Economical High Pressure Wear Resistant Cylinder That Utilizes A High Pressure Field For Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

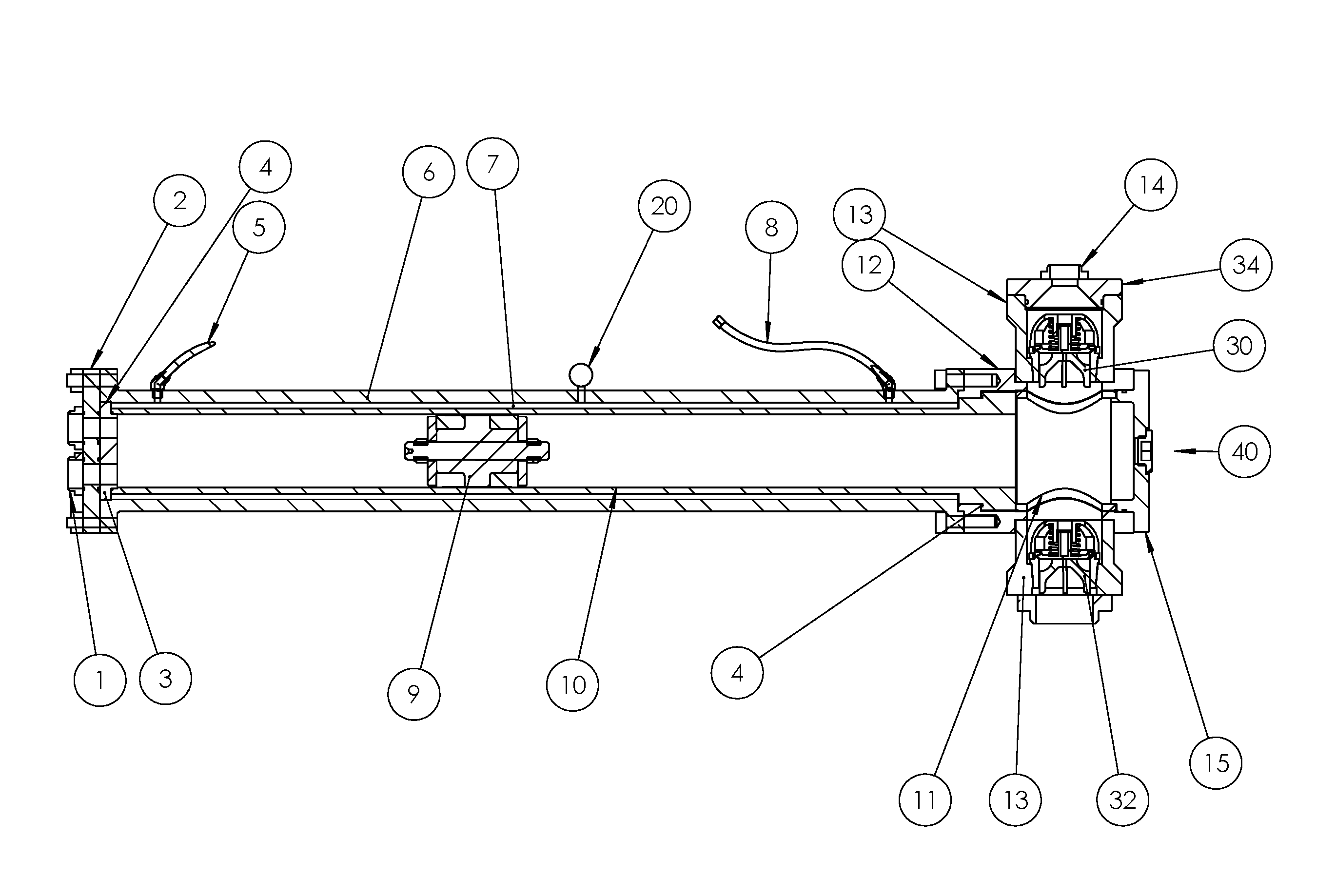

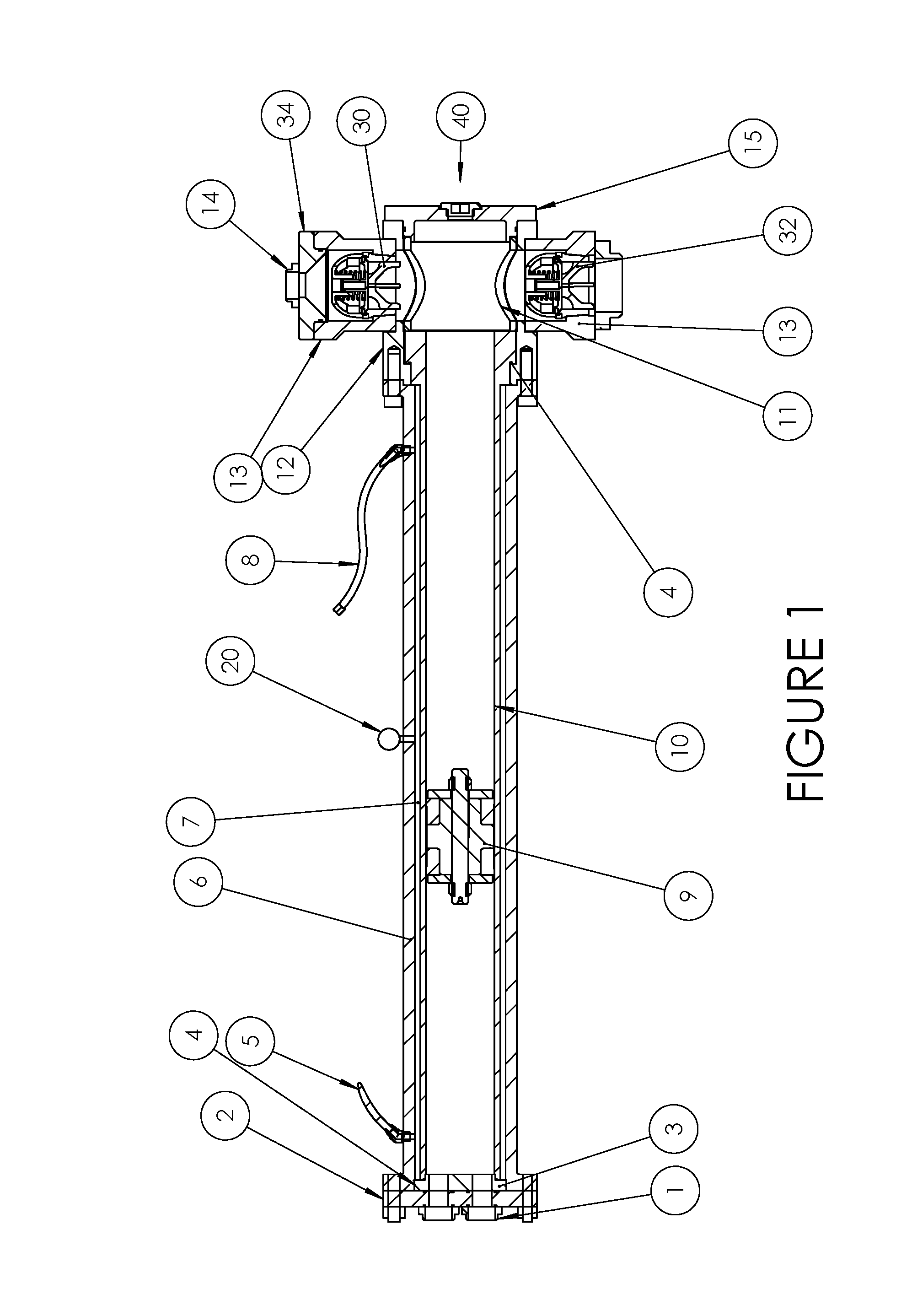

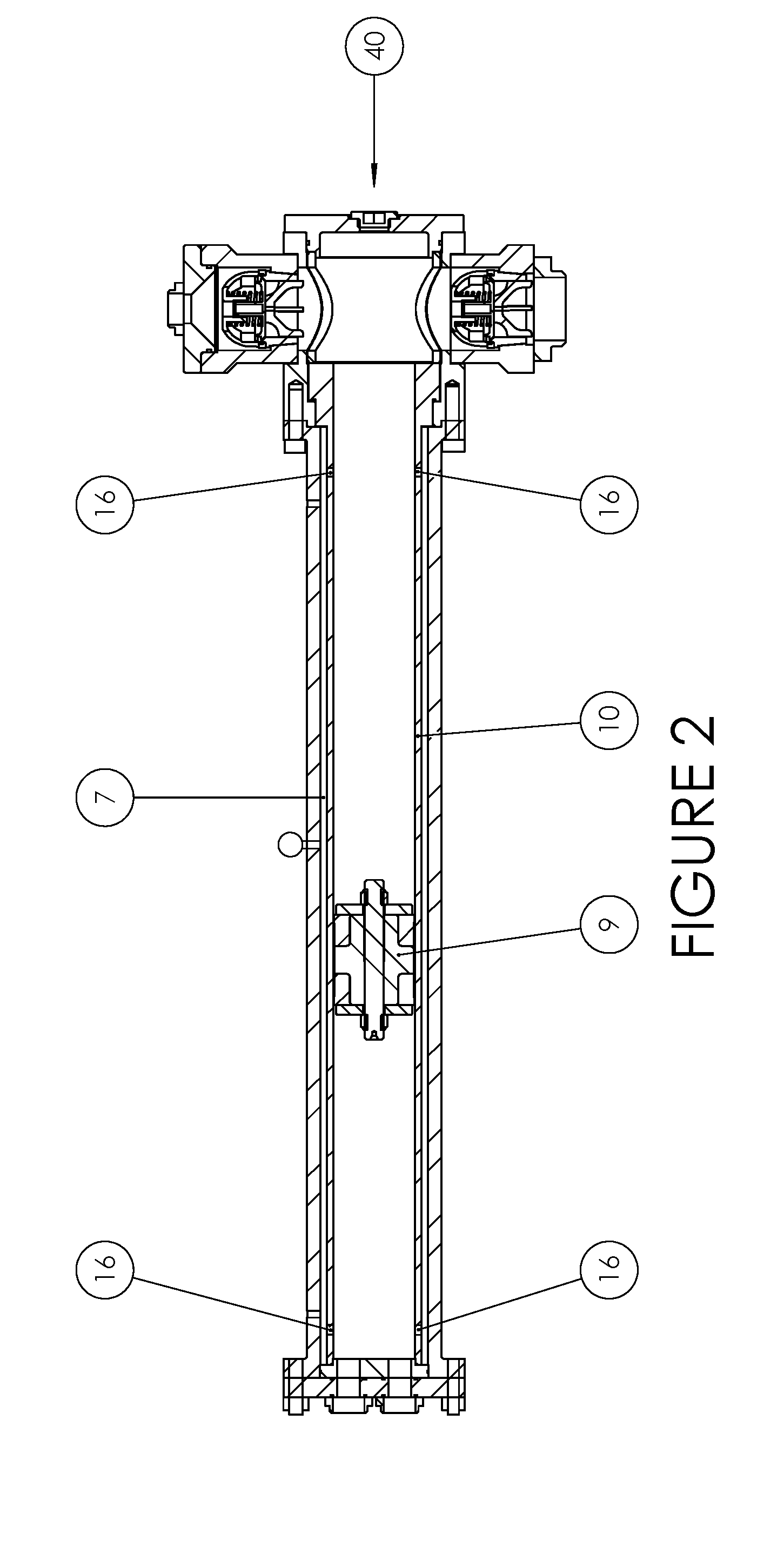

[0027]Referring now to FIG. 1, a reciprocating dual work exchanger is shown. The reciprocating dual work exchanger having a special high-pressure flange (1) that is connected to a main casing flange (2), which holds a support piece (3), for securing a high-pressure wear resistant cylinder (10) that utilizes a high-pressure field (7) for strength. The high-pressure field (7) is created between an outer pressure chamber (6) and the high-pressure wear resistant cylinder (10). The high-pressure field (7) may be fed with charging lines (5 and 8) together with an external pressure source (not shown) such as a dedicated pressure circuit or pressure from the source that drives the work exchanger. A piston (9) will move back and forth through the high-pressure wear resistant cylinder (10). The high-pressure wear resistant cylinder (10) is positioned and sealed in with positioning pieces (3 and 11) in the sealing region (4) through use of O-rings, gaskets or other methods suitable for handlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com