Composite type high-conductivity polymer material and preparation method thereof

A polymer material, high conductivity technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of high content of conductive carbon black, low toughness, backward technology, etc., and achieve excellent extrusion processing performance , environmental stress cracking resistance, good effect of UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

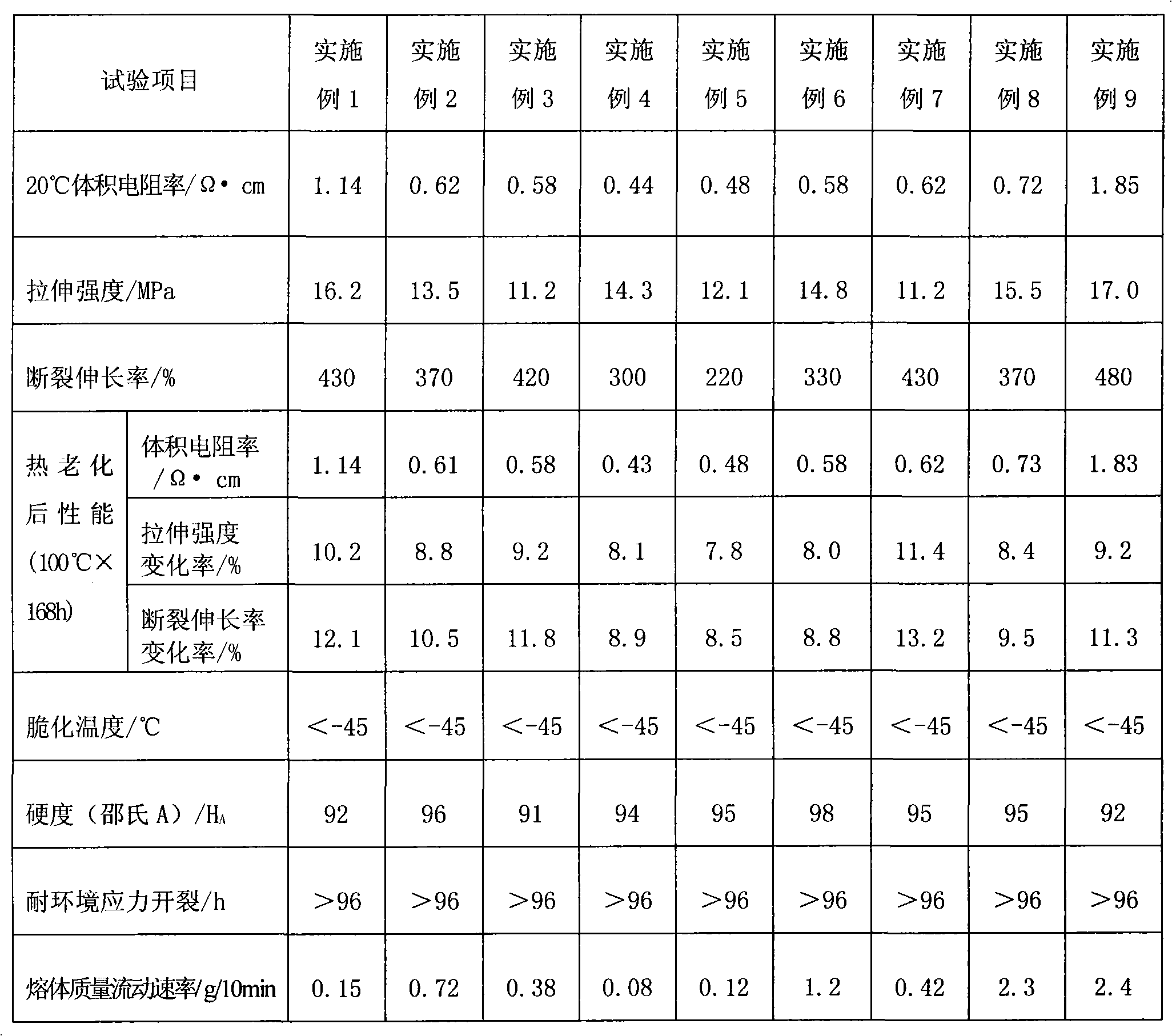

Examples

Embodiment 1

[0037] Taking the production of product 100Kg of the present invention as example used raw materials and weight proportion thereof are:

[0038] LLDPE (MFR=4.0g / 10min) 39Kg

[0039] SBS 18Kg

[0040] Special conductive carbon black (untreated) 20Kg

[0041] Liquid paraffin 17Kg

[0042] PE wax 2Kg

[0043] Oxidized PE wax 1Kg

[0044] PPA 0.2Kg

[0046] Calcium carbonate 1.5Kg

[0047] Antioxidant 1010 0.2Kg

[0048] Anti-copper agent 0.3Kg

Embodiment 2

[0050] Taking the production of product 100Kg of the present invention as example used raw materials and weight proportion thereof are:

[0051] PP (MFR=7.0g / 10min) 14Kg

[0052] POE (MFR=5.0g / 10min) 9Kg

[0053] SEPS 23Kg

[0054] Special conductive carbon black (untreated) 23Kg

[0055] White mineral oil 26.4Kg

[0056] Oxidized PP wax 1.2Kg

[0057] PPA0.4Kg

[0058] Ethylene bis stearic acid amide (EBS) 0.5Kg

[0060] Antioxidant 1076 0.3Kg

[0061] Anti-copper agent 0.5Kg

Embodiment 3

[0063] Taking the production of product 100Kg of the present invention as example used raw materials and weight proportion thereof are:

[0064] POE (MFR=5.0g / 10min) 36Kg

[0065] SEBS 18Kg

[0066] Special conductive carbon black (untreated) 24Kg

[0067] Naphthenic oil 17Kg

[0068] PE wax 1.8Kg

[0069] PPA 0.2Kg

[0071] Calcium carbonate 1.6Kg

[0072] Antioxidant 1010 0.3Kg

[0073] Anti-copper agent 0.5Kg

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com