Continuous fiber fabric reinforced thermoplastic resin composite material and production method thereof

A thermoplastic resin and continuous fiber technology, which is applied in the field of continuous fiber fabric reinforced thermoplastic resin composite materials and its production, can solve the problems of unsatisfactory impregnation effect of fibers and resin, and achieve environmental protection and reliable operation process, simple process and good impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

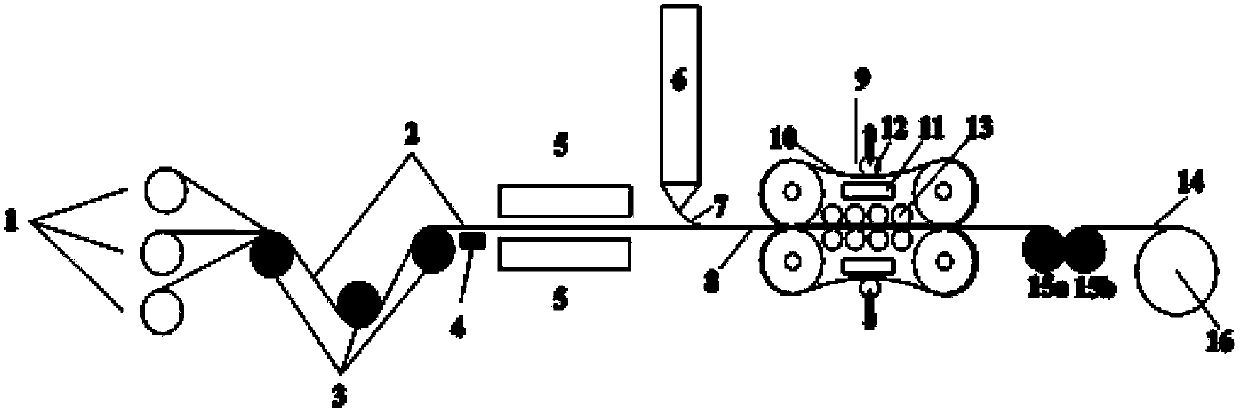

Method used

Image

Examples

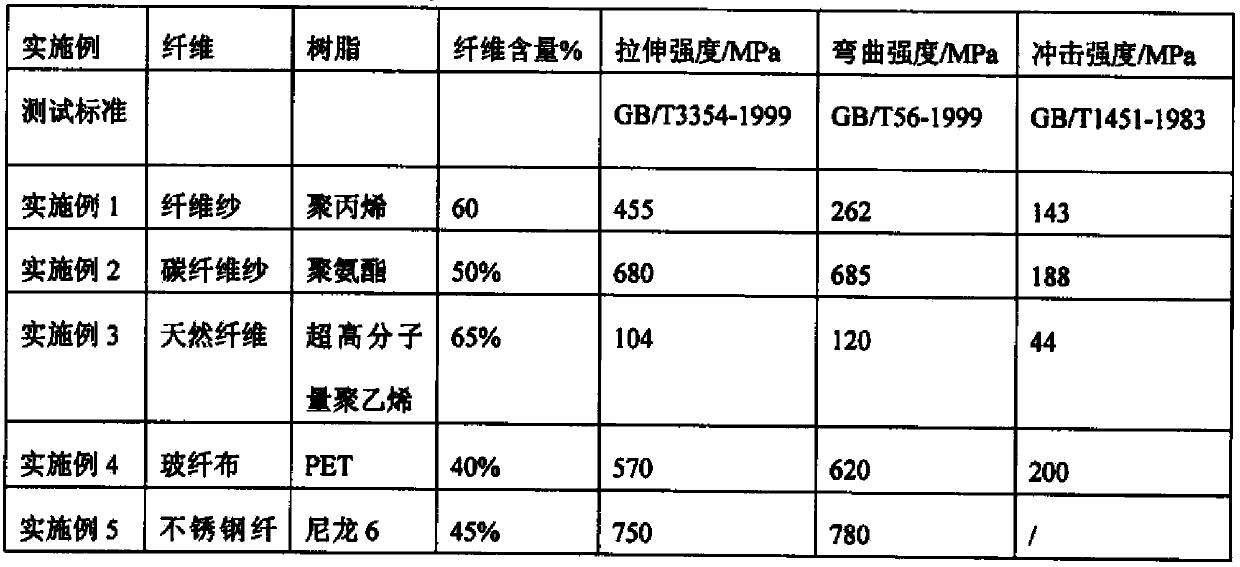

Embodiment 1

[0066] Install the continuous glass fiber roll (PPG company 45882400tex) on the creel 1, draw the continuous fiber yarn in parallel and evenly and pass through the tension roller 3 to ensure the initial dispersion of the fiber, and the glass fiber forms a unidirectional fiber yarn arranged in parallel and evenly. The static electricity of the glass fiber is eliminated by the static elimination device 4, and then the continuous fiber enters the preheating oven 5, and the temperature set in the oven here is 240°C.

[0067] At the impregnation device, the screw extruder extrudes polypropylene resin (7726 of Yanshan Petrochemical), which has a relatively low viscosity, and pours it onto the glass fiber unidirectional yarn 2 and passes through a double-belt roller press 9, which is in contact with the resin The distance between the upper and lower two steel strips 10 faces is 0.25mm. The temperature of the heating oven is 230°C. After the impregnation is complete, it enters the coo...

Embodiment 2

[0069] Install the continuous carbon fiber roll (Toray T70024K) on the creel 1, draw the continuous carbon fiber yarn in parallel and evenly and pass through the tension roller 3 to ensure the initial dispersion of the fiber, and the glass fiber forms a unidirectional fiber yarn arranged in parallel and evenly. The static eliminator 4 eliminates the static electricity of the glass fiber, and then the continuous fiber enters the preheating oven 5, where the temperature set in the oven is 230°C.

[0070] At the impregnation device, the screw extruder extrudes thermoplastic polyurethane resin (Desmpaopan 372X), extruded and poured onto the carbon fiber unidirectional yarn 2, and passes through a double-belt roller press 9, and the upper and lower steel belts 10 of the roller press are in contact with the resin. The distance between the faces is 0.30mm. The temperature of the heating oven is 220°C. After the impregnation is complete, it enters the cooling and setting device. The g...

Embodiment 3

[0072] Install the continuous natural fiber felt (the natural fiber is ramie fiber provided by Nanjing Xinhe Co., Ltd.) on the unwinding roller 1, carefully lead the continuous natural fiber felt out and pass the tension roller 3 to ensure the smoothness of the fiber surface, pass through the static elimination device 4 Eliminate the static electricity of the glass fiber, and then the continuous fiber enters the preheating oven, where the temperature of the oven is set at 210°C.

[0073] At the impregnation device, the screw extruder extrudes ultra-high molecular weight polyethylene resin with low viscosity, poured onto the continuous natural fiber mat 2 and passes through the double-belt roller press 9, the upper and lower two of the roller press are in contact with the resin The distance between the surfaces of the steel strip 10 is 0.20mm. The temperature of the heating oven is 200°C. After the impregnation is complete, it enters the cooling and setting device. The gap betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com