Positioning adjustment workbench of laser scanning detection and servo system

A laser scanning and servo system technology, applied in workbenches, laser welding equipment, manufacturing tools, etc., can solve the problems of narrow space, insufficiency, misoperation, etc., and achieve the effect of simple operation, high precision, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

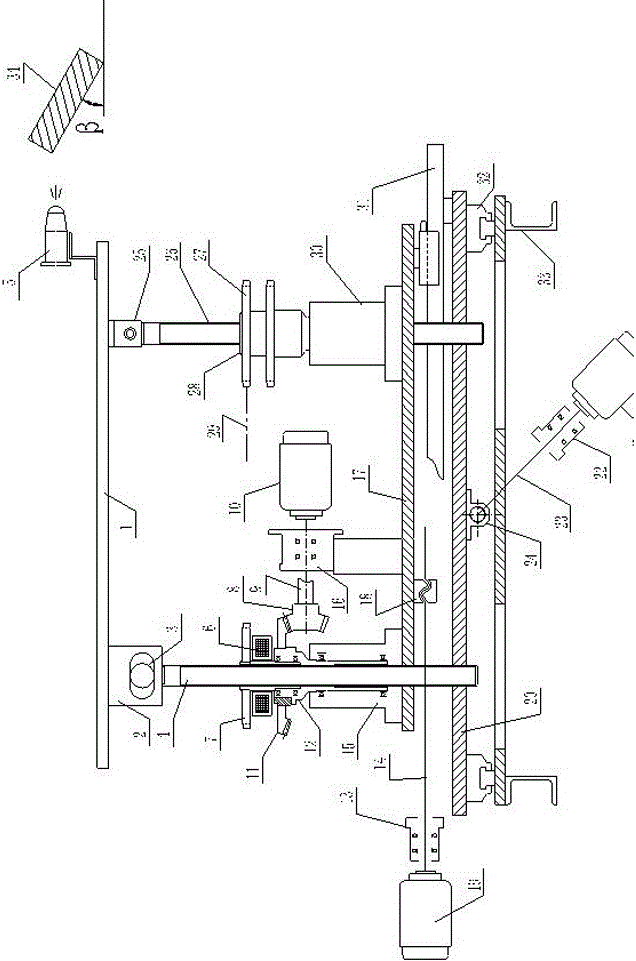

[0024] Such as figure 1 shown. The laser scanning detection and servo system positioning adjustment workbench of the present invention is composed of a laser scanning detection system, an X-axis moving unit, a Y-axis moving unit, a Z-axis moving unit and an angle adjustment system with a horizontal plane.

[0025] Among them, the laser scanning detection system is mainly composed of laser scanning, detection and recorder 5, which is the prior art. The function of the laser scanning detection system is to scan and capture the position of the target 34, detect the location, record and send execution instructions to the servo system.

[0026] The X-axis moving unit mainly includes a laterally moving nut 24, a laterally moving screw mandrel 23, a laterally moving servo motor 21, a laterally moving bearing seat 22, a laterally moving platform 20, and two pairs of linear sliding guide rail pairs 32 installed laterally. The linear sliding guide rail pair 32 is fixedly connected on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com