Ti-ga-sb phase change material, phase change memory and preparation method of ti-ga-sb phase change material

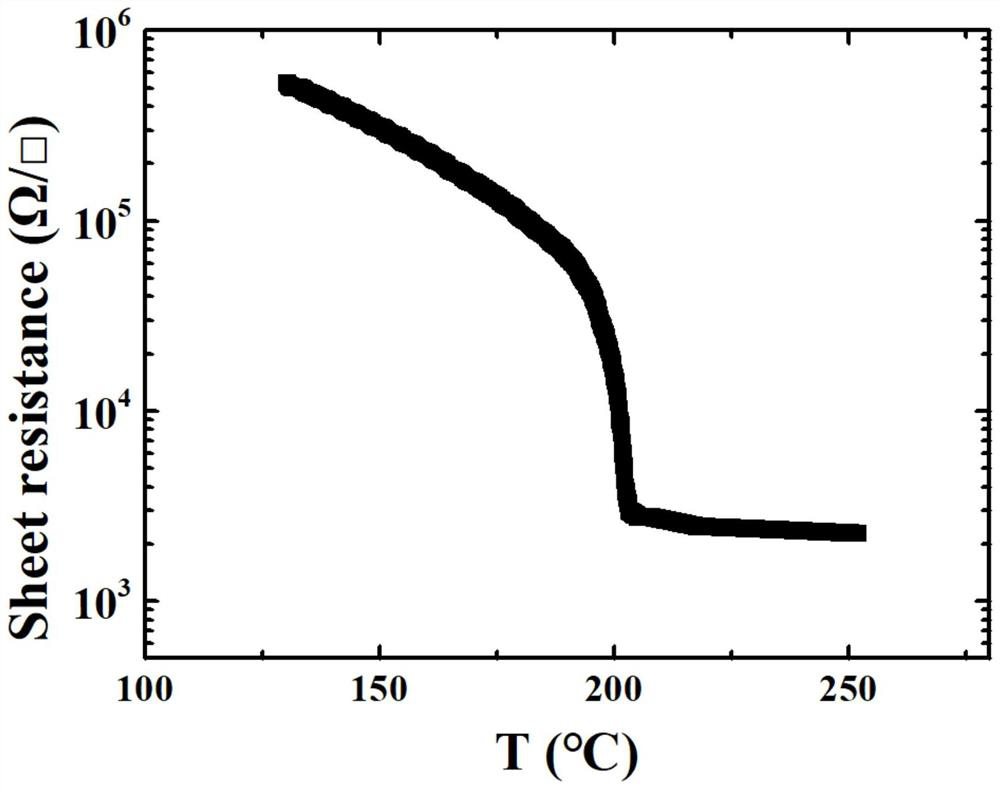

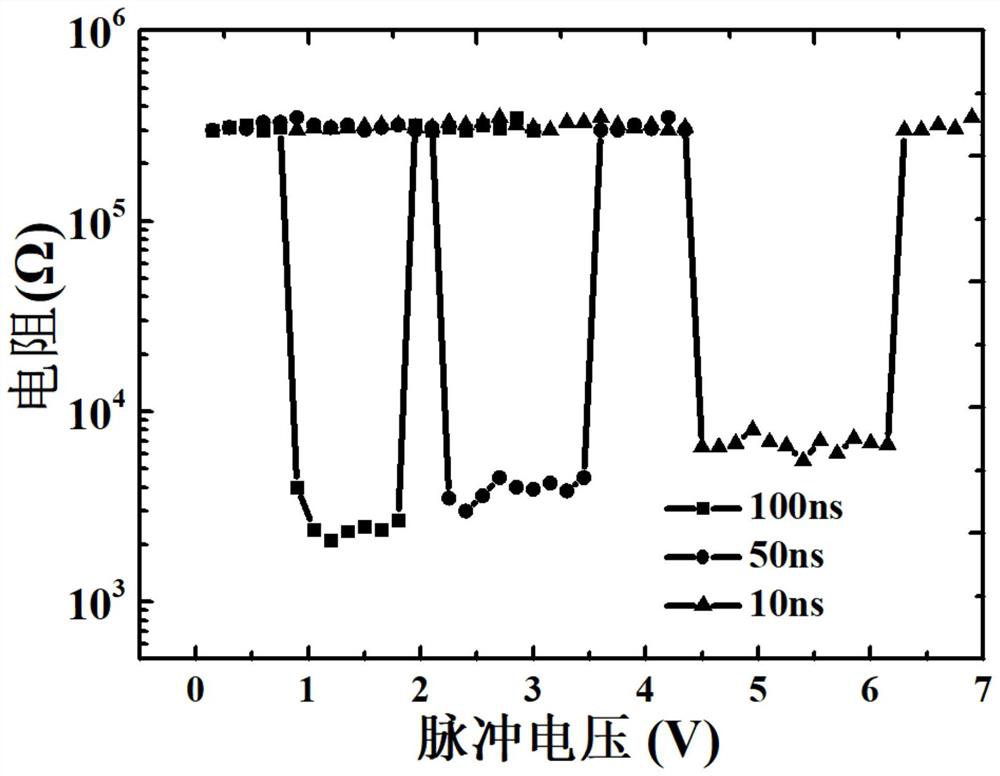

A phase change memory, ti-ga-sb technology, applied in the direction of electrical components, etc., can solve the problems affecting the application reliability and service life of phase change memory, crystallization temperature and low temperature of ten-year data retention, crystalline state and amorphous state Problems such as large density differences, to achieve ultra-fast phase transitions, improve volume stability, and reduce density differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

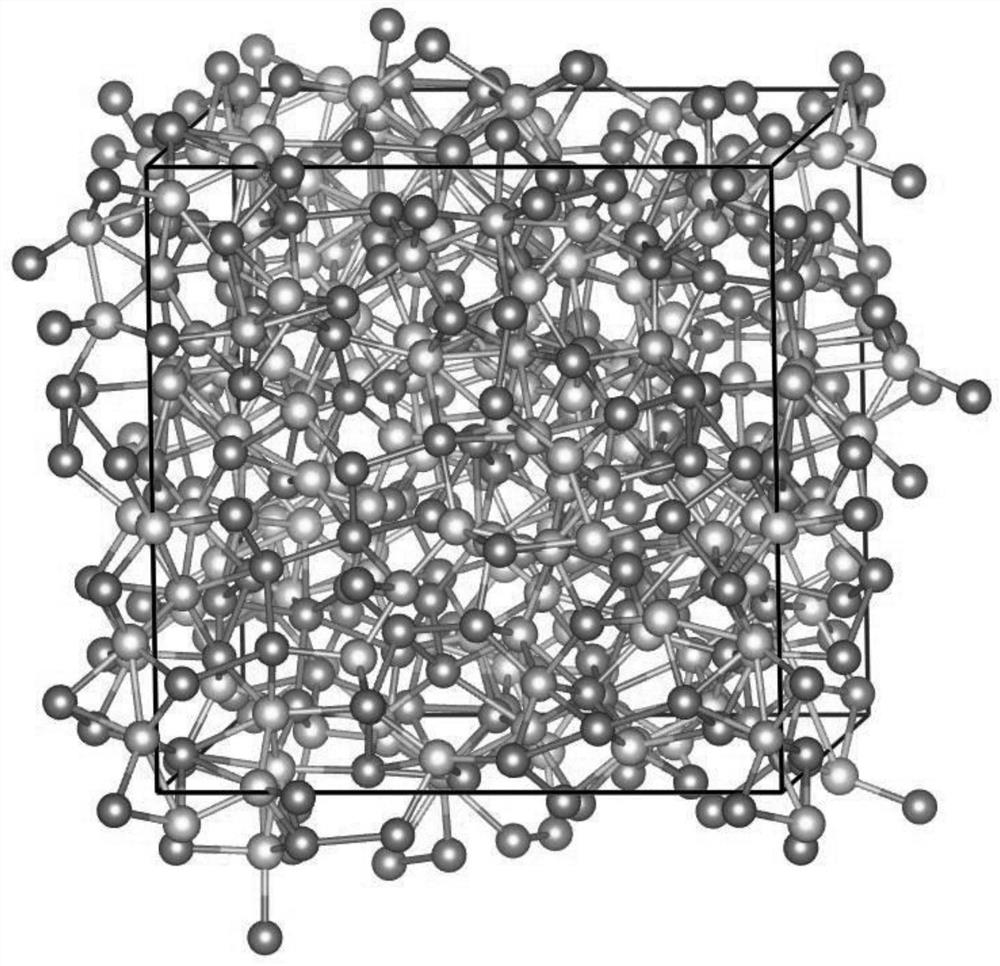

[0040] In this embodiment, the general chemical formula of the nano-Ti-Ga-Sb phase-change film material used in the phase-change memory is Ti x Ga y Sb 100-x-y , where x=9.7, y=18.5, that is, the chemical formula of Ti-Ga-Sb phase change material is Ti 9.7 Ga 18.5 Sb 71.8 .

[0041] The Ti-Ga-Sb nano film material in this embodiment is preferably prepared by magnetron co-sputtering.

[0042] Specifically, it is prepared by selecting the corresponding Ga-Sb alloy target and Ti elemental target for double-target co-sputtering. The Ga-Sb alloy target selected in this example is Ga 20 Sb 80 alloy target.

[0043] During preparation, high-purity inert gas is used as the sputtering gas, the volume percentage of high-purity inert gas reaches more than 99.999%, and the sputtering pressure is preferably adjusted to 0.5Pa; Pure argon was used as the sputtering gas. At the same time, Ga 20 Sb 80 The alloy target preferably adopts a DC power supply, and the power supply is 36W;...

Embodiment 2

[0064] In this embodiment, the preparation method of the Ti-Ga-Sb phase-change thin film material is the same as the above steps, the biggest difference is that the Ga in step S21 20 Sb 80 Alloy target replaced by Ga 30 Sb 70 Alloy target, and adjust the power of DC sputtering power supply for the Ti simple substance target in step S23 to 9W.

[0065] After the above magnetron co-sputtering process, Ti-Ga-Sb phase-change thin film materials with different thicknesses can be obtained according to the sputtering time. After quantitative analysis by X-ray photoelectron spectrometer (XPS), it can be known that the chemical composition formula of the film material obtained in the present embodiment is Ti 19.1 Ga 24.2 Sb 56.7 .

Embodiment 3

[0067] In this embodiment, the preparation method of the Ti-Ga-Sb phase-change thin film material is the same as the steps in the second embodiment, the difference is that the Ga in the step S21 30 Sb 70 Alloy target replaced by Ga 40 Sb 60 , the DC sputtering power supply of the Ti single target is still 9W.

[0068] After the above magnetron co-sputtering process, Ti-Ga-Sb phase-change thin film materials with different thicknesses can be obtained according to the sputtering time. After quantitative analysis by X-ray photoelectron spectrometer (XPS), it can be known that the chemical composition formula of the film material obtained in the present embodiment is Ti 19.1 Ga 30.6 Sb 50.3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com