High-temperature resistant vibration tool for horizontal well

A vibrating tool and high-temperature-resistant technology, which is applied to vibration generating devices, wellbore/well components, earthwork drilling and production, etc., can solve problems such as failure to complete drilling operations, self-locking of coiled tubing, and inclusion of rubber parts, etc. Displacement operation, improve work reliability, and avoid the effect of mechanical transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

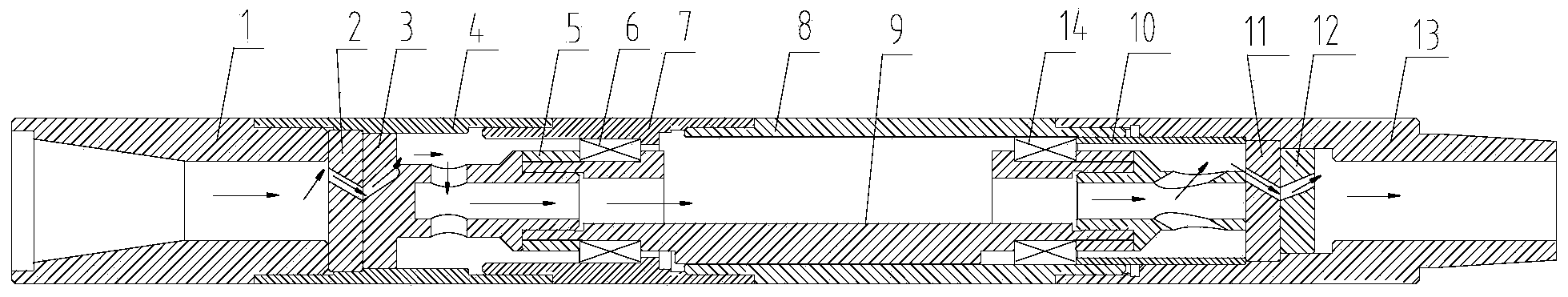

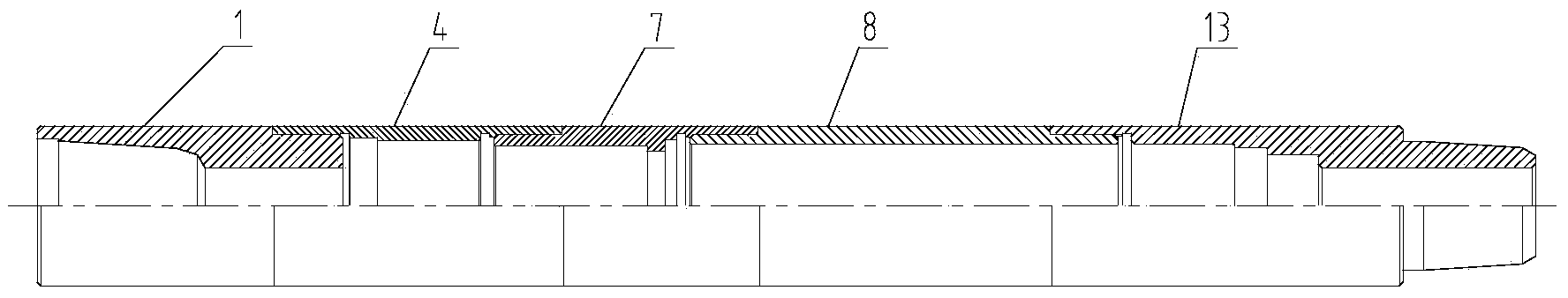

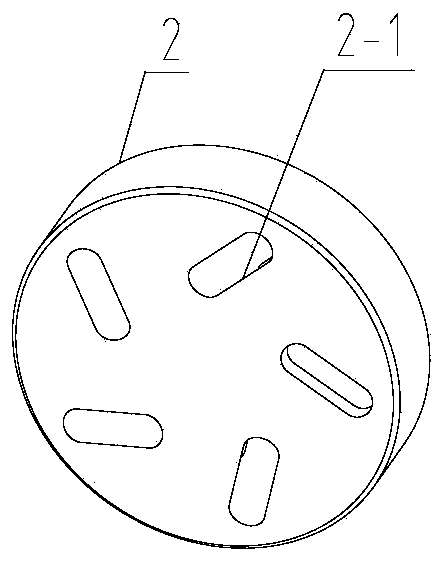

[0026] Such as Figure 1 to Figure 6 As shown, a high-temperature-resistant vibration tool for horizontal wells includes a housing assembly and a vibration assembly located inside the housing assembly:

[0027] The shell assembly includes an upper joint 1, an upper joint sleeve 4, a connecting sleeve 7, an outer sleeve 8 and a lower joint 13 which are sequentially socketed from top to bottom; the vibration assembly includes an upper turbine 3, which is sequentially connected from top to bottom. The eccentric shaft 9 and the lower end turbine 11, the vibration assembly is installed in the housing assembly through the upper end bearing 6 and the lower end bearing 14, and the upper end bearing 6 and the lower end beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com