High-temperature baking resistant jam and preparation method and application thereof

A high temperature resistant and baking technology, which is applied in the field of food processing, can solve the problems of low transparency, easy to change taste, easy to deform, etc., and achieve the effect of high transparency, easy operation, and full body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

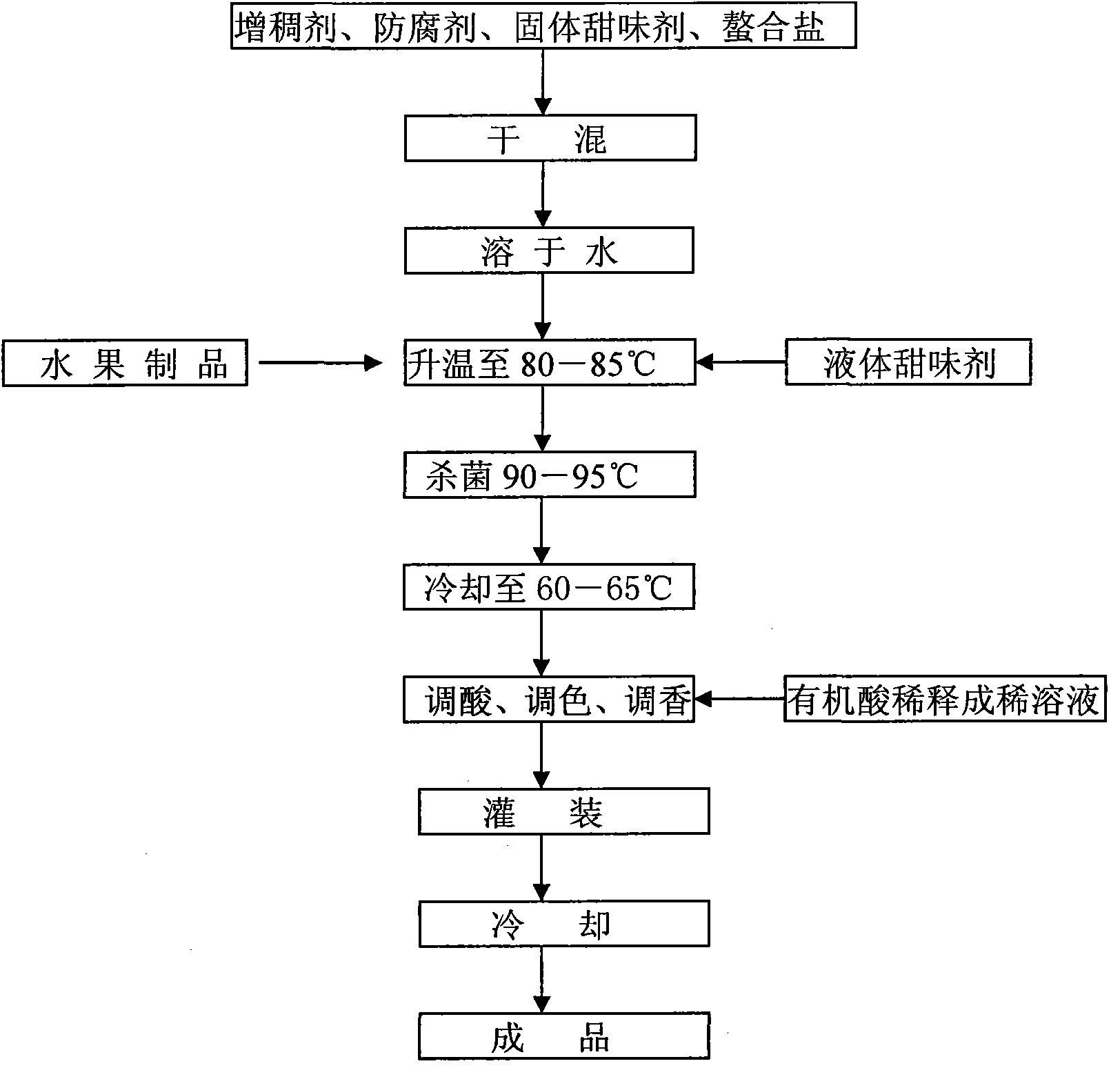

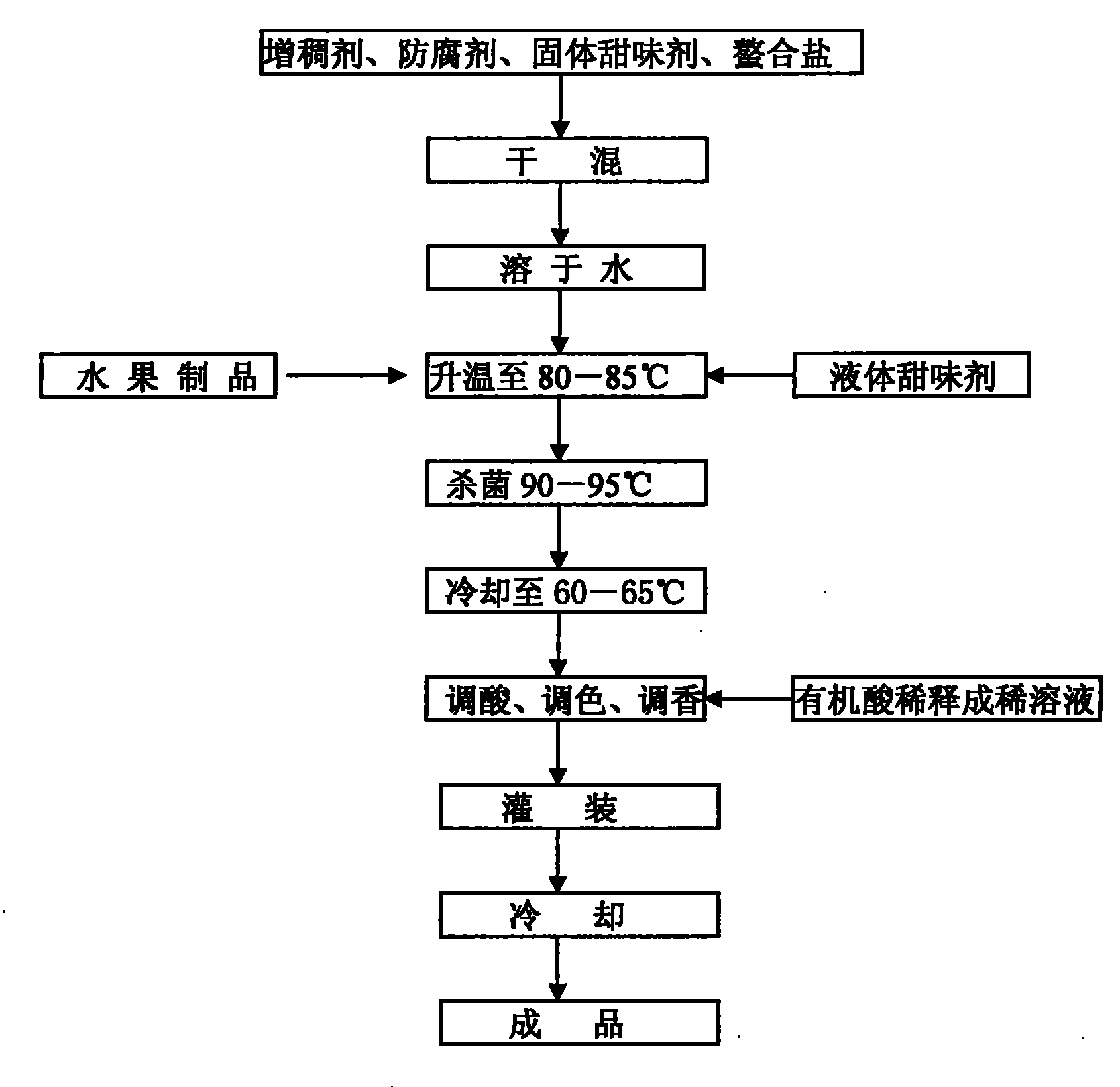

[0041] Prepare high temperature resistant baking jams as described below and figure 1 Shown:

[0042] The composition and content (mass percentage meter) of high-temperature resistant baking jam are as follows: fresh orange juice 25.0%, sucrose 10.0%, sorbitol 5.0%, glucose syrup 10.00%, maltose syrup 10.00%, thickener 4.46% (wherein modified starch 4.0% %, xanthan gum 0.01%, pectin 0.4%, sodium carboxymethyl cellulose 0.02%, konjac mannan 0.02%, gellan gum 0.01%), acidity regulator 0.42% (of which calcium lactate 0.02%, Na 2 HPO 4 0.05%, sodium citrate 0.10%, citric acid 0.25%), potassium sorbate 0.05%, edible β-carotene 0.003%, edible orange essence 0.03%, and the balance is water.

[0043] Weigh or measure the above substances according to the required amount. Then sucrose, sorbitol in thickeners, preservatives and sweeteners, and calcium lactate and Na in acidity regulators 2 HPO 4, sodium citrate dry mix into a uniform mixture, dissolved in water at room temperature,...

Embodiment 2

[0045] The ingredients and content of the baked jam are as follows: 40.0% of fresh pineapple fruit, 10.0% of sucrose, 5.0% of sorbitol, 10.00% of glucose syrup, 20.00% of malt syrup, 5.66% of thickener (wherein 5.0% of modified starch, xanthan gum 0.01%, pectin 0.6%, sodium carboxymethylcellulose 0.03%, konjac mannan 0.01%, gellan gum 0.01%), acidity regulator 0.42% (of which calcium lactate 0.02%, Na 2 HPO 4 0.05%, sodium citrate 0.10%, citric acid 0.25%), potassium sorbate 0.05%, edible β-carotene 0.004%, edible pineapple essence 0.03%, and the balance is water.

[0046] Weigh or measure the above substances according to the required amount. Then sucrose, sorbitol in thickeners, preservatives and sweeteners, and calcium lactate and Na in acidity regulators 2 HPO 4 , sodium citrate dry mix into a uniform mixture, dissolve in water at room temperature, heat up to 80-85°C during continuous stirring, add glucose syrup, maltose syrup, fresh fruit, stir while adding, and then h...

Embodiment 3

[0048] The ingredients and contents of the baked jam are as follows: fresh strawberry pulp 30.0%, sucrose 10.00%, sorbitol 5.0%, glucose syrup 15.00%, maltose syrup 10.00%, thickener 5.16% (wherein modified starch 4.5%, xanthan gum 0.02% %, pectin 0.6%, sodium carboxymethyl cellulose 0.02%, konjac mannan 0.01%, gellan gum 0.01%), acidity regulator 0.42% (of which calcium lactate 0.02%, Na 2 HPO 4 0.05%, sodium citrate 0.10%, citric acid 0.25%), potassium sorbate 0.05%, edible tomato red 0.004%, edible strawberry essence 0.03%, and the balance is water.

[0049] Weigh or measure the above substances according to the required amount. Then sucrose, sorbitol in thickeners, preservatives and sweeteners, and calcium lactate and Na in acidity regulators 2 HPO 4 , sodium citrate dry mix into a uniform mixture, dissolved in water at room temperature, and heated up to 80-85°C during continuous stirring, adding glucose syrup, maltose syrup, and fresh fruit pulp, stirring while adding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com