Two-component solvent-free polyurethane adhesive and preparation method thereof

A polyurethane adhesive, solvent-free technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of large limitations, high viscosity of polyurethane adhesives, and affecting the production of flexible packaging bonding effects. Efficiency and other issues, to achieve the effect of increasing contact opportunities, low viscosity, and solving poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

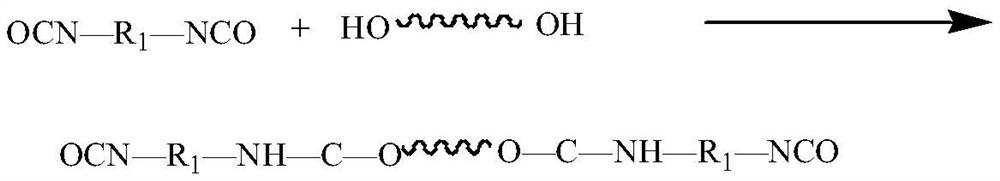

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of above-mentioned a kind of two-component solvent-free polyurethane adhesive comprises the following steps:

[0029] (1) Carry out dehydration treatment on the polyether diol formulated at 110-130°C under reduced pressure, and then add it dropwise to the polyisocyanate at 60-80°C while stirring, and control the dropping time to 0.8-1.2h, Then, under the protection of nitrogen, keep warm for 1.5-2.5 hours, cool to room temperature, and obtain the terminal isocyanate prepolymer of component A;

[0030] (2) Mix the castor oil of the formula quantity with the catalyst, phthalic anhydride, small molecule dibasic acid and small molecule dibasic alcohol, under the protection of nitrogen, heat up to 140-160°C while stirring, and keep the heat for 2.5-3.5h after the reaction, Heat preservation and dehydration for 1-2 hours, then continue to heat up to 200-230°C, keep the temperature of the distillation head below 100°C, keep heat for 2-3 hours, and then c...

Embodiment 1

[0041] A preparation method of a two-component solvent-free polyurethane adhesive, comprising the steps of:

[0042] (1) Carry out dehydration treatment under reduced pressure on the polyether diol PPG1000 of the formulation amount at 120°C, and then add it dropwise to polymethylene polyphenylisocyanate at 70°C while stirring, and control the dropping time to 1h, Then, under the protection of nitrogen, the reaction was kept for 2 hours, cooled to room temperature, and the terminal isocyanate prepolymer of component A was obtained, wherein the molar ratio of polyether diol to polymethylene polyphenyl isocyanate was 4:1;

[0043] (2) Mix the castor oil with the catalyst methanesulfonic acid, phthalic anhydride, adipic acid and neopentyl glycol, under the protection of nitrogen, heat up to 140-160°C while stirring, keep the heat for 3.5 hours, and then dehydrate 2h, then continue to heat up to 210°C, keep the head temperature less than 100°C, keep warm for 3h and then cool to obt...

Embodiment 2

[0046] A preparation method of a two-component solvent-free polyurethane adhesive, comprising the steps of:

[0047] (1) At 120°C, the polyether diol PPG400 of the formulated amount was dehydrated under reduced pressure, and then added dropwise to polymethylene polyphenylisocyanate at 70°C while stirring, and the dropping time was controlled to be 1h. Then, under the protection of nitrogen, the reaction was kept for 2 hours, cooled to room temperature, and the terminal isocyanate prepolymer of component A was obtained, wherein the molar ratio of polyether diol to polymethylene polyphenyl isocyanate was 5:1;

[0048](2) Mix the castor oil in the formula quantity with the catalyst methanesulfonic acid, phthalic anhydride, adipic acid and neopentyl glycol, and under the protection of nitrogen, heat up to 140-160°C while stirring. h, then continue to heat up to 200°C, keep the head temperature less than 100°C, keep warm for 3h and then cool to obtain castor oil modified polyester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com