Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Small density difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

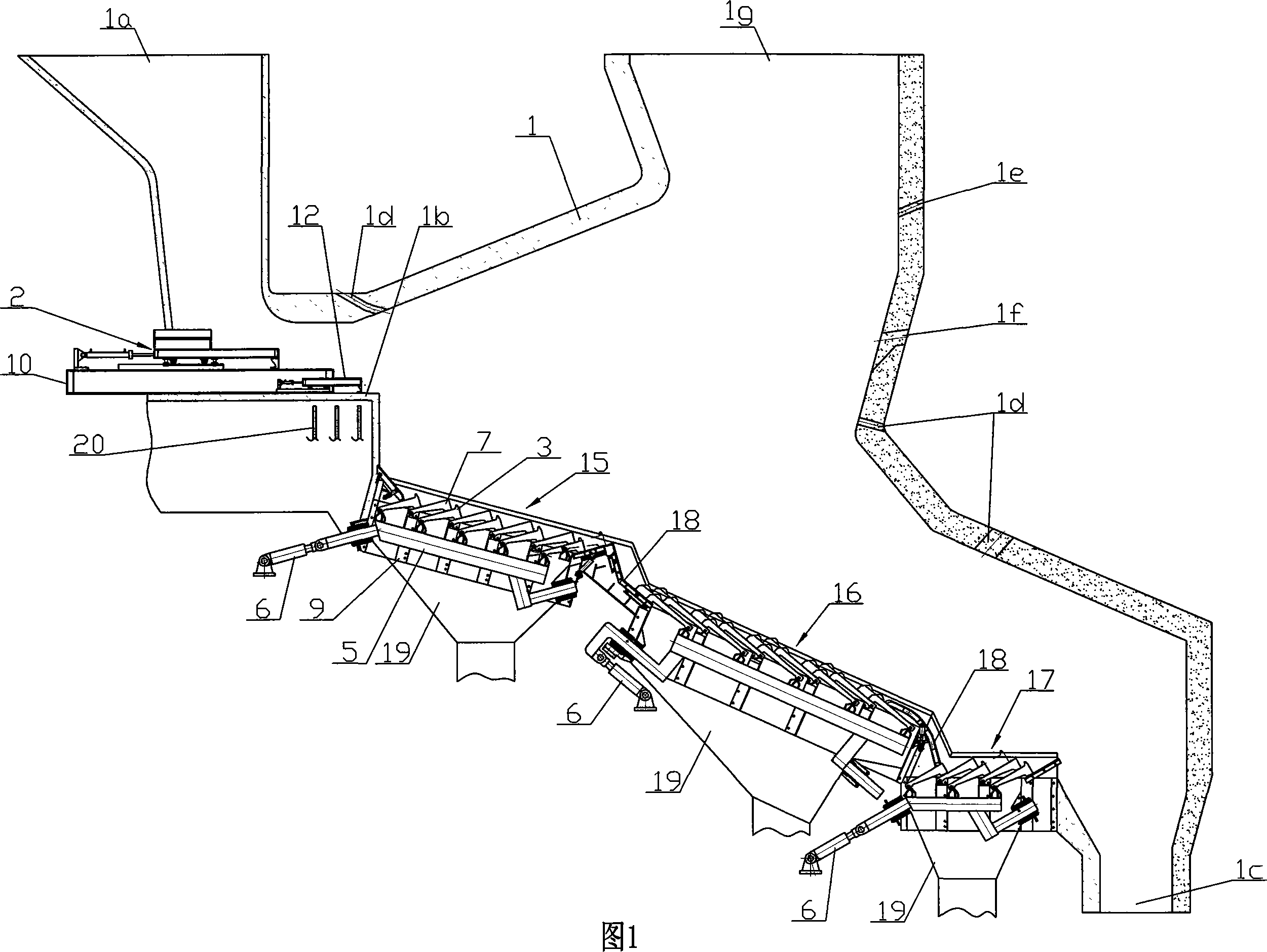

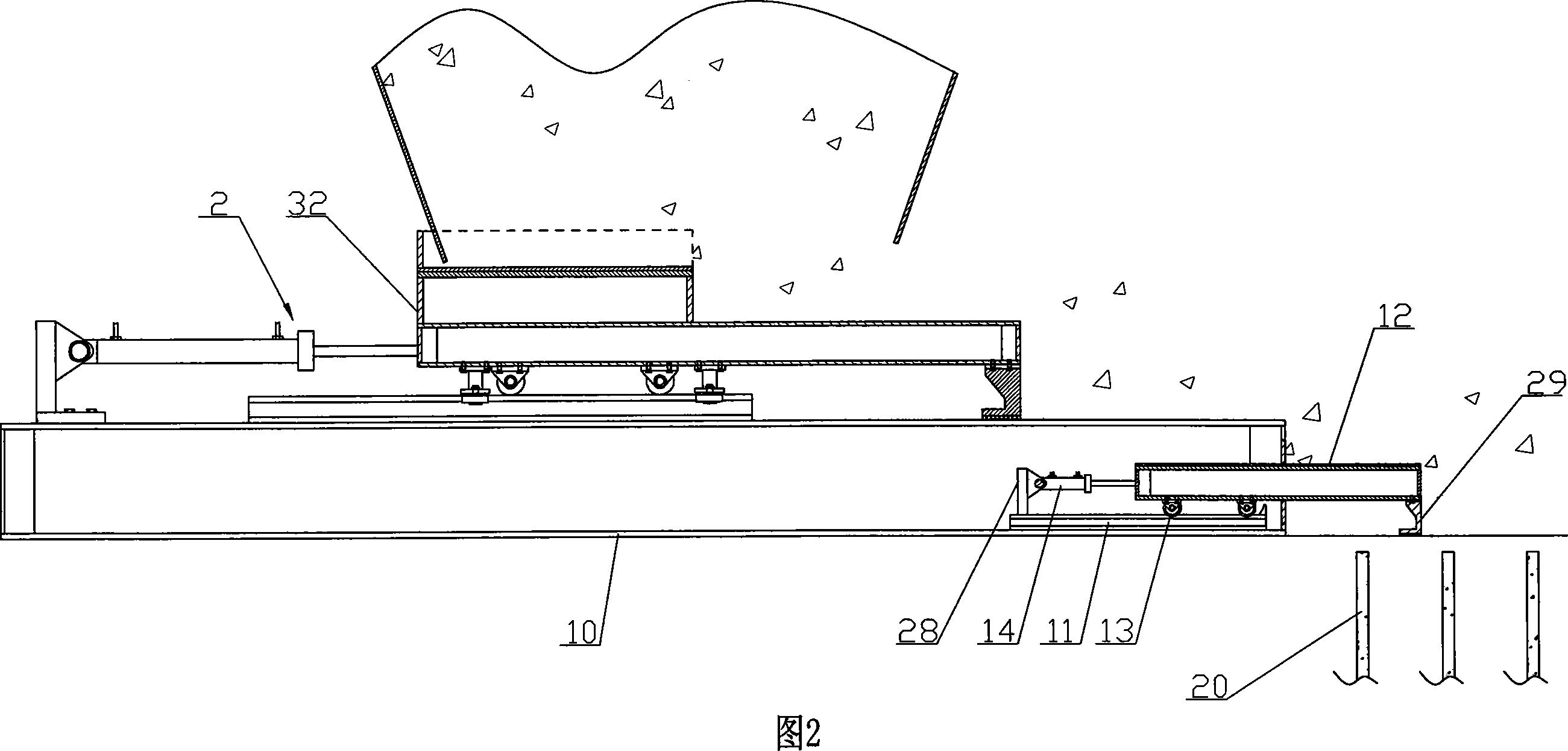

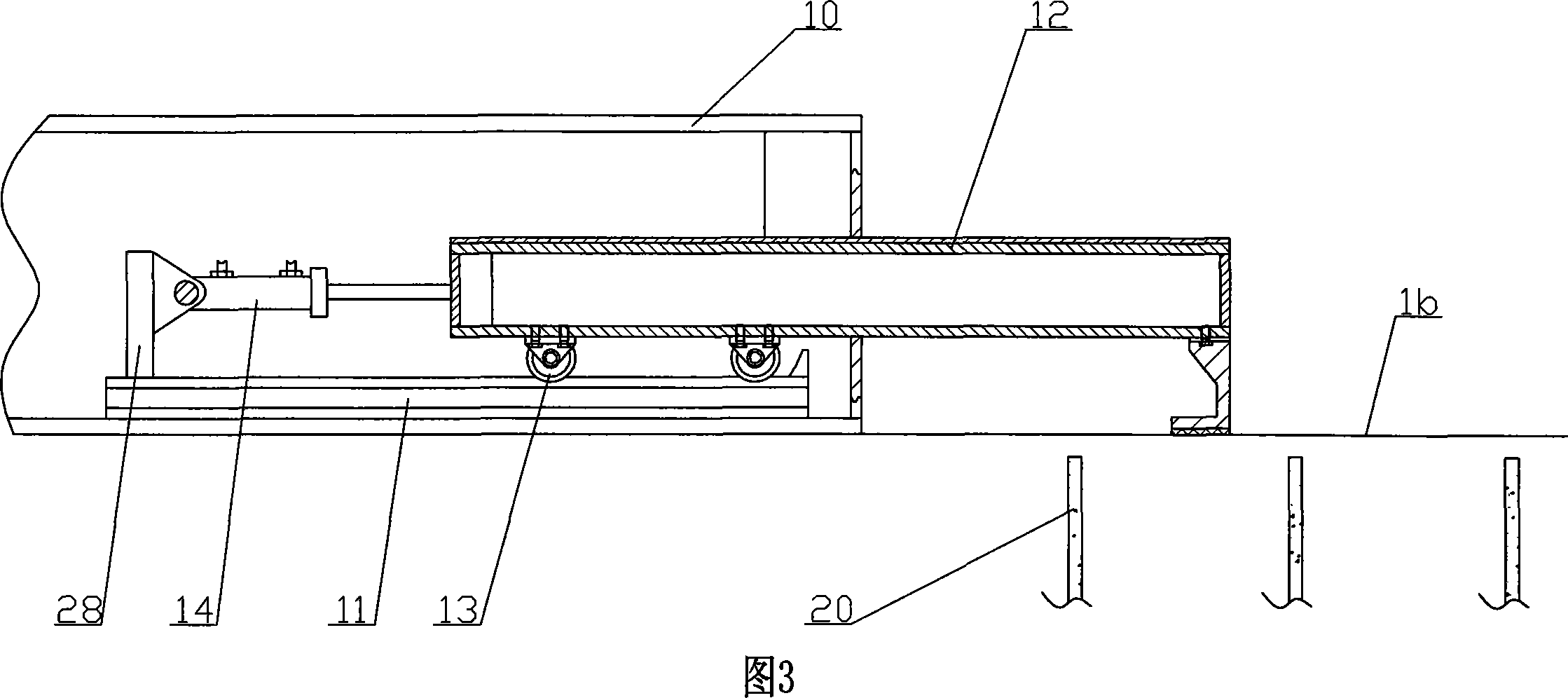

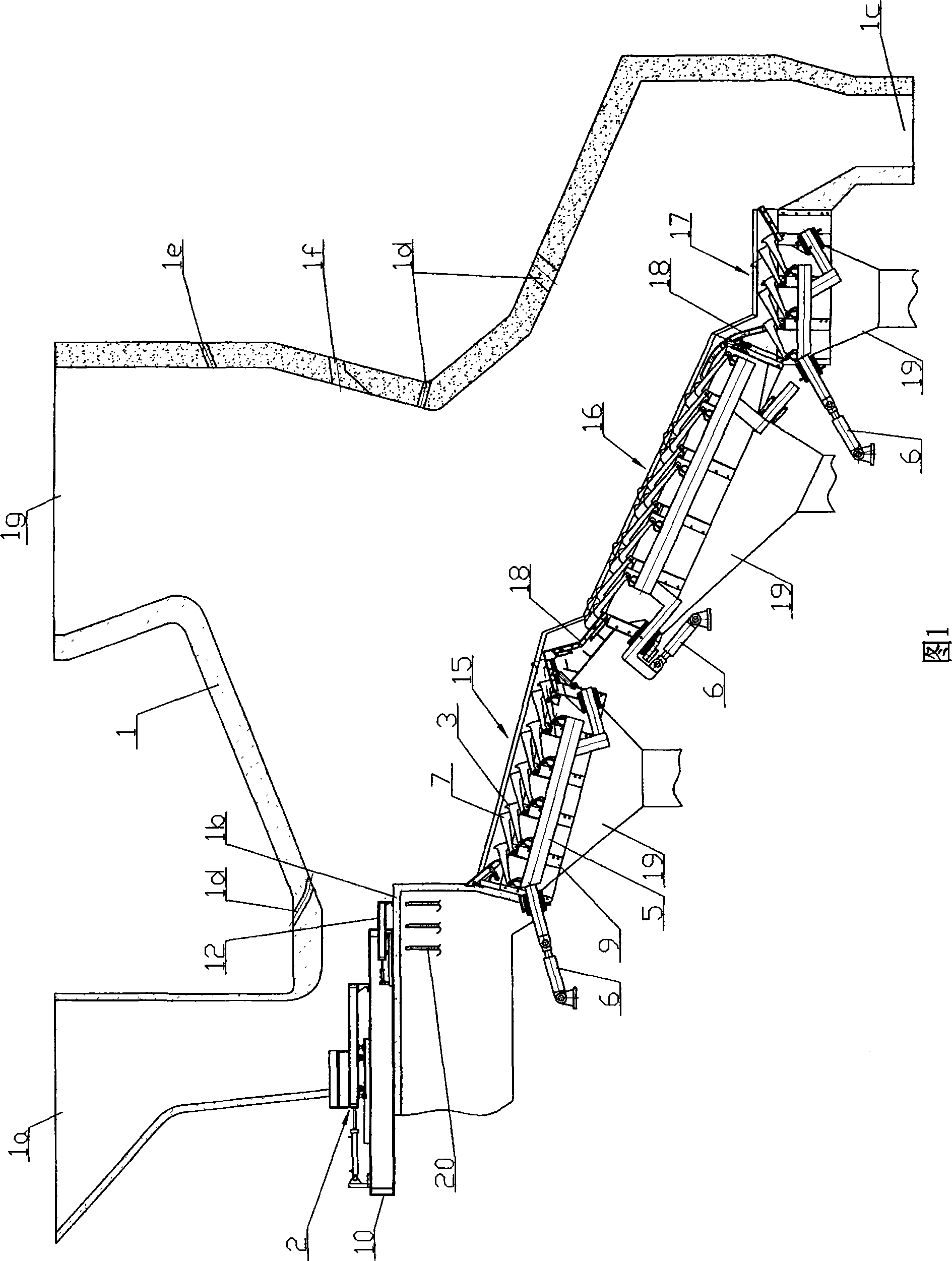

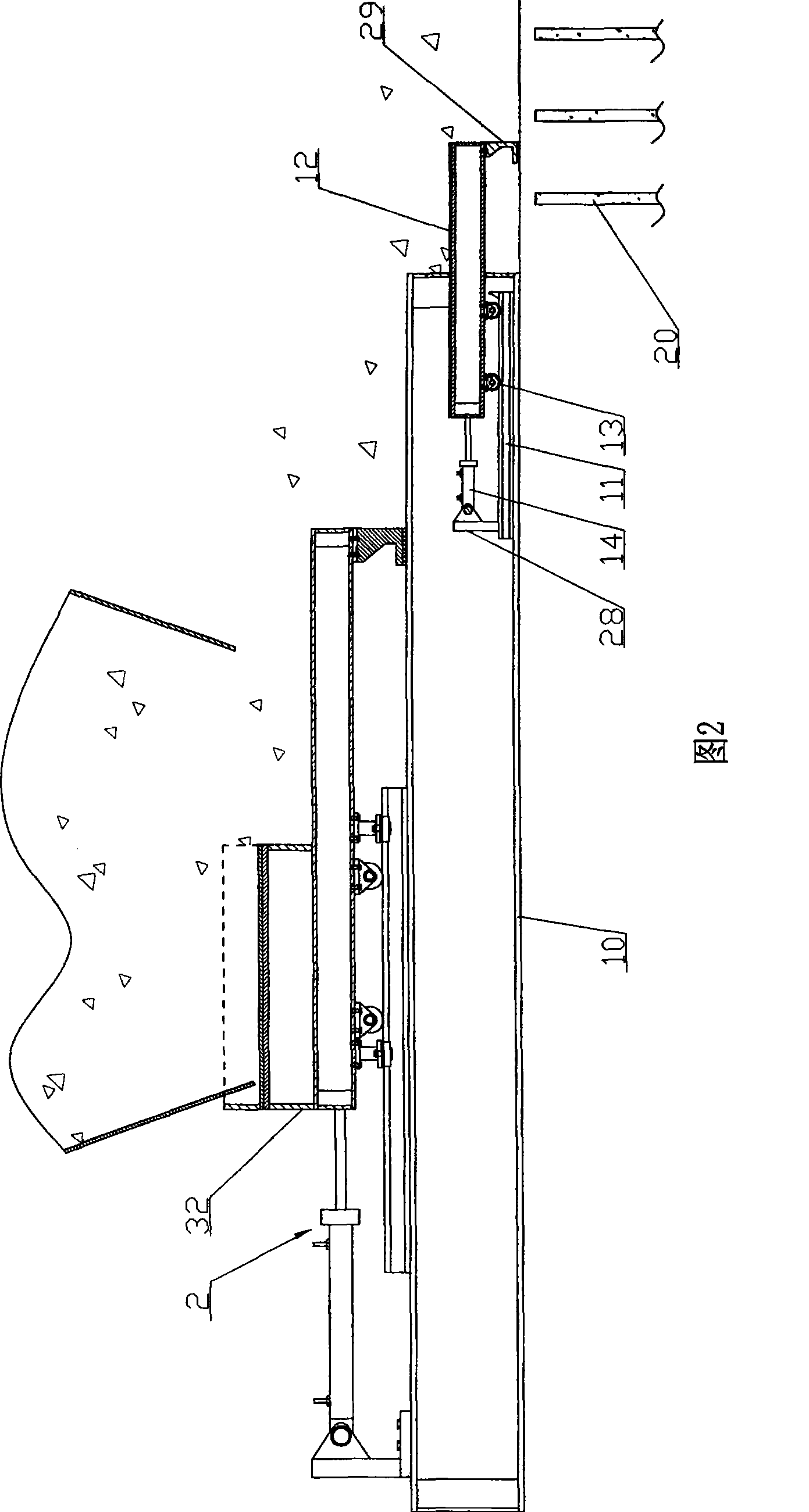

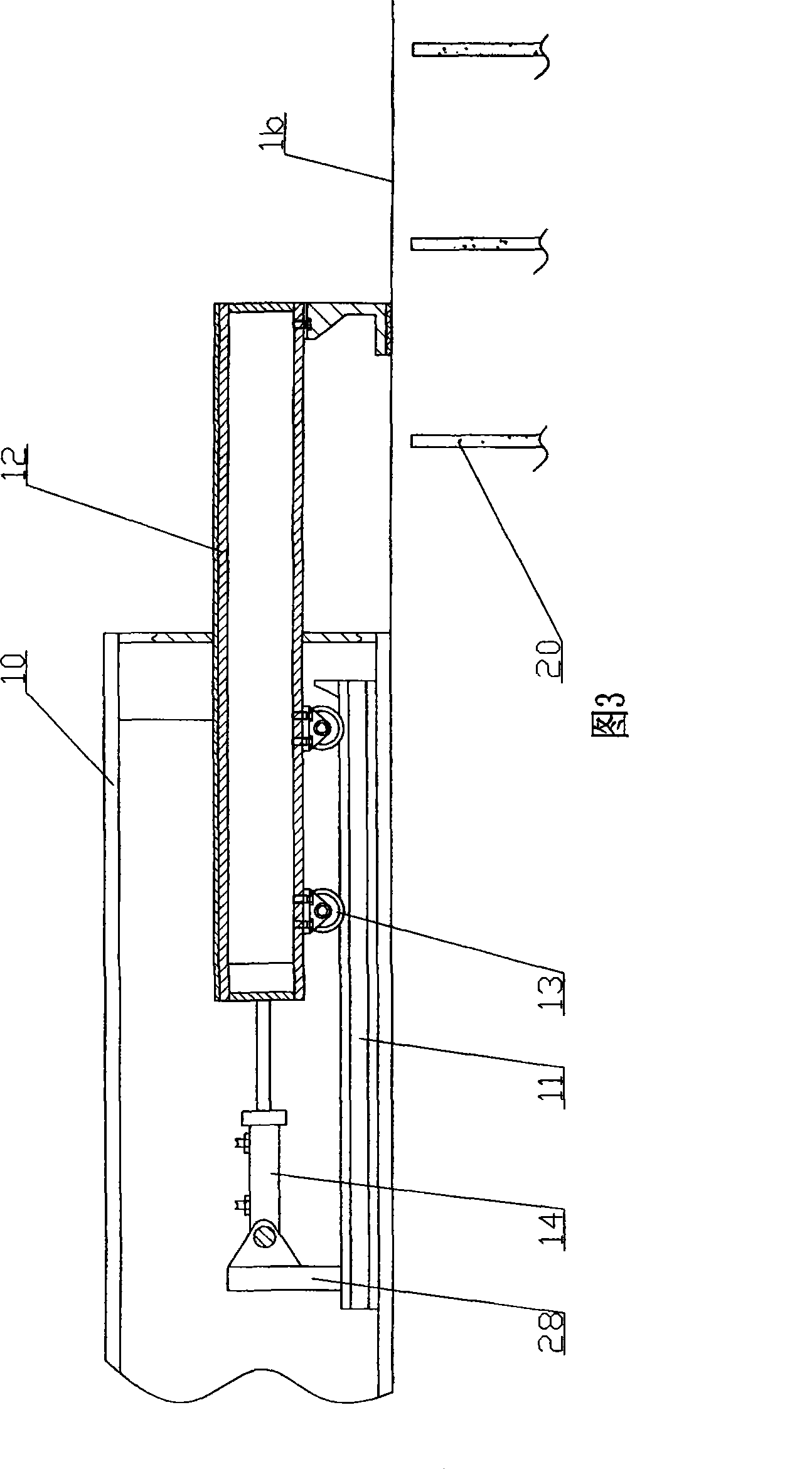

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

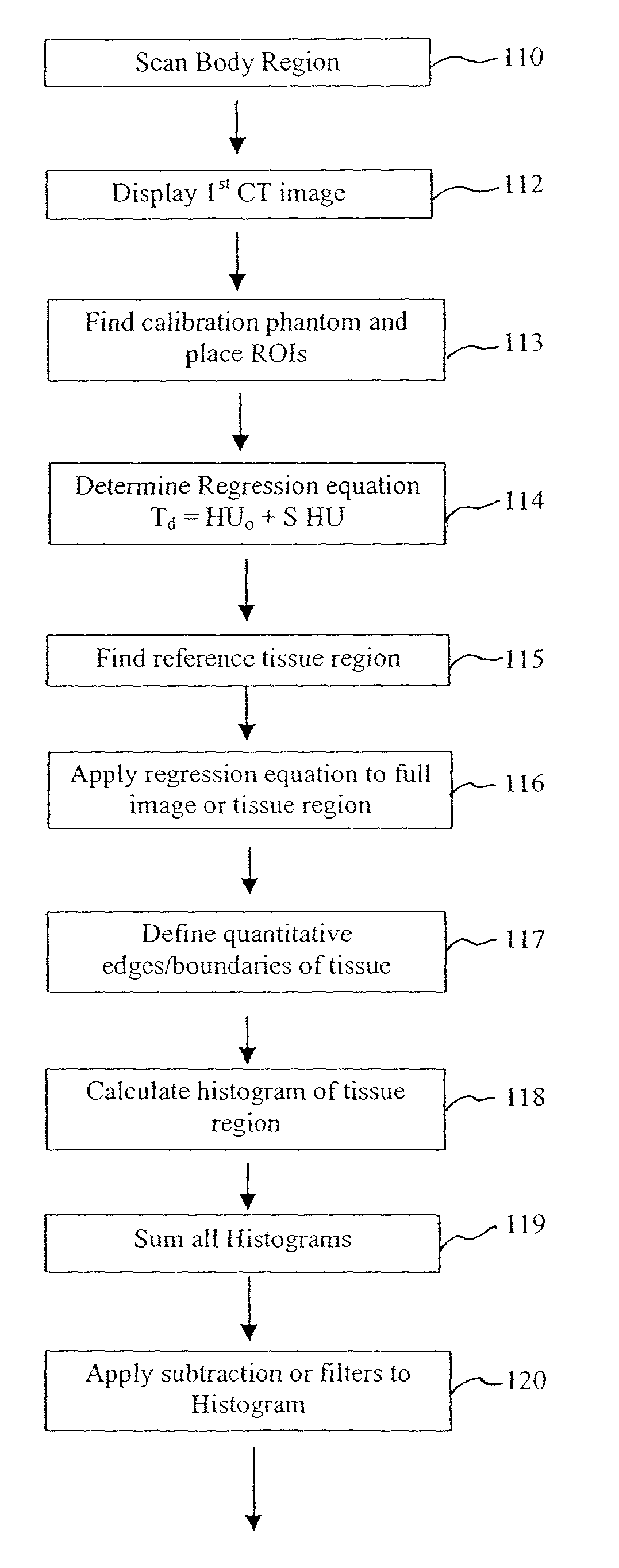

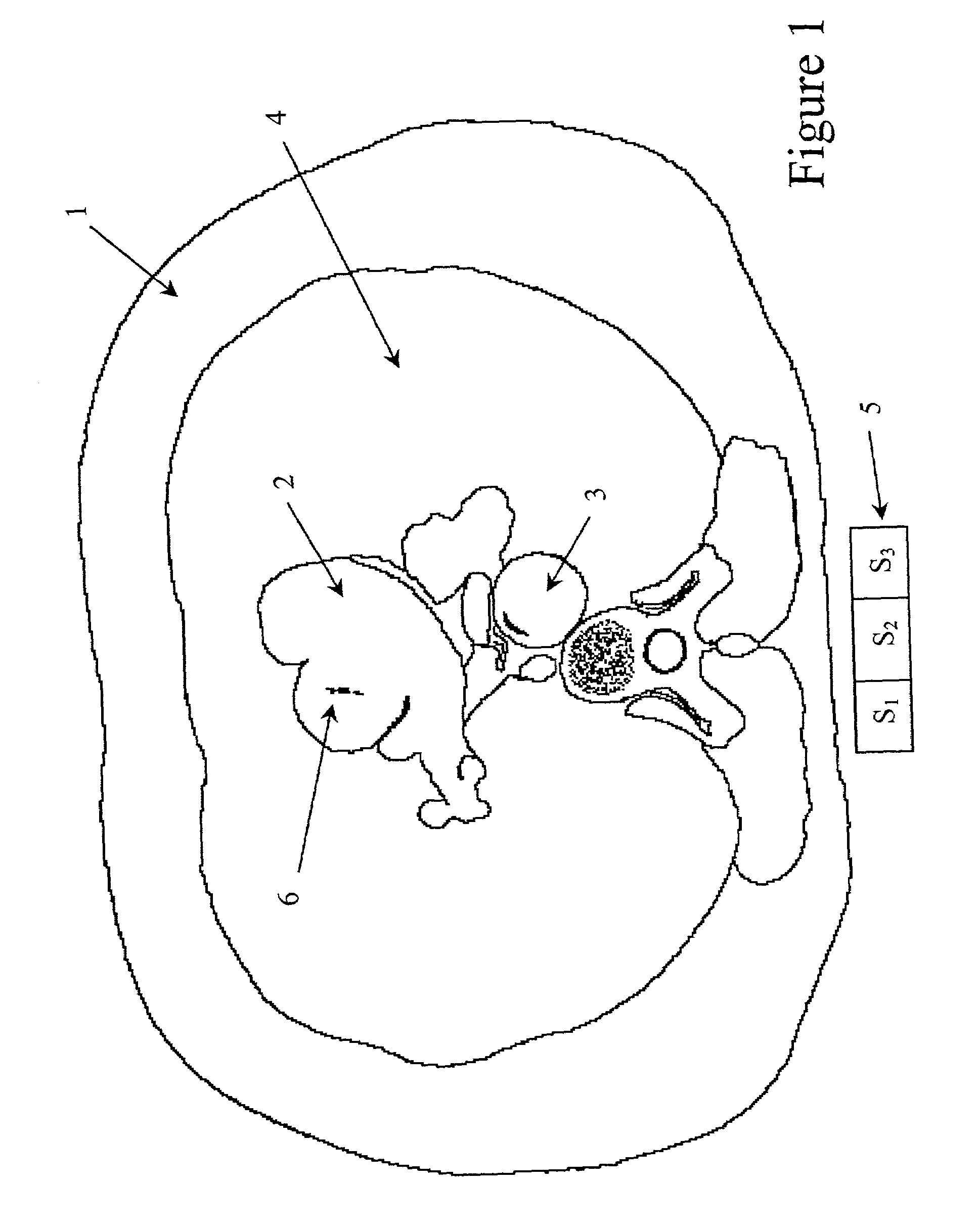

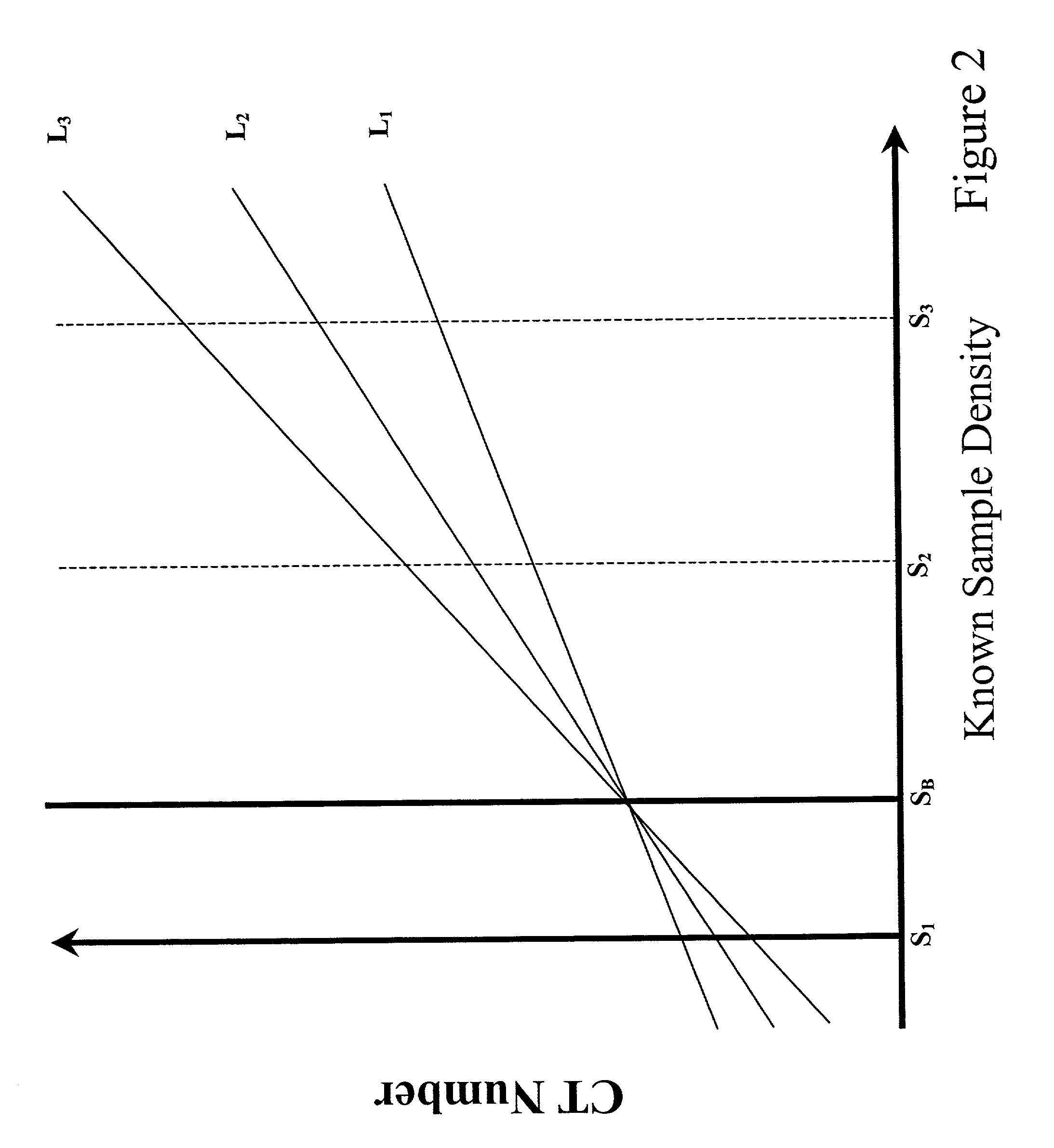

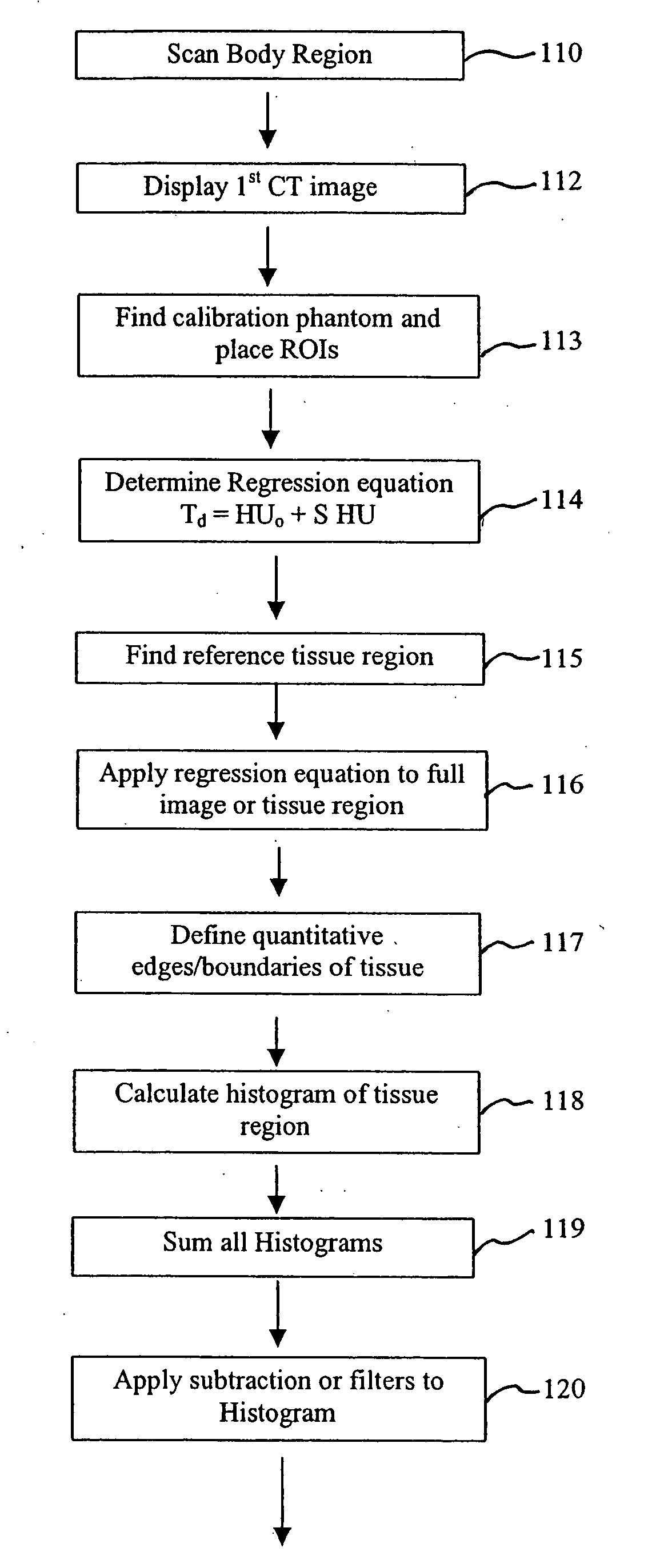

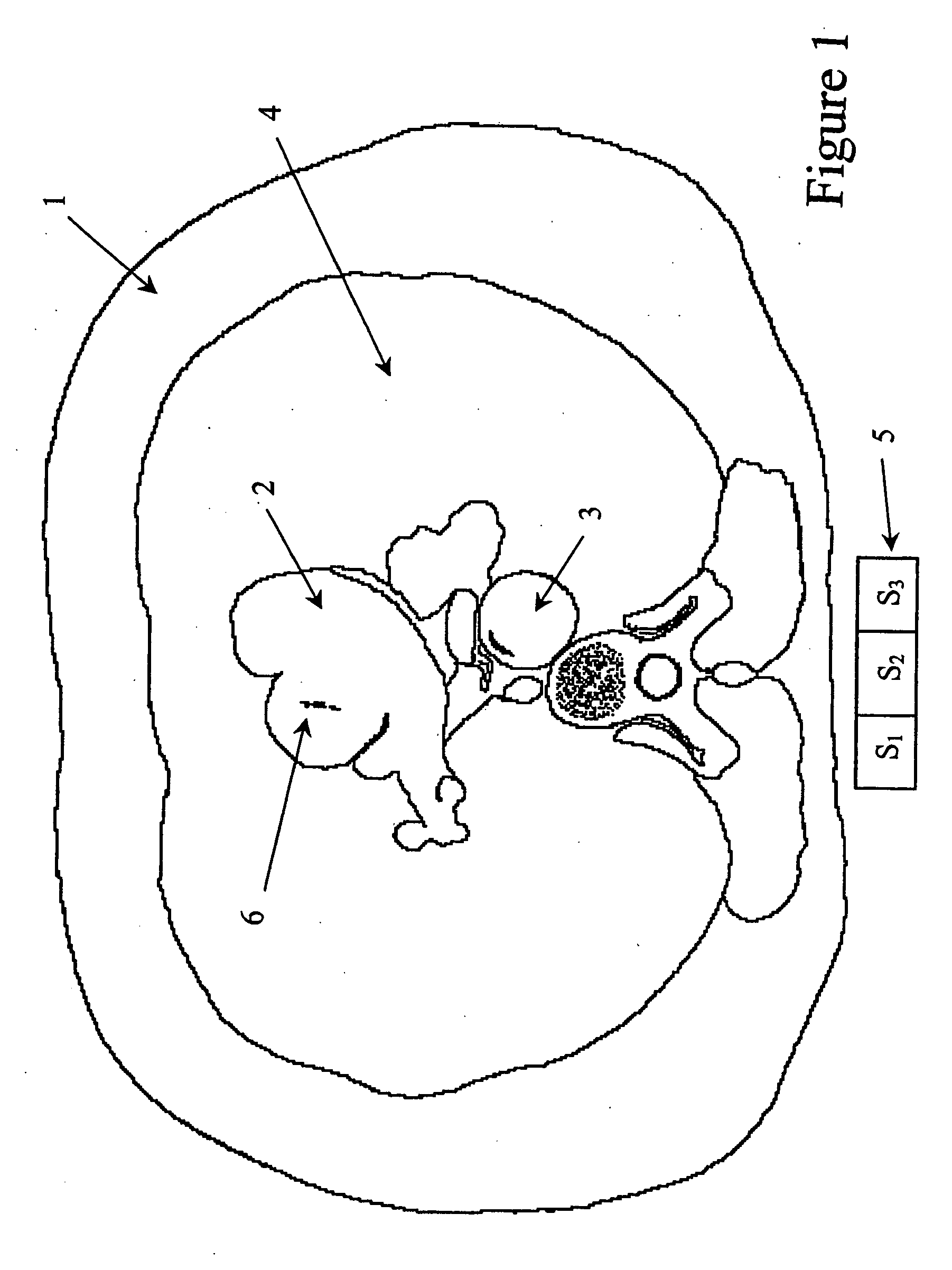

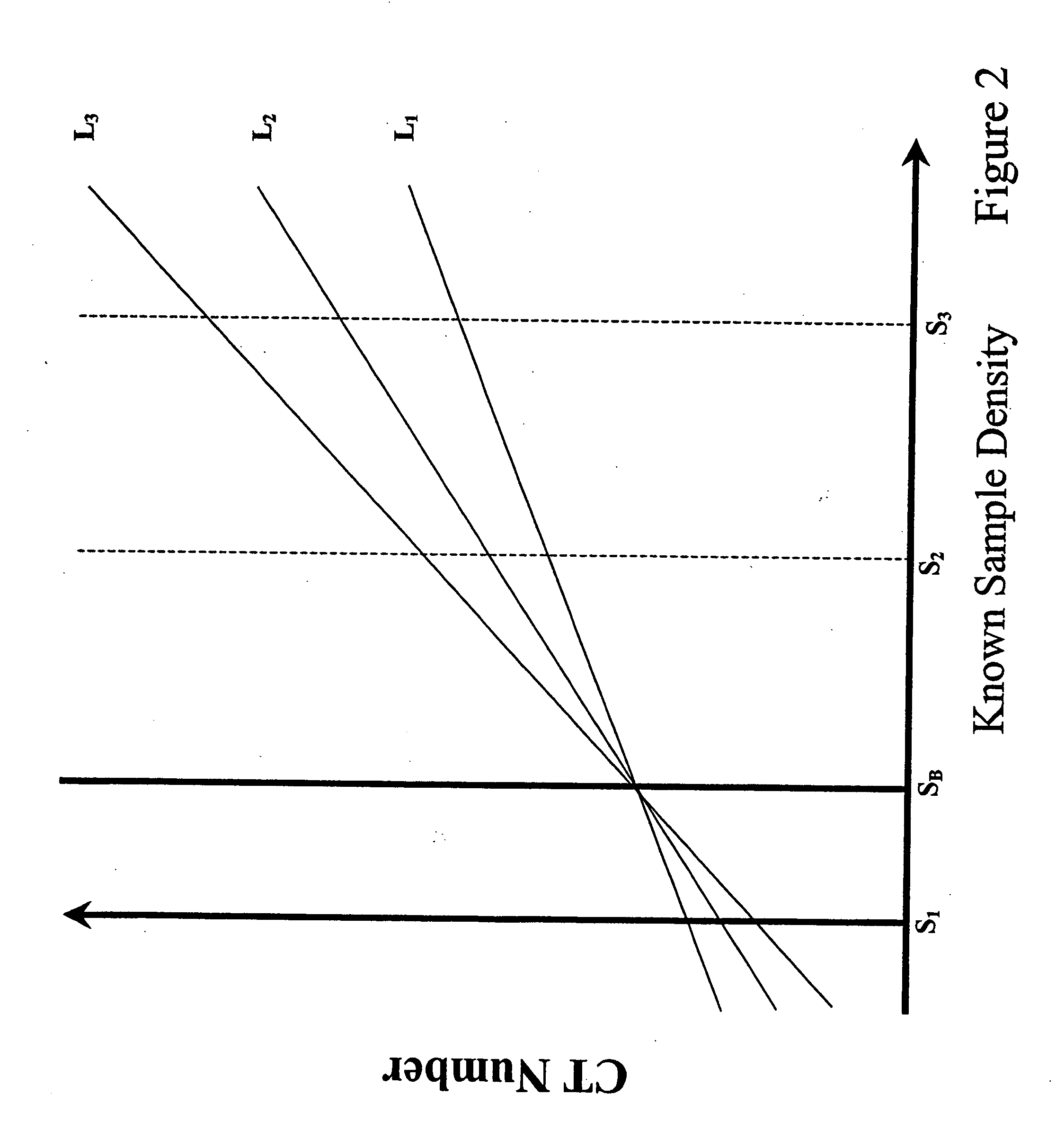

Calibration of tissue densities in computerized tomography

InactiveUS6990222B2Easy to measureEasy maintenanceUltrasonic/sonic/infrasonic diagnosticsImage enhancementMedicineTissue density

A hybrid calibration method uses an calibration phantom (exterior reference) scanned simultaneously with the patient, and one or more known tissues of the subject (interior reference) to create a hybrid calibration reference that improves the measurement of tissue densities throughout the body. In addition, the calibration method is used to quantitatively define boundaries of tissue and organs for more accurate measurements of lengths, areas and volumes. Another aspect of the invention uses the calibrated images to quantitatively preset absolute window / levels for filming and image display, which provides standardized viewing for diagnostic purposes.

Owner:ARNOLD BEN A

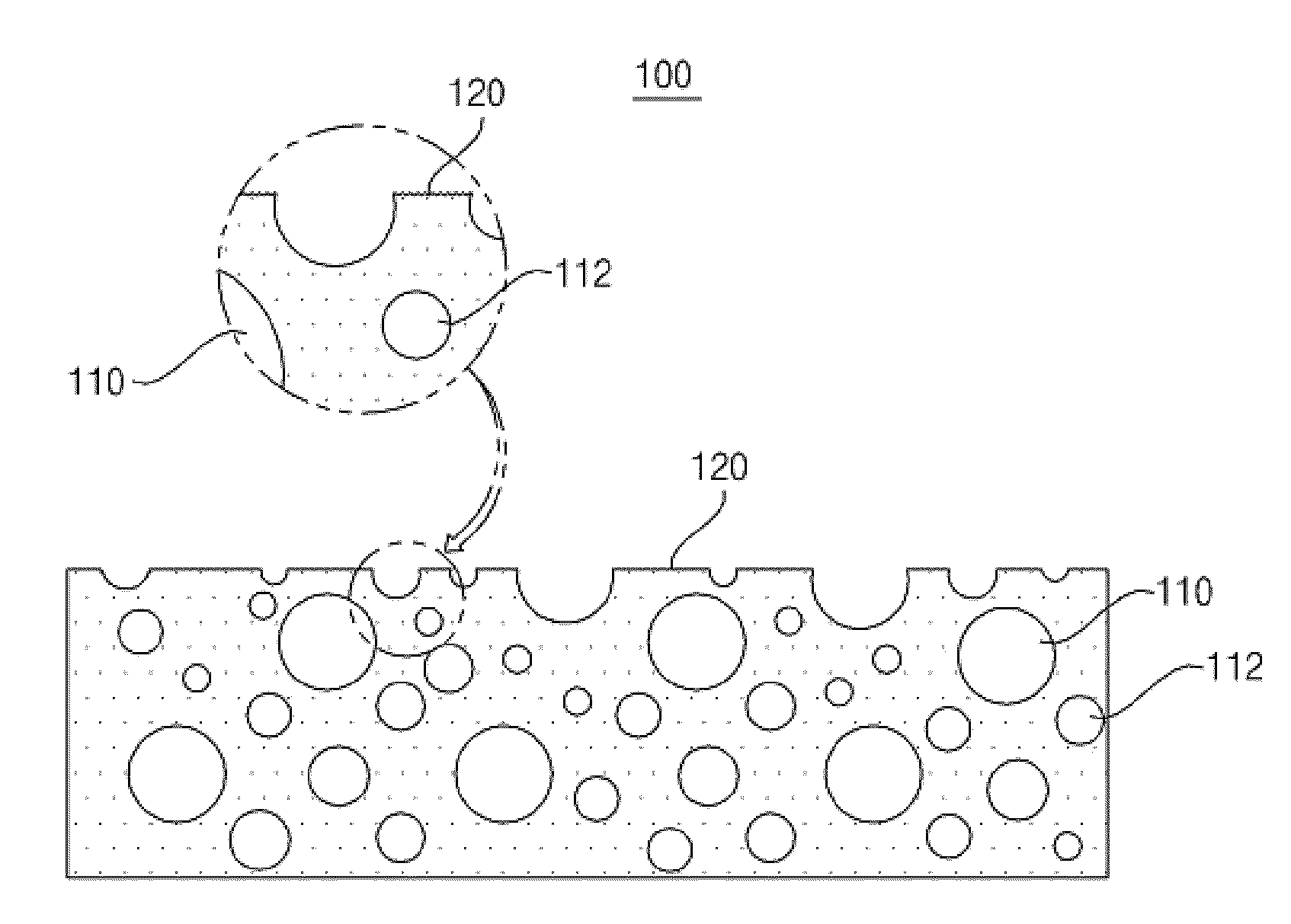

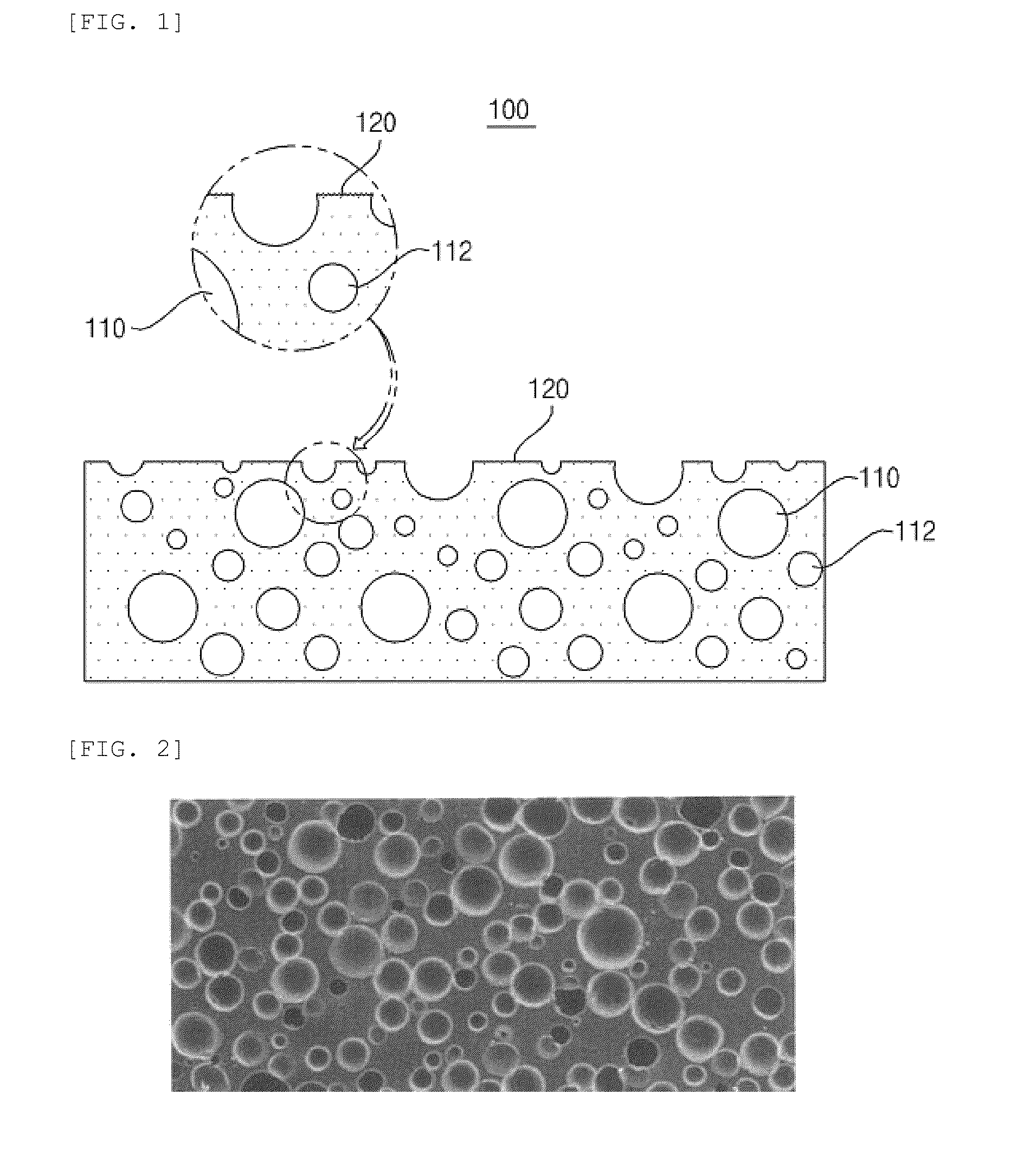

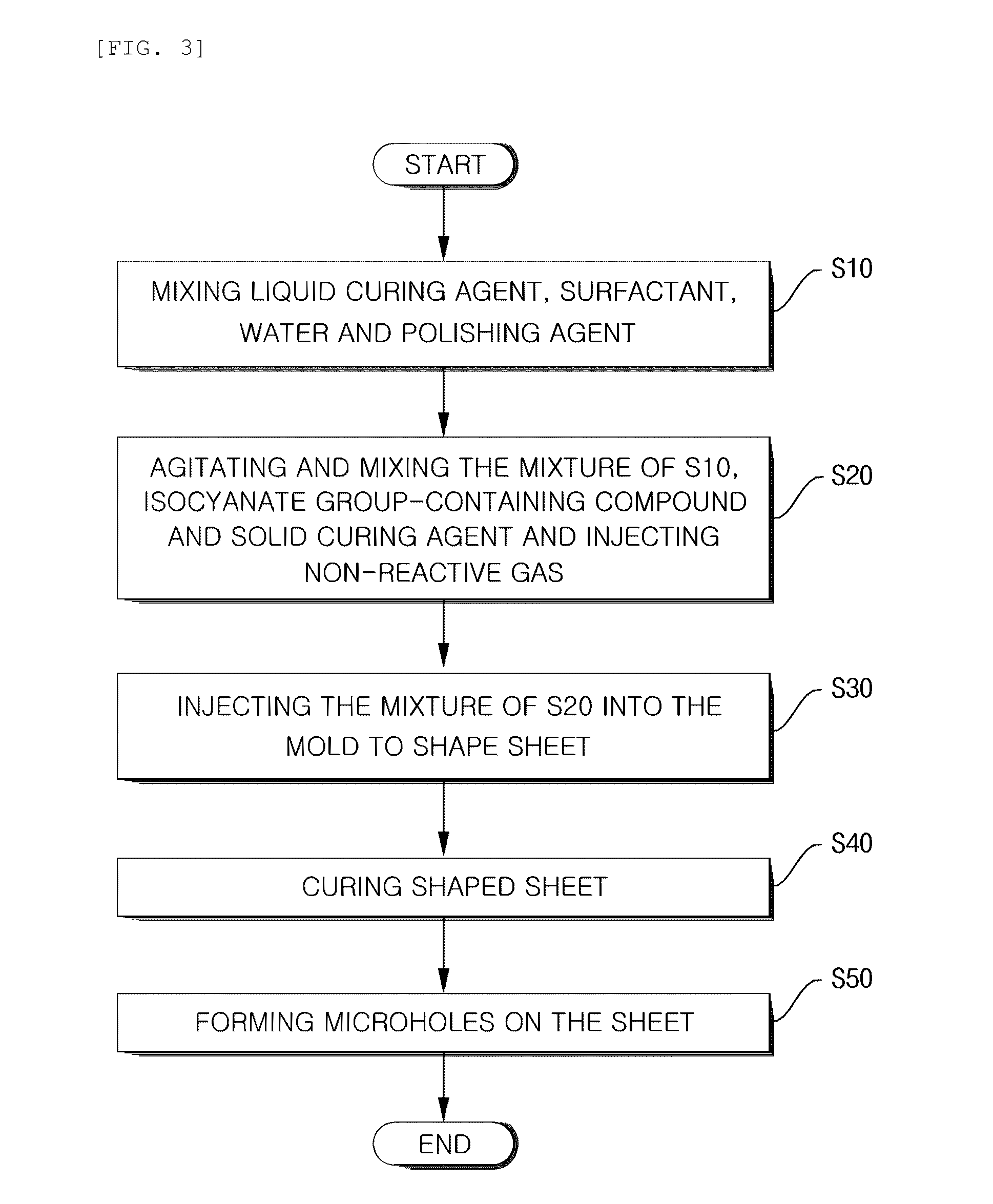

Polyurethane porous product and manufacturing method thereof and polishing pad having polyurethane porous product

InactiveUS20100247868A1Improve stabilityImprove uniformitySynthetic resin layered productsAbrasion apparatusIn planeHardness

The present invention relates to a method for manufacturing a polyurethane porous product, a polyurethane porous product according to the manufacturing method, and a polishing pad having the polyurethane porous product. According to the present invention, it is possible to manufacture a polishing pad that has excellent polishing efficiency and has a minimal difference in the polishing characteristic during a polishing process and improves uniformity in plane of material that will be polished because the polyurethane porous product of the present invention has small density difference, small hardness difference, and the stabilized quality of material.

Owner:CHA YOON JONG +1

Calibration of tissue densities in computerized tomography

InactiveUS20060088198A1Increase the areaIncrease distanceImage enhancementImage analysisMedicineTissue density

A hybrid calibration method uses a calibration phantom (exterior reference) scanned simultaneously with the patient, and one or more known tissues of the subject (interior reference) to create a hybrid calibration reference that improves the measurement of tissue densities throughout the body. In addition, the calibration method is used to quantitatively define boundaries of tissue and organs for more accurate measurements of lengths, areas and volumes. Another aspect of the invention uses the calibrated images to quantitatively preset absolute window / levels for filming and image display, which provides standardized viewing for diagnostic purposes.

Owner:ARNOLD BEN A

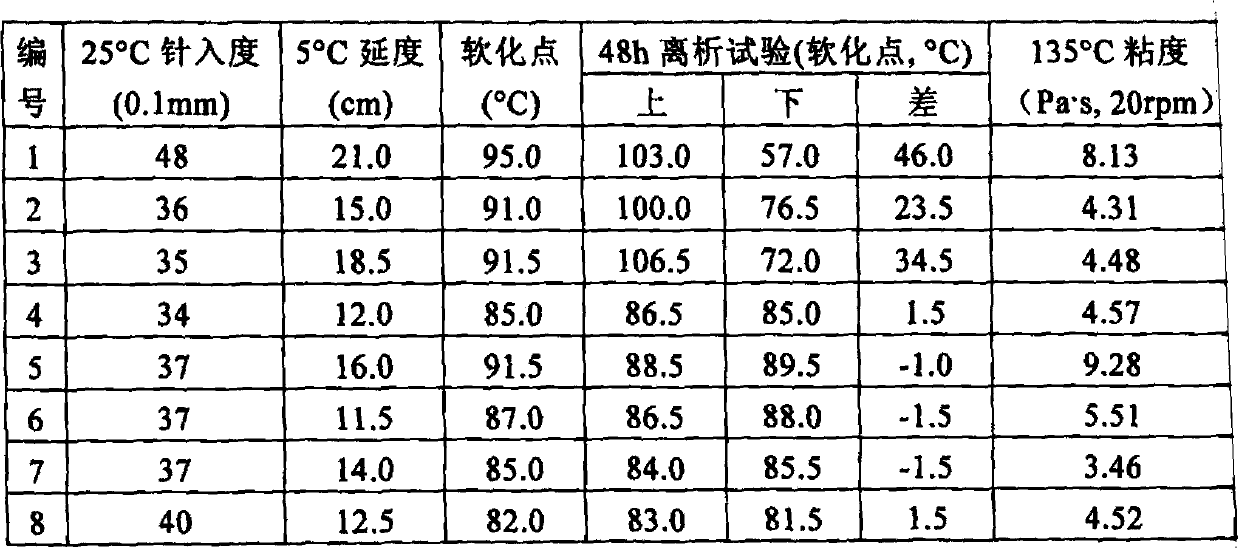

Composite high-viscosity modified asphalt and preparation method thereof

InactiveCN103819918AGood high and low temperature performanceImprove thermal storage stabilityBuilding insulationsEnvironmental effectEconomic benefits

The invention relates to composite high-viscosity modified asphalt and a preparation method thereof. The raw material comprises the following components by weight percent: 84-88% of heavy duty bitumen and 12-16% of modified compounds. The method comprises the following steps: mixing SBS, desulfurized colloidal particles and a compatilizer containing an epoxy group to prepare a modified compound; preparing modified particles after mechanically pelletizing; adding the modified particles to asphalt at 170-190 DEG C; melting and refining compound particles after shearing at a high speed for 30-60 minutes on a high-speed mixing emulsifier; transferring the sheared asphalt to a high-speed disperser, and agitating to obtain the composite high-viscosity modified asphalt. The composite high-viscosity modified asphalt prepared by using the method has the characteristics of stable heat storage, and excellent high and low temperature properties, has good economic benefits and environmental effects because of use of waste rubber, and is free of sulphur as a stabilizer, the construction viscosity can be reduced, the construction environment can be improved, and the problem that incompatible asphalt is difficult to stabilize is solved.

Owner:SHANGHAI JIAO TONG UNIV

Aluminum oxide sintered body, and members using same for semiconductor and liquid crystal manufacturing apparatuses

ActiveUS20050187094A1Suppressing reduction lifetimeDecrease dissipation factorSilicon oxideSemiconductor

An aluminum oxide sintered body contains aluminum oxide in an amount of not less than 99% by weight and at least one selected from magnesium oxide, calcium oxide and silicon oxide, and contains phosphorus of not more than 0.0025 parts by weight to 100 parts by weight of the aluminum oxide sintered body. This avoids that phosphorous exerts adverse effect on the sintering properties of an aluminum oxide sintered body, especially the sintering properties of a large aluminum oxide sintered body, causing the sintered body to lack uniformity between the sintered body inner portions and outer portions. Therefore, this aluminum oxide sintered body is suitably used in semiconductor manufacturing apparatus members or liquid crystal manufacturing apparatus members.

Owner:KYOCERA CORP

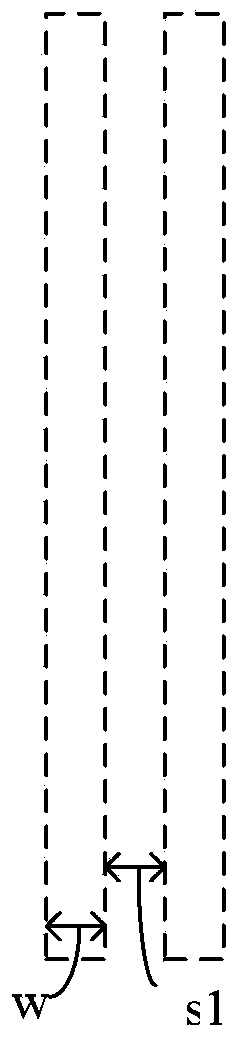

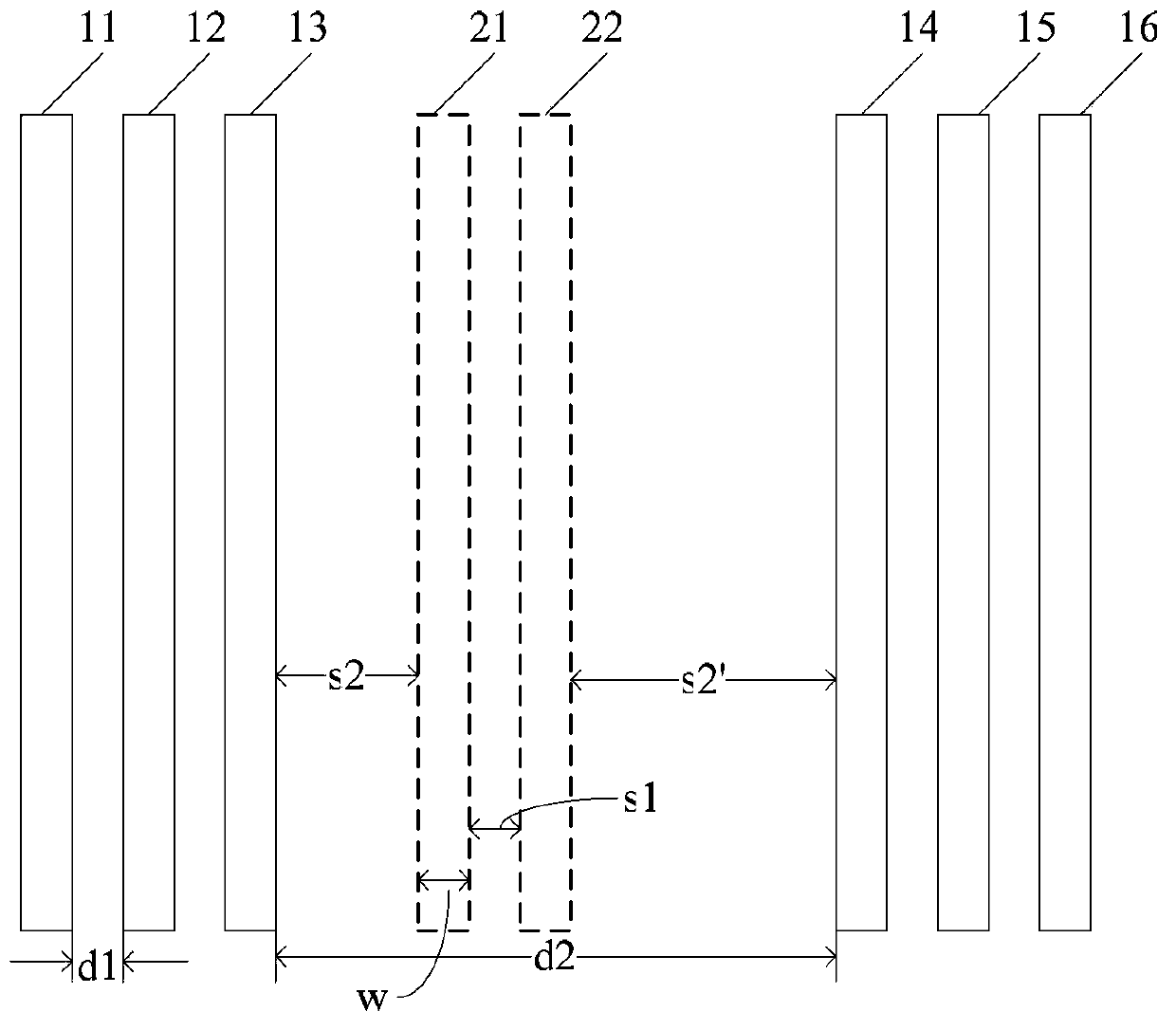

Exposure method

ActiveCN104216233AHigh densityReduce photolithography processSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGraphicsComputer science

The invention relates to an exposure method, which includes: providing a to-be-exposed pattern having several figures with two different spacings; providing a pseudo auxiliary pattern, which includes a certain number of auxiliary figures, with adjacent auxiliary figures having a same spacing; acquiring the width of the auxiliary figures and the spacing of adjacent auxiliary figures; when the spacing of the adjacent figures is greater than or equal to a critical size, determining the area between the adjacent figures as a fill area, with the figures at the edge of fill area being isolate figures; filling the fill area of the to-be-exposed pattern with the auxiliary pattern to form a pseudo to-be-exposed figure; and making a first figure and a second figure form according to the pseudo to-be-exposed figure, and taking the first figure and the second figure as two sets of mask figures of dual graphical exposure respectively. The exposure method provided by the invention can improve the accuracy of etching figures.

Owner:SEMICON MFG INT (SHANGHAI) CORP

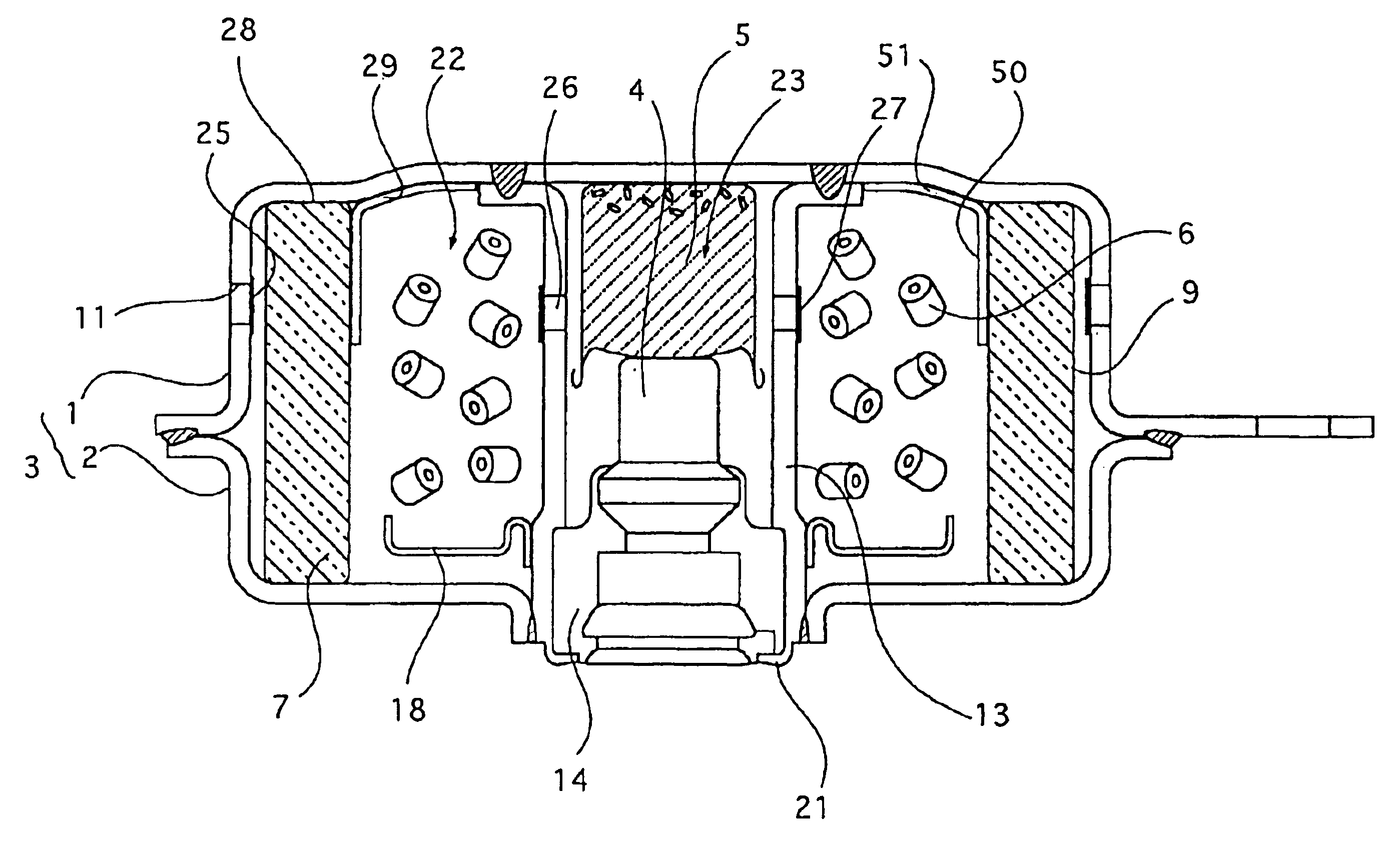

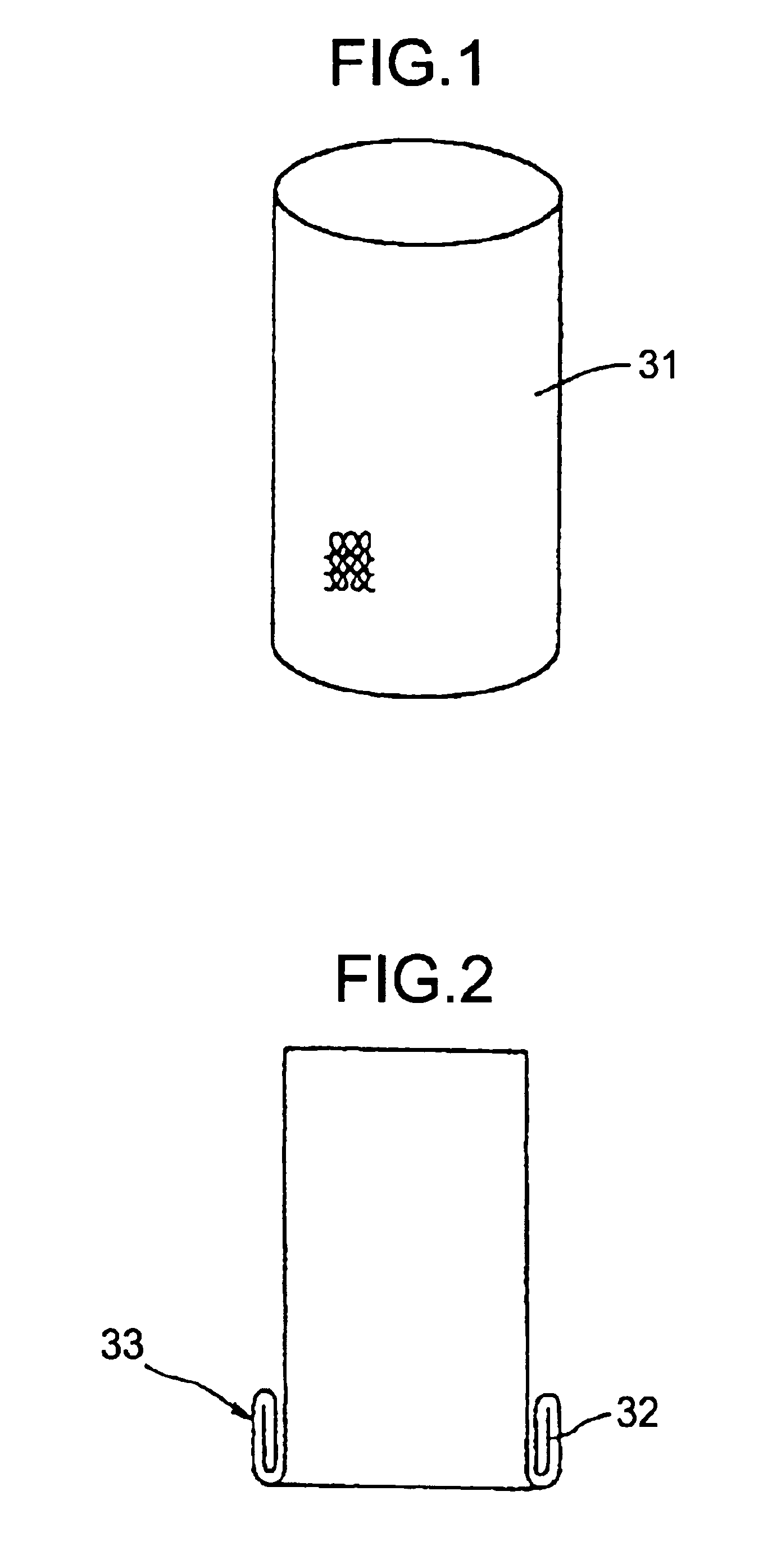

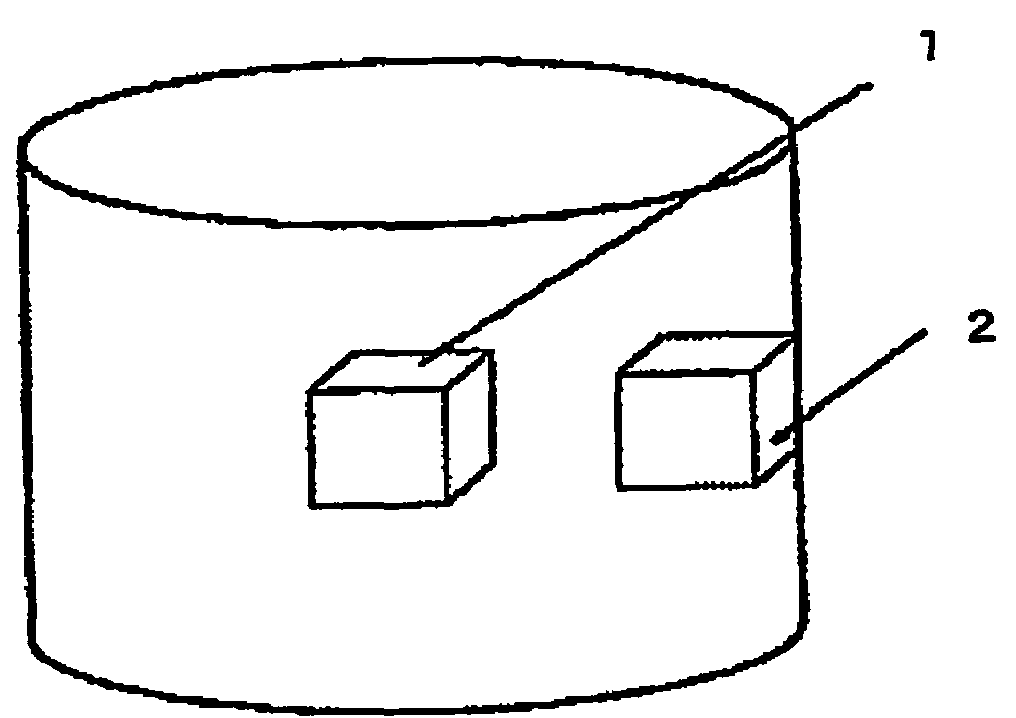

Coolant for air-bag gas generator and production method therefor

InactiveUS6840977B1Improve output performanceLow temperature generationCombination devicesAuxillary pretreatmentWire rodProduct gas

The present invention provides a coolant for an air bag inflator in which unevenness in density in the axial direction is reduced even though the coolant is compressed in its axial direction.The coolant is a molded product made of wire rods and compressed in its axial direction. An absolute value of a difference between a radial pressure loss of the axially upper half portion of the coolant and a radial pressure loss of the axially lower half portion of the coolant is 10 mm H2O or less at a flow rate of 250 liters / minute under the atmosphere of 20° C.

Owner:DAICEL CHEM IND LTD +2

Semiconductor device and electric contact structure and manufacturing method thereof

PendingCN111640748ASmall sizeAvoid exceptionTransistorSemiconductor/solid-state device detailsDevice materialEngineering

The invention provides a semiconductor device and an electric contact structure and a manufacturing method thereof. At least a first contact plug closest to a peripheral region in a core region is formed above an isolation structure at the junction of the core region and the peripheral region and is in contact with the isolation structure; the bottom of the first contact plug can be completely overlapped on the isolation structure; or, a part of the bottom is overlapped with the isolation structure; the bottom of the other part is overlapped with the active region close to the core region of the isolation structure; and even the top of the first contact plug is at least connected with the top of the contact plug close to the upper part of the active region of the core region of the isolation structure, so that the electrical structure originally formed on the outermost side of the boundary of the core region can be at least partially formed above the isolation structure at the junction, the consistency of the electrical structure above the contact plug in the core region is ensured, and the performance of the electrical structure on the boundary of the core region is ensured.

Owner:FUJIAN JINHUA INTEGRATED CIRCUIT CO LTD

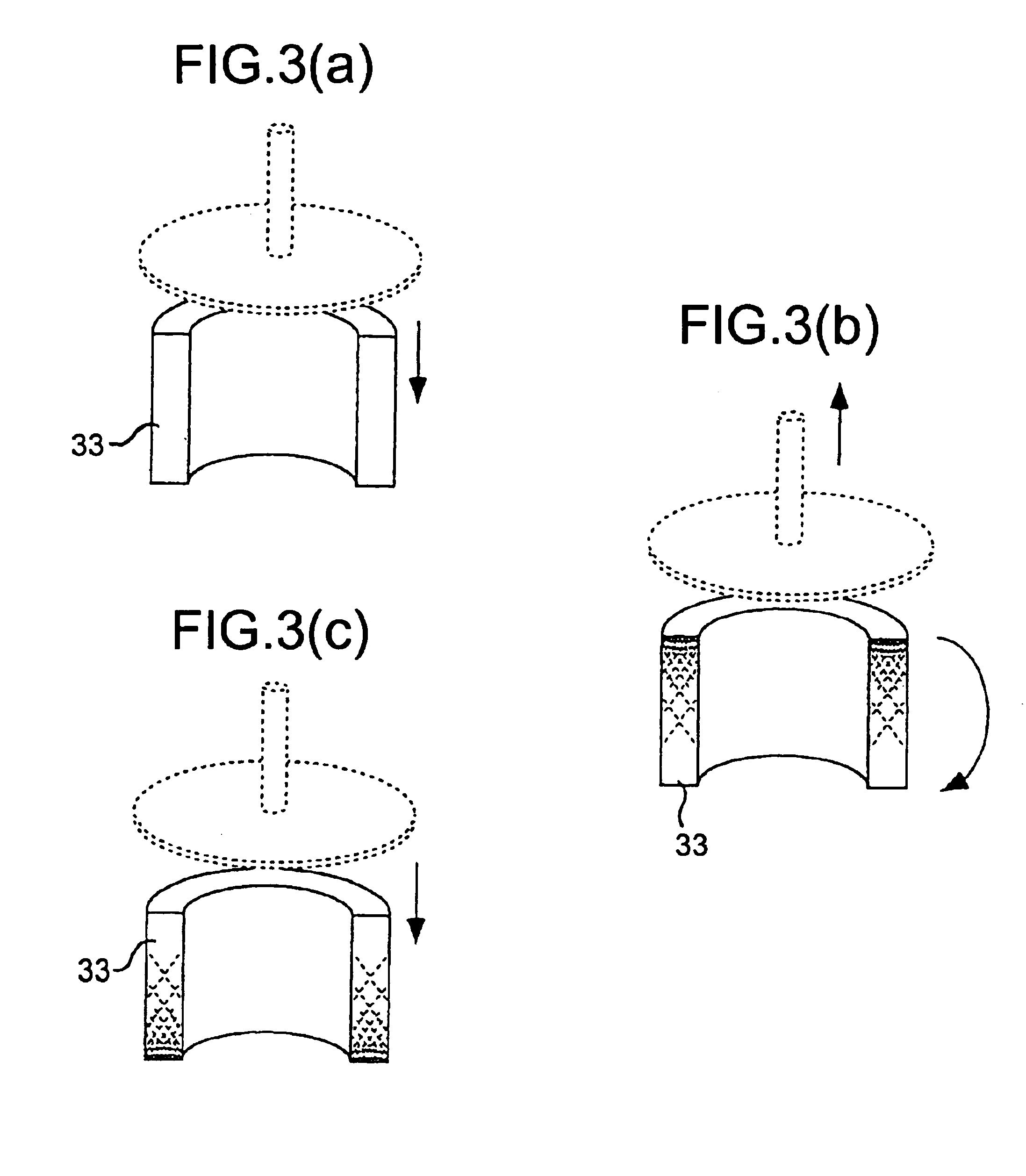

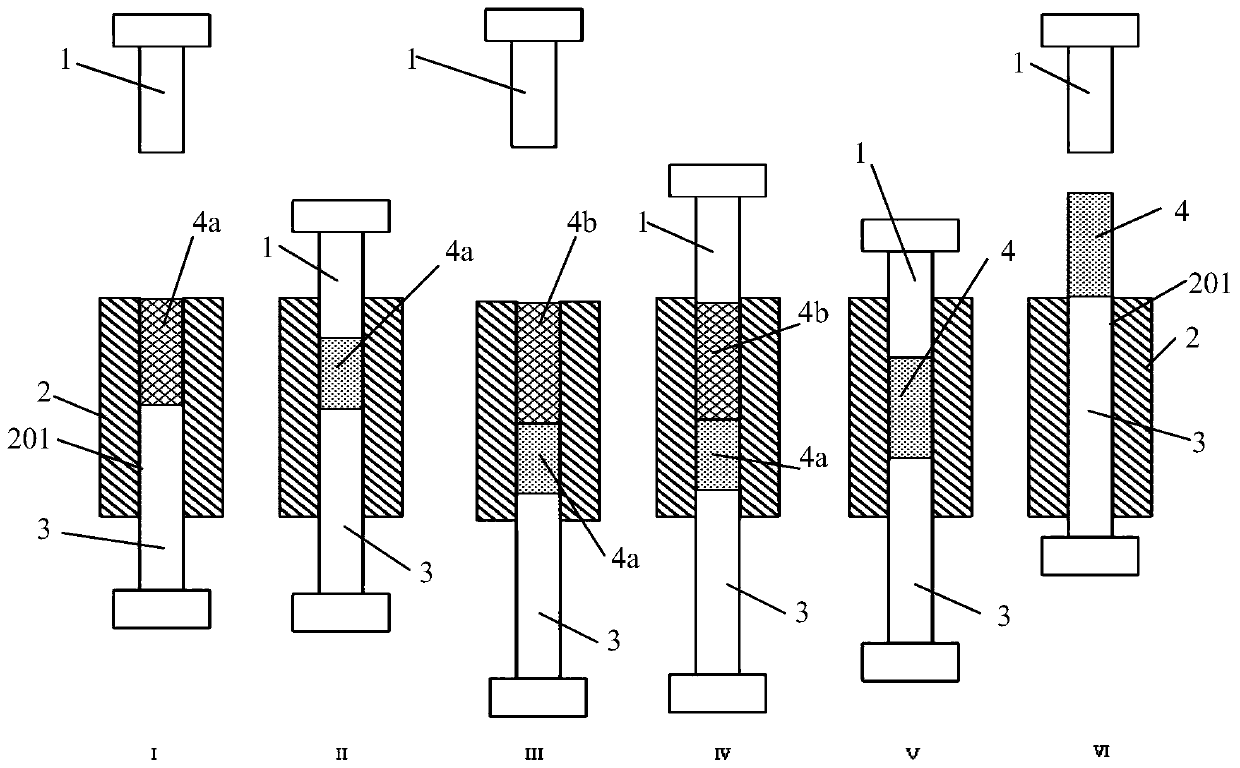

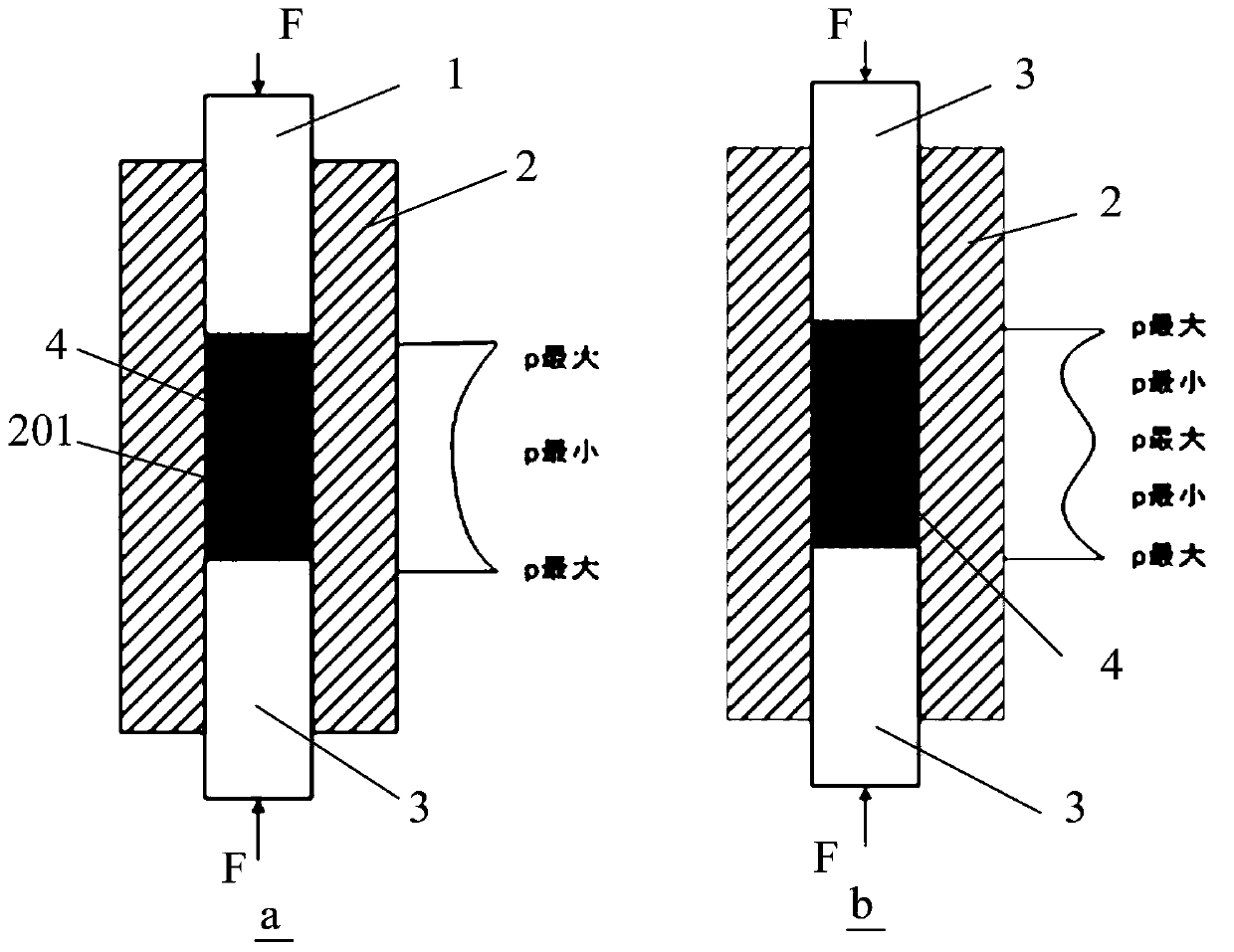

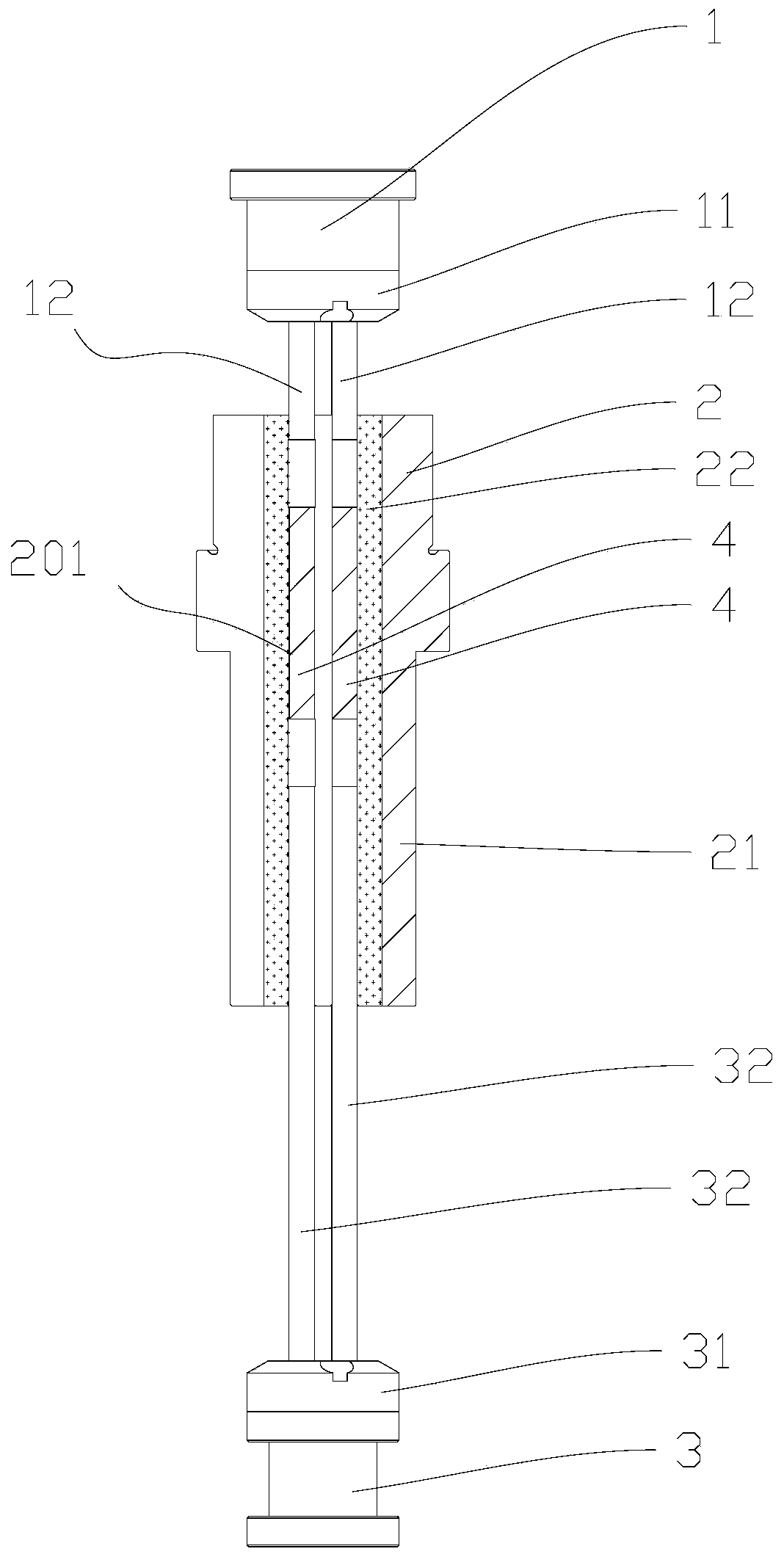

Forming method and forming device for powder metallurgy part

The invention discloses a forming method and a forming device for a powder metallurgy part. The method comprises the steps of: first pressing, final pressing, mold stripping and sintering, the formingdevice comprises an upper plunger, a female die and a lower plunger, the female die is provided with a female die cavity for containing powder, the upper plunger comprises an upper die holder and anupper die stamping piece, the lower plunger comprises a lower die holder and a lower die stamping piece, and the upper die stamping piece and the lower die stamping piece can penetrate into the femaledie cavity to press the powder. A powder part processed by the method and the device has good compactness, the initial density in the middle is increased effectively, the overall density is increased, the relative density difference value is reduced, and the overall green body performance is improved.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Manganese zinc ferrite magnetic core

InactiveCN102693808AMinimize core density varianceProduct deformation is smallInorganic material magnetismInductances/transformers/magnets manufactureMagnetic coreEngineering

The invention discloses a manganese zinc ferrite magnetic core. The bottom of the magnetic core is square, the joint of the bottom surface and side wall of the magnetic core is designed as a chamfer, the bottom surface of the magnetic core is provided with a groove, the joint of the groove and the bottom surface is designed as a chamfer, and a bulge is formed at the outer edge along the groove of the bottom surface. The groove is arranged on the bottom surface of the magnetic core, the bulge is formed at the chamfer, a friction force between the magnetic core and a setter plate is reduced when the magnetic core is sintered, and resistance received by contraction of the magnetic core when the magnetic core is sintered is reduced, so that the density difference of the magnetic core caused by a big chamfer is reduced, and product deformation is reduced. A contact surface between the magnetic core and the setter plate is small when the magnetic core is sintered, so that zinc volatilization caused by contact between the magnetic core and the setter plate is reduced, less cavities are produced inside the magnetic core as zinc on the surface of the magnetic core is volatilized, and the mechanical strength of the magnetic core is enhanced.

Owner:WUXI SPINEL MAGNETICS

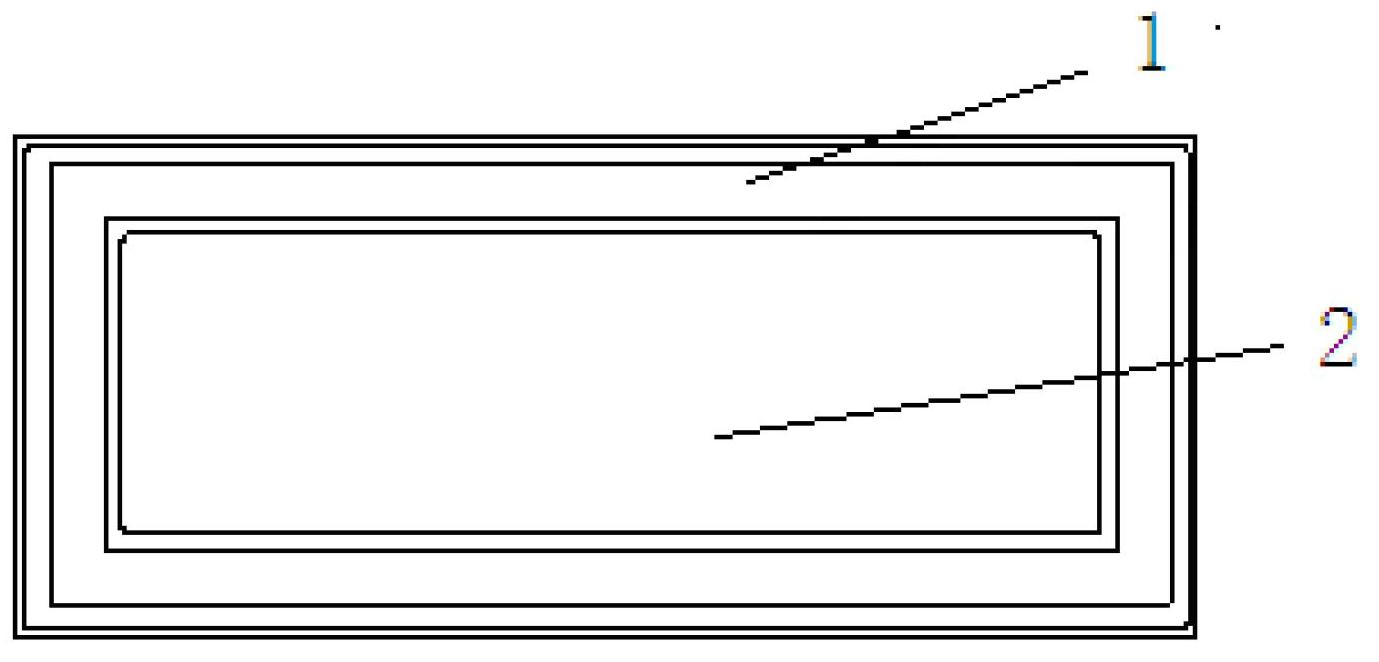

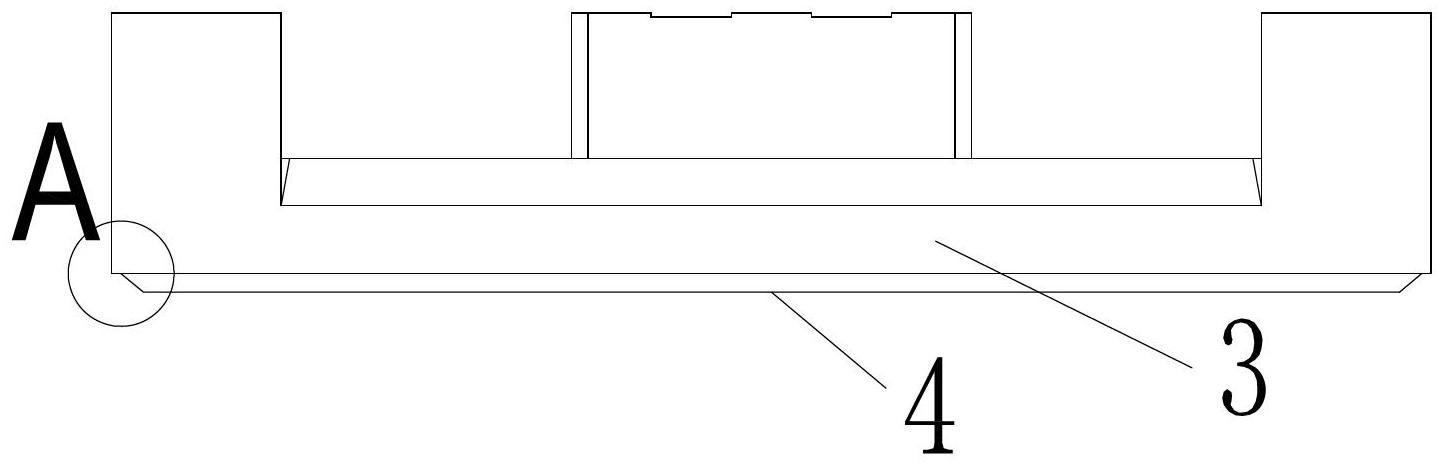

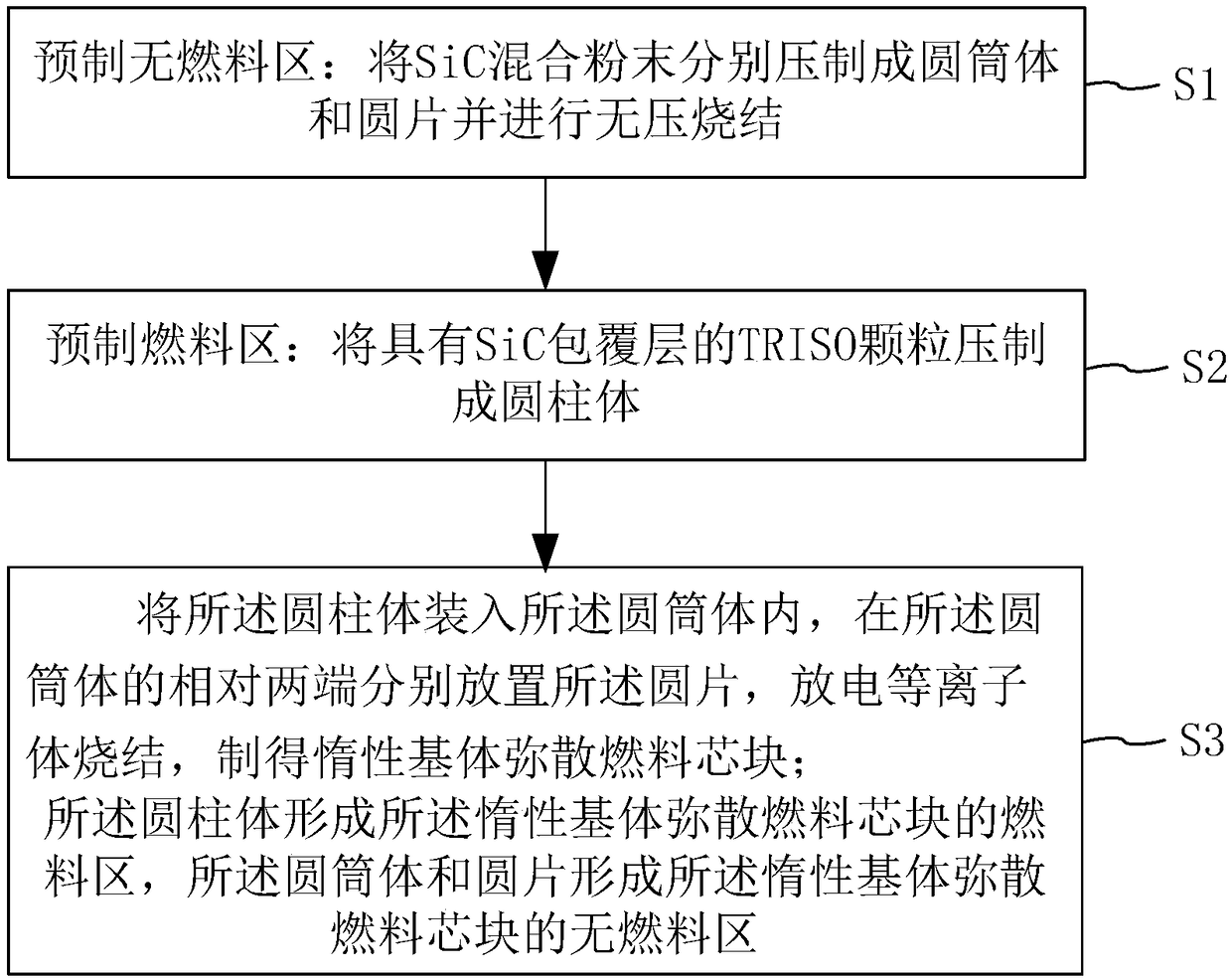

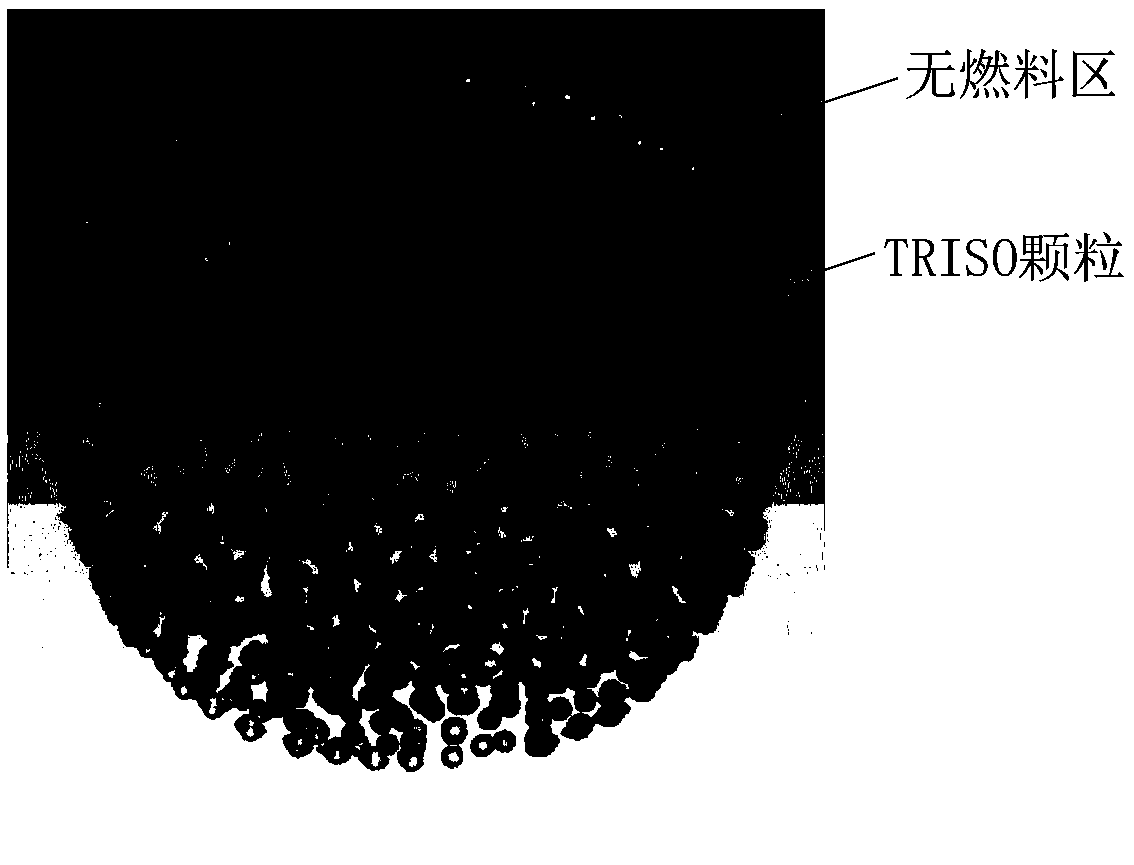

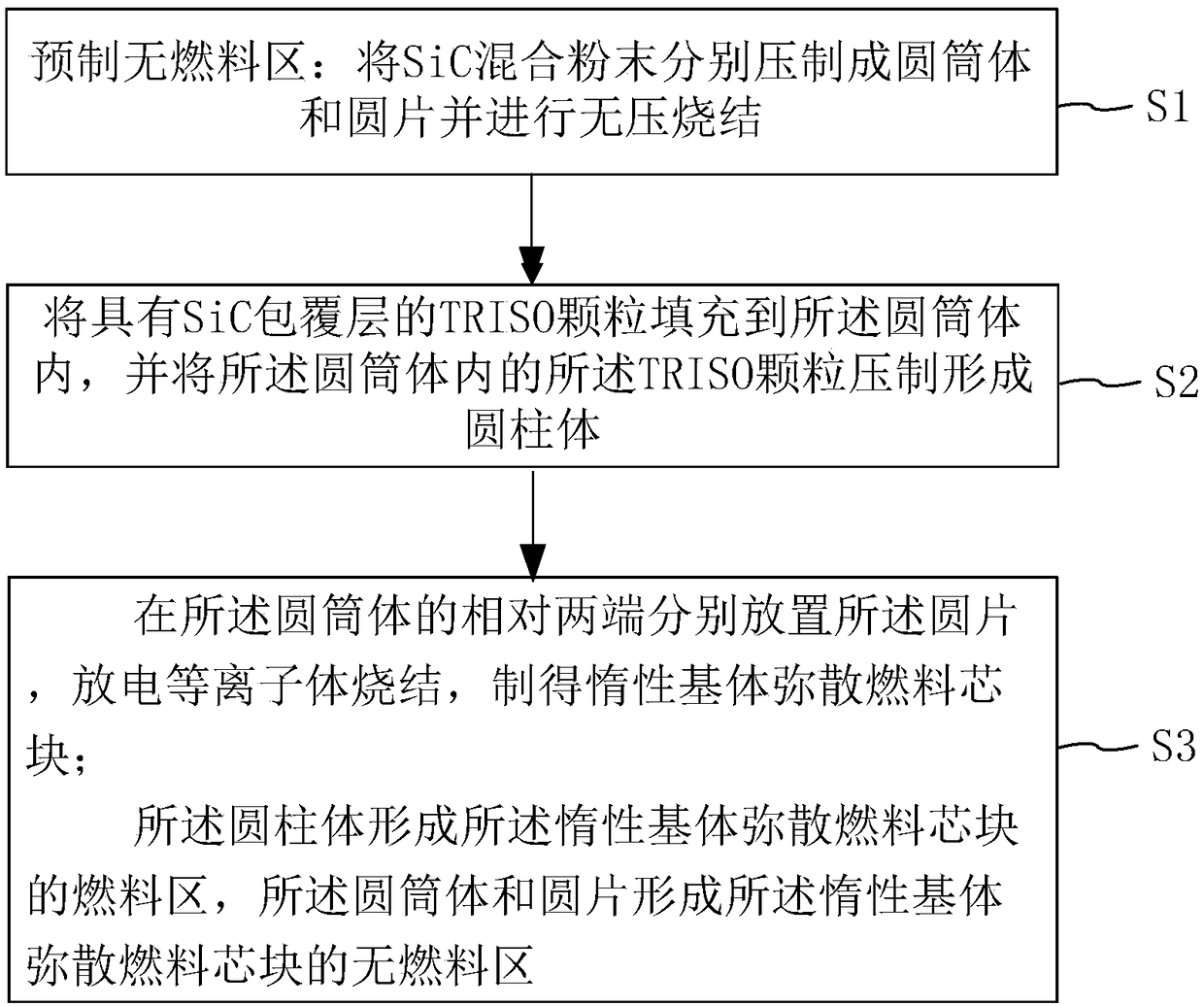

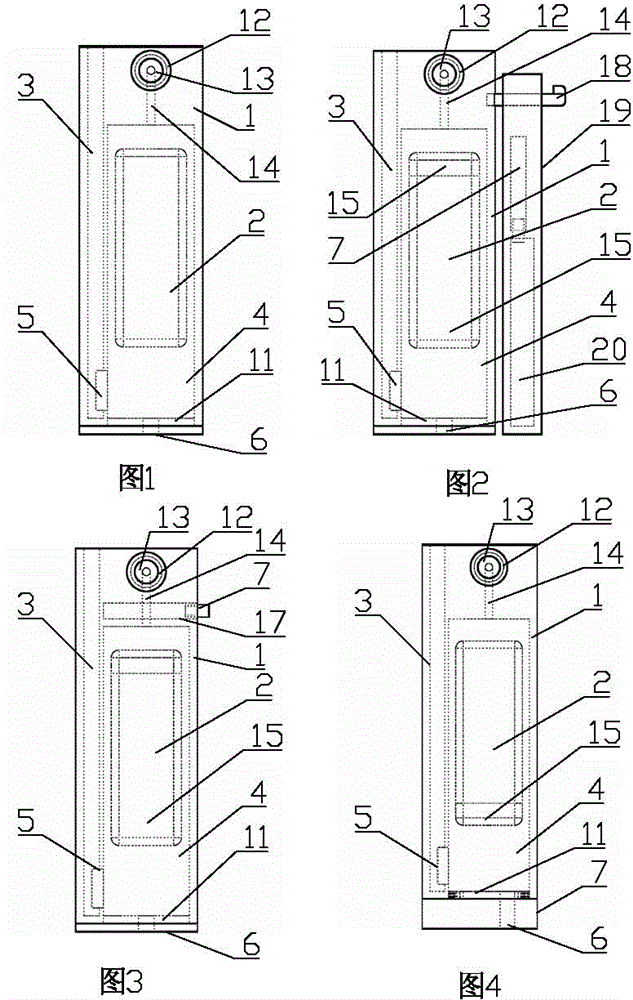

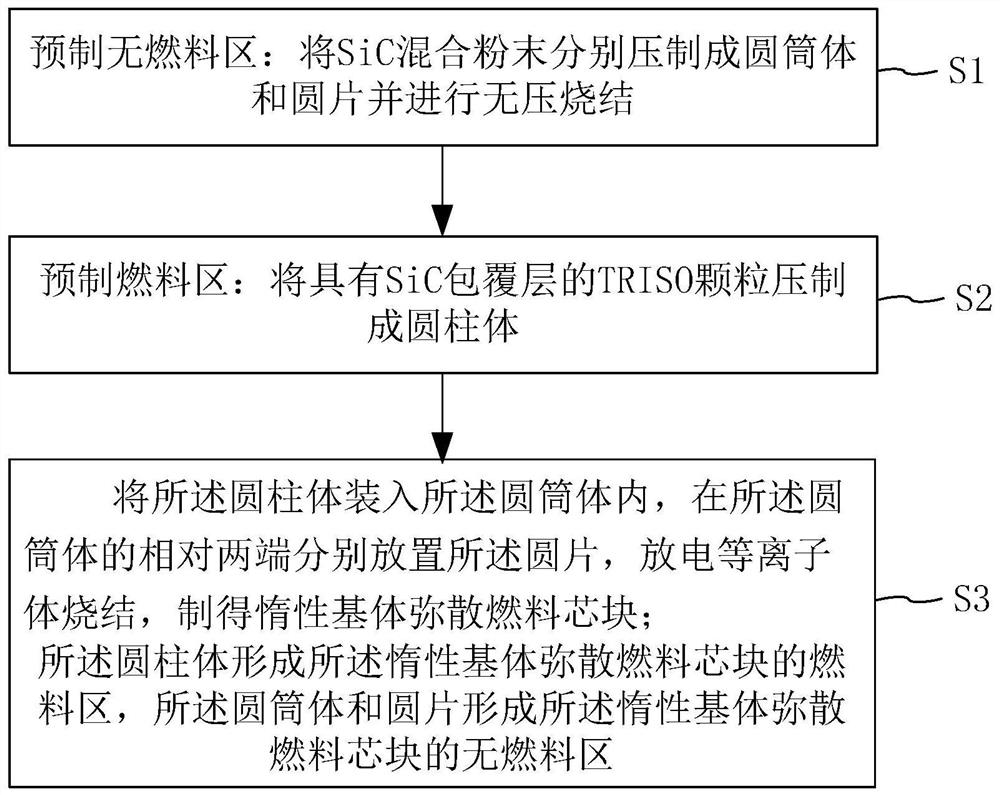

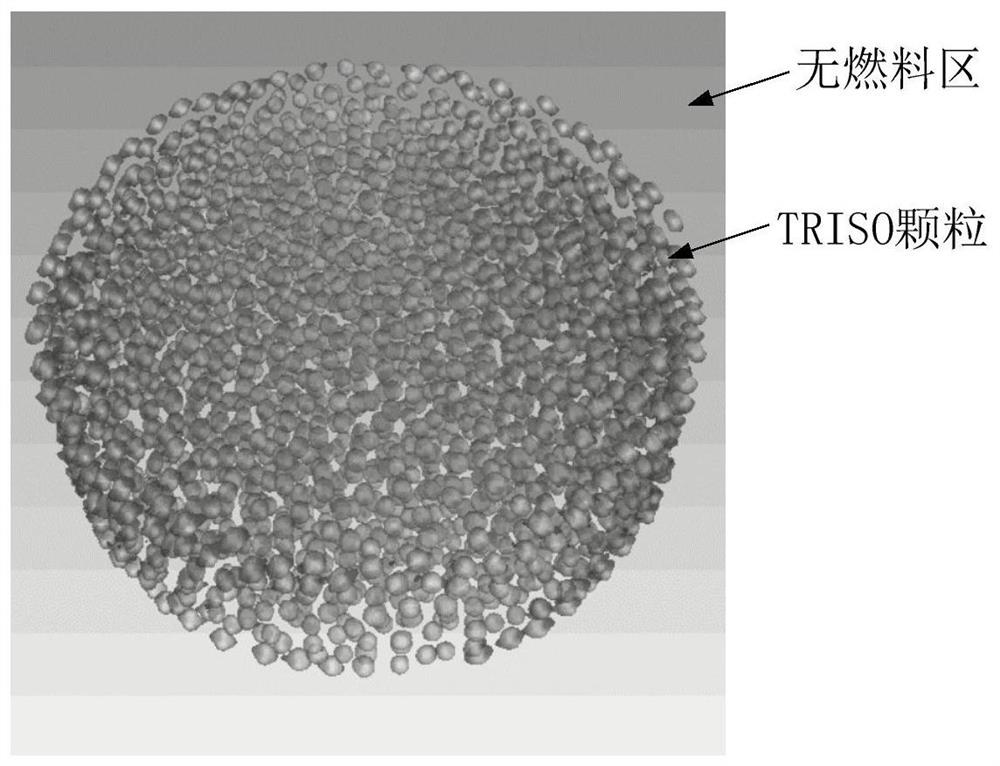

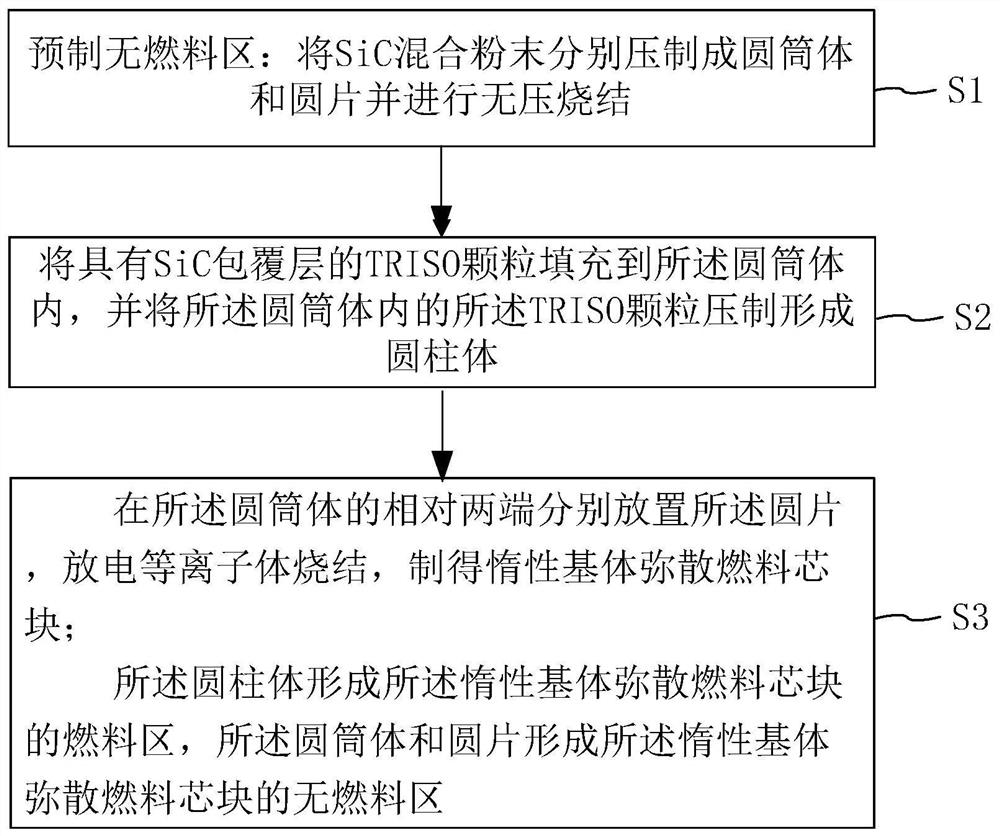

Inert matrix dispersion fuel pellet and preparation method thereof

ActiveCN109461509ASmall density differenceHigh volume contentNuclear energy generationReactors manufacturePressureless sinteringDensity difference

The invention discloses an inert matrix dispersion fuel pellet and a preparation method thereof. The preparation method includes: S1, prefabricating a fuel-free area, specifically, pressing SiC mixedpowder into a tubular shape or a disc shape, and performing pressureless sintering; S2, prefabricating a fuel area, specifically pressing TRISO (tri-structural iso-tropic) particles with SiC coatingsinto a cylindrical shape; S3, filling the cylindrical-shaped materials into the tubular-shaped materials, then placing the disc-shaped materials at the opposite both ends of the tubular-shaped materials, performing discharge plasma sintering to obtain the inert matrix dispersion fuel pellet, wherein the cylindrical-shaped materials form the fuel area of the inert matrix dispersion fuel pellet, andthe tubular-shaped materials and the disc-shaped materials form the fuel-free area of the inert matrix dispersion fuel pellet. According to the preparation method of the inert matrix dispersion fuelpellet, by prefabricating the fuel-free area, the density of the fuel-free area is controlled to be close to that the pressed fuel area, the density difference between the fuel area and the fuel-freearea of the sintered inert matrix dispersion fuel pellet can be reduced, the peripheral contour structure of TRISO particles inside the fuel area can be improved, the fuel area can be expanded, the overall TRISO volume content of the inert matrix dispersion fuel pellet can be increased, and the comprehensive performance of the inert matrix dispersion fuel pellet can be further enhanced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +4

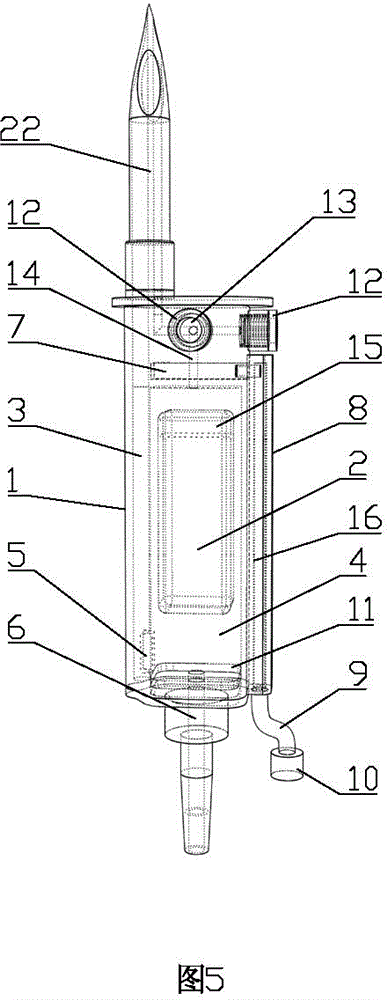

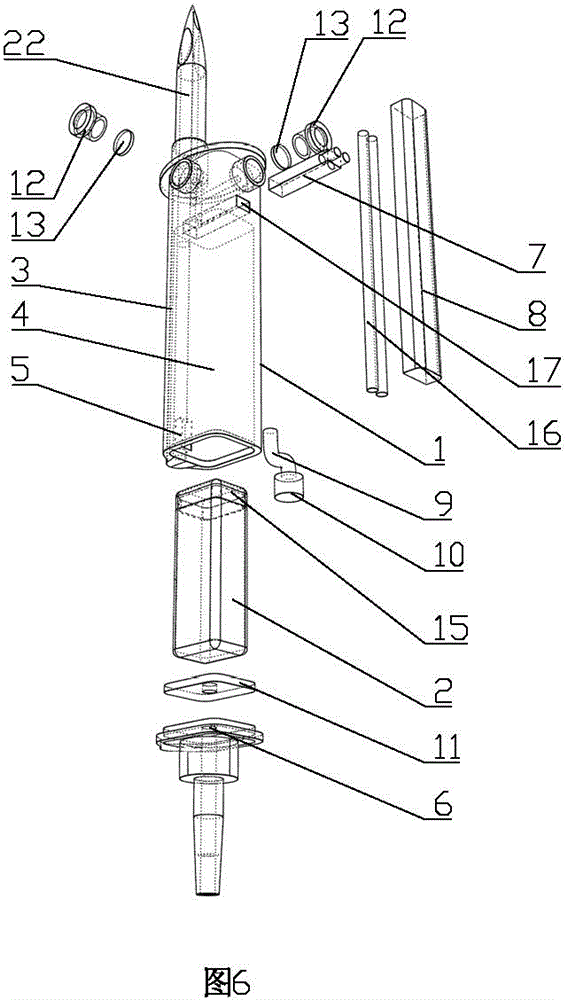

Buoyancy type non-returning transfusion device

The invention relates to the technical field of medical liquid parts and provides a buoyancy type non-returning transfusion device. The buoyancy type non-returning transfusion device comprises a non-returning shell and a floater, wherein a liquid inlet channel and a liquid storage cavity are arranged in the non-returning shell; the upper part of the liquid inlet channel is provided with a liquid inlet formed in the non-returning shell; a communication channel is arranged between the liquid inlet channel and the liquid storage cavity; a liquid outlet is formed in the bottom of the liquid storage cavity; the floater, which can float up when the liquid level height of medicine liquid exceeds the lowest limitation and block the liquid outlet when the liquid level height of the medicine liquid is lower than the lowest limitation, is arranged in the liquid storage cavity above the liquid outlet in a sleeving manner. According to the buoyancy type non-returning transfusion device, the liquid inlet channel and the liquid storage cavity are separately arranged and the acting force on the floater by liquid drops can be effectively eliminated; the restriction of a liquid dropping to a gap between the floater and the liquid storage cavity, and a medicine liquid dropping flow channel and the flow speed can also be effectively eliminated; the non-returning effect is good and the manpower is freed; patients or accompanying people do not need to observe liquid dropping conditions all the time; the adaptability of adopting the buoyancy to control the rising and falling of the floater is strong, the utilization requirements of a plurality of types of medicine liquid can be met and the popularization is convenient.

Owner:张磊

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

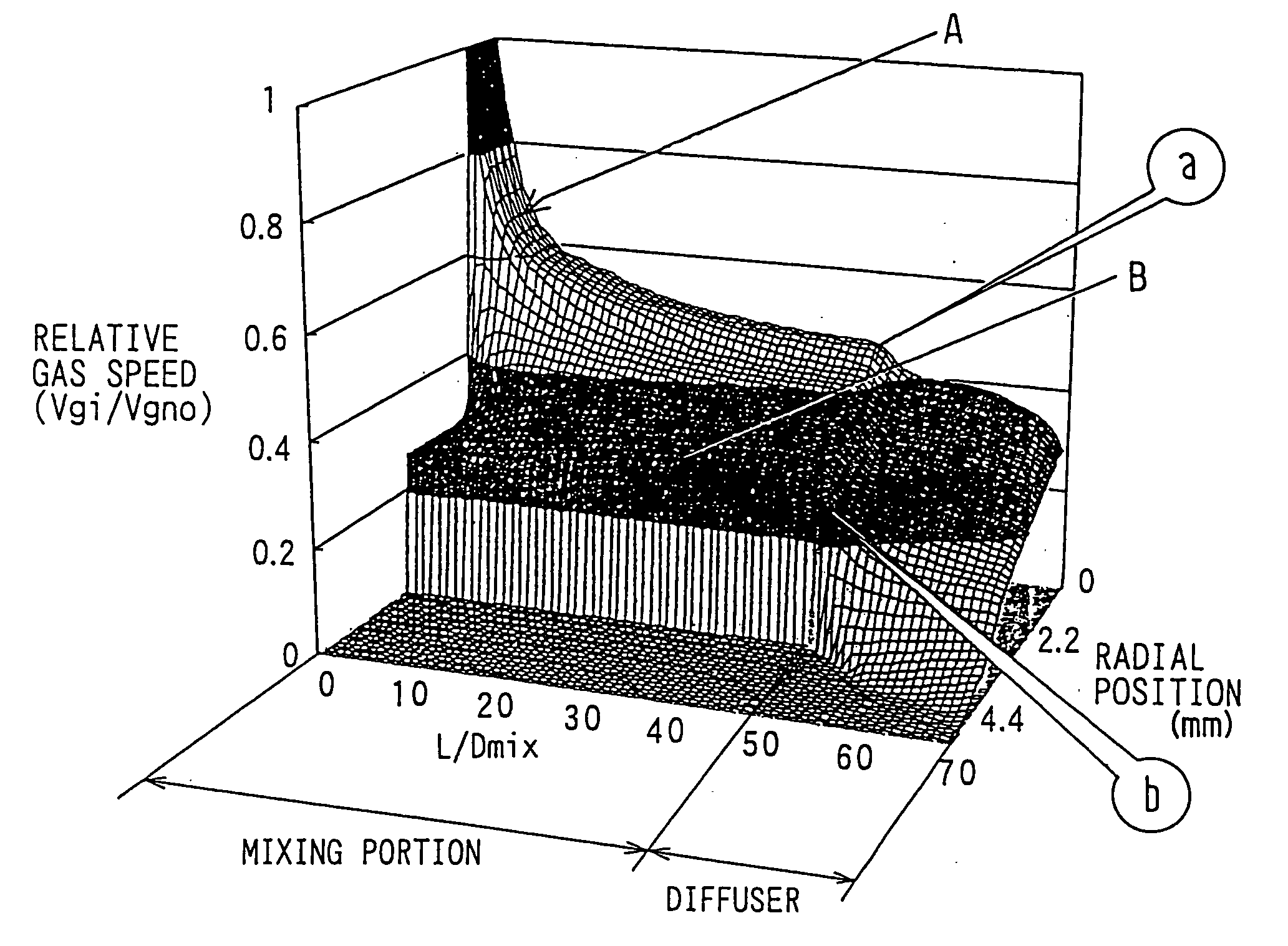

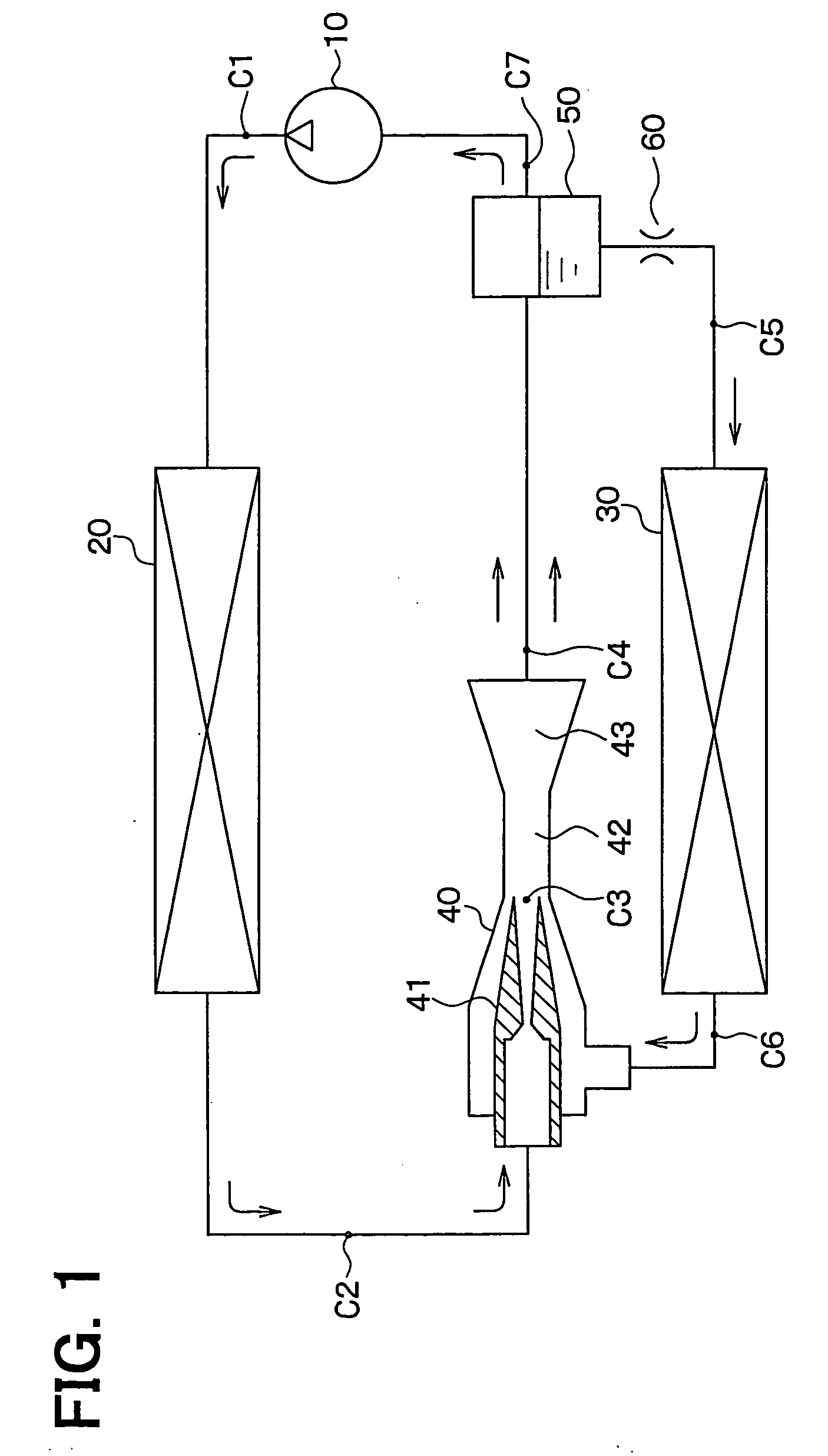

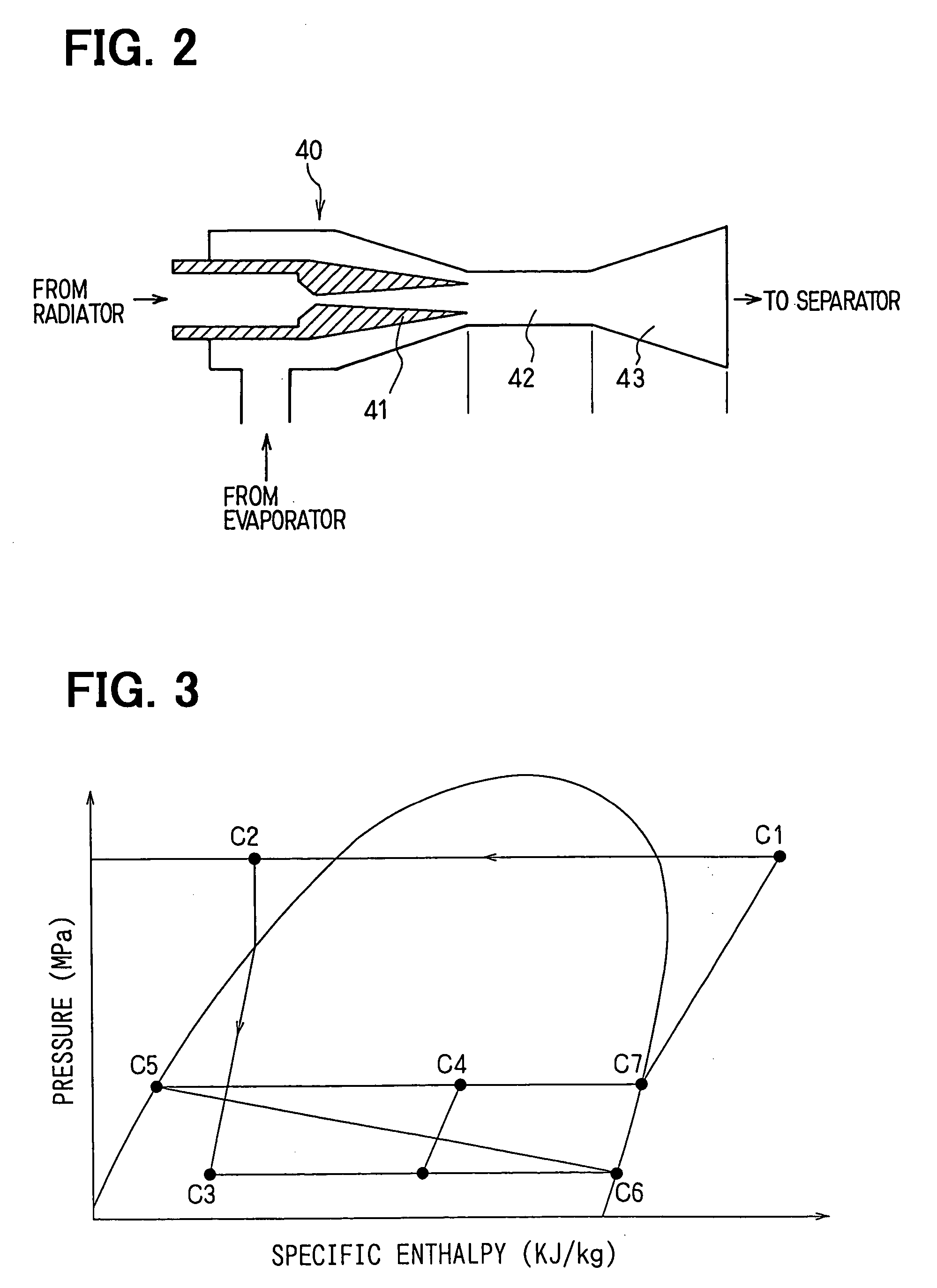

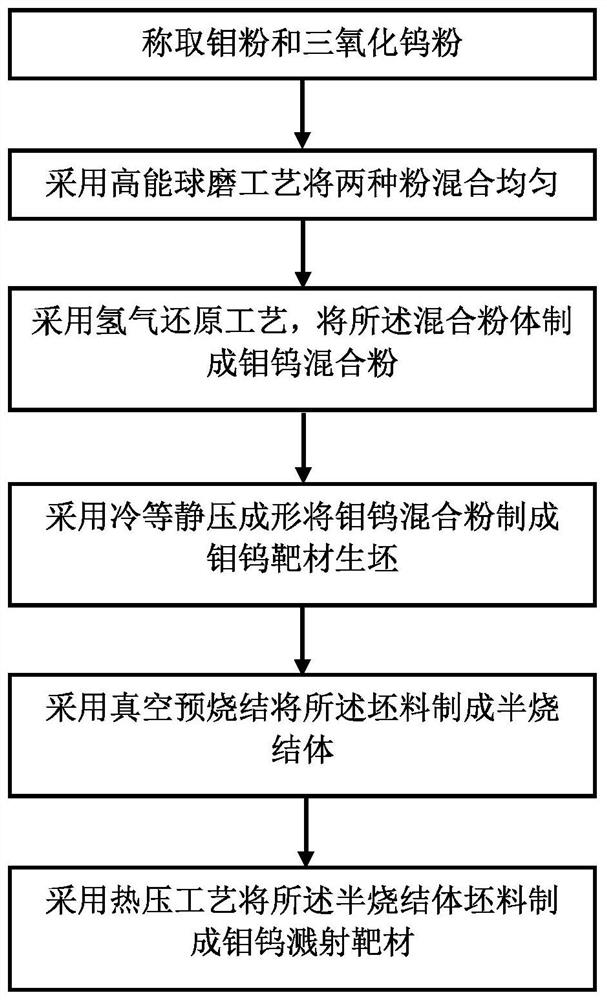

Vapor-compression refrigerant cycle with ejector

ActiveUS20040159120A1Reduce power consumptionImprove cooling effectCompression machines with non-reversible cycleVehicle heating/cooling devicesVapor–liquid separatorGas phase

In a vapor-compression refrigerant cycle having an ejector, a mixture refrigerant of a first refrigerant and a second refrigerant is used. When the mixture refrigerant is decompressed and expanded in a nozzle of the ejector, the first refrigerant has an adiabatic heat drop that is larger than that of the second refrigerant. Further, the second refrigerant has an evaporation latent heat that is larger than that of the first refrigerant. In a gas-liquid separator, a gas-phase amount of the first refrigerant is made larger than that of the second refrigerant, and a liquid-phase amount of the second refrigerant is made larger than that of the first refrigerant. For example, the first refrigerant is propane, and the second refrigerant is butane. Accordingly, expansion energy recovered in the nozzle can be effectively converted to pressure energy in a pressure increasing portion of the ejector while cooling capacity of an evaporator can be improved.

Owner:DENSO CORP

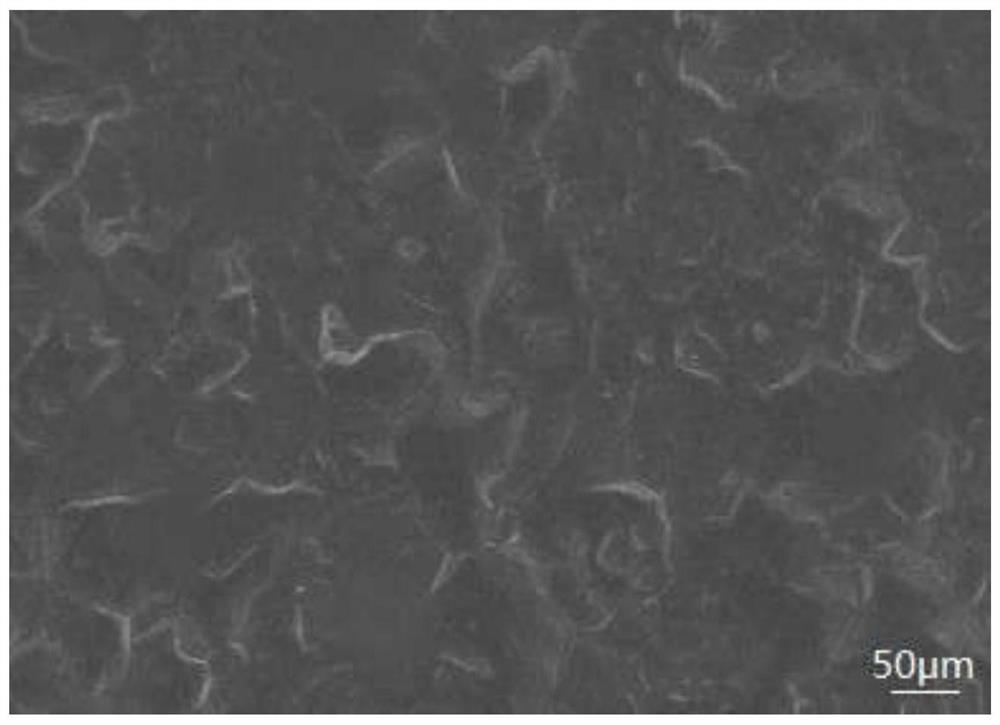

Molybdenum-tungsten sputtering target material and preparation method thereof

ActiveCN111893442AUniform tissueNo holesVacuum evaporation coatingSputtering coatingDisplay deviceTungsten trioxide

The invention discloses a molybdenum-tungsten sputtering target material and a preparation method thereof. The relative density of the molybdenum-tungsten sputtering target material is 99.0-99.5%, andthe oxygen content is 350-600 ppm. The molybdenum-tungsten sputtering target material is prepared from the following raw materials in percentage by weight: 15-20wt% of tungsten trioxide powder with the purity of at least 4N, and the balance of molybdenum powder with the purity of at least 3N, wherein the particle size of the tungsten trioxide powder is 7-10 mum, and the particle size of the molybdenum powder is 4.5-6.5 mum. The molybdenum-tungsten sputtering target material is suitable for preparing a flat panel display, and has the advantages of uniform structure, no holes and low oxygen content.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

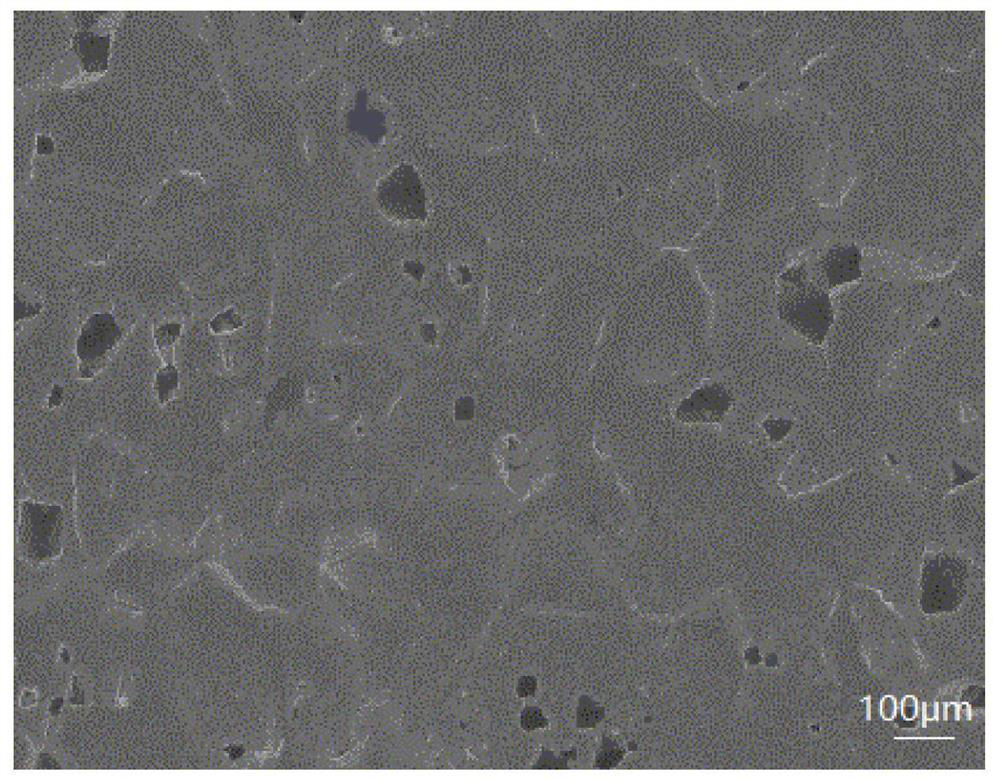

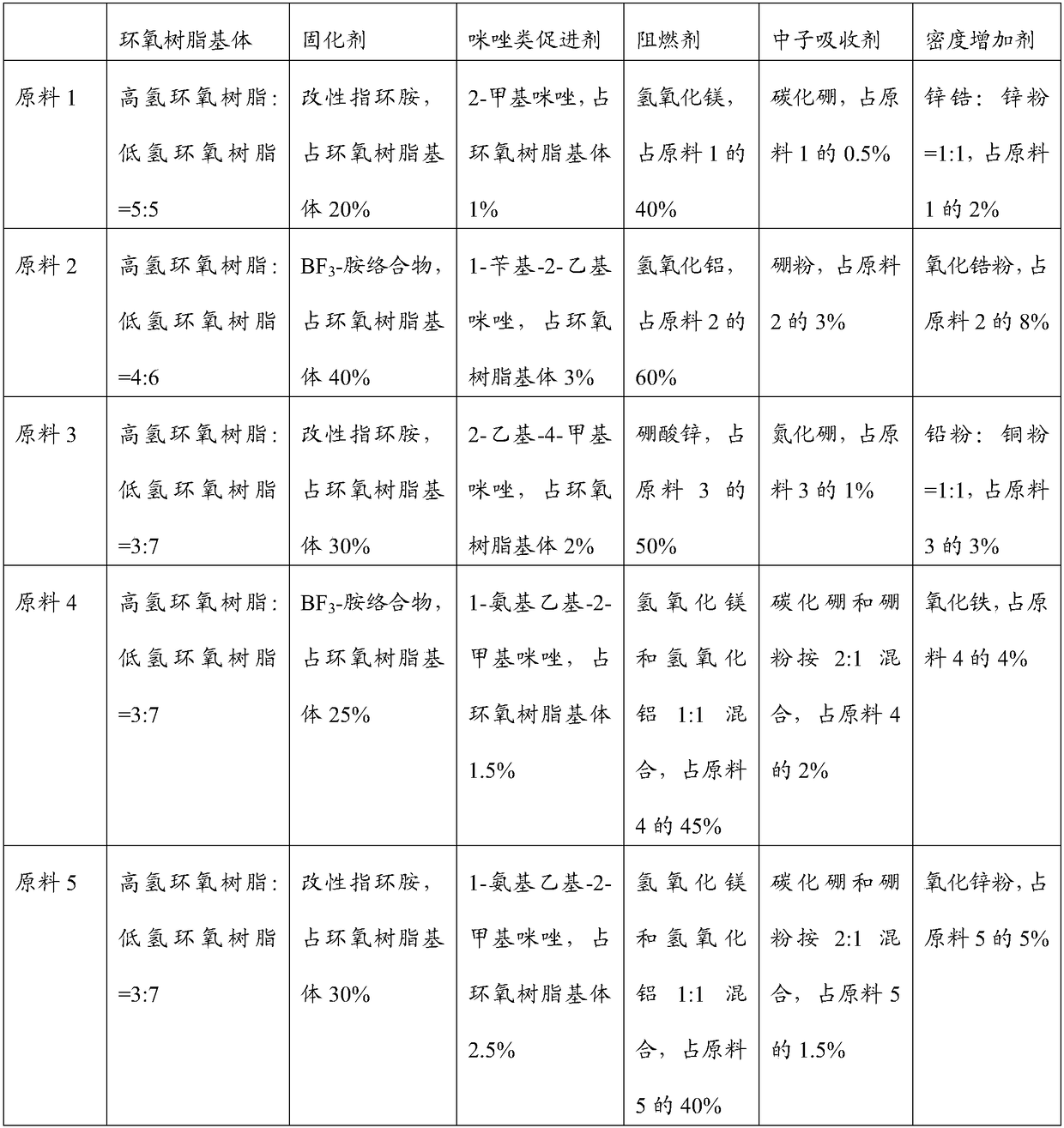

Preparation technology of radiation protection material and radiation protection material

The invention provides a preparation technology of a radiation protection material and the radiation protection material. The preparation technology comprises the following steps that (1) raw materials for preparing the radiation protection material are provided; (2) the raw materials of the radiation protection material are mixed and degassed to prepare a mixture; (3) the mixture is poured; and the preparation technology further comprises solidification treatment after pouring, wherein through the solidification treatment, the mixture is gradually solidified from bottom to top by making the temperature of the upper portion of the poured mixture lower than the temperature of the lower portion of the mixture. After adding the solidification treatment, the mixture is gradually solidified from the lower portion to the upper portion, and the non-solidified mixture at the upper portion can permeate downwards in time and naturally to fill in shrinkage gaps generated by the solidification atthe lower portion, and flowing of the non-solidified mixture can remove fine bubbles in the mixture, so that the prepared radiation protection material has low porosity and small density difference, and radiation generated by spent fuel can be well shielded.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

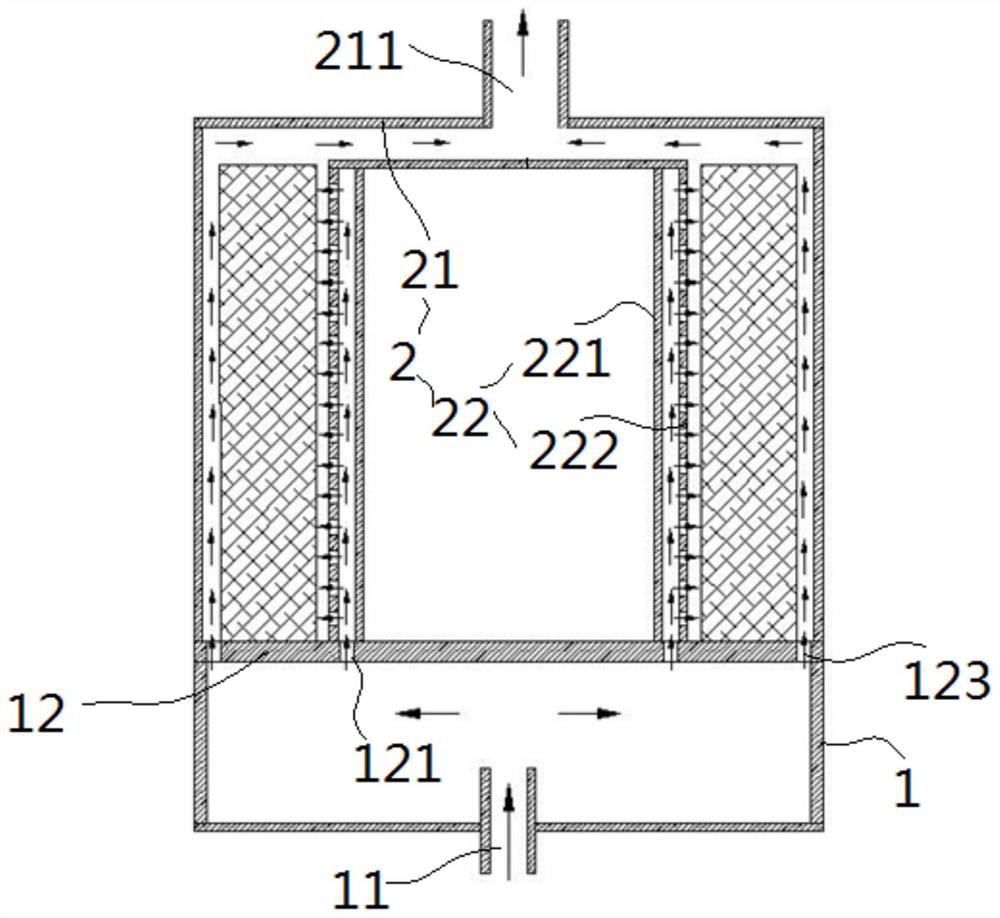

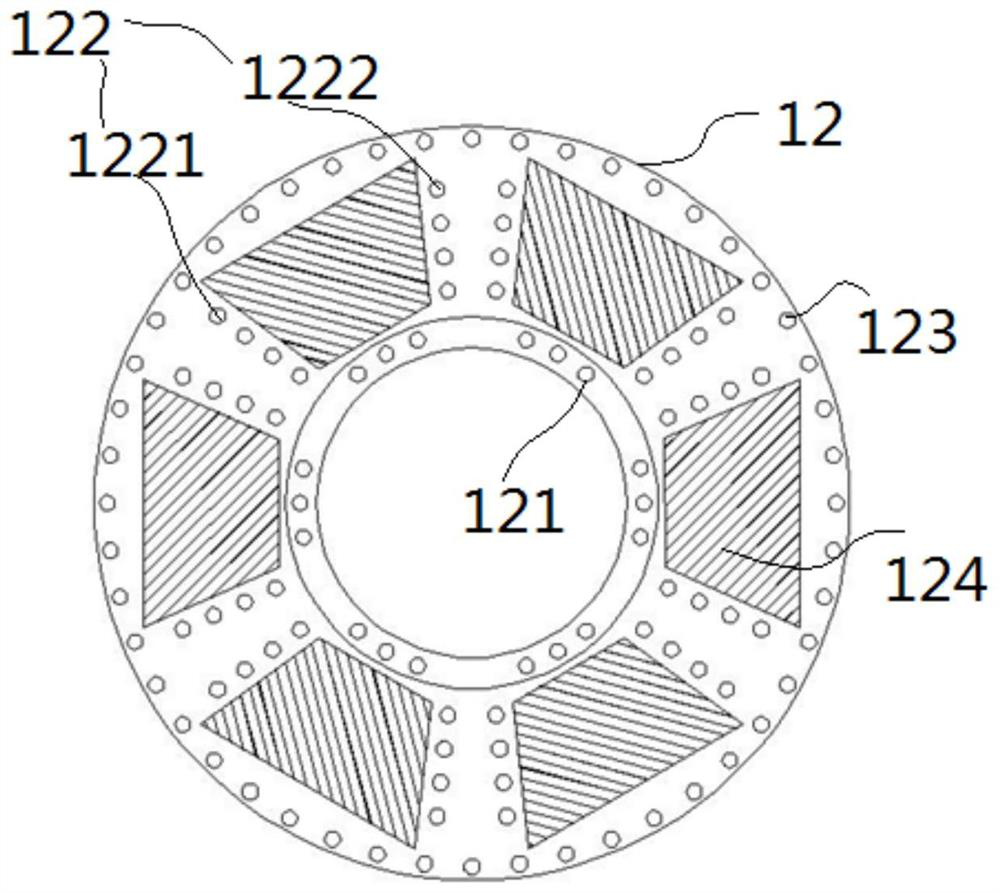

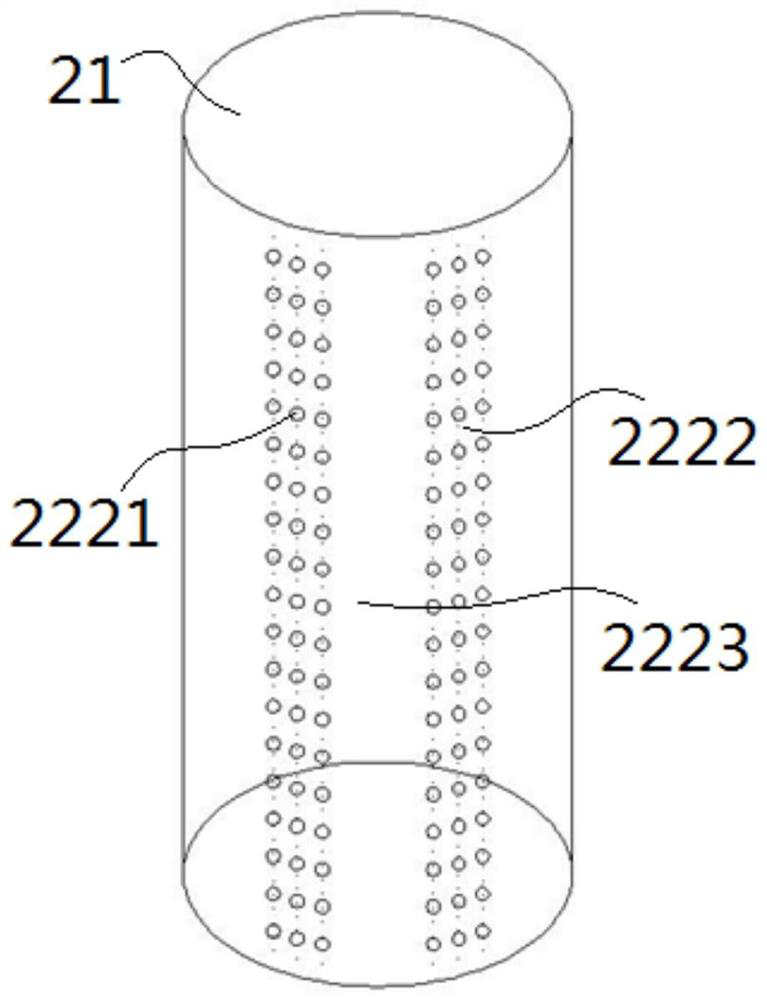

Vapor deposition device and preparation method of carbon/carbon composite material

ActiveCN112830807ASimple structureImprove densification efficiencyCarbon compositesDeposition process

The invention provides a vapor deposition device. The vapor deposition device comprises a base, a material plate and a deposition chamber, and the deposition chamber comprises an outer barrel, an exhaust port and an exhaust sleeve arranged in the outer barrel; the exhaust sleeve comprises an inner cylinder and a sleeve body arranged outside the inner cylinder in a sleeving mode, an airflow channel is defined by the inner cylinder and the sleeve body, and vent holes are formed in the side wall of the sleeve body; a first air inlet hole is formed in the material plate and is positioned between the sleeve and the inner cylinder; the material plate is further provided with an air inlet structure, the air inlet structure comprises an air inlet hole array, and the air inlet hole array is distributed in a radial shape with the exhaust sleeve as the center; and a fourth air inlet is formed in the side, away from the exhaust sleeve, of the air inlet array. The device can effectively control the flowing direction of gas in the deposition process, so that the gas is in full contact with a to-be-treated blank. In addition, the invention also provides a method for preparing a carbon / carbon composite material by using the device, and the method comprises the following step of determining the criterion of the flow of the carbon source gas and the principle that the flow is gradually reduced along with the increase of CVD (Chemical Vapor Deposition) times.

Owner:CENT SOUTH UNIV

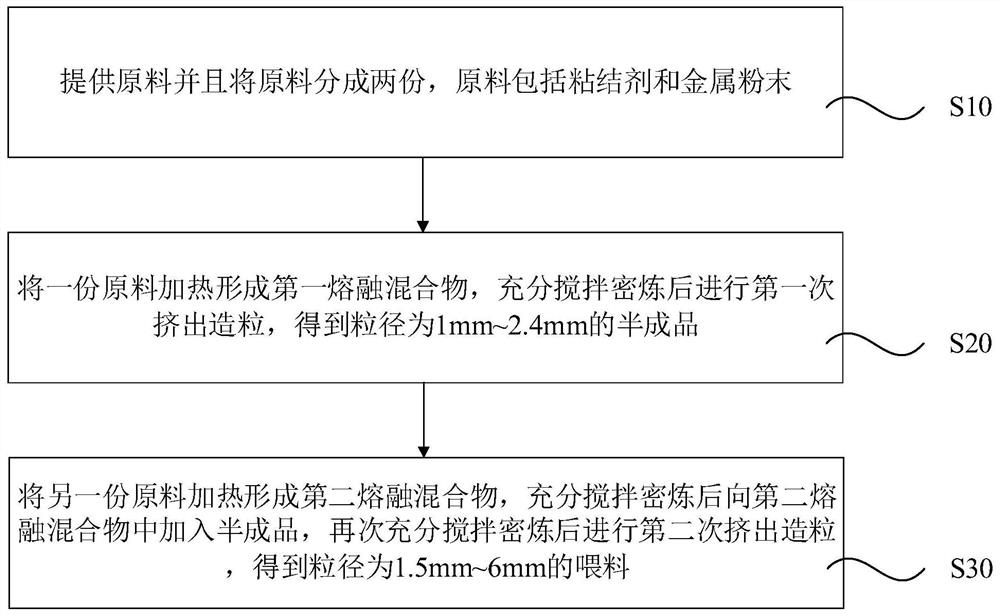

Preparation method of feed for metal injection molding, feed and metal part

The invention discloses a preparation method of a feed for metal injection molding, the feed and a metal part. The preparation method of the feed for metal injection molding comprises the following steps that raw materials are provided and divided into two parts; one part of the raw materials is heated to form a first molten mixture, and after sufficient stirring and banburying, first-time extrusion granulation is conducted to obtain a semi-finished product; and the other part of the raw materials is heated to form a second molten mixture, after sufficient stirring and banburying, the semi-finished product is added into the second molten mixture, and after sufficient stirring and banburying are conducted again, second-time extrusion granulation is conducted to obtain the feed. According to the preparation method of the feed for metal injection molding, the semi-finished product with the small particle size is prepared through first-time extrusion granulation, then the semi-finished product and the second molten mixture are mixed to form the raw materials of the feed, due to participation of the semi-finished product, the density difference of the raw materials of the feed is reduced, particle size distribution of the raw materials of the feed is enriched, and thus the mixing uniformity of the raw materials of the feed is improved.

Owner:深圳市富荣新材料科技有限公司

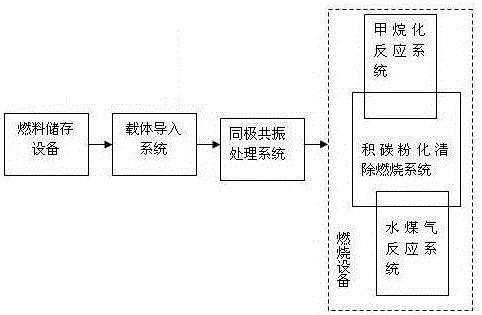

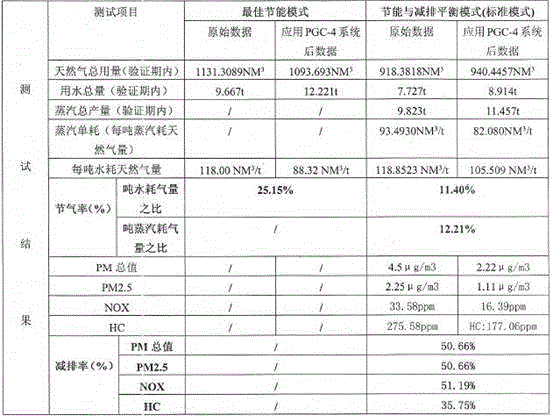

Gas saving, emission reducing and efficiency improving system for industrial gas furnace and kiln

InactiveCN106403624ASmall density differenceGood compatibilityChemical industryGaseous fuelsIndustrial gasCombustion

The invention provides a gas saving, emission reducing and efficiency improving system for industrial gas furnace and kiln. The system comprises a carrier introduction system, a homopolar resonance treatment system, a methanation reaction system, a water gas reaction system and a deposited carbon pulverization removing and combusting system; a liquid carrier is taken by a gas fuel; the fuel taking the liquid carrier passes through each subsystem; the carbon chain structure of the fuel is changed by adopting a homopolar resonance technology; meanwhile, methanation reaction and water gas reaction are generated by carrier catalysis to form chained type combustion enhancement, and the combustion efficiency of the fuel is improved, so the amount of used fuel is reduced; meanwhile, the gas saving, emission reducing and efficiency improving system for the industrial gas furnace and kiln is capable of implementing synergic emission reduction of various pollutants by a selective tail end reduction reaction. The treatment system provided by the invention has the advantages of saving energy and reducing emission.

Owner:佛山市保能特知识产权管理有限公司

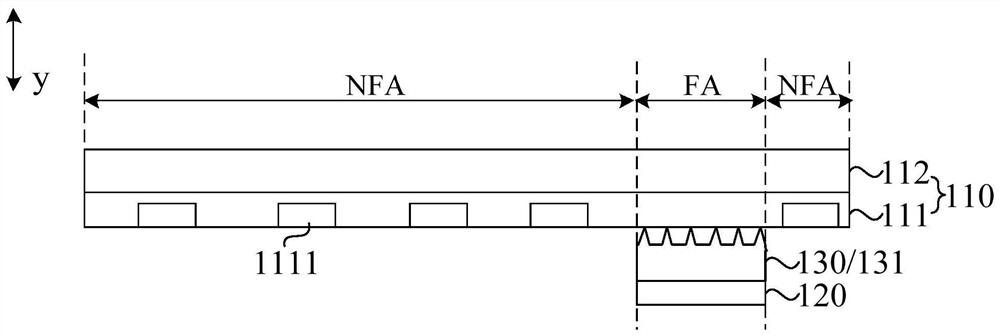

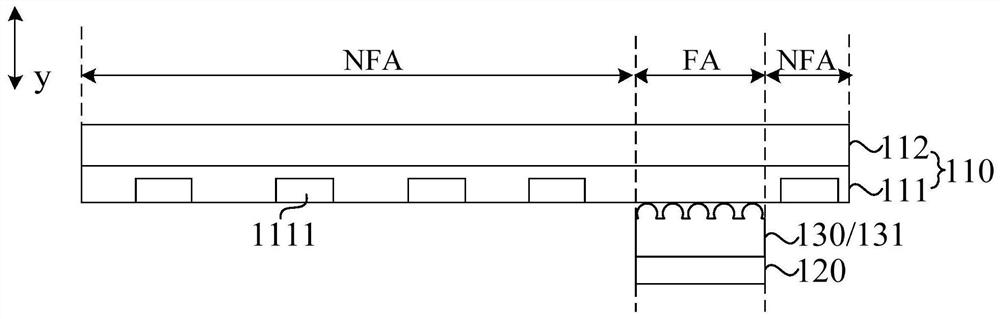

Display device

PendingCN112289839AImprove display uniformityHigh sensitivitySolid-state devicesSemiconductor devicesMicro nanoLight sensing

The invention discloses a display device. The display device comprises: a display function layer which comprises a thin film transistor array and a light-emitting device layer located at one side of the thin film transistor array; a light sensing device arranged on the side, away from the light-emitting device layer, of the thin film transistor array and located in a fingerprint recognition area;and an optical collimation structure layer arranged between the light sensing device and the display function layer, wherein the optical collimation structure layer comprises an optical collimation structure, the optical collimation structure is arranged in the fingerprint recognition area, the optical collimation structure corresponds to the light sensing device in the thickness direction of thedisplay device, and the surface of the side, close to the display function layer, of the optical collimation structure comprises a micro-nano structure array. According to the display device providedby the embodiment of the invention, the intensity of the irradiated light of each thin film transistor channel in the display function layer is relatively consistent, the performance of the thin filmtransistors can be relatively consistent, the brightness of the light emitting device can be relatively consistent, and the display uniformity of the display panel is further improved.

Owner:YUNGU GUAN TECH CO LTD

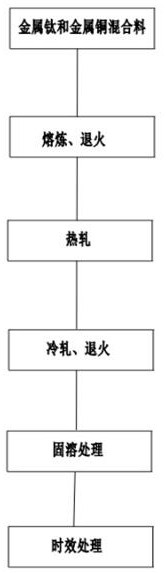

Preparation method of antibacterial plate for tableware

PendingCN112853135AImprove performanceSmall density differenceHazardous substanceSS - Stainless steel

The invention discloses a preparation method of an antibacterial plate for tableware, belongs to the technical field of metal rolling, and solves the problem that coating stainless steel and antibacterial heat treatment stainless steel in food contact materials in the prior art generate harmful substances to human bodies. The preparation method comprises the steps that S1, metal titanium with the granular mass fraction being 97% and metal copper with the granular mass fraction being 3% are mixed, and a mixture is obtained; S2, a non-self-consumption vacuum arc melting furnace is adopted for smelting the mixture into an alloy cast ingot, in the vacuum melting process, electromagnetic stirring is adopted for assisting production, heat preservation is conducted for 3-6 h, and then annealing cooling is conducted; S3, the annealed and cooled cast ingot is heated, and two-pass hot rolling is carried out to form a plate; S4, cold rolling and annealing are carried out: firstly removing an oxidation film on the surface of a hot-rolled plate, and performing cold rolling and annealing treatment on the hot-rolled plate for multiple times; S5, solution treatment is carried out; and S6, aging treatment is carried out on the cold-rolled sheet subjected to solution treatment. The alloy plate is smaller in grain size, the tensile strength, the ductility and other mechanical properties are obviously improved, and meanwhile the good antibacterial property is achieved.

Owner:西安庄信新材料科技有限公司

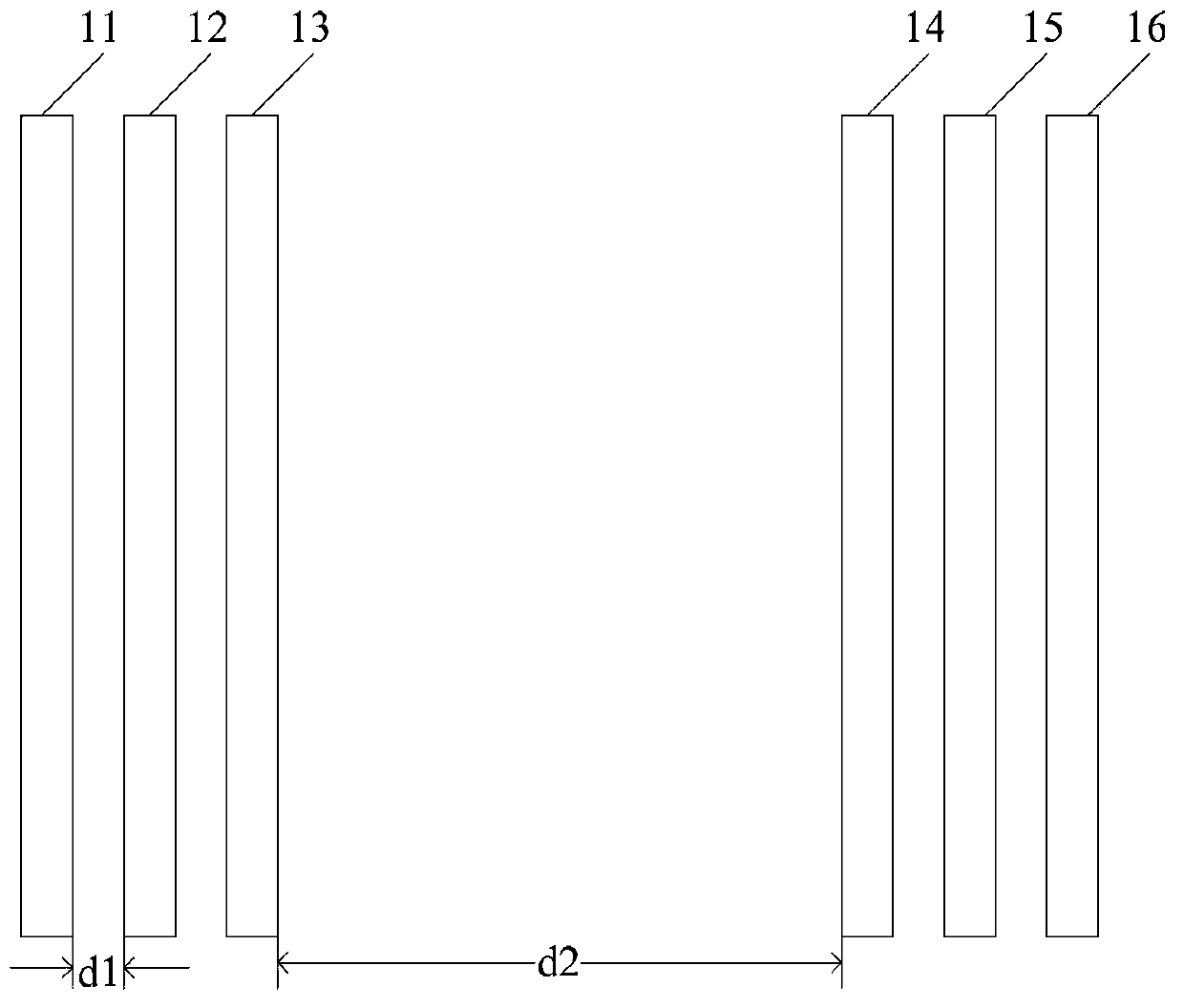

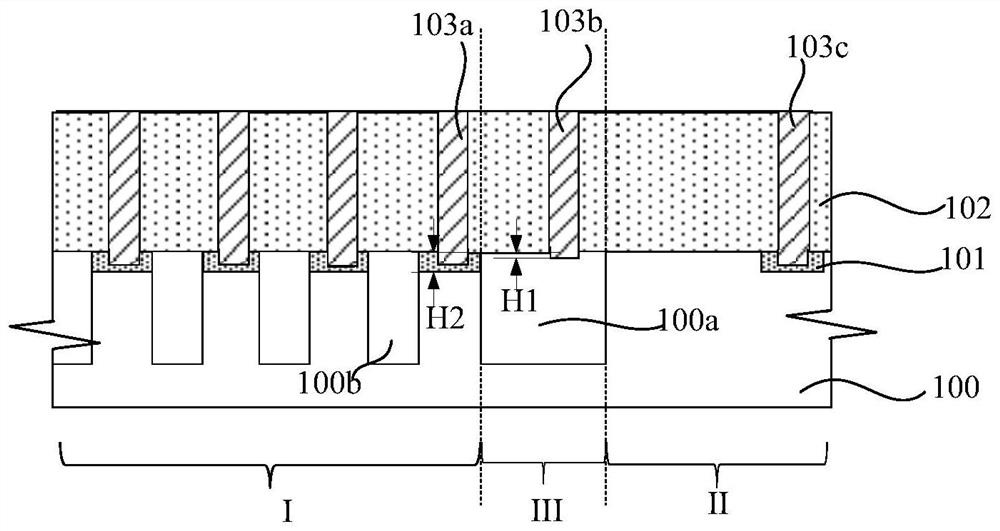

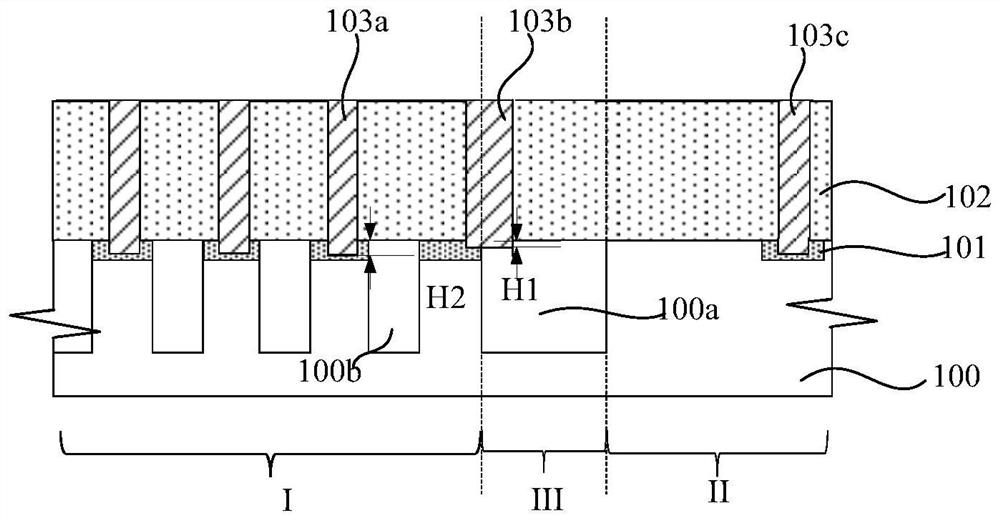

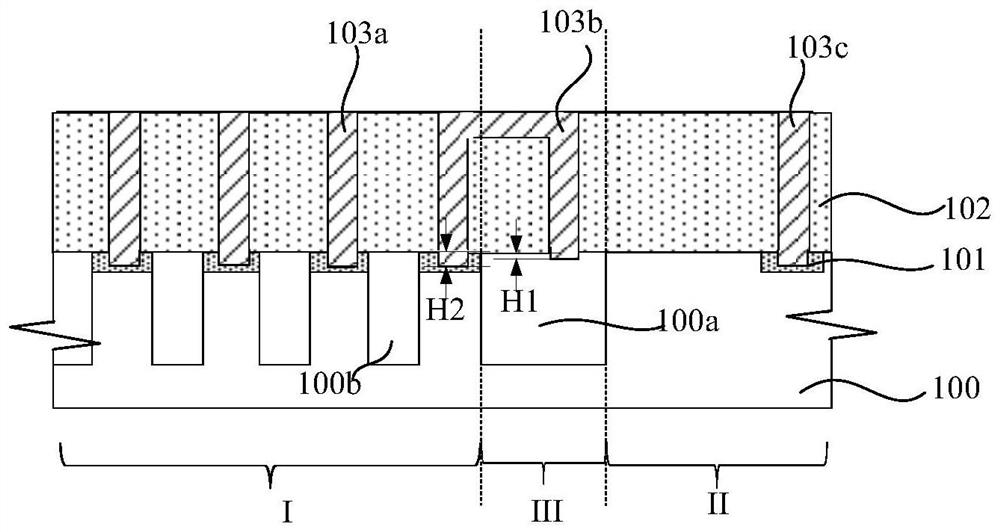

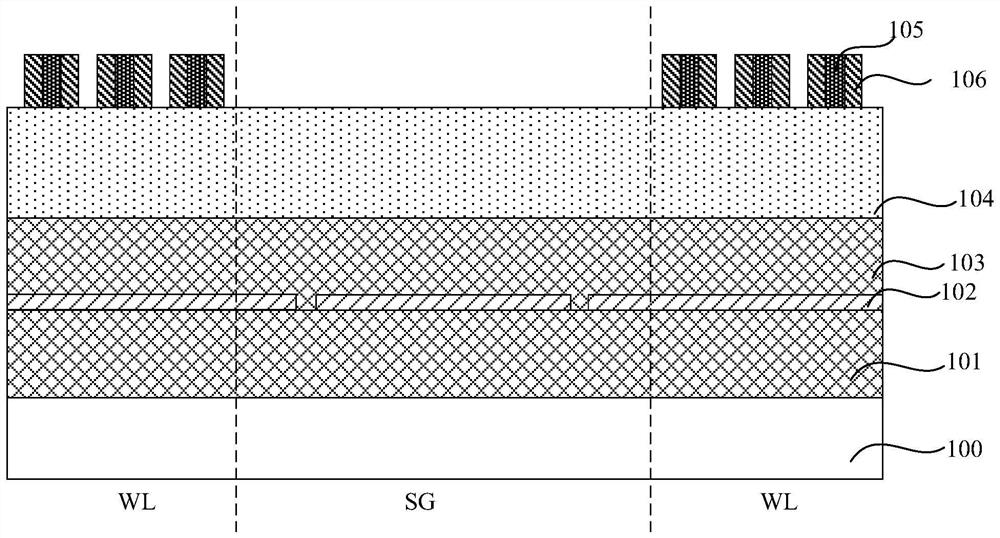

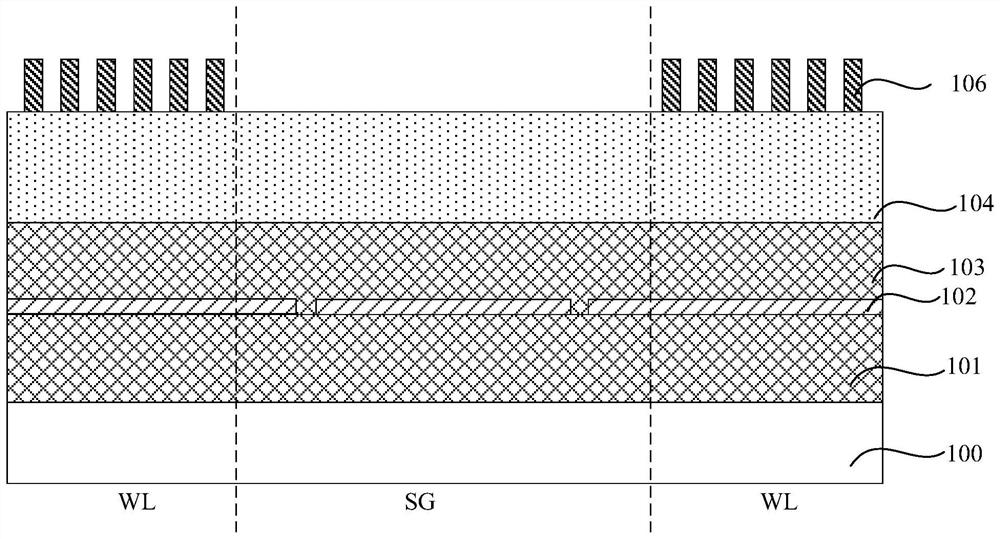

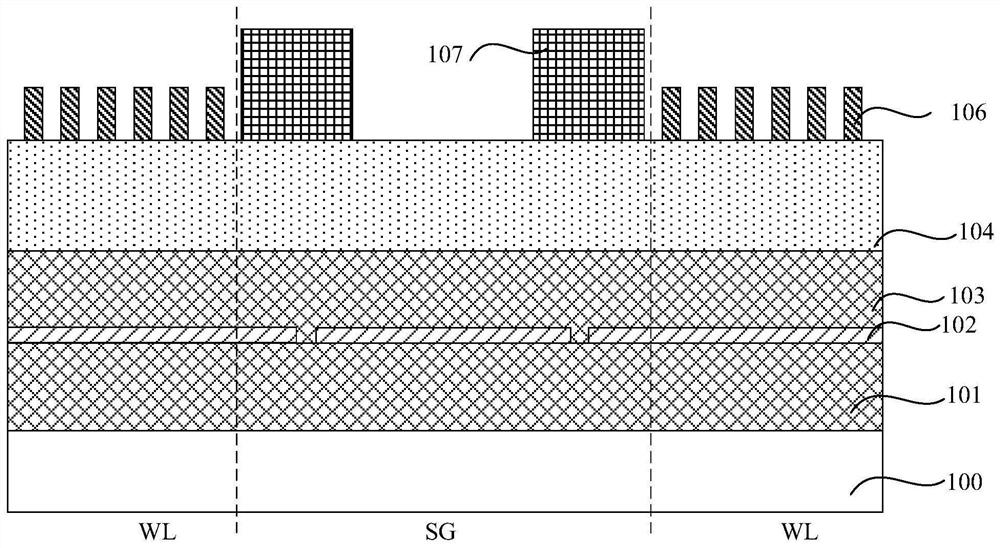

Semiconductor device, manufacturing method and mask

ActiveCN110571220BImprove performanceSmall density differenceSolid-state devicesSemiconductor devicesDevice materialEngineering

The invention provides a semiconductor device and its manufacturing method and mask plate. In the manufacturing method of the semiconductor device, after forming a patterned core layer with a core on the gate dense area and the gate sparse area, the A sidewall is formed on the sidewall of the core, and then the gate layer is etched using the sidewall as a mask to form a first gate on the gate-dense region and a second gate on the gate-sparse region. When the gate base structure is used, the etching load effect between the gate dense area and the gate sparse area can be reduced or even completely avoided, and the uniformity of the critical dimension of the first gate in the formed gate dense area can be improved. The shape of the first gate at the edge is ensured, and then the tops of a plurality of adjacent second gate infrastructure structures on the gate sparse region are connected to form a second gate by means of a connecting gate layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

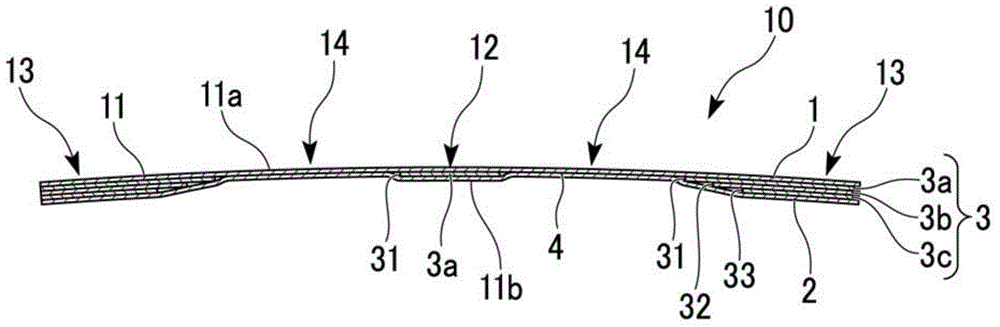

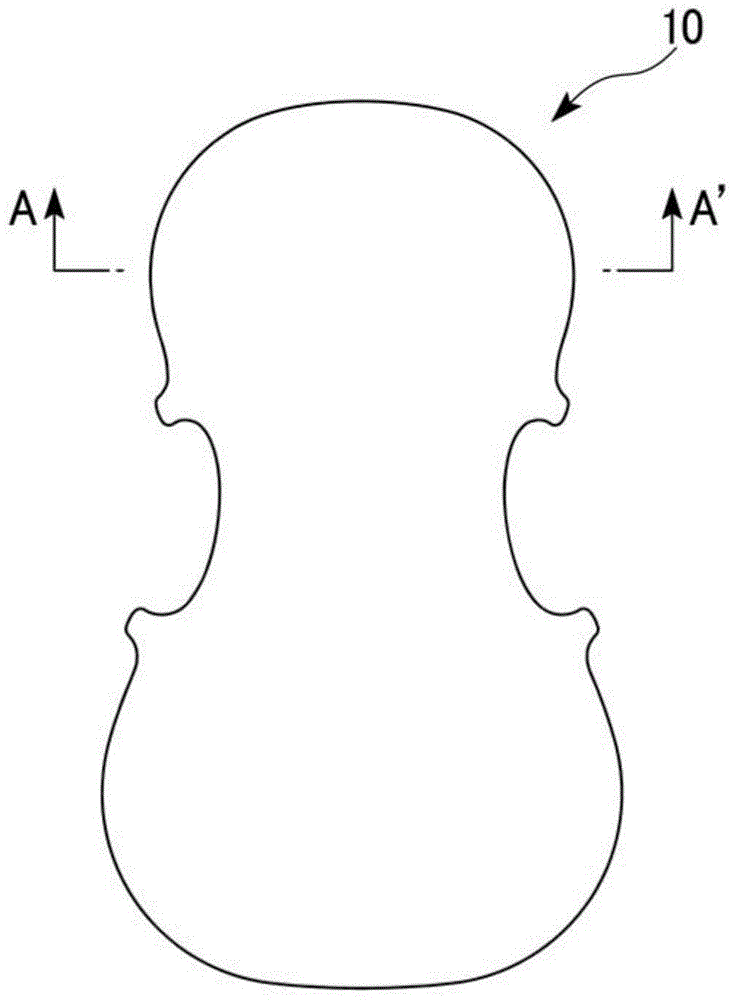

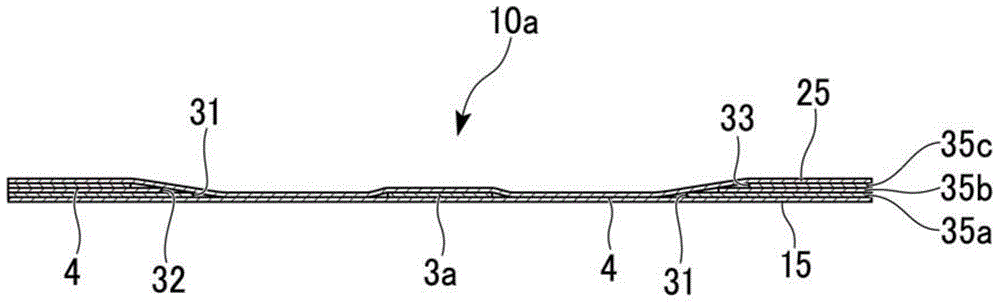

Board for stringed instrument, method of manufacturing board for stringed instrument, and stringed instrument

A board for a stringed instrument which forms a front plate or a back plate of a stringed instrument, includes: a laminated plate (11) that is obtained by laminating a plurality of veneers having a uniform thickness by an adhesive, at least one of the veneers having a different planar shape than the other veneers, in which the laminated plate is curved to be convex toward one surface side and has a thin portion and a thick portion.

Owner:YAMAHA CORP

Aluminum oxide sintered body, and members using same for semiconductor and liquid crystal manufacturing apparatuses

Owner:KYOCERA CORP

Inert matrix dispersed fuel pellets and preparation method thereof

ActiveCN109461509BSmall density differenceHigh volume contentNuclear energy generationReactors manufacturePressureless sinteringComposite material

The invention discloses an inert matrix dispersion fuel pellet and a preparation method thereof. The preparation method includes: S1, prefabricating a fuel-free area, specifically, pressing SiC mixedpowder into a tubular shape or a disc shape, and performing pressureless sintering; S2, prefabricating a fuel area, specifically pressing TRISO (tri-structural iso-tropic) particles with SiC coatingsinto a cylindrical shape; S3, filling the cylindrical-shaped materials into the tubular-shaped materials, then placing the disc-shaped materials at the opposite both ends of the tubular-shaped materials, performing discharge plasma sintering to obtain the inert matrix dispersion fuel pellet, wherein the cylindrical-shaped materials form the fuel area of the inert matrix dispersion fuel pellet, andthe tubular-shaped materials and the disc-shaped materials form the fuel-free area of the inert matrix dispersion fuel pellet. According to the preparation method of the inert matrix dispersion fuelpellet, by prefabricating the fuel-free area, the density of the fuel-free area is controlled to be close to that the pressed fuel area, the density difference between the fuel area and the fuel-freearea of the sintered inert matrix dispersion fuel pellet can be reduced, the peripheral contour structure of TRISO particles inside the fuel area can be improved, the fuel area can be expanded, the overall TRISO volume content of the inert matrix dispersion fuel pellet can be increased, and the comprehensive performance of the inert matrix dispersion fuel pellet can be further enhanced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +4

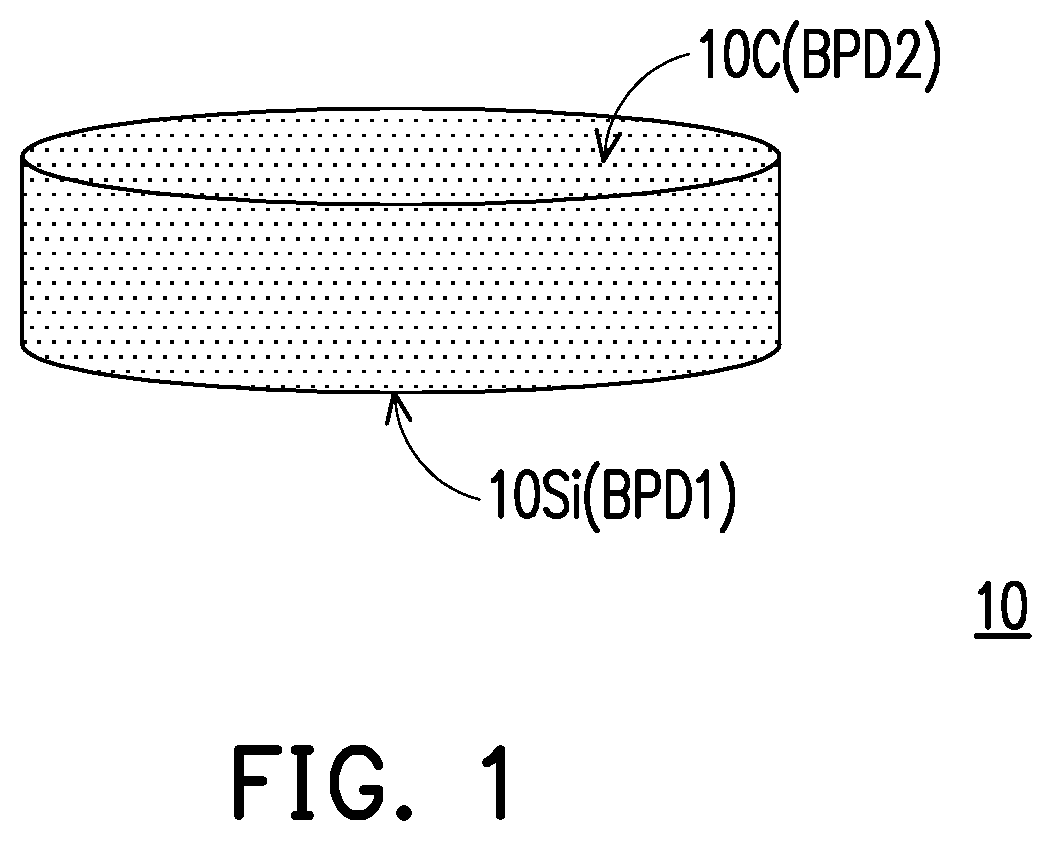

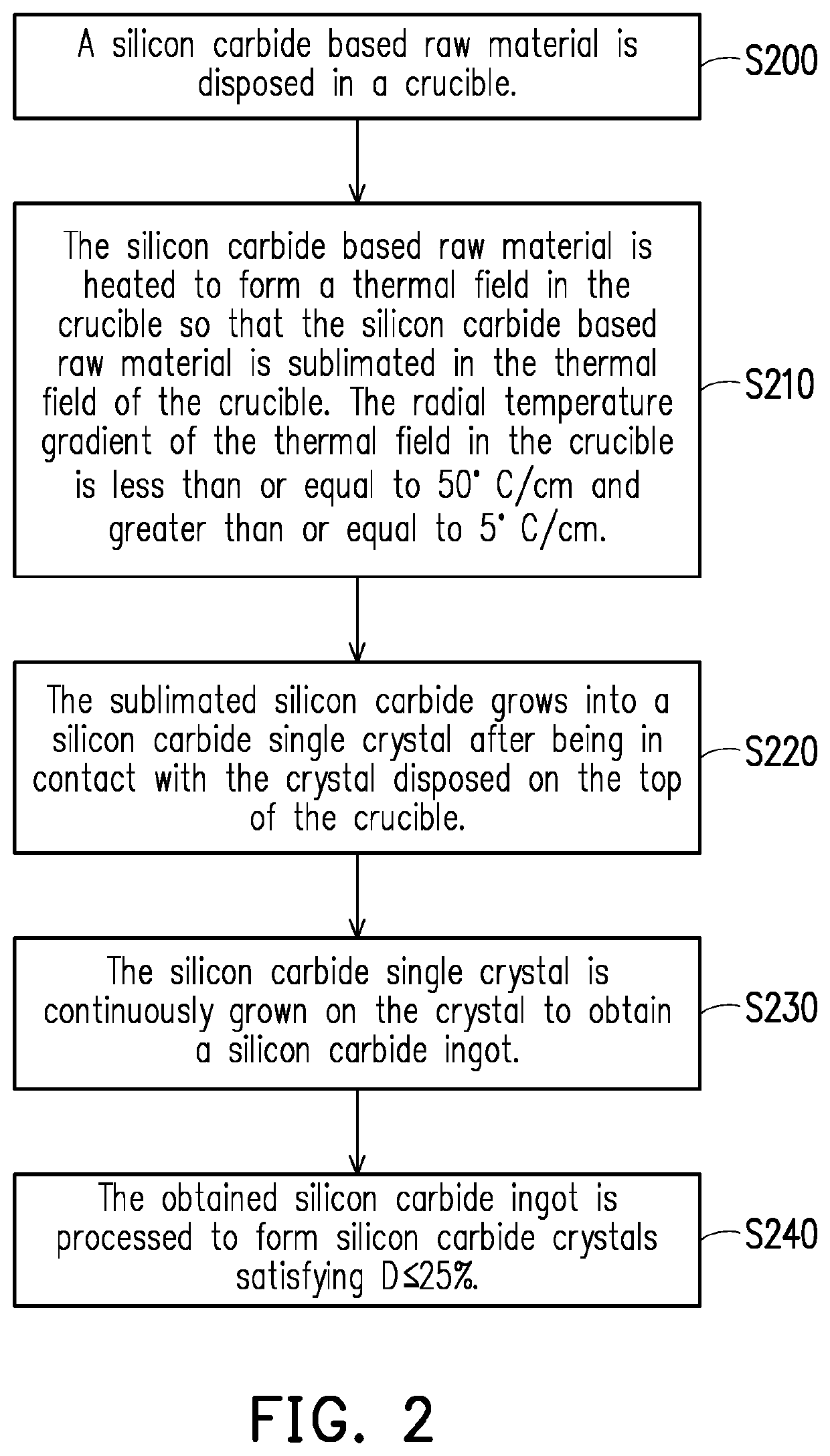

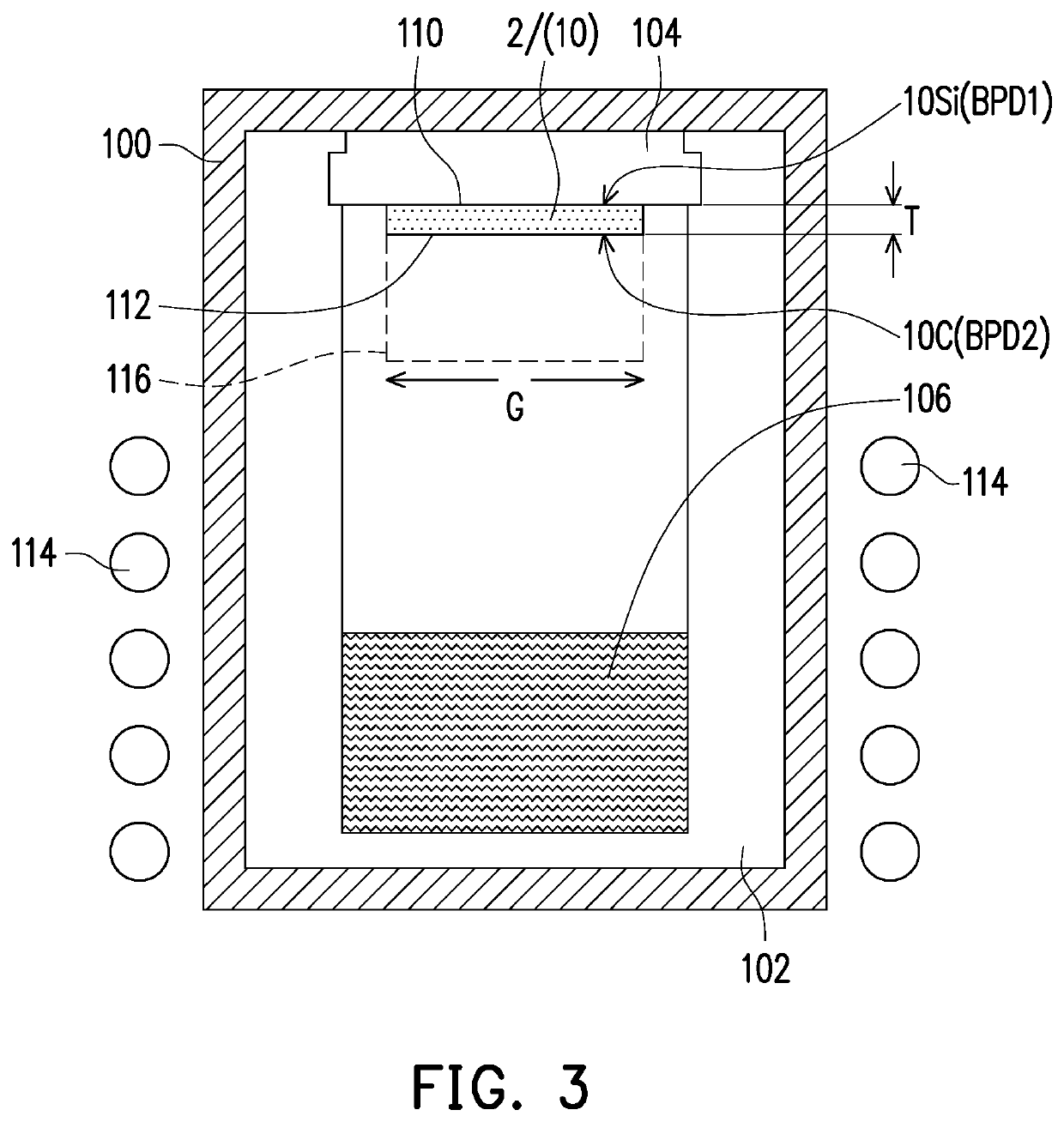

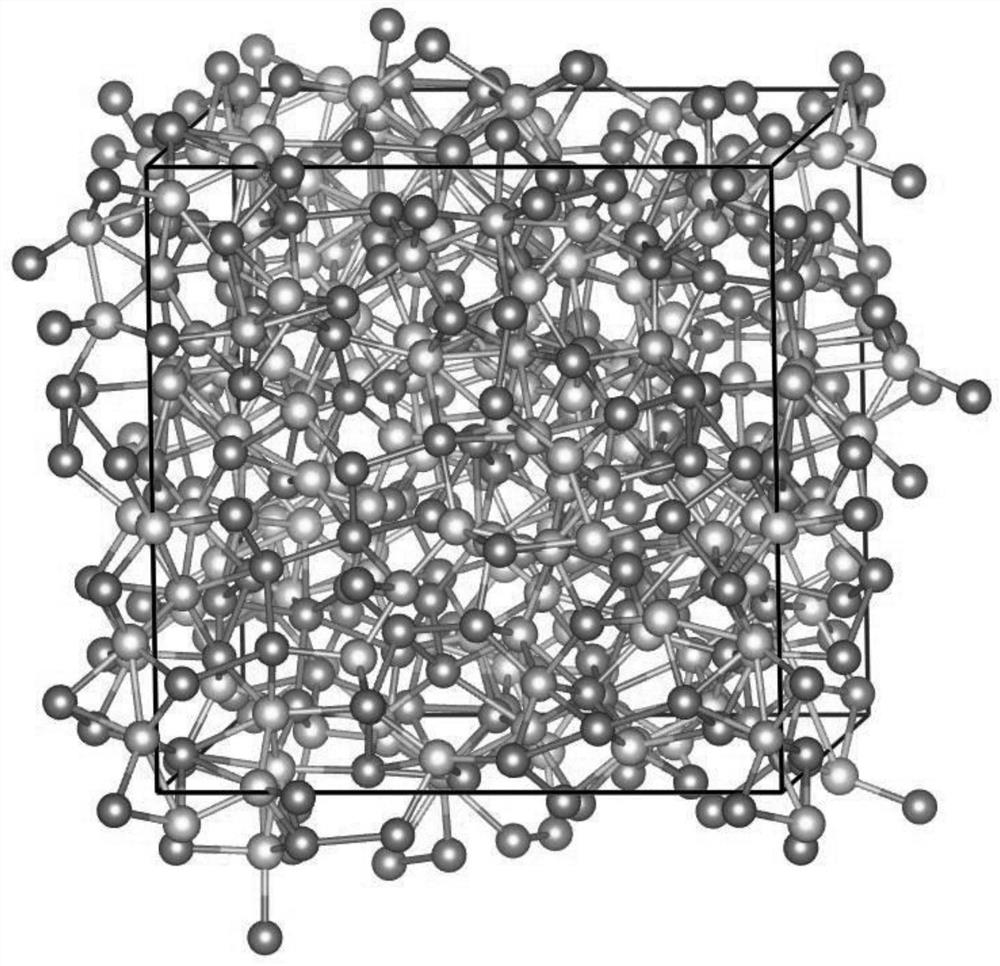

Silicon carbide seed crystal and method of manufacturing the same, and method of manufacturing silicon carbide ingot

ActiveUS20220025543A1Reduce defect structureLow costPolycrystalline material growthSilicon carbideCarbide siliconIngot

A silicon carbide seed crystal and method of manufacturing the same, and method of manufacturing silicon carbide ingot are provided. The silicon carbide seed crystal has a silicon surface and a carbon surface opposite to the silicon surface. A difference D between a basal plane dislocation density BPD1 of the silicon surface BPD1 and a basal plane dislocation density BPD2 of the carbon surface satisfies the following formula (1):D=(BPD1−BPD2) / BPD1≤25% (1).

Owner:GLOBALWAFERS CO LTD

Refractory castable in use for homogeneous stopper plug of floating plug, and preparation method

InactiveCN1317237CHigh bulk densityWide range of density adjustmentManufacturing convertersSlagGranularity

A refractory casting material for the uniform slag plug is prepared from the weighting aggregate (25-40 Wt%) and refractory mixture (60-75) through proportionally mixing metallic filings, super-grade high-Al clinker, brown corundum, silicon micropowder, alpha-Al2O3 powder, water glass, sodium fluorosilicate and melamine, mashing to become blocks, baking, pulverizing, sieving, and proportionally mixing it with refractory mixture.

Owner:武钢集团有限公司

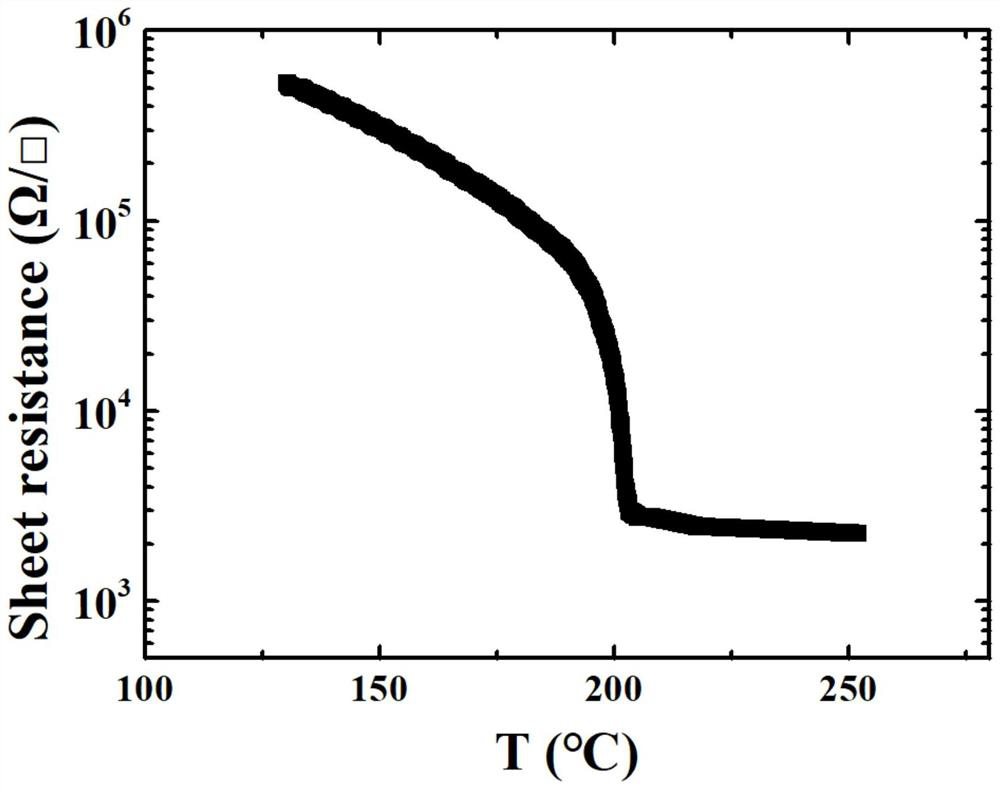

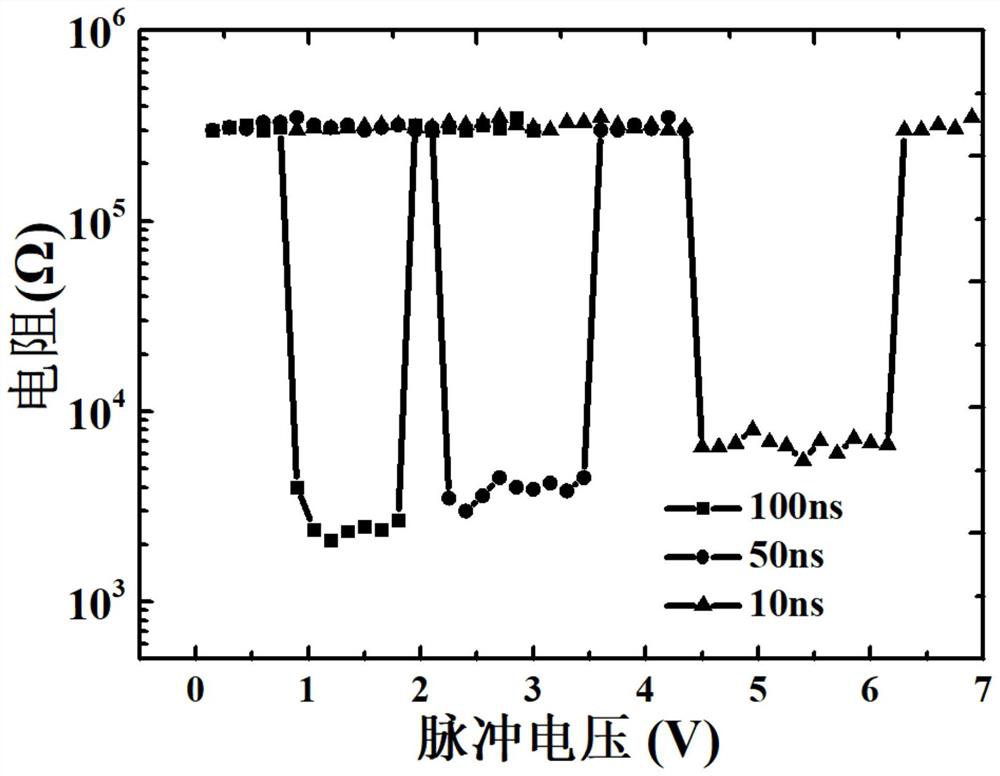

Ti-ga-sb phase change material, phase change memory and preparation method of ti-ga-sb phase change material

ActiveCN110729400BImprove stabilityIncrease the amorphous densityElectrical apparatusPhase-change memoryMetallurgy

Owner:HUAZHONG UNIV OF SCI & TECH

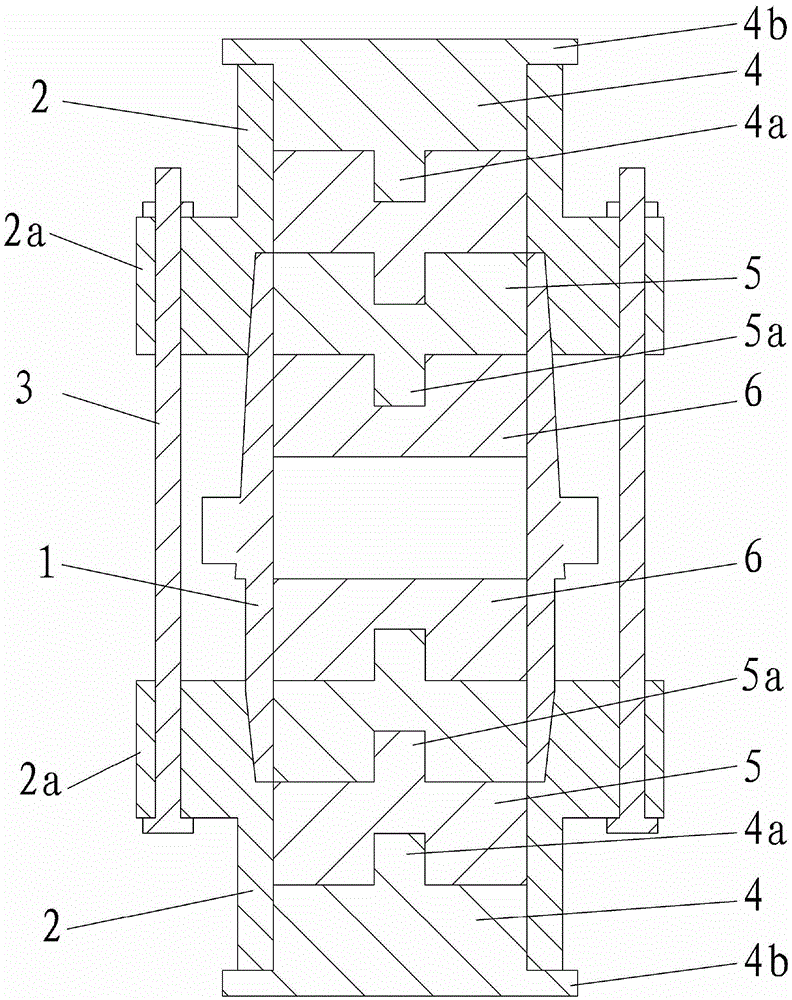

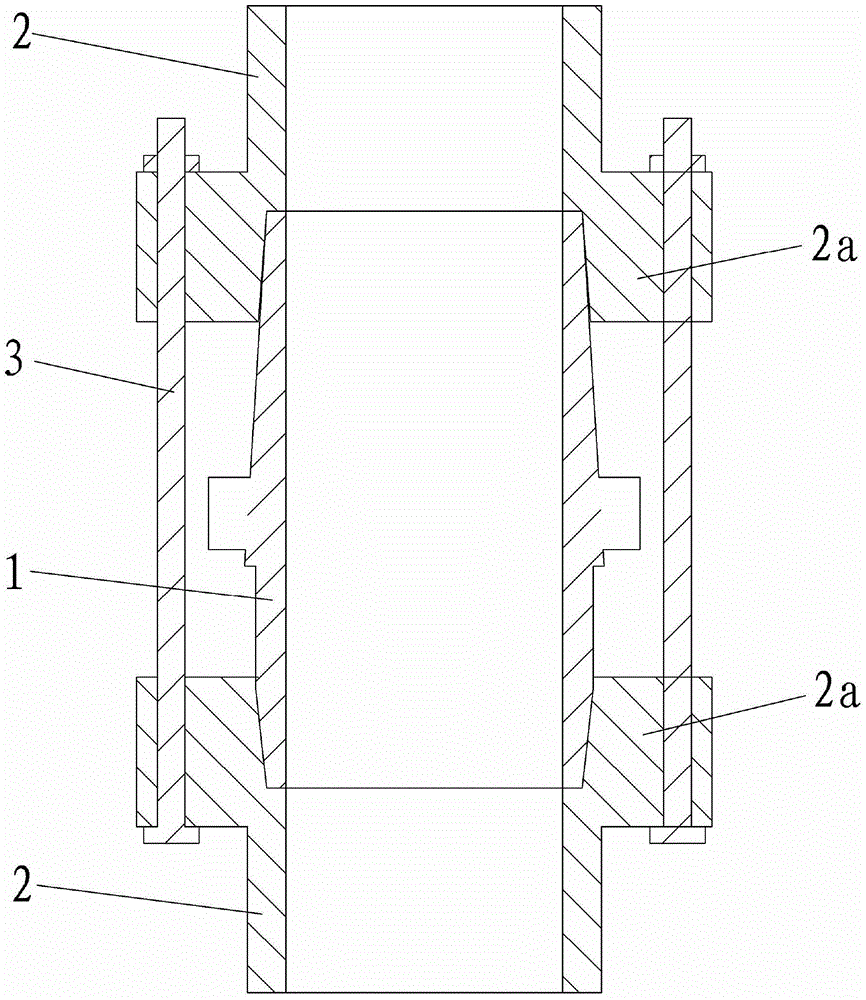

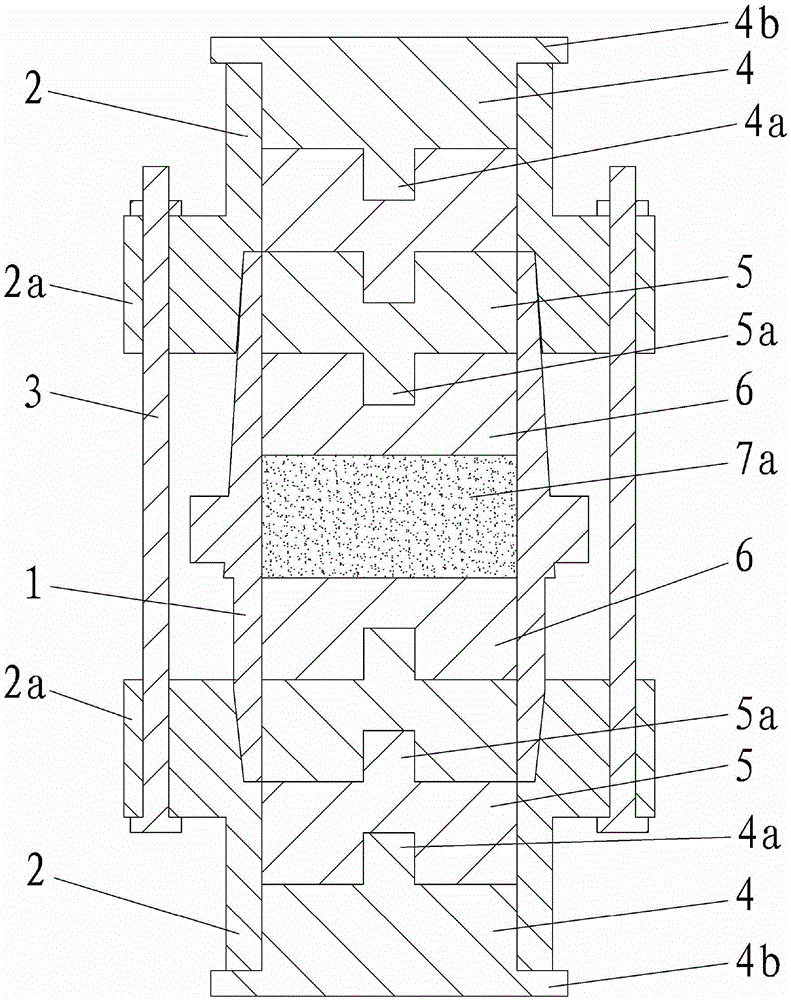

Symmetrical layered sample pressing device and sample preparation method for triaxial test sample preparation

ActiveCN104006992BSmall density differenceImprove uniformityPreparing sample for investigationTriaxial shear testTest sample

A symmetrical layered sample pressing device and sample preparation method for triaxial test sample preparation. The main components of the device are: the outer walls at both ends of the soil sample cylinder are fitted with the slots on the inner wall of the extension tube, and the non-slot parts of the extension tube are The diameter of the inner wall is equal to the diameter of the inner wall of the soil sample cylinder; the extension cylinder and the soil sample cylinder are covered with a pad set, and the pad set is composed of: the outer circumference of the back end of the outer pad protrudes outward to form a cover edge, and the front center of the outer pad There are threaded protrusions; there is a threaded hole in the center of the back of the middle block, there are threaded protrusions in the center of the front, and there are two middle blocks; there are threaded holes on the back of the inner block, and the front is flat; the outer block, the middle The pads and inner pads are screwed to the corresponding threaded holes through protrusions; the height of the inner pads and middle pads is 1 / 5 of the height of the soil sample cylinder; the sum of the heights of the inner pads and the outer pads minus the cover The thickness along the extension tube is equal to the height of the non-card slot part of the extension cylinder. The sample prepared by the device has good uniformity, and can make the test result of the triaxial test more accurate and reliable.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com