Preparation method of polyethylene wax micropowder and spray granulation system

A technology of polyethylene wax micropowder and polyethylene wax, which is applied in the direction of liquid separation into beads and granules, can solve the problems of high equipment investment and operation difficulty, and the lack of widespread use of polyethylene wax micropowder, etc., to improve heat transfer rate and manufacture Good particle effect, easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

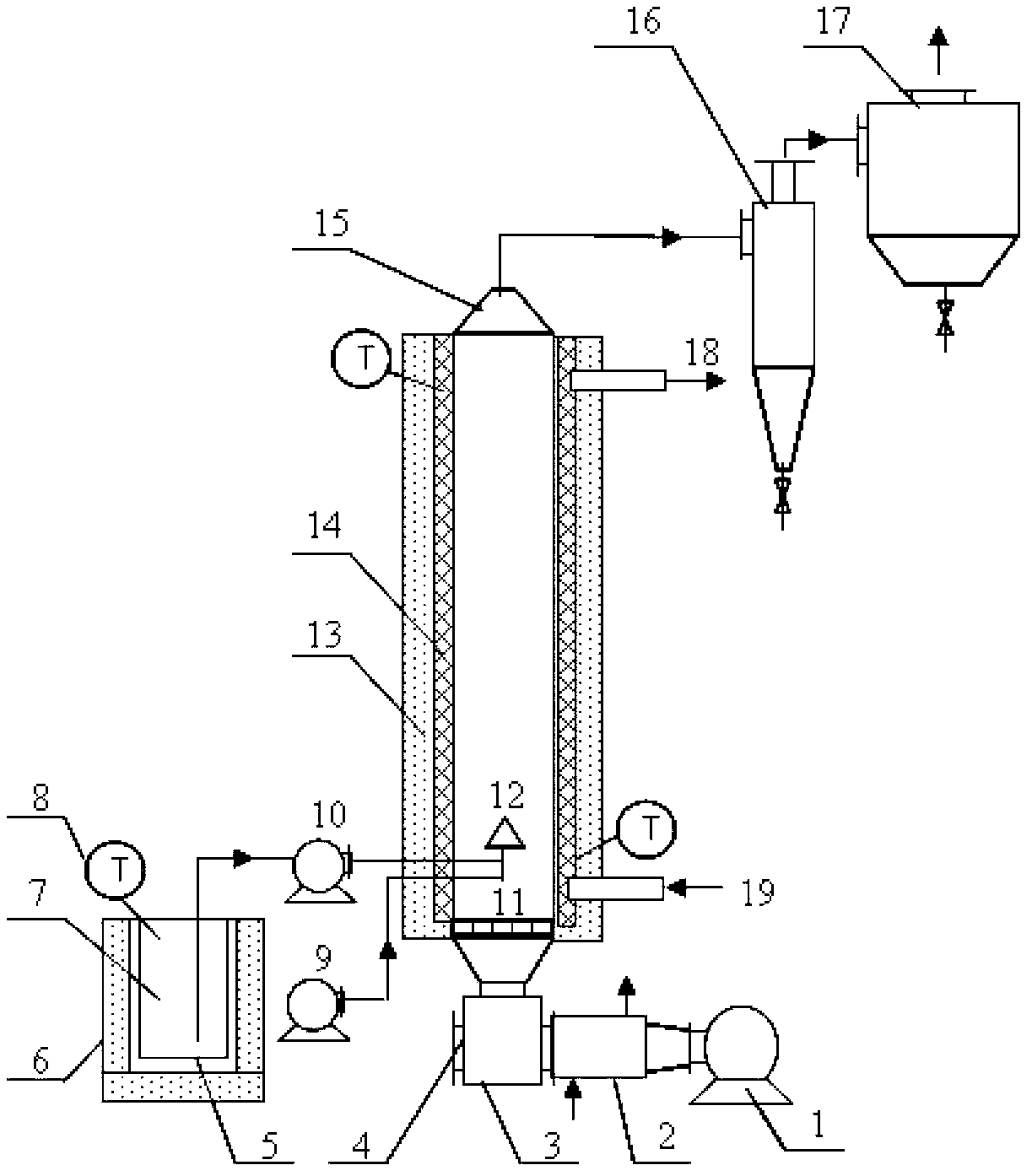

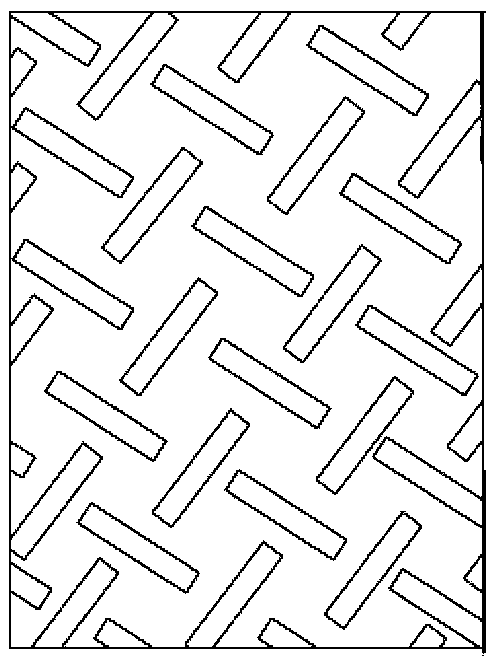

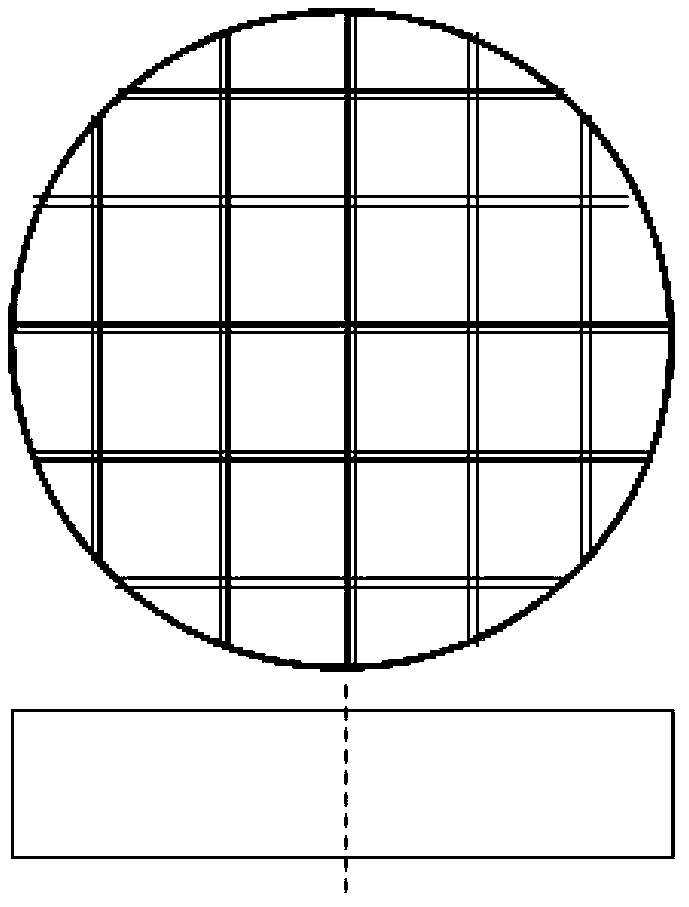

[0032] Such as figure 1 Shown is the spray granulation system under a kind of embodiment of the present invention, the double-deck cylindrical spray granulation tower 15 height 13m that stainless steel material is made, diameter 1.6m, tower wall double-layer jacket distance 30mm, cooling brine from tower The lower cooling brine inlet 19 enters the jacket and flows out from the cooling brine outlet 18 from bottom to top. Stainless steel fins with a height of 20mm and a length of 120mm are welded on the inner wall of the jacket 14, such as figure 2 As shown, a "T"-shaped layout structure is adopted between multiple fins to help increase the turbulence rate when the cooling water flows and improve the heat transfer rate.

[0033] Spray granulation tower 15 The outside of the tower body is wrapped with 150mm thick rock wool insulation material to effectively prevent the loss of cooling capacity in the tower; thermocouple thermometers are installed at the upper and lower ends of ...

Embodiment 2

[0035] Such as figure 1 Shown is the spray granulation system under one embodiment of the present invention. The stainless steel spray granulation tower 15 is a double-layer cylindrical tower body with a tower height of 3.6m and a diameter of 0.8m. The lower part enters the jacket and flows out from the upper cooling brine outlet 18. Stainless steel fins with a height of 20mm and a length of 120mm are welded on the inner wall of the jacket 14, and a "D"-shaped layout structure is adopted between a plurality of said fins, such as figure 2 As shown, it is beneficial to increase the turbulence rate when the cooling water flows.

[0036] The outer side of the tower body is wrapped with 150 mm thick insulation material to prevent the loss of cooling capacity in the tower body, and thermocouple thermometers are installed at the upper and lower ends of the tower body to detect and indicate the temperature of the outer wall of the tower body. The gas distributor 11 is installed at ...

Embodiment 3

[0039] A preparation method of polyethylene wax micropowder, comprising the steps of:

[0040] (1) Melting and conveying of raw materials: add the flake polyethylene wax solid into the polyethylene wax melting tank 7, the outer side of the melting tank is the electric heating oil bath jacket 5 and the insulation layer 6 in sequence, and the temperature range is controlled by the temperature controller 8 110-130°C, the solid polyethylene wax melts into a viscous flowing liquid; the flow rate of the viscous flowing liquid is 1m 3 / h thermal insulation gear pump 10 is transported to the air pressure composite atomizer 12, the gear pump provides a pressure range of 0.06-0.08MPa; the feed liquid is transported by a copper tube with a diameter of Φ20mm, and the outside of the tube is wrapped with a high-temperature-resistant thermal insulation material to prevent the feed liquid from being caused by The cooling condenses in the pipeline; the connecting pipeline from the melting tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com