorless and scratch-free.

[0097] Lithium-ion battery preparation: the difference from Comparative Example 1 is that the aluminum foil in Comparative Example 1 is replaced by the aluminum foil prepared in Example 1.

Embodiment 2

[0099] The aluminum foil is transported into the plasma treatment chamber by means of a conveyor belt for two plasma treatments, and then rolled into rolls. Wherein, each time the plasma emission source is 2cm away from the surface of the aluminum foil, the power of each plasma treatment is 50kW, and the transmission speed of each aluminum foil is 160m / min. Put the plasma-treated aluminum foil roll in a baking oven, let it stand still and raise the temperature from room temperature to 90 °C at a heating rate of 3 °C / min and keep it warm for 30 min, then take it out and naturally cool it to room temperature in the air, wherein, the cooled Aluminum foil is odorless and scratch-free.

[0100] Lithium-ion battery preparation: the difference from Comparative Example 1 is that the aluminum foil in Comparative Example 1 is replaced by the aluminum foil prepared in Example 2.

Embodiment 3

[0102] The aluminum foil is transported into the plasma treatment chamber by means of a conveyor belt for plasma treatment, and then rolled into rolls. Wherein, the plasma emission source is 2 cm away from the surface of the aluminum foil, the power of the plasma treatment is 50 kW, and the conveying speed of the aluminum foil is 120 m / min. Put the plasma-treated aluminum foil roll in a baking oven, let it stand still and raise the temperature from room temperature to 80 °C at a heating rate of 3 °C / min and keep it warm for 90 min, then take it out and naturally cool it to room temperature in the air, wherein, the cooled Aluminum foil is odorless and scratch-free.

[0103] Lithium-ion battery preparation: the difference from Comparative Example 1 is that the aluminum foil in Comparative Example 1 is replaced by the aluminum foil prepared in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com