Method of Producing Carbon Fiber Reinforced Ceramic Matrix Composites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

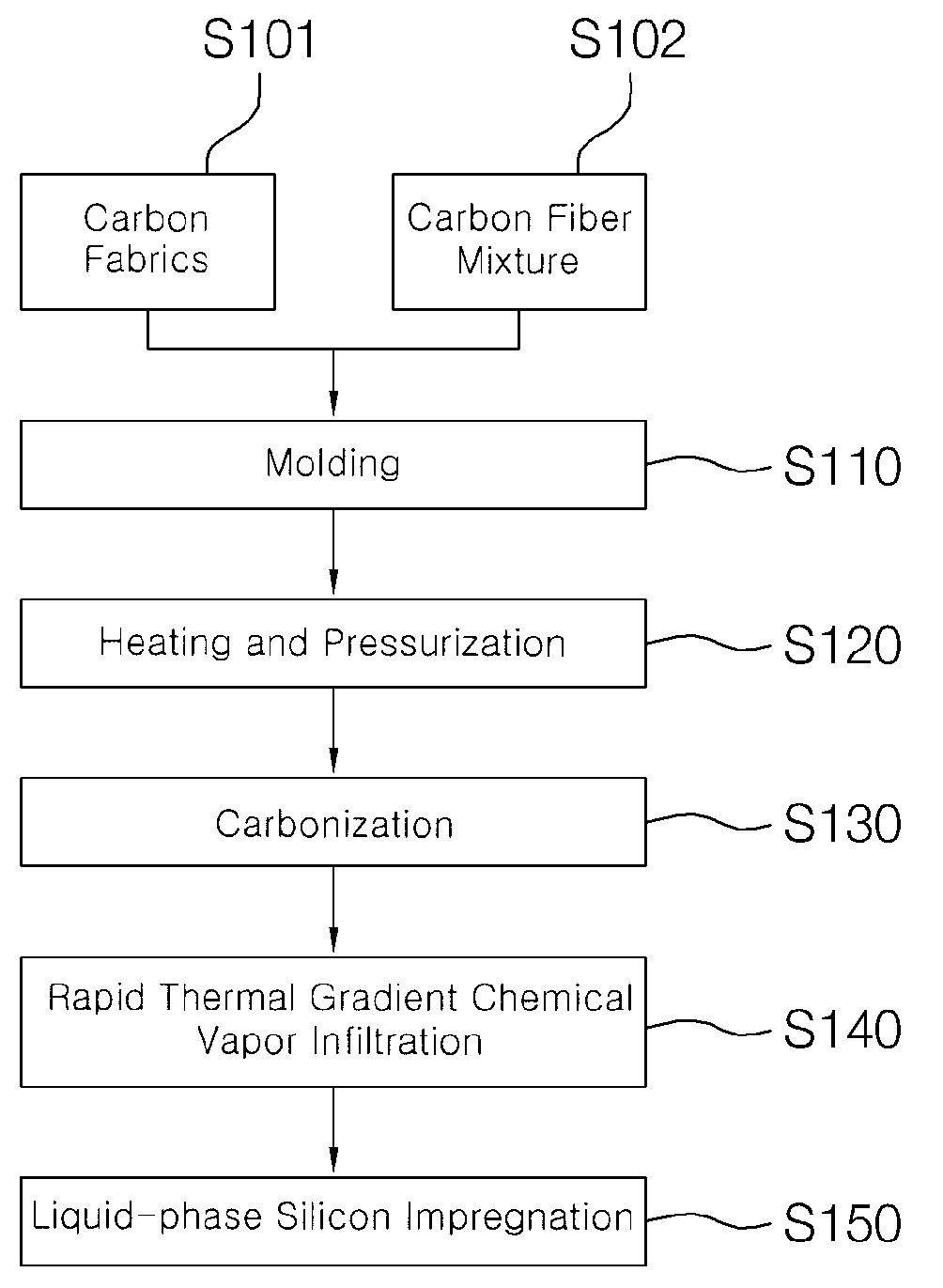

[0066]A mixture comprising 30 wt % carbon fibers that have been cut out in the size of 30 mm, 40 wt % phenol resin, 5 wt % carbon powder, and 5 wt % silicon carbide powder is prepared and stacked alternately with carbon fabrics in the form of 20 wt % satin weave to produce a green body. The produced green body is placed in a mold, and then cured while being pressurized at a pressure 2 MPa for 10 minutes to produce a carbon fiber reinforced resin composite.

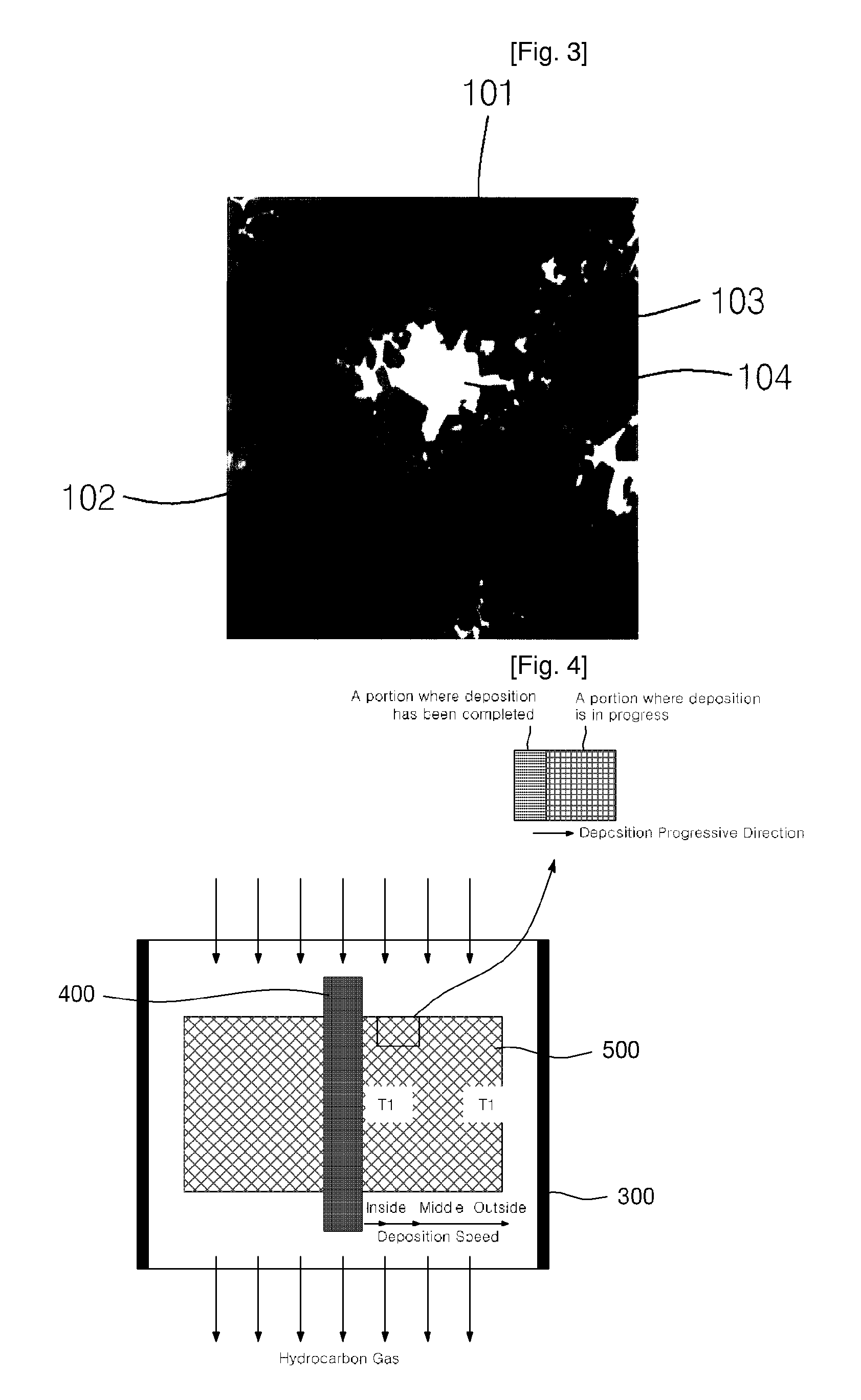

[0067]The carbon fiber reinforced resin composite is subjected to thermal treatment in inert gas atmosphere. Furthermore, pyrolytic carbon is deposited in a condition of rapid thermal gradient chemical vapor infiltration process to produce a carbon fiber reinforced carbon composite.

[0068]The produced carbon fiber reinforced carbon composite is stacked on silicon powder, and heated at 1,550° C. in vacuum atmosphere, and infiltrated with liquid-phase silicon to produce a carbon fiber reinforced ceramic matrix composite. Here, physica...

second embodiment

[0069]A mixture comprising 55 wt % carbon fibers that have been cut out in the size of 30 mm, 35 wt % phenol resin, 5 wt % carbon powder, and 5 wt % silicon carbide powder is prepared to produce a green body. Stacking alternately with carbon fabrics is not implemented in the second embodiment. The produced green body is placed in the mold, and then cured while being pressurized at a pressure 2 MPa for 10 minutes to produce a carbon fiber reinforced resin composite.

[0070]The carbon fiber reinforced resin composite is subjected to thermal treatment in inert gas atmosphere. Furthermore, pyrolytic carbon is deposited in a condition of rapid thermal gradient chemical vapor infiltration process to produce a carbon fiber reinforced carbon composite.

[0071]The produced carbon fiber reinforced carbon composite is stacked on silicon powder, and heated at 1,550° C. in vacuum atmosphere, and infiltrated with liquid-phase silicon to produce a carbon fiber reinforced ceramic matrix composite. Here...

third embodiment

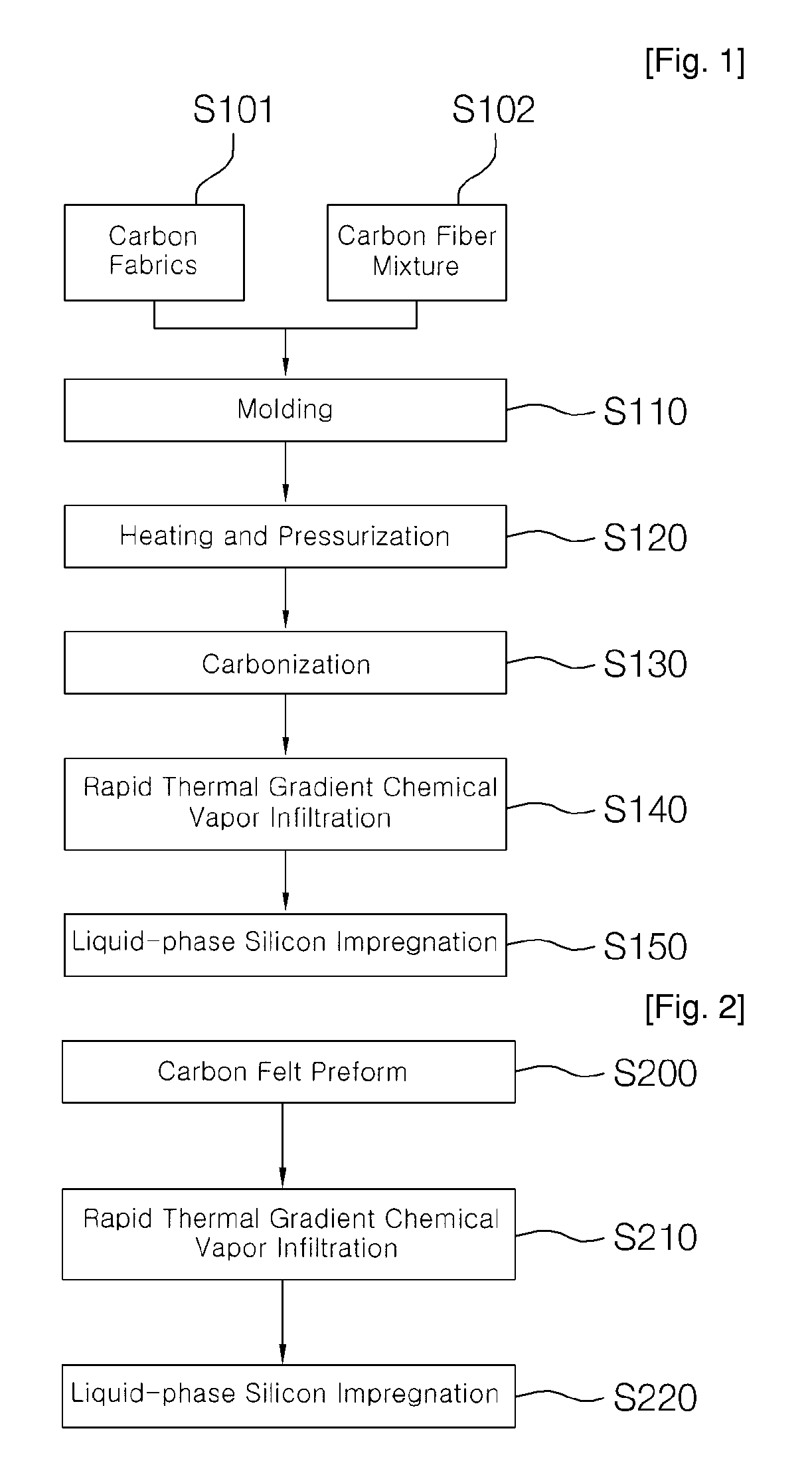

[0072]320K oxyphene carbon fiber is wound around a mandrel to produce unidirectional carbon mats, and the carbon mats produced by this method are stacked together. For stacking method, they are stacked alternately by a method of 0 / +60 / −60°.

[0073]At least two layers are stacked together, and then punched using a needle to reinforce every layer in the z-direction, and the process is reiterated to produce a felt preform having 30 mm in thickness. This felt preform is produced at approximately 45% of oxyphene fiber volume ratio, where the thickness of a layer is approximately 0.9 mm, and the fiber ratio in the z-direction is approximately 10%.

[0074]The produced preform is subjected to thermal treatment at 1,700° C. in vacuum atmosphere to remove the impurities of the preform.

[0075]Pyrolytic carbon is deposited on the produced carbon felt preform in a condition of rapid thermal gradient chemical vapor infiltration process to produce a carbon fiber reinforced carbon composite.

[0076]The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com