A fabric softening agent and preparation method thereof

A fabric softening and finishing agent technology, applied in the field of textile printing and dyeing, can solve the problems of oil floating or sticking rollers in emulsion, low requirements, high price, etc., and achieve low requirements on reaction conditions and equipment, low price, antistatic good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

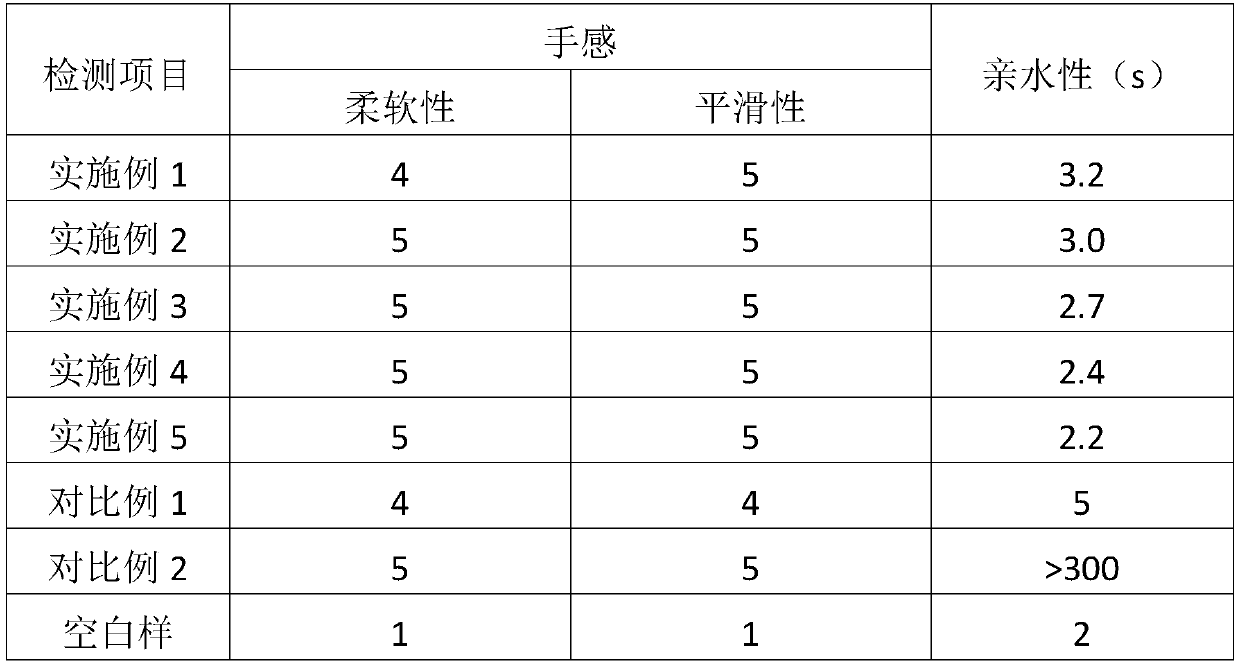

Examples

Embodiment 1

[0020] A preparation method of fabric softening and finishing agent, comprising the steps of: 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxyl-5-tert-butylphenyl]-propionic acid - Dissolve 10 g of polyethylene glycol 300 ester in 80 g of methyl isobutyl ketone to form a solution, then add 30 g of epoxy-terminated silicone oil and 2 g of benzyldimethylamine to it, stir and react for 8 hours at 70° C. in a nitrogen atmosphere, and then The organic solvent is removed by rotary evaporation to obtain a fabric softening and finishing agent.

[0021] A fabric softening and finishing agent, which is prepared by the preparation method of the fabric softening and finishing agent.

Embodiment 2

[0023] A preparation method of fabric softening and finishing agent, comprising the steps of: 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxyl-5-tert-butylphenyl]-propionic acid - 10 g of polyethylene glycol 300 ester was dissolved in 90 g of xylene to form a solution, then 33 g of side chain epoxy silicone oil and 3 g of benzyl triethylammonium chloride were added thereto, and the reaction was stirred and reacted for 8.5 hours under a helium atmosphere at 73°C, Afterwards, the organic solvent is removed by rotary evaporation to obtain a fabric softening and finishing agent.

[0024] A fabric softening and finishing agent, which is prepared by the preparation method of the fabric softening and finishing agent.

Embodiment 3

[0026] A preparation method of fabric softening and finishing agent, comprising the steps of: 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxyl-5-tert-butylphenyl]-propionic acid - Dissolve 10g of polyethylene glycol 300 ester in 100g of N,N-dimethylformamide to form a solution, then add 35g of epoxy-terminated silicone oil and 3.5g of potassium carbonate to it, and stir the reaction for 9 hours under a neon atmosphere at 75°C , followed by rotary evaporation to remove the organic solvent to obtain a fabric softening agent.

[0027] A fabric softening and finishing agent, which is prepared by the preparation method of the fabric softening and finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com