A Walking Straw Extrusion Forming Machine and a Field Straw Extrusion Forming Method

A molding machine and walking technology, which is applied in the direction of harvesters, agricultural machinery and tools, and packaging, can solve the problems of inability to adjust the gap between extrusion dies, the impact of equipment use consistency, and poor wear resistance of dies, etc., to achieve convenience Effect of controlling extrusion molding production, reducing processing time, and reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

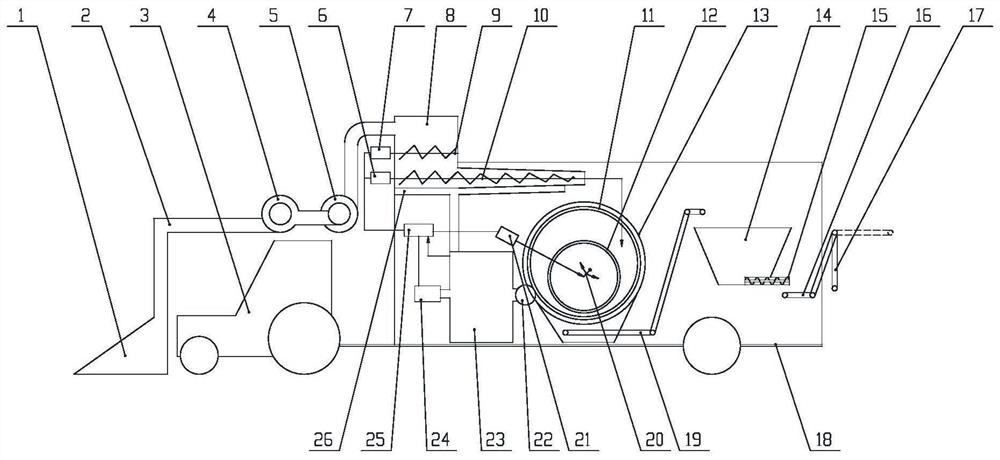

[0024] A walking straw extrusion molding machine, which includes a tractor, a straw harvesting device, a feeding device, a crushing device, a raw material storage box, a feeding device, an extrusion molding device, a molding material conveying device, a finished product hopper, and a discharging device and bodywork. The tractor is connected with the car body, and is driven and turned by the tractor. The car body is successively installed with a crushing device, a feeding device, a raw material storage box, a feeding device, an extrusion molding device, a molding material conveying device, a finished product hopper, and a discharging device. The front part of the tractor is equipped with a straw harvesting device. After harvesting the straw, the straw harvesting device processes the straw through each component in turn, so as to finally form a straw extrusion molding material.

[0025] In this embodiment, the tractor is preferably a tractor, and the vehicle body is driven and ...

Embodiment 2

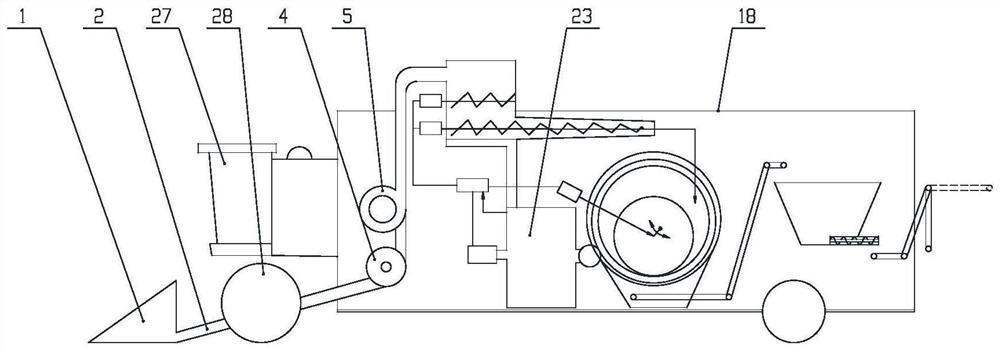

[0036] In this embodiment, only the part of the tractor is different from the first embodiment, and according to the difference of the tractor, the arrangement of the conveying pipeline, pulverizer and vacuum feeder is adjusted accordingly, and the rest are the same, and the similarities will not be repeated. .

[0037] In this embodiment, the tractor includes a cab assembly, driving and steering drive systems. The cab assembly is installed on the car body, and the operation functions of the whole vehicle are located in the cab assembly. The driving and steering drive system is connected to the engine, and the engine provides power to drive the vehicle to drive and turn, so the equipment can be driven by itself without additional tractors or other tractors for traction. The straw harvesting device is placed at the front of the vehicle and is also powered by the engine. The conveying pipeline is located in the space at the bottom of the cab, the pulverizer and the vacuum feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com