Manganese zinc ferrite magnetic core

A manganese-zinc ferrite, magnetic core technology, applied in the direction of magnetic core/yoke, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc., can solve the problem of uneven magnetic core density, poor magnetic core strength, damaged circuits, etc. problems, to achieve the effect of reducing the difference in magnetic core density, reducing zinc volatilization, and reducing voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

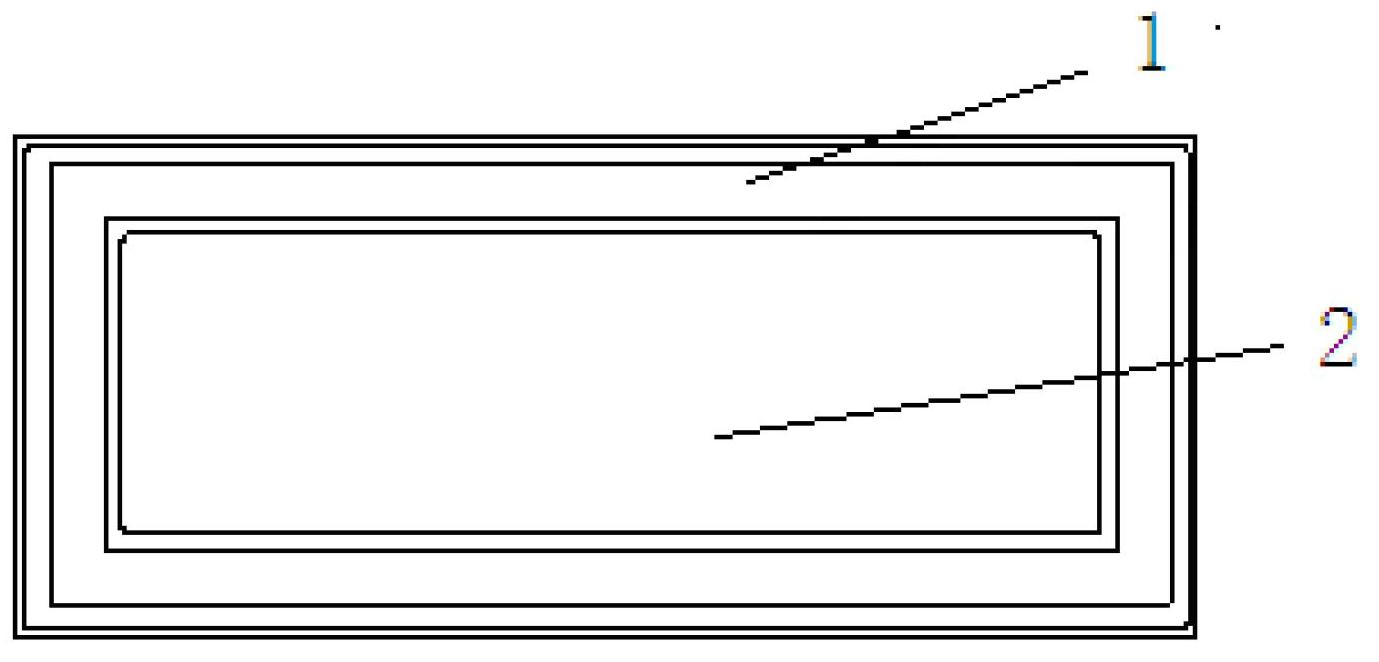

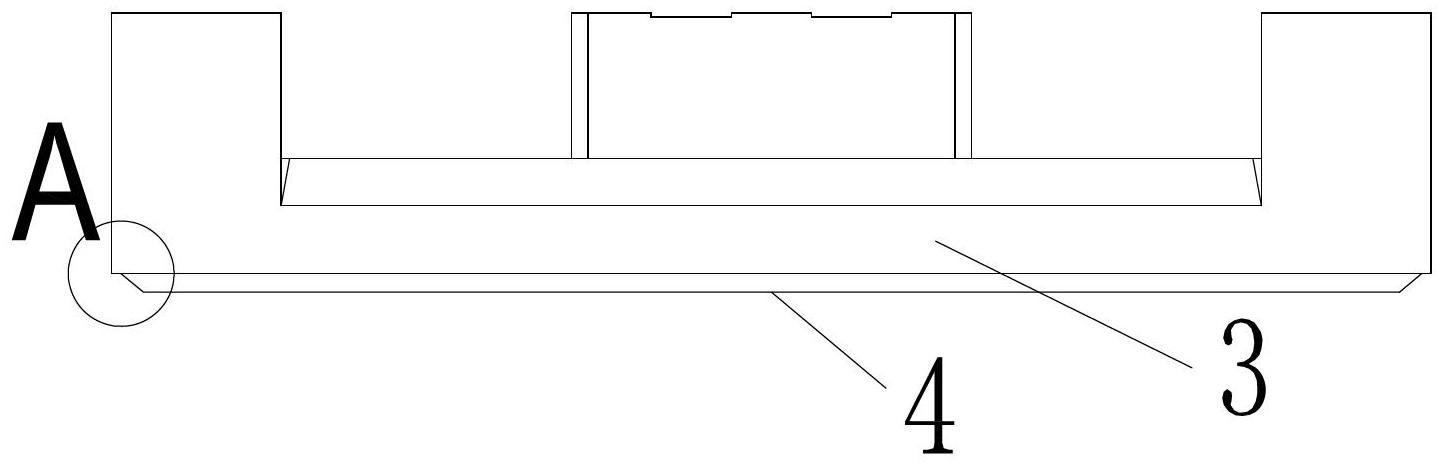

[0020] like figure 1 Shown is the existing magnetic core bottom structure. like figure 2 , Figure 4 As shown, for the manganese zinc ferrite core, the bottom of the magnetic core is square, the connection between the bottom surface of the magnetic core and the side wall is set as a chamfer, the bottom surface of the magnetic core is provided with a groove, and the connection between the groove and the bottom surface Set as a chamfer, and form a protrusion along the outer edge of the groove on the bottom surface. The depth of the groove is 0.05-0.5 mm, and the width of the protrusion is 0.5-3.0 mm. The chamfer angle of the connection between the bottom surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com